CNC Automatic 6 Axis Robotic Laser Welding Machine

The six-axis fiber robot welding machine is the most typical robot. It is mainly composed of joints and connecting arm. The robot arm and wrist cooperate to complete the target trajectory movement, with 6 degrees of freedom in space.

Laser welding robotic system offer a great mix of speed, reach, payload capacity, and reach. These robots can cover the vast majority of laser welding applications. They excel in small to medium-sized welding tasks. Their excellent range of motion helps them weld complex part geometries.

The labor cost of mass production is high, and the robot arm can work 24 hours a day, and can turn left and right to double-station work, which greatly improves work efficiency and saves costs.

- The laser welding robot is equipped with easy-to-use video tutorials, making it easy for beginners without welding experience.

- Intelligent trajectory optimization strategy to optimize control performance.

- Integrate multiple sensors such as vision sensor, torque sensor, stability sensor, etc., combined with the alarm mode and auxiliary mode of the sensor.

- Based on rich actual cases and integrated processing technology, a variety of technology packages such as welding technology package have been developed, which greatly reduces the difficulty of programming.

- Laser welding robot has double guarantee of performance and stability.

- Dapeng welding robots can provide professional customized services to meet various special production needs of customers.

Advantages of Automatic Six Axis Laser Welding Robot

- Intelligence and Flexibility: The robot is equipped with an intelligent control system, and its six-axis design allows it to weld in any space without being restricted to a specific plane, thus improving flexibility and applicability.

- Customised fixtures: Customers can customise fixtures according to actual production requirements to ensure that the workpiece is securely fixed during the welding process, improving productivity and welding quality.

- Dual-station or station welding: The robot can achieve dual-station or station welding operations, saving time for product installation of fixtures and significantly improving production efficiency.

- Advanced Oscillating Welding Head: Adopting advanced oscillating welding head, its unique wedge-shaped vibration mode makes the weld seam wider and expands the applicable range of laser welding, which can deal with larger-sized workpieces.

- Efficient and precise laser welding: For workpieces with wider weld seams, the robot is able to achieve efficient and precise laser welding, with better weld seam quality and a smoother, more aesthetically pleasing surface, thus enhancing the quality and appearance of the product.

- High Repeatability and Low Running Costs: Robots have high repeatability to ensure welding accuracy and consistency, and at the same time, they require no consumables, are flexible in manufacturing, and have low running costs.

- Replacement of manual operation: In some difficult welding spaces, robots can replace manual operation, improving safety and productivity while reducing human resource costs.

Features:

