About DPLASER

ABOUT US

Founded in 2008, Shenzhen Dapeng Laser Technology Co., LTD. is a leading national high-tech enterprise specializing in laser equipment. We seamlessly combine research, development, manufacturing, sales, and service to provide comprehensive solutions.

Our main product lines encompasses over 200 cutting-edge laser equipment and solutions. These cover a wide range of applications, including laser marking, laser cutting, laser welding, and laser cleaning machines. These technologies find widespread utilization across 60+ diverse industries, such as metal processing, automotive manufacturing, printing and packaging, electronic components, the hardware sector, jewelry, clothing, medical equipment, craft gifts, and new energy.

- ISO9001 & CE/SGS/FDA Certification

- Latest Standard ECE R22.06

- Experts More than 20 Years in Laser Technology

- OEM/ODM Service

- Factory & Fast Delivery

GROWING

DPLASER began to build expert team in 2008, and launched a new generation of laser marking machine.

- 2008, Founded in Shenzhen

- 2009, Launched Laser Marking Machine Series

- 2011, Launched Laser Welding System

- 2012, Wenzhou, Xiamen Branch Was Established

- 2015, Laser Cutting Division Was Established

- 2017, Dongguan Production Base Established

- 2020, Nantong Industrial Park Project Starts

- 2023, 27 Branches & Multiple Overseas Service Stations

- 2024, Jiangsu Nantong Industrial Park Was Established

In the past three years, DP Laser has been advancing at a high growth rate of 25%-35% every year in terms of laser equipment sales. More than 10,000 machines are sold overseas each year. In the laser industry, we have become a well-known laser equipment and system solution provider based on our technical level, production and R&D strength and service system.

LASER BUSINESS

The main products include: laser cutting machine, laser welding machine, laser marking machine, industry-specific and automatic laser equipment, etc., which are used in electronics component, IC chips, electrical appliances, lighting, jewelry, hardware tools, automobile and motorcycle parts, mobile phone communication parts, moulds, precision machinery, medical equipment, metal casings, military aviation parts, clothing leather, craft gifts, advertising print, models and other industries.

Laser Welding Machine

Laser welding equipment are designed R & D, production operations, marketing, improve product quality, meet customer customization needs, open up the market of Dapeng welding equipment.

It is suitable for the welding of all kinds of metals such as titanium, steel, copper, aluminum, chromium, niobium, gold and other alloys and their alloys. It can also be used for welding between different materials and dissimilar metals, such as mobile communications, electronic components, glasses watches and clocks, jewelry spot welding, metal processing, precision instruments, medical equipment, auto parts and other industries.

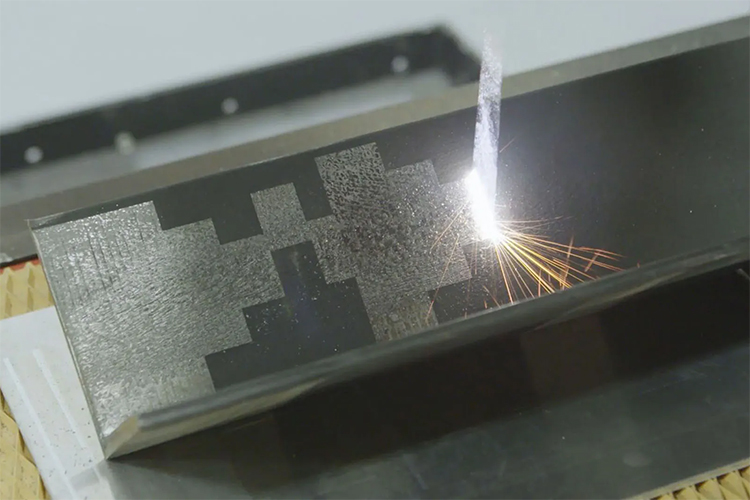

Laser Marking Machine

Laser marking machines are one of Dapeng Laser’s flagship products, with over 80 models available. We are focuses on providing customized laser equipment solutions, such as assembly line automatic marking machines, flying laser marking machines, and multi-station laser marking systems. These are available with fiber, CO₂, and UV laser sources for

1. Ceramics, wood and leather: crafts, greeting cards, decorations, etc.

2. EP materials laser marking: electronics component, packaging, IC chip, PCB board etc.

3. Plastic: electrical power shell, electronic products such as serial number, LOGO etc.

4. Metal: stainless steel, copper, aluminum and oxidation plating, commonly used in hardware, daily necessities, electrical appliances, nameplates, medals, mobile phone shell etc.

