Robotic Laser Applications

Laser Robotic Applications Supplier

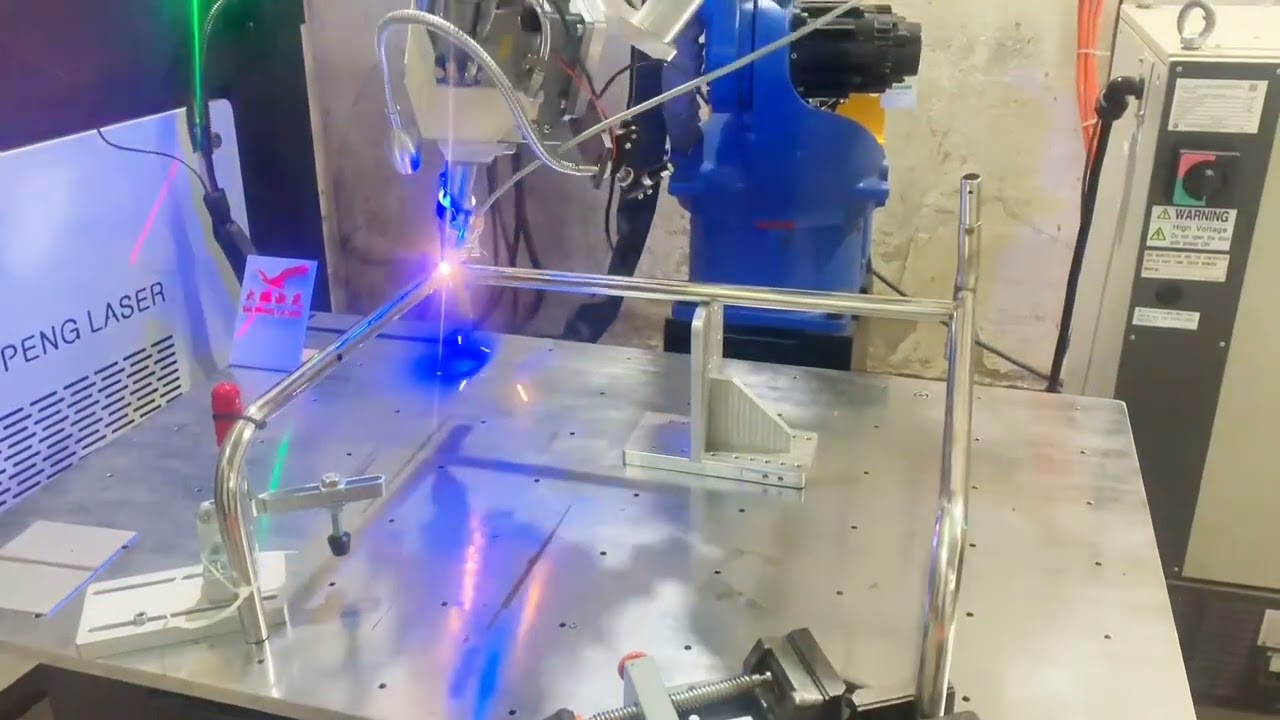

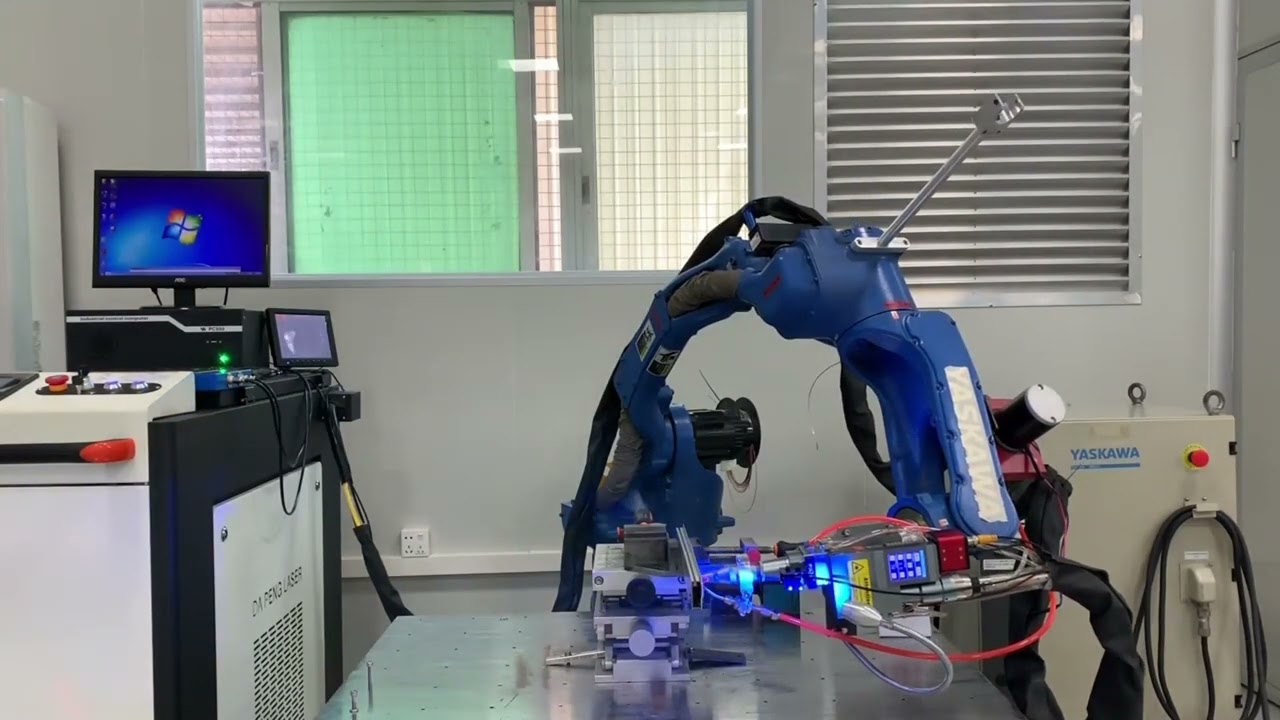

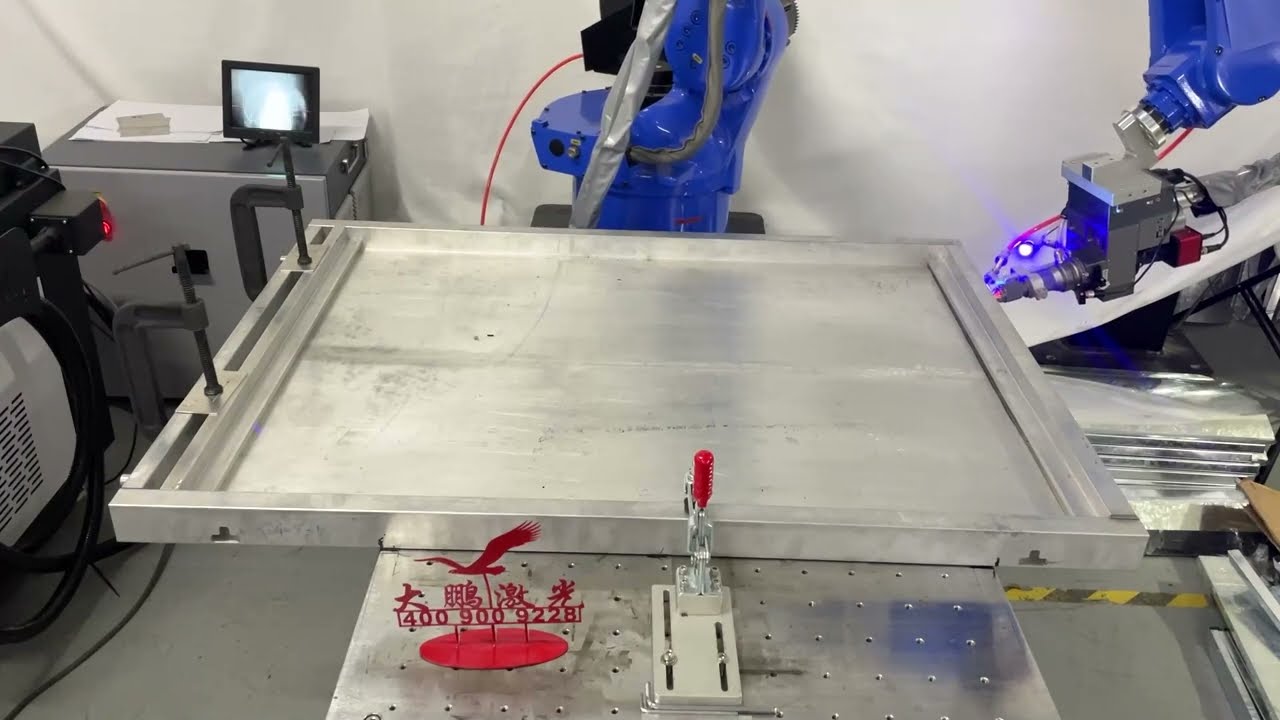

DPLASER is a comprehensive solution provider for robot laser applications involves offering a comprehensive range of products and services to meet the needs of customers looking to integrate laser technology with robotic systems.

We understand customers specific needs and customize configurations according to their requirements and application scenarios. We always focuses on developing high-quality, high-performance laser equipment solutions, including laser equipment selection, system integration and optimization.

DPLASER has rich experience in laser device development and can provide customers with customized robotic laser application development services. Whether in industrial automation, automobile manufacturing & repair, electrical appliance manufacturing, metal processing, medical equipment, hardware manufacturing, electronic parts etc., our professional team can help customers realize various complex laser application needs, including laser cutting, laser welding, laser cleaning and rust removal, etc.

Advantage of Robotic Laser Applications

- Clean edges, clean weld paths, no grinding required

- Fast laser processing speeds

- Flexible cutting of any 3D object surface with automatic navigation

- Large dimensions (orbital integration)

