Committed to delivering ongoing innovation, precise and efficient laser equipment solutions.

17 years Pioneering in laser industry

300+ Laser Expert

200+ Types of Laser Solutions

8,000 Enterprise Partners

100,000 units sold globally

50,000㎡ Manufacturing Area

Laser Machines - DPLASER

Founded in 2008, DPLASER is a high-tech enterprise integrating innovation, manufacturing, sales, and customized services in laser equipment. For the past 17 years, we have been dedicated to the research and development of laser equipment and technical services. Our main products and services include laser welding, cleaning, marking, cutting, non-standard automation, ultrafast laser micro machining, and more—offering over 200 types of laser solutions.

- Professional Assistance

- Quality Assurance

- Wide Range of Applications

- Customized Laser Solution

- Efficient Delivery

Voice of the Customers

Meeting All of Your Machining Requirements

We provide range of customized laser equipment caters to all your machining needs, enhancing productivity and consistently delivering high-quality results.

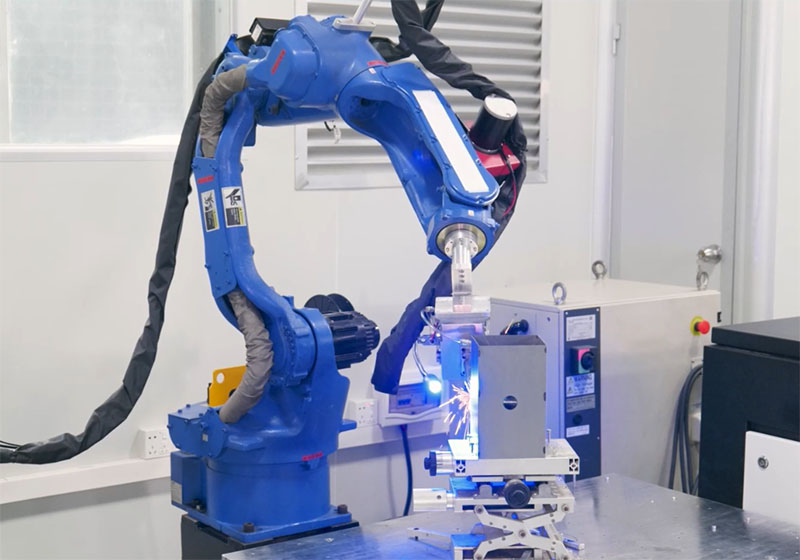

Laser Welding Machine

Minimal Heat | Fast Welding Speeds | Clean Welds

Laser welding is a precise and fast process, capable of welding a wide range of materials and thicknesses with minimal heat input and distortion. Suitable for various metal and non-metal materials, including titanium, zinc, steel, copper, aluminum, chromium, niobium, gold and other metals and their alloys.

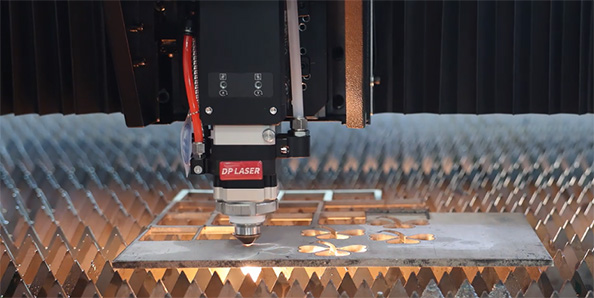

Laser Cutting Machine

Precision Cutting | High Speed | Minimal Material Cost

Laser cutting machine uses a high-powered laser beam to cut through a variety of materials, including metals, plastics, wood, and fabrics. Laser cutting is a precise and fast process, capable of producing complex shapes with high accuracy and repeatability. It can also produce clean, smooth edges with minimal material waste.

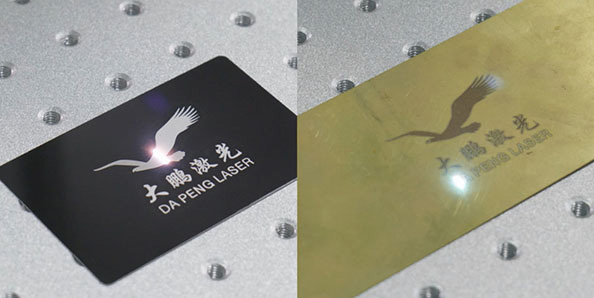

Laser Marking Machine

High Precision | Permanent Marking | Various Materials

Laser marking machines use laser beams to create permanent marks on various materials. Depending on application needs, they may use fiber, CO₂, or UV laser sources.

Ultrafast laser marking & cutting machines, utilizing ultrashort laser pulses such as infrared and UV picosecond lasers, offer even greater precision and speed. They produce permanent, high-contrast marks with minimal thermal impact, making them ideal for metals, plastics, ceramics, glass, film and transparent materials.

