Industrial Fiber Laser Cutting Machine

DP Laser Technology Co., Ltd. is a professional laser equipment manufacturer specializing in the research, development, manufacturing, and sales of laser machines. Its laser cutting machine products cover various types, including plate, shaped tube, coils, and pipe.

Sheet laser cutting machine: DPLASER Laser’s flatbed laser cutting machine is suitable for the flat processing of various metal materials. It uses high-precision laser cutting heads, which have the advantages of high speed, high precision, high efficiency, and low cost, making it suitable for development-oriented enterprises and large-scale production enterprises used in metal processing industry, such as metal structural parts, kitchen utensils, electrical appliance housings, construction materials and so on.

Pipe laser cutting machine: DPLASER pipe laser cutting machine is suitable for various tube processing, can meet customer’s complex pipe processing requirements, and has the characteristics of high efficiency, high precision, and high quality. It also has multiple advantages such as saving labor and material costs and improving product competitiveness, suitable for pipe manufacturing, furniture manufacturing and other fields.

DPLASER laser cutting systems is professional, efficient, intelligent, and easy to use, with wide adaptability and flexibility, and can meet customers’ customized requirements for different processing needs.

Sheet Laser Cutting Machine Series

The main components of laser cutting system: machine bed and host part, laser generator, CNC system, voltage stabilized power supply, laser cutting head, laser chiller, industrial dust collector (or dust extraction fan, etc.), waste collection device (chip conveyor or waste trolley, etc.) and oil and gas circuit system and other components.

Fiber laser cutting engraving machine according to the structure composition can be divided into: large surrounded (parallel exchange), exchange table, single table, plate and tube integrated machine.

Fully Enclosed Laser Cutting Machine

Switchboard Laser Cutting Machine

Single Platform Laser Cutting Machine

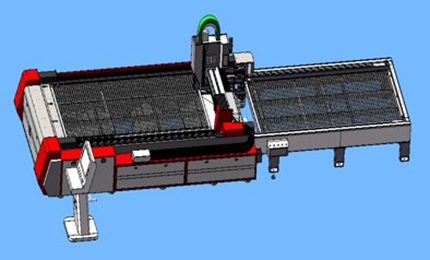

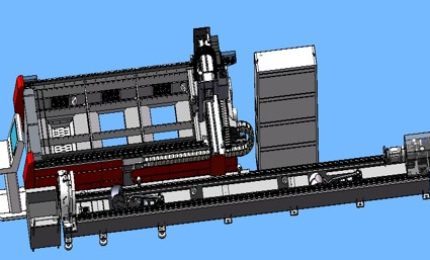

Tube and Plate Integrated Machine

A Series Laser Cutting Machine for Sheet

1. The cutting bed is welded as a whole and processed after annealing to eliminate internal stress. The process includes welding, stress relief annealing, rough machining, vibration aging, and finishing. This effectively addresses the stress caused by welding and processing, greatly improving the stability of the machine tool and maintaining its accuracy over a long period.

2. The bed is designed with a hollow structure, ensuring that it does not deform even during high-power and ultra-high-power cutting operations.

3. The bed body can accommodate laser cutters of all power ranges (≤8kw), allowing the same bed body to be used for medium, high, and ultra-high-power cutting machines.

4. The bed body adopts a double-foot support structure, providing enhanced stability during high-speed movements of the equipment.

5. The bed body features a segmented ventilation system at 45°, improving the effectiveness of dust extraction.

6. The crossbeam adopts a welded integrated aluminum structure design, which makes it lightweight, rigid, and compact in structure.

7. The Z-axis structure is optimized with a combination of screw and slider, resulting in a significant improvement in precision and rigidity.

8. The cutting performance of the machine tool has been greatly improved, leading to a substantial enhancement in cutting precision. The maximum cutting acceleration can reach 1.5G.

Sheet & Pipe Laser Cutting Machine Series

1. The cutting bed is welded as a whole and processed after annealing to eliminate internal stress. The process includes welding, stress relief annealing, rough machining, vibration aging, and finishing. This effectively addresses the stress caused by welding and processing, greatly improving the stability of the machine tool and maintaining its accuracy over a long period.

2. The bed is designed with a hollow structure, ensuring that it does not deform even during high-power and ultra-high-power cutting operations.

3. The bed body can accommodate laser cutters of all power ranges (≤8kw), allowing the same bed body to be used for medium, high, and ultra-high-power cutting machines.

4. The bed body adopts a double-foot support structure, providing enhanced stability during high-speed movements of the equipment.

5. The bed body features a segmented ventilation system at 45°, improving the effectiveness of dust extraction.

6. The crossbeam adopts a modular aluminum structure design, making it lightweight and rigid.

7. The Z-axis structure is optimized with a combination of screw and slider, resulting in a significant improvement in precision and rigidity.

8. The sheet metal design is simple and elegant, in line with ergonomics principles, and facilitates manual loading.

9. When cutting pipes on the machine, over-position cutting with the chuck can be achieved, allowing for zero tailings processing. This results in shorter waste material, maximizing material utilization, and reducing customer costs.