- No distortion of the workpiece

- Optimal material utilization

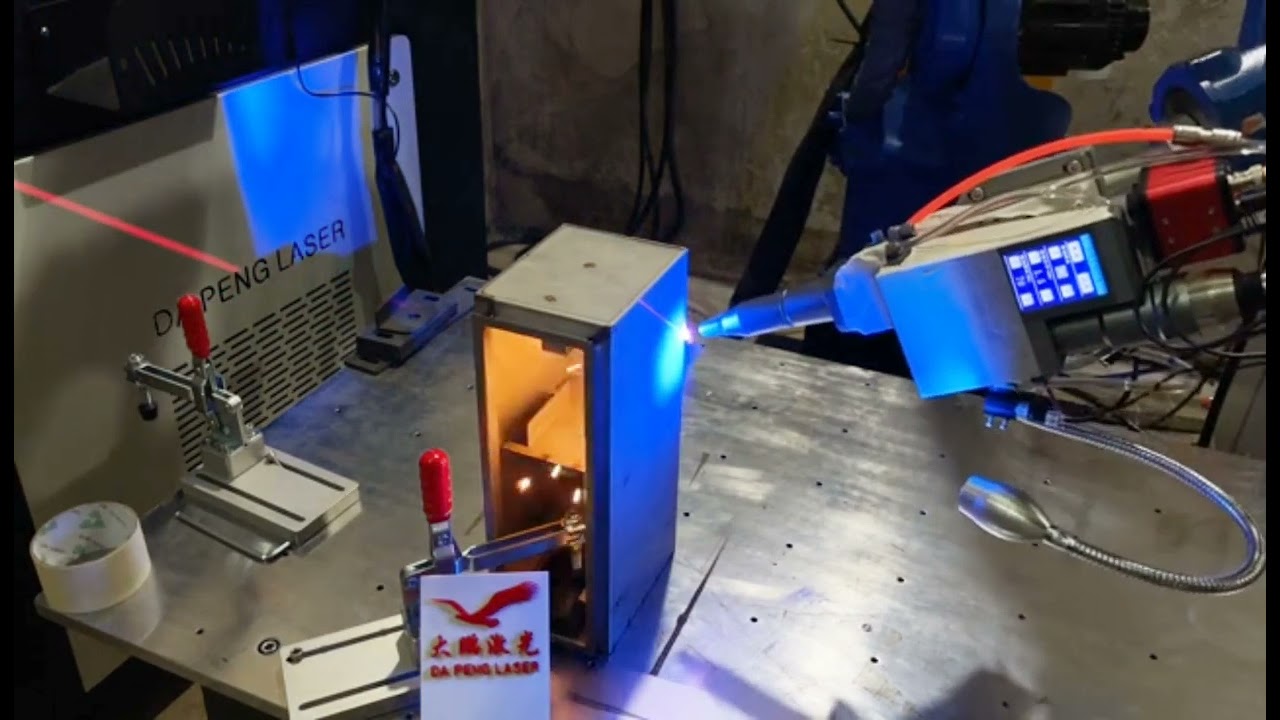

Laser Welding Robots

| Items | M1550-12 | M1840-25 | M2010-12 | F10-05 | F14-10 |

| Degrees of freedom | 6 axis | 6 axis | 6 axis | 6 axis | 6 axis |

| Max working radius | 1550mm | 1840mm | 2010mm | 922mm | 1400mm |

| Max load | 12kg | 25kg | 12kg | 5kg | 10kg |

| Repeatability | ±0.05mm | ±0.08mm | ±0.08mm | ±0.02mm | ±0.05mm |

| Robot body weight | 170kg | 260kg | 185kg | 22kg | 40kg |

| Robot control cabinet weight | 60kg | 80kg | 60kg | / | / |

| Robot rated power | 4.5kw | 4.5kw | 4.5kw | 24V/1.5A | 24V/1.5A |

| Operating temperature | 0-45°C | 0-45°C | 0-45°C | 0-45°C | 0-45°C |

| Applicable laser power | 1000~3000W | 1000-6000W | 1000-3000W | 1000-3000W | 1000-3000W |

| Material (carbon steel, stainless steel) | 0.5-5mm | 0.5-10mm | 0.5-5mm | 0.5-5mm | 0.5-10mm |

| Applicable material (aluminum) | 0.5-4mm | 0.5-8mm | 0.5-4mm | 0.5-4mm | 0.5-8mm |

