Build Your Laser Cleaning Machine

DPLASER focuses on designing and customizing laser cleaning machines for different industries to meet the individual needs of customers. We have a professional engineer and technical team with rich laser equiment technology and experience, and adopt the most advanced equipment and technology to ensure the efficiency, precision and durability of our laser cleaning machines.

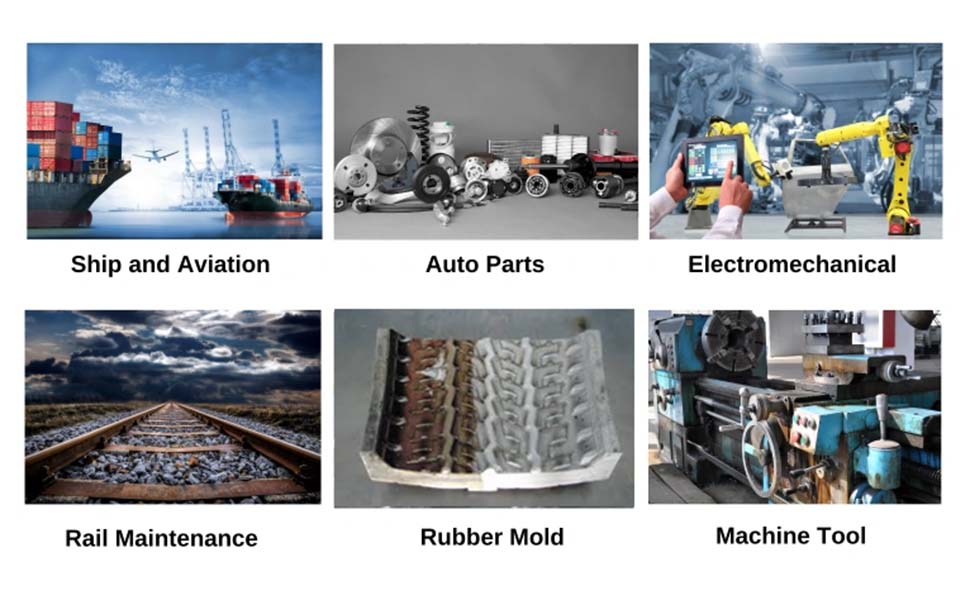

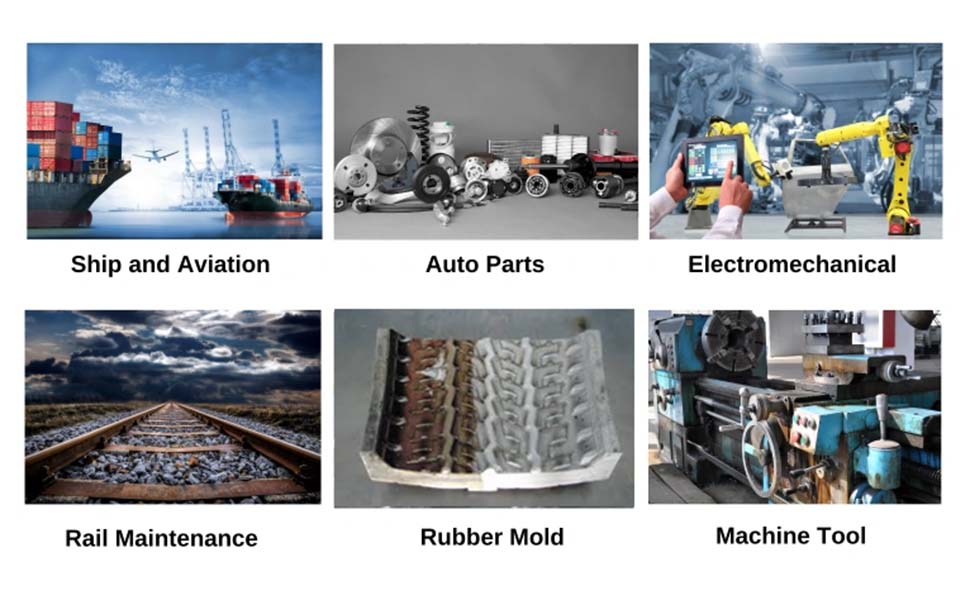

Laser cleaning equipment is suitable for surface cleaning of various materials, including metal, rubber, plastic and composite materials, and can be customized according to customer requirements, such as the size, cleaning material and cleaning precision, etc. We serve a variety of industries including aerospace, automotive, electronics and medical devices. We are committed to providing customers with the best quality service, ensuring that they get the perfect industrial laser cleaning machine to make their production process more efficient, safer, high quality and more environmentally friendly.

