DP LASER QUALITY MANAGEMENT

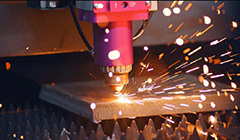

Shenzhen Dapeng Laser Technology Co., Ltd. is a laser equipment supplier integrating R&D, manufacturing, sales and service. The main products and services include laser engraving machine, laser cutting machine, laser soldering machine, non-standard automation, laser cleaning machine, precision micro-processing and more series of more than 100 kinds of industry-specific laser equipment and solutions. The laser product quality of DP Laser is stable and reliable. It has a professional R&D team. While pursuing excellent quality, we also provide customers with timely and comfortable pre-sales, sales, after-sales services and excellent cost-effective laser solutions.

Quality Inspection

We adhere to stringent industry standards and are certified under both the ISO9001 Quality Management System and ISO14001 Environmental Management System, ensuring excellence in product performance while minimizing environmental impact.

Our end-to-end quality control spans R&D, production, shipping, and after-sales service, with rigorous checks on every component and finished machine. By integrating these systems, we guarantee that our laser equipment delivers exceptional stability, reliability, and sustainability at every stage.

1. Laser Source Testing

2. Incoming Material Testing

3. Rack Installation & Testing

4. Gantry Milling

5. Motor & Reducer Testing

6. Accuracy Detection

7. Calibration

8. Testing Machine

Production Process

In the assembly of the machine, every step of production strictly follows the quality management standard. We assign the processing engineer with the rich skills to head all custom project to ensure that all projects are approved by customers. Every equiment is 100% tested for functionality before it is submitted to final inspection and packing. Dapeng quality department maintains records on each component and laser machine to trace the source at any time for maintain.

1. Machine Bed Welding

2. First Polishing

3. Heat Treatment

4. Measurement Accuracy

5. Spray Paint

6. Gantry Milling

7. Wiring Test

8. Technique Debugging

9. Test Running

Packing & Shipping

The laser equipment requires multiple protect during the packing and shipping to ensure that each component is not affected by the accident. In the delivery, we focus on the best customer experience and check every risk of transportation. Make sure the machine is safe and delivered as soon as possible.

1. Cleaning

2. Brush Oil

3. Protective Film Wrapping

4. Wooden Box Delivery

5. Box Nailing

6. Wooden Boxseal

7. Container Loading

8. Shipping and Delivery