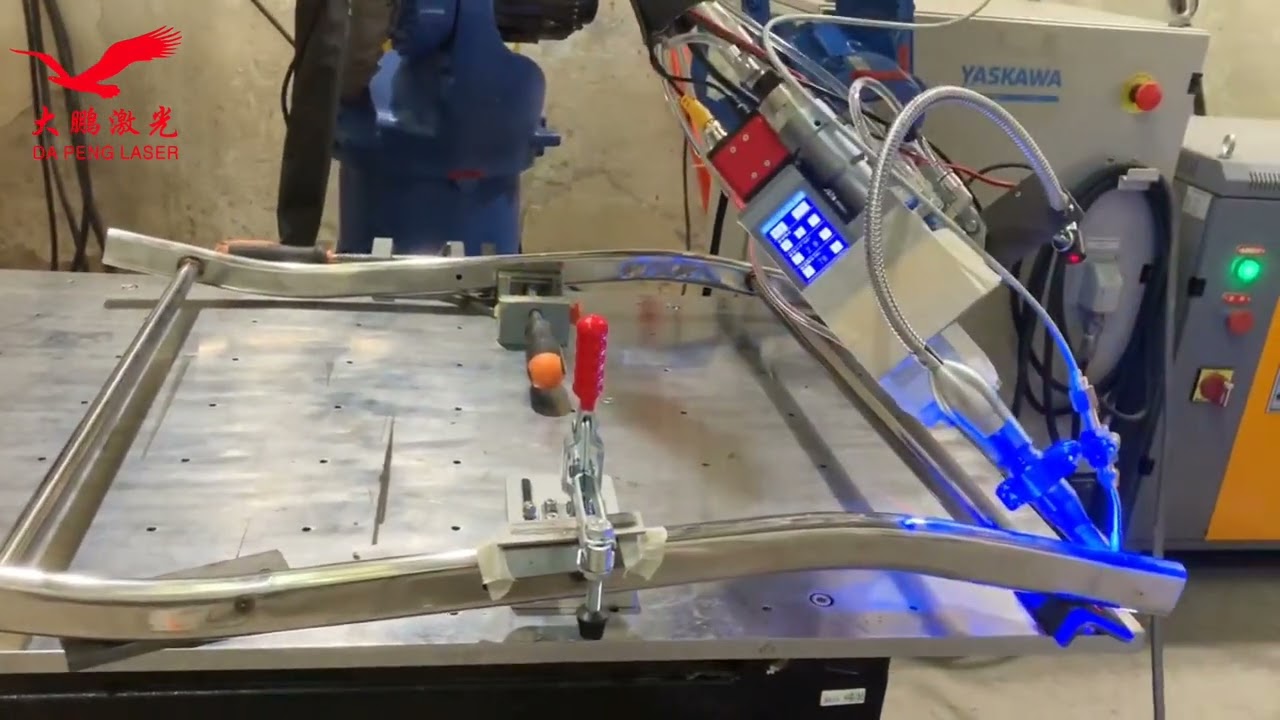

Automatic laser welding robot for hardware sheet metal, metal window and door frames, chassis, control cabinets, electrical boxes, hardware lighting, hardware furniture, automotive manufacturing, solar energy, energy storage and other industries.

Laser Handheld Welding VS Robot Laser Welding Machine

| Items | Laser Handheld Welding | Robotic Laser Welding Machine |

| Assignment | Hand work | 24 hours work, saving labor |

| Quality | Smooth surface with little or no grinding | Less or no grinding, smooth surface, more stable quality |

| Product surface | Low distortion, contact welding | Less distortion, contactless welding |

| Filling | Wirefill welding | No wire feeding for small weld seams, saving wire |

| Apply to | Small quantities, irregular products | Mass production, stable product quality |

Platform Automatic Laser Welding VS Robot Laser Welding

| Items | Automatic Continuous Wave Fiber | Robotic Arm |

| Axis | Standard 3-axis & 2-axis | Standard 6 axis + 3 axis (extended) |

| Flexibility | Linkage cost is high and not flexible enough | Can realize more angle welding, wider application. |

| Large workpiece | Gantry structure, suitable for high volume products with high consistency | Higher efficiency, the same table can weld multiple products allows for small batches with variable welding requirements |

