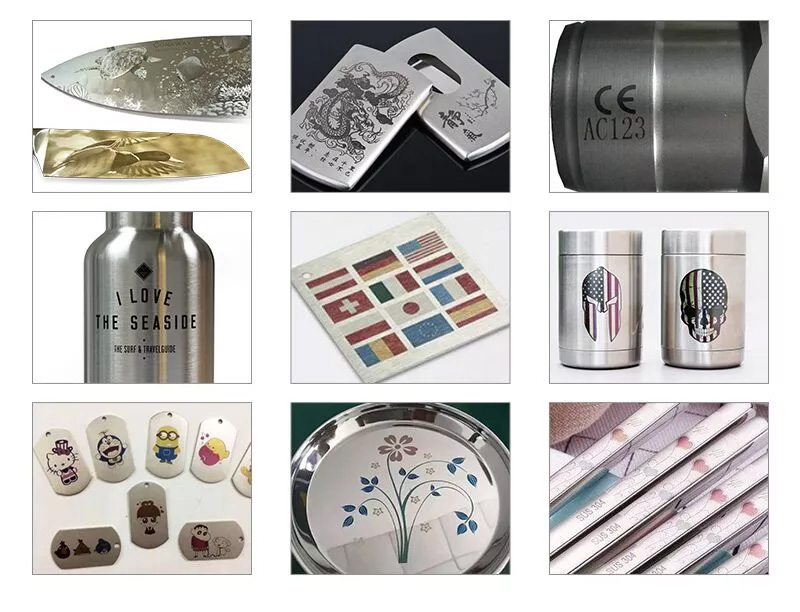

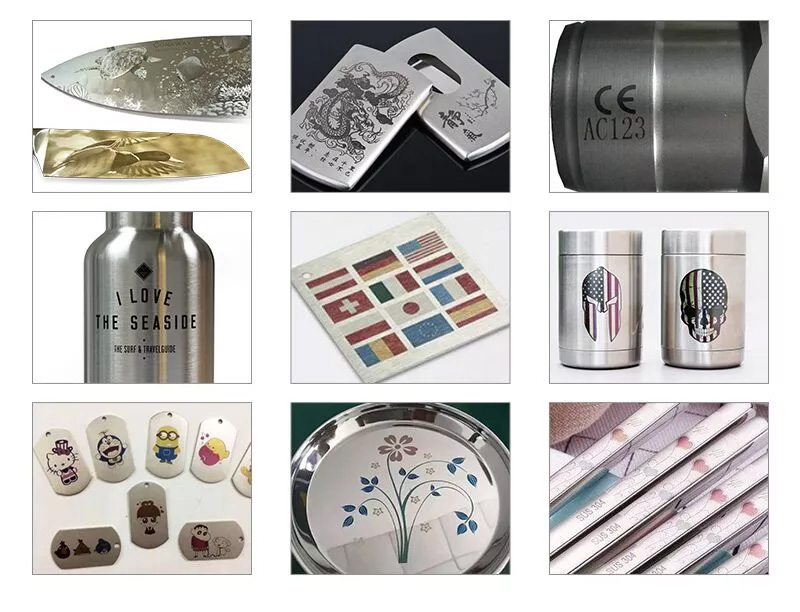

Color laser marking machine can etch intricate patterns, logos, images, and text onto various surfaces. Unlike traditional engraving methods, color laser engraving machines offer unparalleled precision, speed, and permanent. This has led to their widespread adoption for industries such as arts and crafts, personalized gifts, signage, jewelry, and more. We will explore how to laser engrave with color, the functionalities, applications, and benefits of color laser engraving machines.

Lasers can mark stainless steel, plastic, wood and other materials. Generally, laser marking colors are black, white, gray and other single colors. The marked color depends on the laser parameter settings and the marking material.

How Does Color Laser Engraving Work?

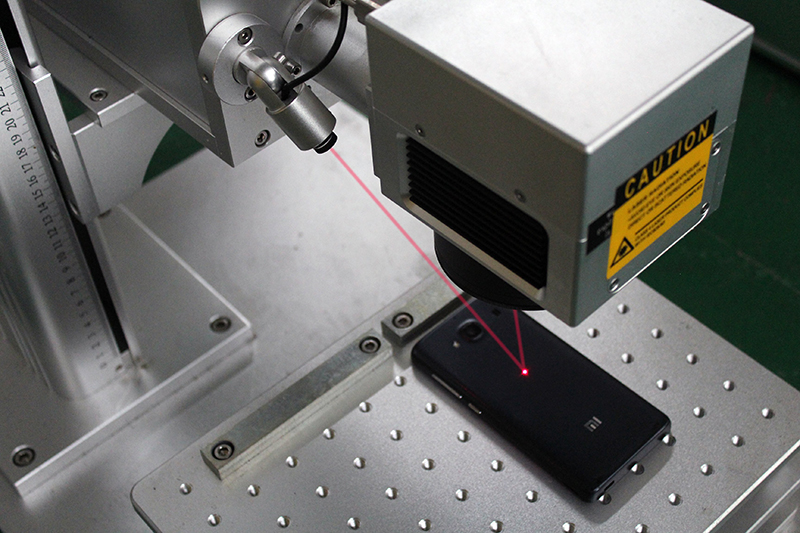

Color laser marking is a laser marking machine that can mark multiple colors on the surface of objects. The laser marking machine uses advanced lasers to generate high temperature through laser focusing to evaporate the surface material expose the deep material, or to display the marking information through the chemical and physical changes of the surface material.