The Benefits of Laser Cleaning Machine

Laser cleaning machines provide precise cleaning capabilities that can remove contaminants without damaging the underlying material. This is particularly useful in manufacturing, where precision is critical.

Laser cleaning machines can quickly and effectively clean large areas without the use of harsh chemicals or abrasives. This reduces the amount of time and resources needed for cleaning, and also eliminates the need to dispose of hazardous waste.

Laser cleaning machines can quickly and effectively clean large areas without the use of harsh chemicals or abrasives. This reduces the amount of time and resources needed for cleaning, and also eliminates the need to dispose of hazardous waste.

Regular cleaning with laser cleaning machines can help to prevent the accumulation of contaminants, reducing the need for expensive maintenance and repairs.

Laser cleaning machines do not use harmful chemicals or create hazardous waste, making them a more environmentally friendly cleaning option.

4 Types of Laser Cleaning Machines

1. Handheld laser rust removal machine

Handheld laser descaling machine is a kind of portable equipment specialized in descaling metal surface, users can directly hold the laser head on the target rust area for accurate and efficient removal operations. It is especially suitable for local rust removal, historical building restoration, ship maintenance, industrial equipment maintenance and other fields.

2. Handheld laser cleaner

Handheld laser cleaner has a wider range of applications, in addition to metal descaling, can also be used to remove a variety of material surface contaminants, such as paint, oxidation layer, grease, glue residue. The same handheld operation is mainly suitable for small-scale operations, complex parts cleaning or the need to flexibly respond to a variety of cleaning needs of the scene.

3. Automatic laser cleaner

Automatic laser cleaning machine is a kind of integrated in the fixed worktable or mobile platform, through the preset program or mechanical movement to realize automatic continuous cleaning equipment. Suitable for large-scale production, high-volume workpiece processing or highly standardized cleaning process, can significantly improve the cleaning efficiency and consistency.

4. Robot laser cleaning system

Laser cleaner robot combined with advanced robotics, with six-axis or multi-axis robotic arm, capable of realizing the three-dimensional space in any angle and complex surfaces of the precise cleaning. This type of equipment is suitable for high-precision, high-complexity parts cleaning, as well as the need to strictly control the cleaning quality and repeatability of high-end manufacturing areas.

Handheld laser rust remover and handheld laser cleaning machines rely on manual operation and are extremely flexible, suitable for localized, small range or complex surface cleaning. Automatic and robotic laser cleaning equipment, realizes automated or intelligent operation, and is suitable for large-volume, continuous production or high-precision, complex three-dimensional contour cleaning tasks.