10. The chuck uses a top-notch brand’s huck, expanding the cutting range for square pipes and enhancing the processing capabilities of the machine tool.

Fiber Laser Cutting Machine Bed Size & Type

Dapeng fiber laser cutting machines offer a variety of bed size options, including 3015 (3000×1500mm), 4015 (4000×1500mm), 4020 (4000×2000mm), 6020 (6000×2000mm), 6025 (6000×2500mm), 8025 (8000×2500mm), and 12025 (12000×2500mm) and more. If you have more customized requirements, feel free to let us know on website.

Exchange Table Fiber Laser Cutting Machine

An exchange table allows for the loading and unloading of materials on one side of the table while cutting operations are performed on the other side. This reduces idle time and optimizes the use of machine time, resulting in higher productivity and throughput. Additionally, exchange tables can help reduce material waste by allowing for more precise cutting and nesting of parts.

Single Table Plate Fiber Laser Cutting Machine

Single workbench laser cutting machine is a cost-effective and space-saving cutting solution.

1. Limited space: If you have limited space in your workshop or facility, a single table laser cutting machine can be an ideal solution. These machines are generally more compact than other types of laser cutting machines, making them a space-saving option.

2. Budget constraints: Single platform laser cutting machines are usually cheap than other type, making it is a good option for businesses that are just starting out or have a limited budget.

Tube Plate Integrated Fiber Laser Cutting Machine

Enclosed laser cutting machines offer enhanced safety by containing laser radiation, improved efficiency with better dust and fume extraction, reduced noise, and a cleaner work environment. The full cover design also ensures higher precision cutting by providing stable operating conditions and minimizing external interference.

Tube and plate integrated cutting machine allows for the cutting of not only flat materials like metal & non-metal sheets, plates but also cylindrical or three-dimensional objects like tubes, pipes, and profiles.

By using a single machine to cut both tubes and plates, you eliminate the need for multiple machines or manual cutting processes, which can help to maximize productivity and reduce production time.

Fiber laser cutting machine for plate and tube can handle a wide variety of materials and thicknesses, making them an ideal choice for a range of applications and industries.

High Precision Laser Cutting Machine

The precision laser cutting machine of DPLASER include linear precision laser cutting machines and driver screw precision cutting machines.

It is a type of tool used to cut, engrave, or mark various materials with extreme accuracy and precision using a laser beam. These machines use a focused laser beam to cut, slice, or engrave materials like metal, wood, plastics, and many others.

They use computer-controlled programming to create intricate shapes and cutouts accurately, resulting in parts with tight tolerances, clean edges, and smooth surfaces for a wide range of applications, including aerospace, automotive, medical, jewelry, and more. High precision laser cutting machines allow for the creation of highly detailed and intricate pieces that would be difficult or impossible to achieve with traditional cutting engraving methods.

Professional Pipe Laser Cutter

DPLASER professional pipe laser cutting machine designed specifically for cutting various types of pipes and tubes, including round, square, and rectangular tubes, with extreme precision.

Professional pipe laser cutters offer many advantages over traditional cutting methods, such as sawing or drilling. Firstly, they produce clean and smooth edges, reducing the need for additional finishing processes and reduced material waste. Secondly, they can be programmed to cut complex shapes and patterns, including angled cuts, bevels, and intricate designs. Finally, they can cut through a wide range of materials, including steel, stainless steel, aluminum, copper, and other metal alloys.

- Laser Cutting

Laser Cutting

Laser Cutting Machine Maintenance Instruction-CN

DPE-3015 Fiber Laser Cutting Machine Manual

Build Your Own Laser Cutting & Engraving Machine

Configurations and options can be customized for laser cutting machines depending on your application and specific needs. Just tell us your application, material, thickness requirements. We will provide you with professional laser cutting solutions and proofing for free.

These are the laser cutter configurations you can customize,

🌟1. Laser type: Different types of lasers are suitable for different materials. CO2 lasers are commonly used for cutting and engraving non-metallic materials, while fiber lasers are ideal for cutting and engraving metals.

🌟2. Laser power: The wattage of the laser can be adjusted to suit the thickness and type of material being cut.

🌟3. Cutting bed size: The size of the cutting bed can be customized to fit the dimensions of the material being cut.

🌟4. Cutting head type: Different types of cutting heads can be selected based on the application, including fixed, programmable, and 2D or 3D cutting heads.

🌟5. Automation options: Automatic nozzle changing, material handling, and other advanced automation features can be added to increase productivity and efficiency.

🌟6. Software: Software packages can be chosen to suit specific applications, providing features such as CAD/CAM integration, nesting optimization, and material tracking.

🌟7. Other options: Other customization features include positioning accuracy, cutting speed, cooling and smoke removal system, safety systems and sensors, etc.