What is the difference: Laser Marking Machines vs. Inkjet Printers?

Laser Marking Machines:

Laser marking machines use laser technology to create permanent marks on various materials. The laser beam interacts with the surface of the material, altering its properties through processes like engraving, etching, or ablating. The precise and controlled nature of lasers enables high-quality, durable markings.

Inkjet Printers:

Inkjet printers are widely used for printing images, text, or graphics onto surfaces. These printers spray small droplets of ink onto the material to create the desired markings.

Differences:

– Technology: Laser marking machines use laser beams to modify the material, while inkjet printers spray ink droplets onto the surface.

– Process: Laser marking involves engraving, etching, or ablating the material, while inkjet printing applies layers of ink to form the desired image or text.

– Marking Speed: Laser marking machines generally offer higher marking speeds and throughput compared to inkjet printers.

– Material Compatibility: Laser marking machines can mark on a wide range of materials, including metals and plastics, whereas inkjet printers are suitable for printing on paper, textiles, and some plastics.

– Durability: Laser markings tend to be more durable and resistant to wear and environmental factors, while inkjet prints may be susceptible to fading or smudging over time.

– Application Areas: Laser marking is commonly used in industrial and manufacturing settings for permanent marking and traceability, while inkjet printers are more prevalent in office, home, and commercial printing applications.

How to Add Color to Laser Engraving?

1. Standard method of laser engraving or marking design: provide color engraving by oxidation method. It depends on the material type, commonly used in metal materials.

2. According to the standard method, some materials cannot be engraved in color. Additional colorants are used during engraving to create colorful designs on the surface of the material. Laser coating and laser powder can be used to match the laser marking machine to produce color patterns.

3. MOPA fiber laser marking machine can be used to color engraved designs. MOPA laser marking machine can control the frequency and speed to make color engraving marks on the surface on some metals, plastics and other materials.

Color laser engraving usually requires professional equipment and specific process parameters to achieve, and the effect may be limited by the material, the power of the laser and the control system. Before choosing a laser and process, it is best to consult a professional laser equipment manufacturer or supplier for more specific advice and solutions.

The Principle of Stainless Steel Laser Color Marking

Under the action of laser heat source, stainless steel material will generate colored oxide on the surface, or form a colorless and transparent oxide film. Due to the thin film interference effect of light, various colors are presented, which is the basic principle of stainless steel color marking. The products of oxidation of metal elements in stainless steel will also show color.

The Method of Marking Stainless Steel with Colors

1. Laser Marking Machine: Select a laser marking machine capable of producing color markings on stainless steel. Fiber lasers are commonly used for this purpose.

2. Color Marking Additives: Obtain laser marking additives that are suitable for stainless steel. These additives typically consist of pigments or dyes specifically designed for laser marking applications.

What Affects the Color Laser Engraving on Metal?

Understanding the color effect of fiber laser marking machine can help you set up and choose the right laser marking machines for perfect laser marks.

1. Laser Wavelength: The laser wavelength of the marking machine will affect the color of the marking product. The wavelength of fiber laser marking machine is 1064nm. Laser marking on ABS plastic, the color produced by CO2 laser tends to be burnt yellow, the color marked by optical fiber or semiconductor is grayish black, and the color marked by ultraviolet or green laser the effect is black.

2. Laser Parameters: The laser parameters, including power, speed, frequency, and pulse duration, can influence the color outcome. Adjusting these parameters can affect the depth, intensity, and contrast of the engraved color. The marking effect of each product is different, and the desired color can be printed out after debugging and selecting the appropriate parameters.

3. Focal Distance: If the light spot is closer to the surface of the object, the color of the mark will be brighter and the pattern will be clearer. Different equipment parameters will affect the marking style and color.

4. Material Composition: Different metals or metal alloys have varying reactions to laser engraving, resulting in different color outcomes. The composition of the metal can affect how it interacts with the laser energy and the marking additives used.

5. Laser Focus and Beam Quality: The focus of the laser beam and the quality of the laser beam profile can affect the precision and uniformity of the color engraving. Proper alignment and calibration of the laser system are crucial to achieving desired results.

There are many factors that affect the marking effect of fiber laser marking machine. Please feel free to contact us if you want to find the most suitable fiber laser marking machine model, parameters and price. As China’s top manufacturer of industrial laser marking machines, we can provide you with professional laser marking solutions through 12 years and more than 50 industries of laser equipment customization experience.

What Laser Can Use for Color Etching?

