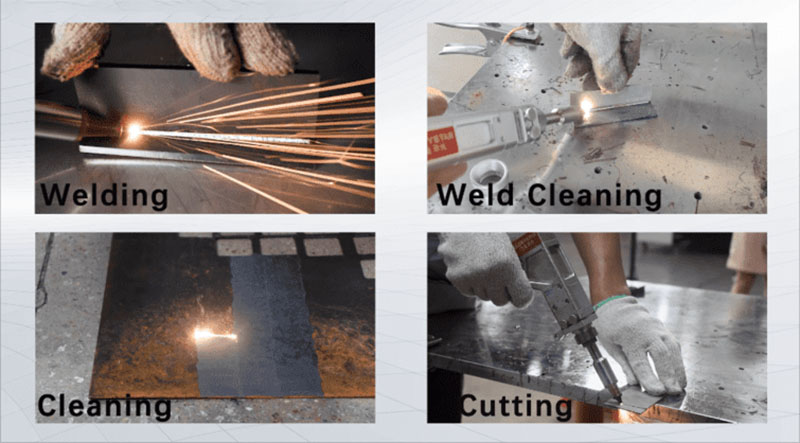

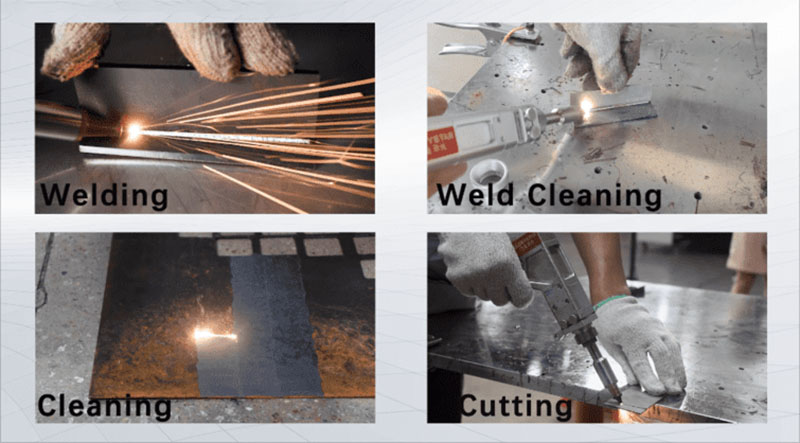

4 in 1 Handheld Fiber Laser Welding Machine for Welding, Cutting, Cleaning & Weld Path Cleaning

4 in 1 handheld laser welding machine is composed of fiber laser source, handheld laser gun, water chiller, and 4 in 1 control system, which is used for handheld welding, cleaning, cutting and weld path cleaning. Its handheld laser guns can weld, cut metals and clean the weld bead, rust, paint, resin, coatings, oil, and stains. The product can be adapted to various brands of fiber lasers, and the optical and water-cooled design is optimized so that the laser head can work stably for a long time under 3000W.

With the additional of weld cleaning, the user-friendly design eliminates the need to purchase multiple laser machines for these various metal processing tasks. Whether you need to join two metal pieces, make precise cuts or remove residue, this handheld laser welder has you covered.

- Laser Welding:

This fiber laser welding machine allows for precision laser welding of various materials, including metals like steel, aluminum, and copper. With the ability to deliver high-power laser output, it enables efficient and accurate welding operations. The handheld laser welding systems is easy to learn and operate, capable of producing high-quality welding results on various materials and thicknesses. The weld seams are smooth and aesthetically pleasing, requiring no secondary grinding or post-processing. The high-speed welding efficiency contributes to increased productivity. This handheld metal laser welding machine has 5-in-1 metal welding functions, including spot welding, seam welding, pulse welding, continuous welding and repair welding, which can meet a variety of welding needs.

- Laser Cleaning:

The machine is also capable of laser cleaning, which is a non-abrasive method used to remove contaminants, rust removal, paint, and oxides from the surface of different materials. It offers a fast and efficient way to clean surfaces without damaging the underlying material.

- Laser Cutting:

In addition to welding and cleaning, this machine can perform laser cutting operations. By focusing a high-power laser beam onto a specific area, it can cut through various materials with precision, including metals, plastics, and composites.

- Weld Path Cleaning:

After welding, there may be excess material, splatter, or contaminants on the weld surface or in the weld path. This function likely involves using laser energy to clean and prepare the weld area for subsequent passes or finishing.

4 in 1 handheld laser welder with quadruple functions of laser welding, welding seam cleaning, cleaning, and cutting simultaneously. It can quickly and easily remove oil, rust, and coatings before welding, and clean debris and welding seam after welding, while performing various sheet metal cutting processes. It can conveniently and efficiently assist customers in achieving optimal work efficiency and meet the requirements of most working scenarios.

- 4 in 1 Handheld Laser Gun

The handheld laser gun offers welding, cleaning, welding seam cleaning and cutting capabilities through an intelligent controller. It facilitates flexible processing, is compact and portable, and comes with low operating costs due to it requires no consumables. - Mobile Use

Handheld 4-in-1 welding gun, 10 m fiber optic cable length - Easy Function Switching

Welding function converts to cleaning function by simply replacing the focusing lens and laser head. - Fiber Laser Generator Options

Options for fiber laser generators include brands like Ruike, MAX, and IPG, which offer higher photoelectric conversion efficiency, lower power consumption, maintenance-free operation, and a compact structure. - Built-in Cooling System Design

The built-in cooling system design eliminates the need for tangled wires, making it compact and portable for various production. It also provides excellent dust protection. - Intelligent Control Panel

With an integrated parameter adjustment range and one-touch start feature, the intelligent control panel ensures simplicity and ease of use.