Laser Removal of Contaminants

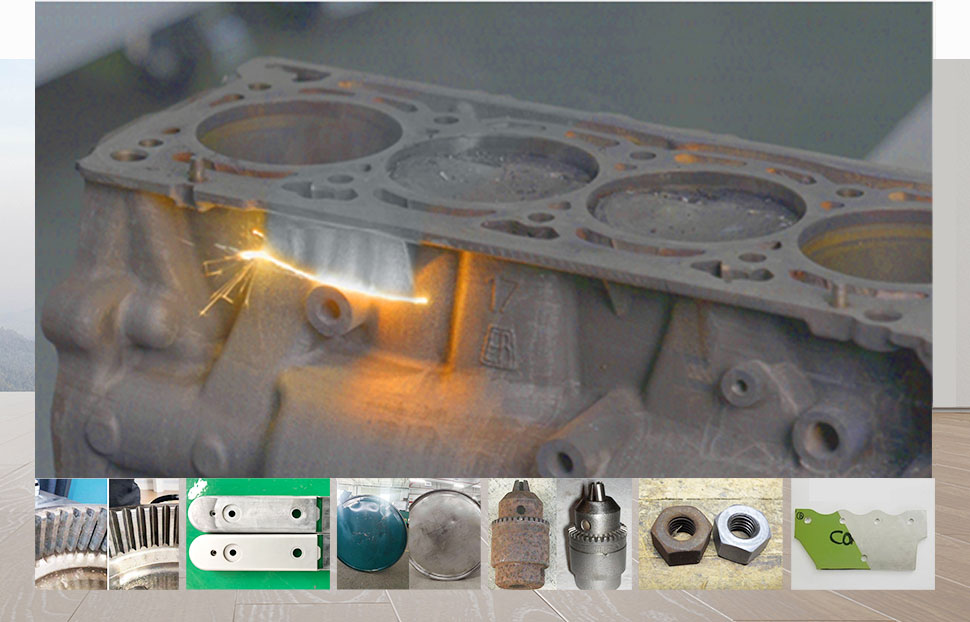

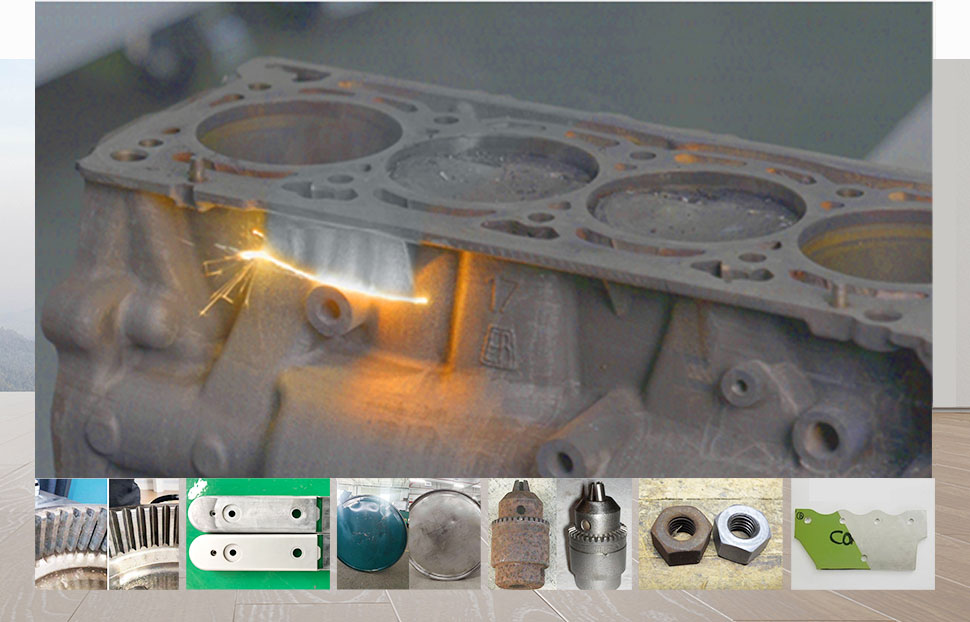

Laser cleaner is used to remove contaminants, such as rust, paint, oil, grease, coating and other stains from surfaces. It works by emitting a high-intensity laser that heats the surface, causing the contaminant to evaporate or break down into smaller particles that can easily be swept away.

- Removes contaminants: including oxides, coatings, electrolytes, dust, etc.

- Prepare surfaces for bonding, thermal spraying, welding, etc. by cleaning and texturizing surfaces.

- Removes electrophoretic, phosphate and powder coatings.

- Non-contact, non-polluting cleaning method that replaces traditional cleaning methods such as sandblasting, plasma cleaning, and chemical cleaning.