5. Keyboard and buttons: keyboard, buttons, cell phone battery labels, panels, cell phone keys, small daily necessities accessories and other fine marking.

Laser Cutting Machine

Dapeng laser cutting machines have precision manufacturing, flexible cutting, special-shaped processing, fast, high efficiency advantages, design research and development, complete industrial laser cutting equipment.

Widely used in advertising signs production, sheet metal structure, high and low voltage electrical cabinet production, textile machinery parts, kitchen utensils, automobiles, machinery, metal crafts, saw blades, electrical parts, glasses industry, spring, circuit boards, electronics, hardware, tools and other tools.

Suitable for stainless steel, carbon steel, alloy steel, spring steel, galvanized sheet, copper plate, aluminum plate, gold, silver, titanium and other metal sheet and pipe cutting.

Laser Cleaning Machine

The laser cleaning machine utilizes laser energy to clean the surface of the target object in a non-contact manner, removing rust, dirt, oil stains, oxides, and other pollutants while preserving the integrity of the object’s surface.

Dapeng fiber laser cleaning machines mainly used in various industries, including the mobile phone manufacturing, electronic components, circuits board, metal processing, optical devices, automotive parts, aerospace, and more. In the electronic components and integrated circuits, it can remove solder residues and metal oxide on the surface, ensuring the performance and reliability of electronic devices.

DPLASER provides customized laser cleaning machine solutions according to customer requirements, achieving efficient, non-destructive, and environmentally friendly cleaning processes that improve production efficiency and enhance product quality.

Robot Laser Application

We offer six-axis robotic laser application systems that cover a wide range of applications such as welding, cutting, rust removal and cleaning. With years of experience in laser technology, we provide you with efficient and professional laser solutions for a wide range of manufacturing needs.

Our technical team understands that every manufacturing process is distinct, which is why we offer comprehensive customization services for our robotic laser equipment. Customized solutions encompass not only the hardware aspects of the equipment but also the software interfaces and controls. We collaborate with you to define the optimal parameters, laser settings, and motion paths, ensuring that the robotic system performs flawlessly to meet your exacting standards.

Non-standard Automation

Mainly for the laser application market, such as the mobile phone industry, electronic components, electrical appliances, integrated circuits, metal parts, mold manufacturing, handicrafts, pharmaceutical food packaging, auto parts, chip manufacturing and other industries, according to customer needs custom models, specific pipeline design, high automation level for enterprise production efficiency, reduce energy consumption.

DP Laser has production bases in Shenzhen, Wenzhou, Kunshan and Jiangsu, a large laser equipment production base in Dongguan, and more than 27 offices in major cities and regions in China and the world.

DPLASER (Xiamen) Branch

DPLASER (wenzhou) Branch

DPLASER (kunshan) Branch

DPLASER (Jiangsu) Industrial Park

DPLASER (Dongguan) Industrial Park

DPLASER (Shenzhen) Headquarters

DPLASER (Shenzhen) Headquarters

PRODUCTION BRANCH

DPLASER has set up production and R&D bases in more than 27 major cities across the country. These bases not only have modern production lines and R&D center, but also provide research and production services for laser equipment and technology for surrounding provinces and cities.

Our branches are not only product sales and service centers, but also important leaders in the development of the local laser industry. Through our R&D and production bases in various cities, we can better understand the local market demand, and provide professional technical support and services in time, continuously promote the development of laser technology, and help the laser industry to achieve leapfrog development.

FEATURED PRODUCTS

LASER FAIR

Global Market

Office all over the country's major industrial cities, products are exported to more than 50 countries.

Brand Influence

The annual sales more than 10,000 units, and there are more than 30,000 cooperative enterprises. We are committed to assisting industrial application laser equipment and helping partners to obtain more business value and benefits.

Certification

Dozens of patent owners. Reliable laser machine due to our technology, manufacture, R&D and support.

Technical Strength

Independent design, research and development of laser equipment and solution experience for more than 10 years. About 2,000 thousand USD in technical innovation and technology experiment every years.

Certification

The procedure of production from design to manufacturing are guaranteed to comply with national safety regulations, electricity regulations, environmental laws and regulations to meet the global customer’s demand.