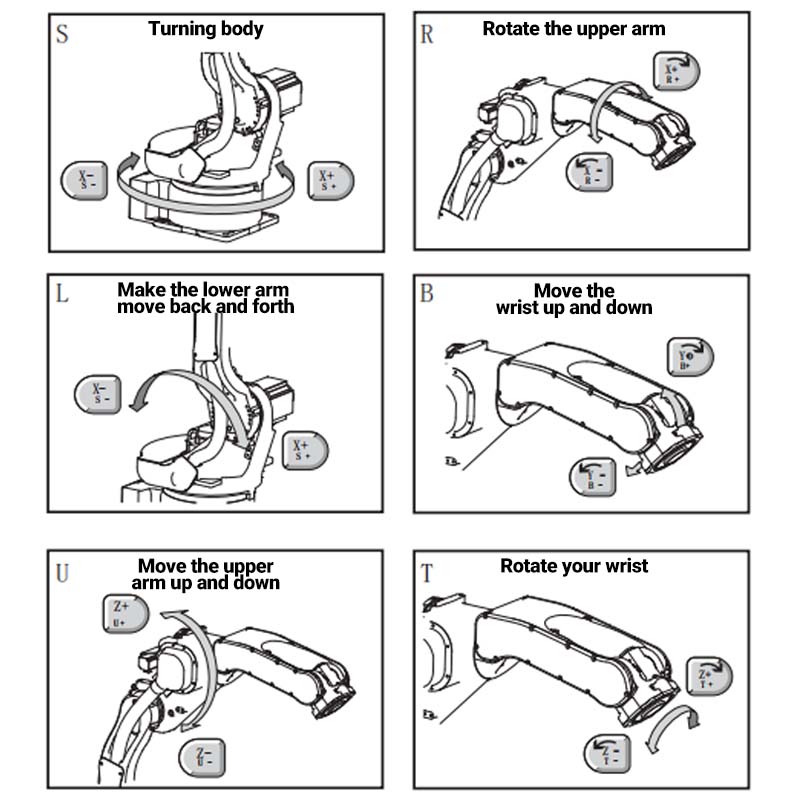

The six-axis robot consists of six joints: rotation (S axis), lower arm (L axis), upper arm (U axis), wrist rotation (R axis), wrist swing (B axis) and wrist rotation (T axis). The synthesis of 6 joints realizes the 6-DOF movement at the end, which makes the 6-axis automatic robot have many advantages such as high flexibility, super large load, and high positioning accuracy.

What is the role of each axis of robot arm?

- The first axis: It is the position of the link chassis, which is the load-bearing and core position. It carries the weight of the entire robot and the large swing of the robot left and right.

- The second axis: it is mainly an important axis to control the robot to swing back and forth and stretch.

- The third axis: It controls the robot to swing back and forth, but the swing range is smaller than the second axis, but this is also determined by the arm span of the six-axis robot.

- The fourth axis: It is an axis that controls the 180° free rotation of the upper arm, which is equivalent to the human forearm.

- The fifth axis: It is very important. When you adjust the position and accurately locate the product, you need to use the fifth axis, which is equivalent to the human wrist.

- Sixth axis: After the fifth axis is positioned on the product, some minor changes are required, and the sixth axis is required. The sixth axis is equivalent to a turntable that can rotate 360° horizontally. Products can be positioned more precisely

Structure of CNC Laser Robot Welding Machine

1. Laser part (laser source, chiller, welding head, wire feeding part)

2. Robot arm

3. Auxiliary devices and workstations (single/double/three-station workbench, positioner, fixture, etc.)

Application:

Laser welding is commonly used in metal materials and can join most of metal or non-metal materials, such as weld stainless steel, aluminum, aluminum alloy or a combination of different metals. Copper joints, copper-copper and copper-aluminum welding, which are often required in the production of lithium batteries, are also suitable for laser welding machines.

We have automation solutions for different industries, such as automobile production, electronic component manufacturing, medical equipment, and battery pack production in the energy field. Please contact us for better solutions. Robotic laser welding is an accurate, clean and flexible option for a wide variety of welding applications.

Why Choose DP Laser?

We have more than 16 years of experience in industrial laser equipment research and development, focusing on laser marking, cutting and welding systems. We are experts in the laser industry. Our application experts and engineers have decades of work experience and can provide the most professional systems and services. All of our machines come assembled and ready to work after the simplest setup. Even beginners can get started quickly.

| 6-axis Robotic Arm Collaborative robot arms can effectively handle laser welding operations and help achieve flexible, efficient and free welding processes which is responsible for holding and positioning the welding tool. These robots are programmed to follow specific welding paths. |

| Laser Welder Small deformation, beautiful welding seam with no need for post-weld grinding. Parameters can be adjusted according to material and process, making it versatile for such as Internal fillet welding, external fillet welding, splice welding, spot welding, fish scale welding. Suitable for welding common metals like iron, stainless steel, galvanized alloys, and aluminum alloys. |   |

| Automatic Laser Welding Head They offer the advantages of speed, accuracy, and minimal distortion in the welded material compared to traditional welding techniques, making them a valuable tool for modern manufacturing processes. |

| Laser Source All key components are sourced from globally renowned companies, and production follows international standards and production processes within the international laser industry, ensuring reliable guarantees for product quality and stability. The specially designed optical resonator and gas flow system, combined with high-precision laser optical components, guarantee high reliability. |   |

| Cooling System The chiller is designed for laser cutting, laser welding, laser engraving, laser marking and other equipment. It can provide cooling medium for the above application scenarios. |

| Welding Control System Intelligent control system, stable and reliable, easy and convenient setup, and rich in functionality. It supports modular, automated, and information-based welding solutions. |   |