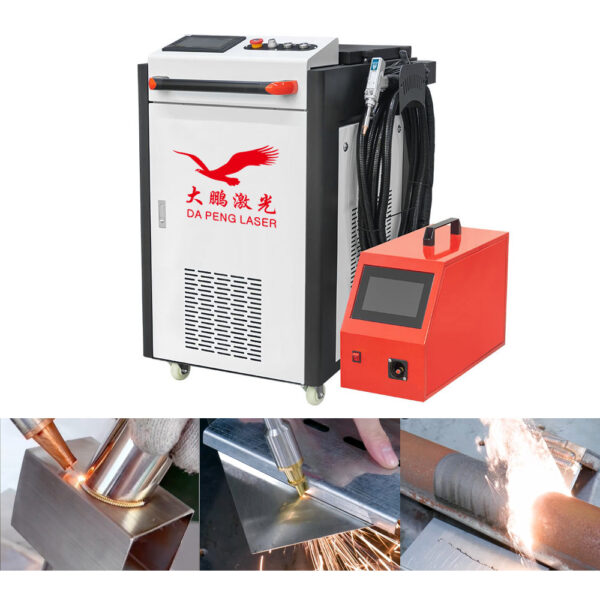

Laser welding machine uses a high-energy laser beam to join metals with speed and precision, requiring little post-weld polishing. A fiber laser welding machine offers high precision and delivers 4X faster welding speed than TIG and MIG welding. It can produce high-quality welds with minimal distortion and heat-affected zones. Laser welders have the capacity to weld a wide range of materials and thicknesses, including both similar and dissimilar metals, such as stainless steel, aluminum, copper, steel, iron, galvanized sheet, or a combination of dissimilar metals.

Why choose laser welding machines?

Speed & Efficiency: Laser welding is 3~5 times faster than TIG, MIG, and arc welding, increasing production efficiency.

Precise and Clean Welds: Provides precise and clean welds with minimal heat distortion.

Strong and Durable Welds: Offers strong and durable welds.

Minimal Post-Weld Treatment: Minimal polishing & cleaning required, reducing labor costs.

Various Materials: Ability to weld a wide range of materials, including metals, alloy, plastics, and non-metals.

Contact us to customize a laser welder

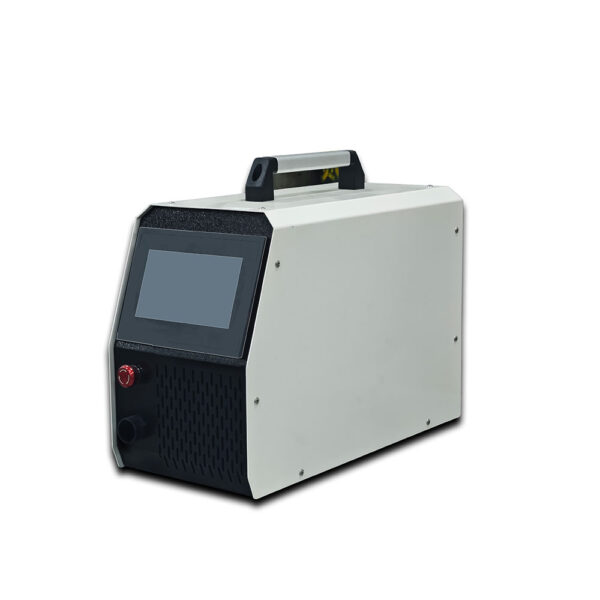

Our laser welding machines are categorized based on functions or applications: handheld laser welding machine, automatic laser welding machine, jewelry laser welding machine, mold laser welding machine, and robot laser welding machine. The configuration, parameters, fixtures, and accessories of laser welding machines can be customized.

Contact DPLASER now, and our laser experts will provide you with a tailored laser welding solution and quote!