Laser welding is a process that uses a high-energy laser beam to melt and join two or more materials. Laser welding system is highly accurate and welding speed compared to TIG and MIG welding, it can produce high-quality welds with minimal distortion and heat-affected zones. Laser welder have the capacity to weld a wide range of materials and thicknesses, including both similar and dissimilar metals. Such as stainless steel, aluminum, copper, galvanized sheetor a combination of different metals.

Advantages of laser welding machines:

1. Speed & Efficiency: Laser welding is typically 3~5 times faster than TIG/MIG and other arc welding, which reduces production time and saves labor costs.

2. Automation: Just simply set the welding parameters on the CNC system and start working. It’s easy to begining and can be used without any welding experience.

3. Precision: The combination of lasers and CNC allows laser welding machines to produce precise welds, resulting in high quality parts that meet tight tolerances.

4. Versatility: Laser welding machines can be used to weld a wide range of materials, including metals, alloy materials, plastics, and non-metals. This makes them suitable for many different industries.

Standard configuration or contact us to customize a laser welder:

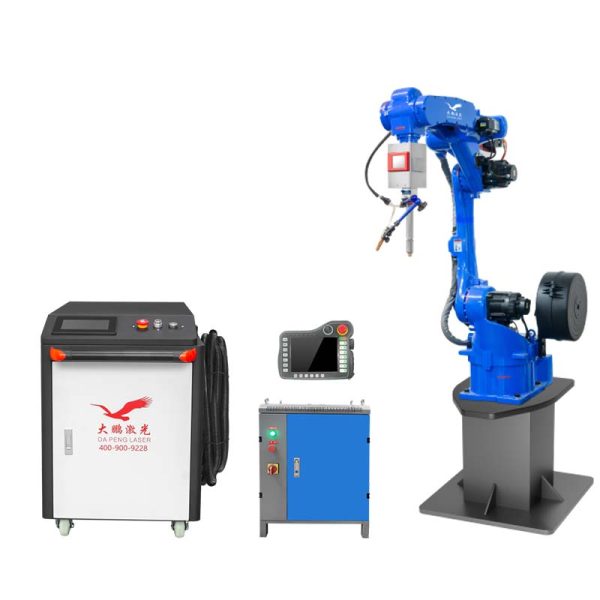

Dapeng laser welding machines have some categories based on functions or applications: fiber handheld laser welding machine, galvo laser welding machine, platform automatic laser welding machine, jewelry laser welding machine, mould laser welding machine and robot laser welding machine. The configuration, parameters, fixture and accessories of all laser welding system can be customized.