Cutting Thickness & Material Reference

| 500W | 1000W | 2000W | 3000W | 4000W | 6000W | ||

| Material | Thickness(mm) | Speed(m/min) | Speed(m/min) | Speed(m/min) | Speed(m/min) | Speed(m/min) | Speed(m/min) |

| Carbon steel(Q235A) | 1 | 8-13 | 15-24 | 24-30 | 30-42 | 40-55 | 60-80 |

| 2 | 3-4.5 | 5-7.5 | 5.5-8 | 7-9 | 8-10 | 9-12 | |

| 3 | 1.8-3 | 2.4-4 | 3.5-4.8 | 4-6.5 | 4.5-6.5 | 4-7 | |

| 4 | 1.3-1.5 | 2-2.4 | 2.8-3.5 | 3.5-4.5 | 4-5 | 4.2-5.5 | |

| 5 | 0.9-1.1 | 1.8-2 | 2.5-3 | 3.-3.5 | 3-4.2 | 3.5-4.2 | |

| 6 | 0.6-0.9 | 1.4-1.6 | 1.8-2.6 | 2.5-3.2 | 3-3.5 | 3-4 | |

| 8 | 0.8-1.2 | 1.2-18 | 1.8-2.6 | 2-3 | 2.2-3.2 | ||

| 10 | 0.6-1 | 1.1-1.3 | 1.4-2 | 1.5-2.5 | 1.8-2.5 | ||

| 12 | 0.5-0.8 | 0.9-1.2 | 1.2-1.6 | 1.4-2 | 1.6-2 | ||

| 14 | 0.7-0.8 | 0.9-1.4 | 1-1.6 | 1.5-1.8 | |||

| 16 | 0.6-0.7 | 0.8-1.2 | 0.8-1.2 | 0.8-1.5 | |||

| 18 | 0.4-0.6 | 0.7-1 | 0.8-1.1 | 0.9-1.2 | |||

| 20 | 0.6-0.8 | 0.7-1 | 0.8-1.1 | ||||

| 22 | 0.4-0.6 | 0.6-0.8 | 0.7-0.9 | ||||

| 25 | 0.3-0.5 | 0.4-0.6 | |||||

| Stainless steel(201) | 1 | 8-13 | 18-25 | 24-30 | 30-42 | 40-55 | 60- 80 |

| 2 | 2.4-5 | 7-12 | 10-17 | 18-21 | 20-30 | 30-42 | |

| 3 | 0.6-0.8 | 1.8-2.5 | 4-6.5 | 8-12 | 12- 18 | 18-24 | |

| 4 | 1.2-1.3 | 3-4.5 | 6-9 | 8-12 | 10-18 | ||

| 5 | 0.6-0.7 | 1.8-2.5 | 3-5 | 4-6.5 | 8-12 | ||

| 6 | 1.2-2 | 3-4.3 | 4-6.5 | 6-9 | |||

| 8 | 0.7-1 | 1.5-2 | 1.8-3 | 4-5 | |||

| 10 | 0.8-1 | 0.8-1.5 | 1.8-2.5 | ||||

| 12 | 0.5-0.8 | 0.6-1 | 1.2-1.8 | ||||

| 14 | 0.5-0.8 | 0.6-0.8 | |||||

| 20 | 0.4-0.5 | 0.5-0.8 | |||||

| 25 | 0.4-0.5 | ||||||

| Aluminum | 1 | 4-5.5 | 6-10 | 20-25 | 25-40 | 40-55 | 55-65 |

| 2 | 0.7-1.5 | 2.8-3.6 | 7-10 | 10-18 | 15-25 | 25-35 | |

| 3 | 0.7-1.5 | 4-6 | 7-10 | 10-15 | 13- 18 | ||

| 4 | 2-3 | 4-5.5 | 8-10 | 10-12 | |||

| 5 | 1.2-1.8 | 3-4 | 5-7 | 6-10 | |||

| 6 | 0.7-1 | 1.5-2.5 | 3.5-4 | 4-6 | |||

| 8 | 0.7-1 | 1.5-2 | 2-3 | ||||

| 10 | 0.5-0.7 | 1-1.5 | 1.5-2.1 | ||||

| 12 | 0.7-0.9 | 0.8-1.4 | |||||

| 16 | 0.5-0.7 | 0.7-1 | |||||

| 20 | 0.5-0.7 | ||||||

| Brass | 1 | 4-5.5 | 6-10 | 14-16 | 25-35 | 35-45 | 50-60 |

| 2 | 0.5-1 | 2.8-3.6 | 4.5-6.5 | 10-15 | 10-15 | 25-30 | |

| 3 | 0.5-1 | 2.5-3.5 | 5-8 | 7-10 | 12-18 | ||

| 4 | 1.5-2 | 3.5-5 | 5-8 | 8-10 | |||

| 5 | 1.4-1.6 | 2.5-3.2 | 3.5-5 | 6-7 | |||

| 6 | 1.2-2 | 1.5-2.5 | 3.5-4.5 | ||||

| 8 | 0.7-0.9 | 0.8-1.5 | 1.6-2.2 | ||||

| 10 | 0.5-0.8 | 0.8-1.4 | |||||

| 12 | 0.6-0.8 |

Get a Free Laser Cutting Machine Quote!

Do you have a question for us? Are you looking for career advice on laser machines? Contact us if you have a query about the laser equiment and laser industry.