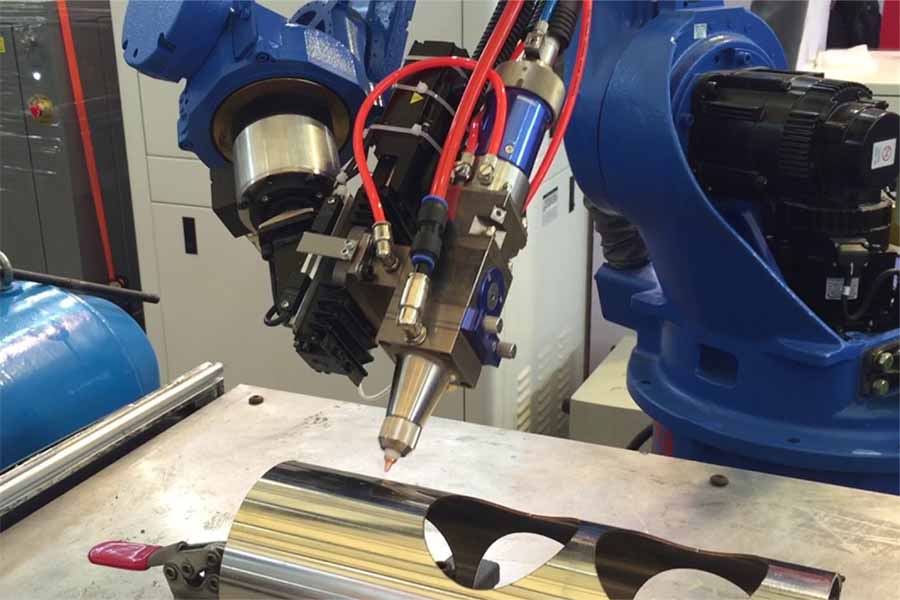

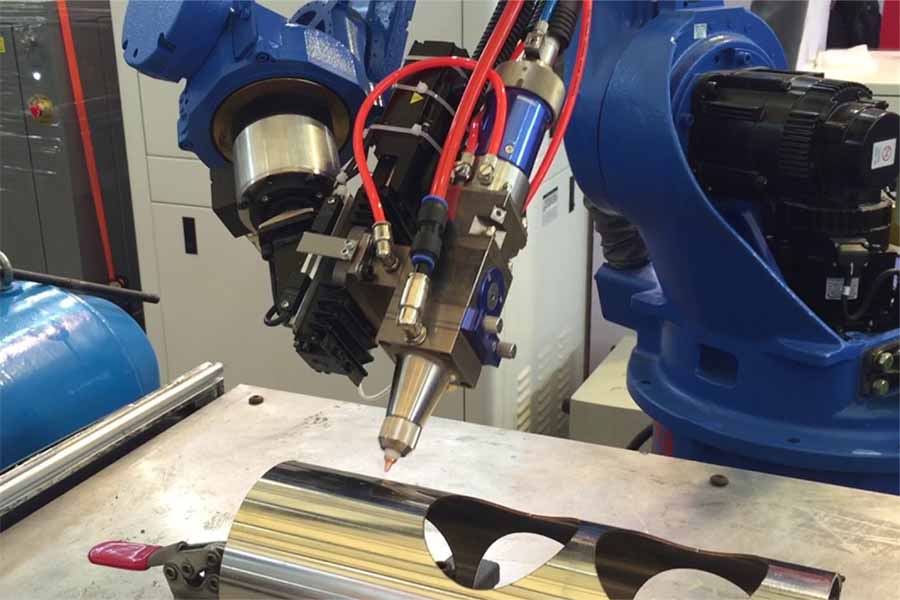

Robotic Laser Cutting Machine

| Items | M1840-25 |

| Degrees of freedom | 6 axis |

| Max working radius | 1840mm |

| Max load | 25kg |

| Repeatability | ±0.08mm |

| Robot body weight | 260kg |

| Robot control cabinet weight | 80kg |

| Robot rated power | 4.5kw |

| Operating temperature | 0~45°C |

| Applicable laser power | 1000-6000W |

| Material (carbon steel, stainless steel) | 0.5-10mm |

| Applicable material (aluminum) | 0.5-8mm |

The industrial robotic laser cutting machine, with its high flexibility, precision, and efficiency, is the ideal method for processing intricate, complex, and diverse metal workpieces.

For cutting various types of curved and contoured pipes such as bent pipes, rectangular pipes, round pipes, and irregular pipes, including hole drilling, slotting, and bevel cutting; components like electrical enclosures, frames, and heat sinks; metal frames for architectural doors and windows, curtain wall support structures; hardware components like stair handrails, fences; automotive chassis parts, suspension system components, seat frames; various brackets, connecting rods, flanges for machinery equipment; pre-processing or hole punching of fasteners and connectors.

Traditional Metal Mold Cutting VS Robot Laser Cutting

| Items | Traditional Metal Mold Cutting | Robot Laser Cutting Machine |

| Process | Forming, punching, blanking, and trimming requirements | One machine can produce independently after blank molding |

| Cost | The cost of the press machine is high, and the cost of molds is also high; different products require the development of different molds, and the mold development cycle takes 3~6 months. | Low equipment cost, simple process. Short preparation time, fast production speed. Easy adjustments, can be operated by one person. |

| Applicability | Suitable for super large batch production of single variety | Suitable for new product development and multi-species small and medium batch production |