Laser Cleaning for Pre-treatment

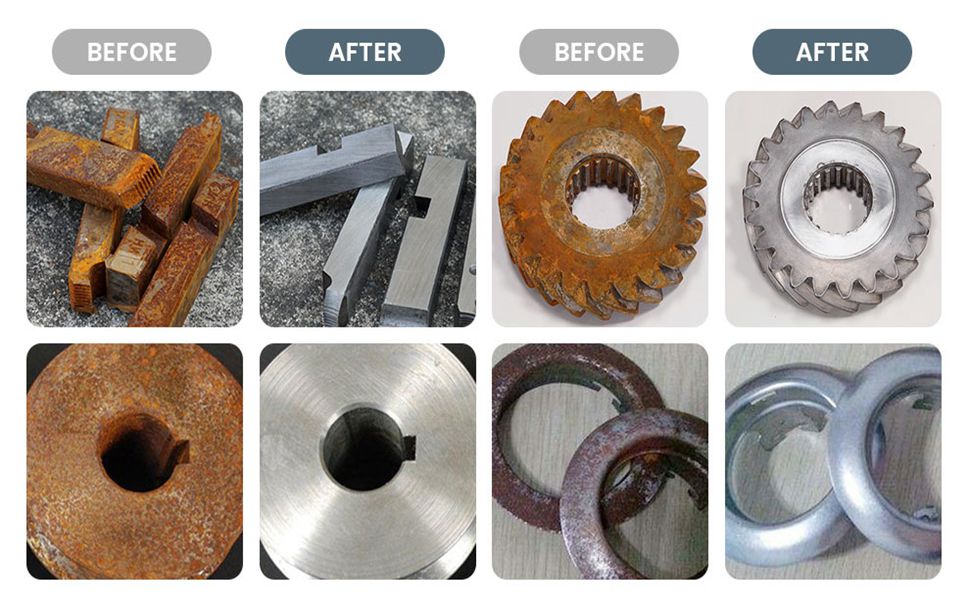

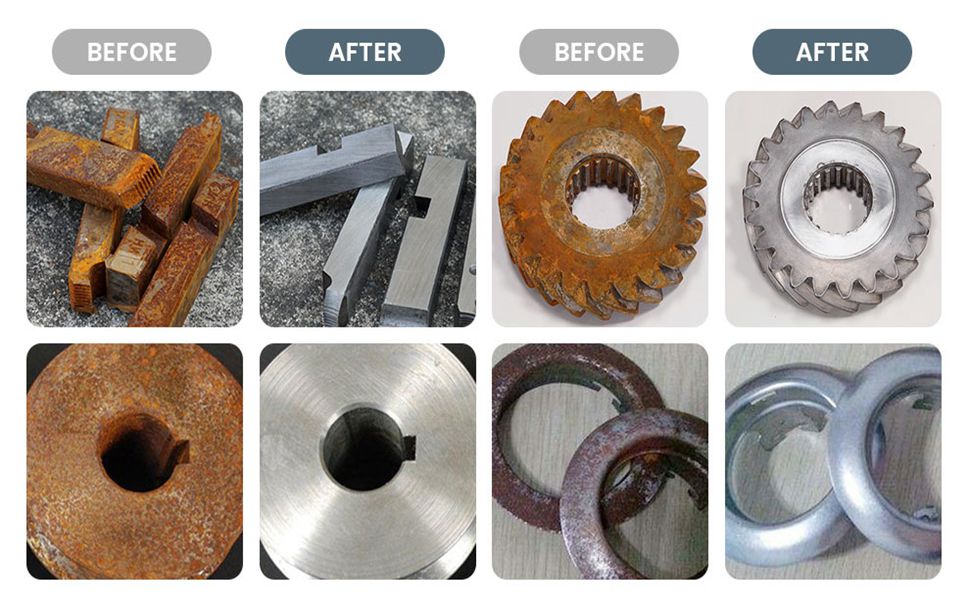

Before cleaning, a surface or material may have visible contaminants, such as rust, oil, paint, stains, coating, oxide or dirt. The surface may be discolored or have uneven texture. After cleaning with a laser cleaning machine, the contaminants are removed, revealing a clean and smooth surface. The color and texture may also be restored to their original state. The laser cleaning process completely removes rust, ensuring you get high-quality coated parts.

Industrial Applications of Laser Cleaning

Laser cleaning is an effective and versatile method of surface cleaning that finds applications in numerous fields, including manufacturing, automotive, aerospace, and art restoration for tool & mould cleaning, paint stripping of metallic components, cleaning of sensitive materials without damaging the metal underneath.

- Laser Cleaning

Laser Cleaning

Handheld Laser Rust Removal Cleaning Machine Brochure v.2023

Handheld-Laser-Rust-Removal-Cleaning-Machine-Brochure v.2024

3 in 1 Fiber Handle Laser Machine Manual

Custom Your Laser Cleaning Machines – DPLASER

Welcome to DPLASER laser cleaning machine business! We specialize in providing innovative solutions for your industrial cleaning needs. Our state-of-the-art laser cleaning systems are designed to effectively remove rust, paint, oil, oxidation, corrosion, adhesives and other contaminants from a wide range of surfaces without causing damage or leaving residue.

Our experts team works closely with each customer to understand their unique cleaning requirements and provide customized solutions that meet their specific needs. Whether you’re looking to clean large industrial application or precision electronic components, our laser cleaning machines can provide a efficient cleaning effect. We also can provide advanced laser cleaning solutions that are integrated into your production line.

What Do You Need?

When choosing a laser cleaner, we will ask you a variety of questions about your project and what you hope to achieve, including:

- Cleaning Requirements: Define specific cleaning parameters, such as the object (material base and contaminant), the cleaning area, the cleaning depth and the accuracy required.

- Current cleaning type, rate

- Processing steps before parts are cleaned

- Processing steps after cleaning

- Productivity and process: Consider the need for integration into production lines, cleaning frequency, quantity, and requirements for cleaning consistency and efficiency.

- Customization and technical support: whether there are special cleaning needs or complex application scenarios.

If you’re looking for a reliable and effective laser cleaning solution for your industrial and production application. Contact us now to get a application evaluation.

Get a Free Laser Cleaning Machine Quote!

Do you have a question for us? Are you looking for career advice on laser machines? Contact us if you have a query about the laser equiment and laser industry.