Handheld & Automatic Integrated Laser Welding Machine

The manual automatic all-in-one laser welding machine is a laser welding equipment that combines handheld welding and automation functions. This type of equipment allows users to switch between two different operating modes on the same machine, accommodating various types and scales of welding tasks. The advantage of the integrated laser welding machine lies in its flexibility and versatility. It can adapt to various process requirements, whether it’s for batch production or special welding needs.

Manual Operation Mode: In the manual mode, the equipment can be controlled manually by the operator, similar to traditional handheld welding devices. This makes the equipment highly suitable for small-batch production, on-site repairs, and welding of special-shaped workpieces.

Automated Operation Mode: In the automated mode, the equipment is equipped with a programming system that can perform automatic batch welding tasks according to pre-set welding paths and parameters. This automation feature makes the equipment suitable for large-scale production and high-repetitive welding tasks, enhancing welding productivity and consistency.

Main advantages:

- Integration of handheld and automatic welding in one machine.

- It maintains the flexibility of handheld welding while allowing for automatic welding through programming via the control system.

- The handle programming is simple, making it easier to achieve automation. It can store up to 100 different programs to meet the needs of automatic welding for various products.

- Additionally, the handheld welding system can be customized to meet specific customer requirements, such as single rotation axis, one-axis, two-axis, three-axis, and other configurations.

- Automatic welding workstation: The workpiece can undergo planar trajectory movement, allowing for welding of points, straight lines, circles, squares, or any planar pattern composed of straight lines and arcs.

- Swing-type handheld welding head: Equipped with a 10-meter imported optical fiber, it can weld various complex weld seams and irregular workpieces of large size, enabling welding at any angle.

Control System

The control system developed for fiber laser welding CNC equipment features simple operation and high power accuracy. The software runs on a platform and works in conjunction with the control card to accomplish various laser welding processes. Compared to similar products, it offers advantages such as simple and stable communication and fast transmission speed.

Welding Head

This welding head is suitable for fiber laser welding machines with a power of 2000W and below. It is specifically optimized and upgraded for particular operating environments, ensuring reliable and stable operation in everyday industrial settings. With excellent welding quality and speed, it seamlessly integrates with the system, achieving deep fusion and further enhancing production efficiency. The control system is designed with modular components for ease of use and maintenance.

High Quality Lasers

This brand’s laser has significantly superior divergence angle parameters compared to other types of lasers. As a result, it allows the use of medium and long focal length processing lenses, greatly increasing the depth of field and reducing the probability of damage to optical components. This makes it an ideal choice for long-distance welding applications.

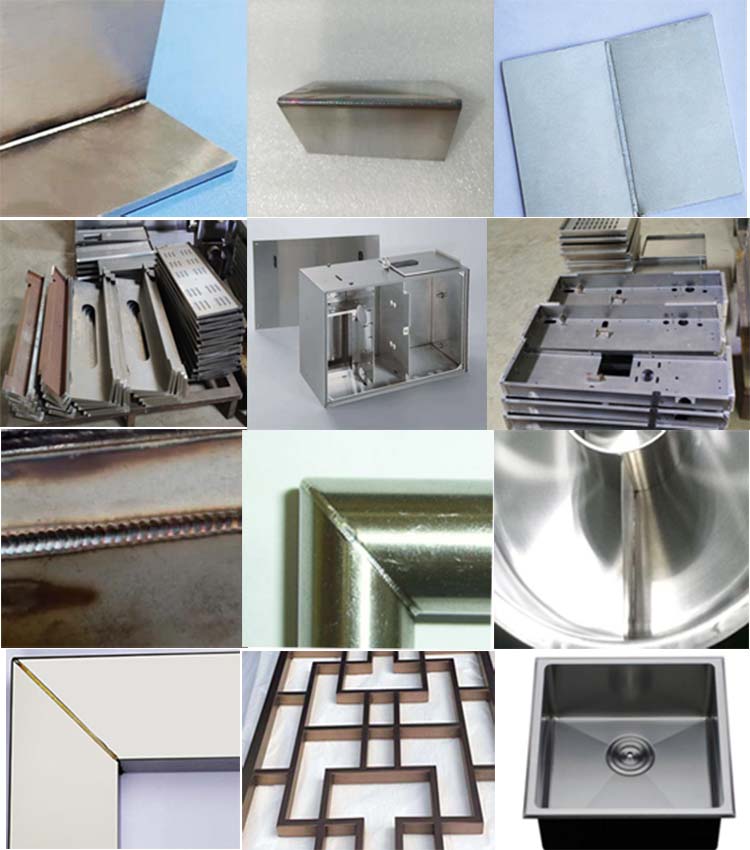

Welding Materials:

Carbon steel, stainless steel, aluminum alloy, brass, bronze, galvanized sheet, silicon steel sheet, electrolytic sheet, titanium alloy, manganese alloy, and so on.

Application Scope:

It is widely used in hardware accessories, new energy battery industry, bathroom industry, eyewear, kitchen and bathroom, home appliances, motors, instruments, advertising, molds, stainless steel doors and windows, crafts, furniture, automotive accessories, and other industries.

Reviews

There are no reviews yet.