Robot Laser Cleaning Machine

| Items | M1550-12 | M1840-25 | M2010-12 |

| Degrees of freedom | 6 axis | 6 axis | 6 axis |

| Max working radius | 1550mm | 1840mm | 2010mm |

| Max load | 12kg | 25kg | 12kg |

| Repeatability | ±0.05mm | ±0.08mm | ±0.08mm |

| Robot body weight | 170kg | 260kg | 185kg |

| Robot control cabinet weight | 60kg | 80kg | 60kg |

| Robot rated power | 4.5kw | 4.5kw | 4.5kw |

| Operating temperature | 0~45°C | 0~45°C | 0~45°C |

| Applicable laser power | 1000-3000W | 1000-6000W | 1000-3000W |

| Items | M1550-12 | M1840-25 | M2010-12 |

| Degrees of freedom | 6 axis | 6 axis | 6 axis |

| Max working radius | 1550mm | 1840mm | 2010mm |

| Max load | 12kg | 25kg | 12kg |

| Repeatability | ±0.05mm | ±0.08mm | 土0.08mm |

| Robot body weight | 170kg | 260kg | 185kg |

| Robot control cabinet weight | 60kg | 80kg | 60kg |

| Robot rated power | 4.5kw | 4.5kw | 4.5kw |

| Operating temperature | 0-45°C | 0-45°C | 0-45°C |

| Applicable laser power | 100~300W | 500W | 100-300W |

Robotic laser cleaning & rust removal is widely utilized in manufacturing, construction, and mold industries. It ensures high-quality and precision by precisely cleaning, stripping paint, removing rust, and pre/post-weld treatment of metal components. In the mold industry, it refines rubber and plastic molds, prolonging their lifespan and improving product quality. In the construction, it can remove rust, oil and other contaminants from large metal sheets and structures. Through 3D visual positioning and automatic navigation, robots execute precise operations on complex surfaces and hard-to-reach areas, boosting efficiency and quality in manufacturing.

| Items | F10-05 | F14-10 |

| Degrees of freedom | 6 axis | 6 axis |

| Max working radius | 922mm | 1400 |

| Max load | 5kg | 10kg |

| Repeatability | +0.02mm | +0.05mm |

| Robot body weight | 22kg | 40kg |

| Robot control cabinet weight | / | / |

| Robot rated power | 24V/1.5A | 24V/1.5A |

| Operating temperature | 0-45°C | 0-45°C |

| Applicable laser power | 1000-3000W | 1000-3000W |

| Material (carbon steel, stainless steel) | 0.5-5mm | 0.5-10mm |

| Applicable material (aluminum) | 0.5-4mm | 0.5-8mm |

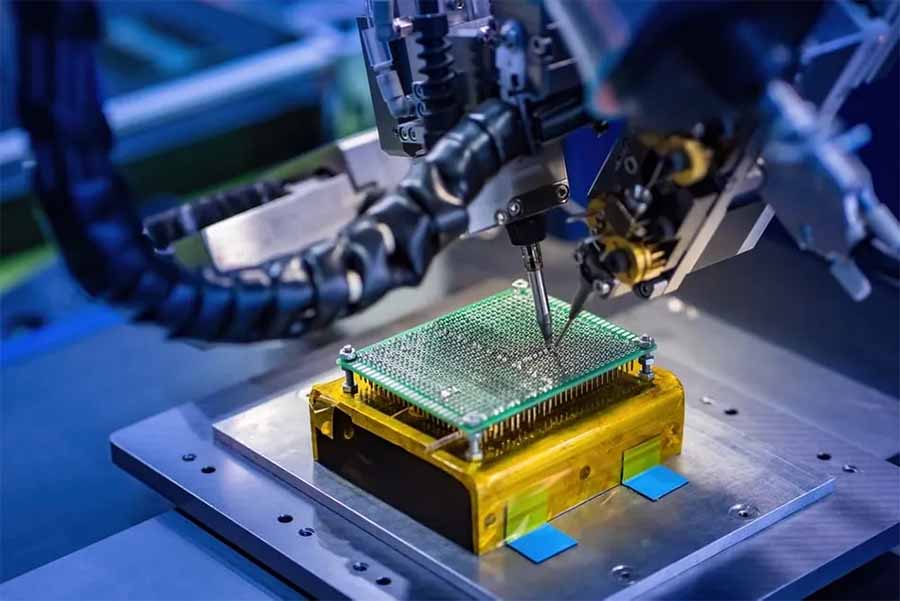

For various precision hardware parts, such as electronic components, electrical appliance shells, precision instrument frames, hardware tools, architectural hardware, furniture hardware, etc., collaborative laser welding robots are able to carry out fine welding and realize high-precision welding, which is especially suitable for welding thin-walled materials and complex shaped parts to ensure the precision of dimensions and aesthetic appearance.

Customizable Components

Single Axis Positioner

Dual Axis Positioner

Horizontal Axis Positioner

Underground Track

Visual Tracking Systems

Three-dimensional Workbench

- Laser Robot Applications

Laser Robot Applications

Laser Robotic Industrial Application

Robot Laser Application

Automotive Industry

With our robotic laser solutions for the automotive repair and production industry you are ready for Industry 4.0.