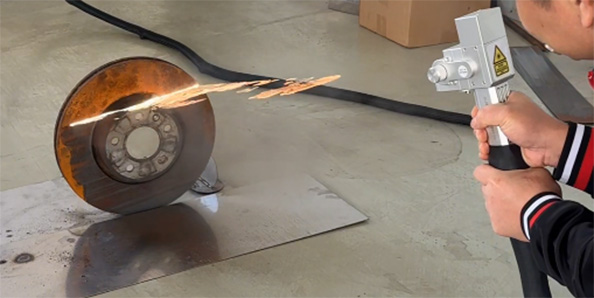

Laser Cleaning Machine

Non-chemicals | Precision | Efficiency

Laser cleaning machine often use to remove contaminants, such as rust, paint, oil, and coatings from the surface of a material. Laser cleaning is a non-contact, eco-friendly, and efficient process that can be used on a variety of surfaces, including metals, plastics, rubber, wood and more. It is commonly used in mold, components cleaning before and after welding and cutting, preparation and maintenance.

Professional Laser Equipment Manufacturer

More than 60 professional innovation team members, including engineer, designers, and product managers. Develop more than 50 laser machines development and ODM projects every year.

Laser processing is a single pulse energy acting on the surface of the material in a very short time, and through high-frequency repetitive work, drilling, cutting, marking, welding and other applications are formed.

Nanoseconds, picoseconds, and femtoseconds in laser processing equipment refer to the time control units in the laser processing process.

The following is the time unit:

1ms (millisecond) = 0.001 second = 10^-3 second

1μs (microsecond) = 0.000001 = 10^-6 second

1ns (nanosecond) = 0.0000000001 second = 10^-9 second

1ps (picosecond) = 0.0000000000001 second = 10^-12 second

1fs (femtosecond) = 0.000000000000001 second = 10^-15 second

Why Use Picosecond and Femtosecond Lasers for Marking & Cutting?

Picosecond (10^-12 second) and femtosecond (10^-15 second) lasers, with their ultra-short pulse durations and minimal heat impact, achieve micron-level precision, making them ideal for high-precision marking and cutting of plastic, glass, and delicate substrates. Even on heat-sensitive or ultra-thin materials, they prevent burning or yellowing. These ultrafast lasers are suitable for industrial and precision applications, including OLED and LCD manufacturing.

Dapeng Laser is a laser equipment R&D manufacturer integrating R&D, manufacturing, sales and service. The company covers more than 200 kinds of laser equipments, including laser cutting machine, laser marking machine, laser welding machine, laser engraving machine and laser cleaning machine products. DP Laser is committed to providing customers with laser processing solutions and professional technical support to become a trusted partner. Please contact our technical team online for customized laser equipment solutions and quotes!

When the temperature is low in winter, in order to ensure the normal use of the laser machine and equipment maintenance, antifreeze will be added to the water tank. So, what happens in hot climates? When working in hot weater, as long as the water tank cannot reach the cooling effect, the equipment will alarm and suspend operation. How to avoid similar situations from happening? The water tank is the key, the size of the water tank determines the operating time to maintain normal temperature. The smaller the water tank, the weaker the constant temperature capability, and the water tank larger the stronger, and there is also certain gap in cost. In order to reduce production costs, many manufacturers also equip with small water tanks, which is why there are price differences.

Metal laser engraving machines are generally fiber laser engraving machines. The wavelength of this fiber laser machine is 1064nm, which can be absorbed by metals and some non-metals. Its effect on metals is very obvious. By adjusting the parameters, it can print black and white content and the power of the laser. Metal laser engraving machines can also engrave some plastics, but the effect is not ideal, because plastics are heat-sensitive materials, the content printed by this machine will not fine enough. The plastic laser marking machine is actually an UV laser engraving machine. The light it emits is purple, so it is also called a purple light machine. It is mainly used for laser engraving on various plastic, wood, fabric and non-metals products.

Laser welding machines, especially handheld fiber laser welding machines, have a wide range of applications and can weld various metals. They work well with most metals, including stainless steel, carbon steel, aluminum, copper, nickel, titanium, steel, magnesium, and alloy products. The precision of handheld fiber laser welding makes it an ideal choice for clean and strong welds across various metal sheet and pipe.

Yes, laser welding, especially when using tools like handheld fiber laser welding machines, can be as strong as arc welding and is more efficient, with over three times the efficiency of traditional welding. Laser welding generally offers better accuracy and cleaner connections.

Frequently Asked Questions

These are some of the most frequently asked questions about laser technology. Please be sure check if your question has been answered here before submitting a support ticket. If you can’t find the answer here and knowledge base, we’re happy to help anytime!