4 in 1 Fiber Laser Welder Cleaner Cutter Features

- Portable design: These handheld laser welders are compact and portable, making them easy to carry and operate in different settings.

- Three functions: These welders have three functions, including laser welding, laser cutting, and laser cleaning, making them versatile tools for different welding applications.

- High precision: These laser welders are capable of achieving high levels of precision, leading to accurate and aesthetically pleasing welds.

- Wide range of metal weldability: These handheld laser welders can weld a wide range of metals, including stainless steel, aluminum, copper, brass, titanium, and others.

- User-friendly control panel: Handheld 4 in 1 laser welders feature a user-friendly control panel that is easy to understand and use, making it easy to adjust power and frequency settings.

- Safety features: To reduce the risk of accidents, these handheld laser welders come equipped with various safety features that prevent damage to the machine or injury to the user.

Advanced Laser Source

User-friendly and efficient, achieving faster and more precise results than TIG/MIG welding!

Digital Control System

Adjust welding parameters with ease, and switch between multiple welding modes at will! From precise spot welding to continuous welding, ensure you get the best results and quality every time you weld. The operation screen has a user-friendly touchscreen. It enables quick startup for users at any skill level.

Humanized Design

Our hadheld laser welding gun is lightweight, ergonomic design weighs just 0.8kg. It’s built for comfort during long hours of work.

HandHeld Laser Welding Mode

Various Metal Materials

|   |   |   |

| laser welding aluminum | laser welding carbon steel | laser welding stainless steel | laser welding copper |

Laser Cleaning VS Traditional:

- No damage to substrates, better appearance of molded.

- Laser cleaning machine is the high efficiency, energy saving metal laser cleaning equipment.

- Simple operation, can be hand-held or with manipulator to achieve automatic cleaning.

- Flexibility, removes almost any organic material

- Laser cleaning since rust is removed with greater precisionis, it is a great alternative to manual and chemical cleaning methods.

- Non-contact 360° cleaning, not limited by space and location, environmentally friendly without consumables.

- With universal casters, it is easy to move and install.

4 in 1 Handheld Laser Welding Machine Applications:

This 4 in 1 handheld fiber laser welding machine can be used to weld thin sheet metals, such as stainless steel, carbon steel, galvanized sheet, copper, aluminum alloy, gold, silver, chrome, nickel, titanium, tantalum and other various metals or alloys. In addition, it can also be used for irregular welding and cleaning work between dissimilar materials.

It is widely used in a variety of industries, including sheet metal manufacturing, mold manufacturing, medical equipment, cabinet kitchen and bath, sinks, lighting, billboards, door and window frames, household appliances, stainless steel doors and windows, handicrafts, furniture, automobile parts, chassis, power distribution boxes, stairs and elevators, shelves, ovens, stainless steel products, aluminum products, copper products, alloy materials, clocks and glasses, jewelries, and hardware components.

Why Choose DPLASER ?

Quality Management

According to the IS09001 quality management system, our company controls the finalized products in their incoming materials, processing process, complete machine and shipment to ensure the performance and quality of the shipped products. Several product series have obtained EU CE certification.

Service Network

The company has set up a marketing management center, sales and service network.

The network covers the whole country, all over the world. DPLASER has established a complete production, sales and after-sales service system, established a laser industrial park in Nantong, Jiangsu, Shenzhen, Wenzhou, Suzhou. We more than 20 offices in major domestic industrial cities and regions office, each office has equipment display, process proofing, sales and after-sales service, resident technical service personnel, to provide customers with timely and comfortable pre-sale, sale and after-sale support and services.

Rich Product

DPLASER provides a complete set of laser solutions and related supporting facilities for foreign customers. The main products include: laser marking machine series, laser welding machine series, laser cutting machine series, green laser demonstration series, PCB laser drilling machine series, linear There are more than 200 kinds of industrial laser equipment and supporting products in multiple series such as motor series. Widely used in electronic circuits, integrated circuits, instruments, instruments, printed circuits, computer manufacturing, mobile communications, auto parts, precision instruments, building materials, clothing, urban lighting, gold and silver jewelry, craft gifts, printing plate making and other industries.

FAQs

1. Are you a factory?

Yes, we have laser machine factory and the price is very competitive. We have after-sales technology to provide 24-hour service.

2. Which model should I choose?

Please tell us your materials, thickness, size, and the cutting objects (plates, tubes, etc) then we will provide you with professional suggestions.

3. If I do not know how to operate the fiber laser machine, how you can help me?

First, we have a detailed user manual and videos for your learning. Second, our engineers will provide you with technical support in time. If you want, we can provide you with training door to door.

4. How about the price? Can you make it cheaper?

The price depends on your configuration and requirements (function, size, quantity). Please contact us online now, our laser engineers can customize laser welding machine for your project.