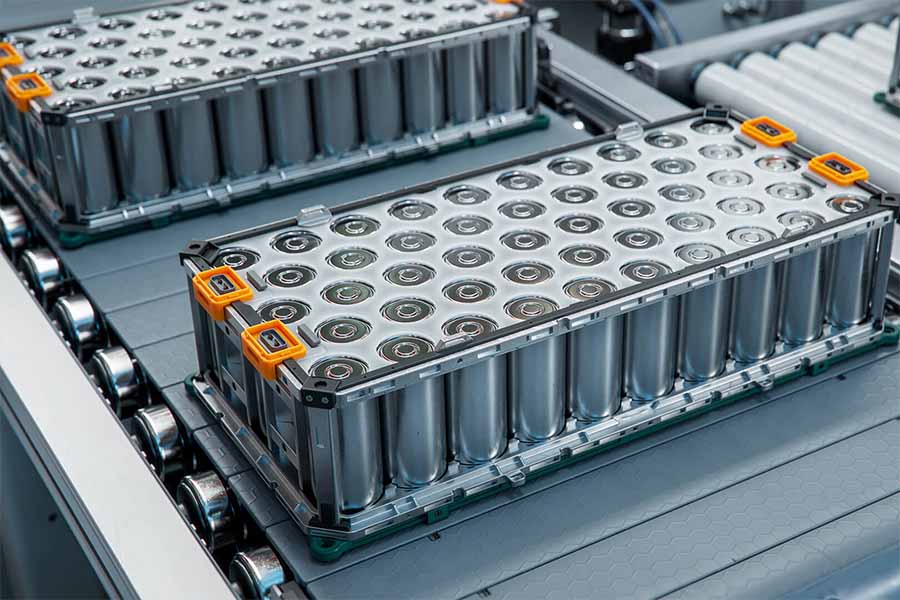

New Energy Manufacturing

Robot laser system ensures structural stability and safety in battery module assembly through precise welding, enhancing battery production.

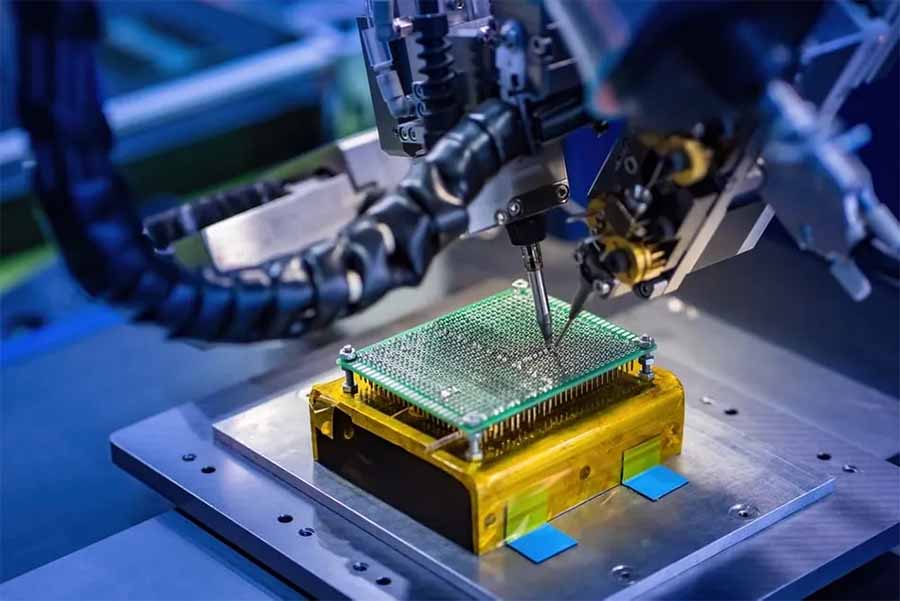

Electronics Industry

Robotic laser applications drive miniaturization and automated production with high accuracy and consistency for precision machining, accurate assembly and high quality welding and cutting.

Chassis Manufacturing

Laser welding and cutting robot in chassis and household appliance casing manufacturing can improve production efficiency, while achieving precise control over welding depth and cutting position, enhancing product processing quality and appearance.

Get a Custom Laser Robotic Quote!

Do you have a question for us? Are you looking for career advice on laser machines? Contact us if you have a query about the laser equiment and laser industry.