CO2 Laser

CO2 lasers are one of the most commonly used types for laser engraving. They generate a laser wavelength of 10.6 micrometers, suitable for processing many non-metallic materials and some metal materials. CO2 lasers are advantageous due to their high power and fast processing speed, making them applicable in various industries.

Fiber Laser

Fiber lasers are also widely employed in laser engraving. They typically generate a laser wavelength of 1.06 micrometers, making them suitable for engraving metal materials such as stainless steel and aluminum. Fiber lasers offer high beam quality and small focal spots, allowing for precise and detailed engraving.

Fiber and CO2 lasers produce different wavelengths, and each material absorbs and reflects different wavelengths. To maximize energy transfer from a laser beam to a material, you need the right wavelength.

The metal absorbing fiber laser is more efficient at the wavelength (1,064 nm) than the CO2 laser (10,600 nm). Therefore, fiber laser engraving machine is a better choice for metal. Among them, the mopa fiber laser is the most commonly used for metal marking.

Why Mopa Fiber Laser Marking Machine is a Good Choice for Color Engraving on Metal?

MOPA (Master Oscillator Power Amplifier) fiber lasers are often chosen for metal marking due to their specific advantages and capabilities.

1. Pulse Control: MOPA fiber lasers offer excellent pulse control, allowing for precise adjustment of pulse duration, frequency, and energy. This versatility enables greater control over the marking process, resulting in finer and more accurate marks on metal surfaces.

2. Marking Variety of Metals: MOPA fiber lasers are capable of marking a wide range of metals, including stainless steel, aluminum, brass, copper, and more. With the ability to adjust pulse parameters, they can handle different metal types and achieve optimal marking results with enhanced contrast and legibility.

3. High Peak Power: MOPA fiber lasers can generate high peak power, allowing for efficient material removal during metal marking. This capability enables fast marking speeds and deep engraving, making them suitable for various industrial applications.

4. Enhanced Marking Flexibility: MOPA fiber lasers offer flexibility in terms of mark customization. They can produce a wide range of marking effects, such as grayscale marking, surface texturing, color marking with laser additives, and more. This versatility allows for creative and aesthetically appealing metal markings.

5. Minimal Heat Affected Zone (HAZ): MOPA fiber lasers have excellent beam quality and focus ability, resulting in a small heat affected zone during marking. This characteristic reduces the risk of material damage, distortion, or discoloration, particularly on heat-sensitive metals or delicate components.

The MOPA fiber laser engraving machine is convenient and easy to use, environmentally friendly and pollution-free, and the engraving speed is fast. It can not only help your laser engraved products more beautiful and permanent marks, but also help labor saving and high efficiency.

It’s important to consider specific application requirements, material characteristics, and budget constraints when choosing a laser for metal engraving and marking. The effect of marking depends on the adjustment of various parameters, please refer to MOPA fiber laser engraving parameters setting or consult our technical experts.

Which Industries are Color Marking Machines Suitable for?

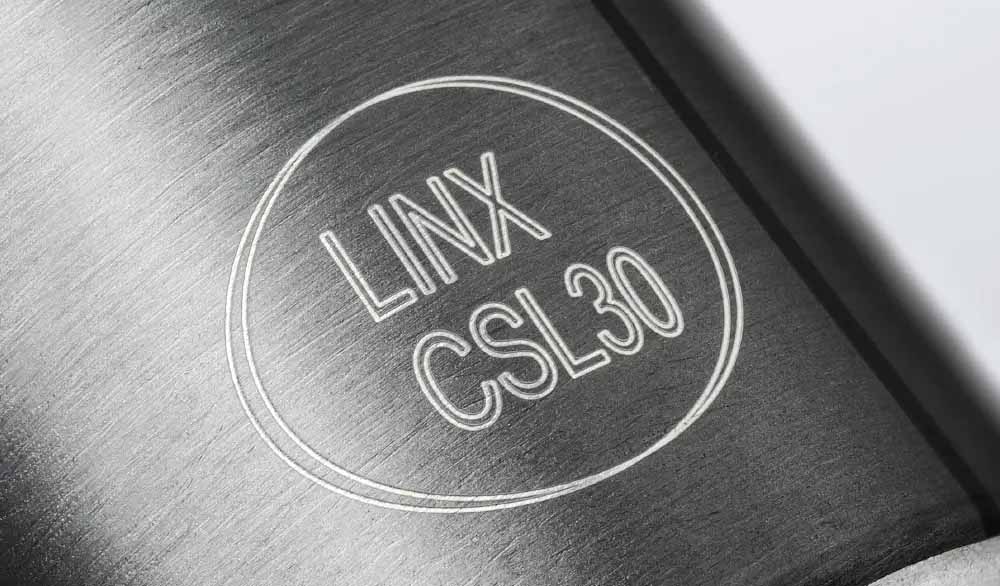

The stainless steel processing industry is suitable for using color laser engraving machines for laser marking processing, which can enrich the color and improve the color saturation and appreciation of the product. The pattern marked by the color laser engraving machine is clear, the surface is smooth and flat, it is not easy to wear, exquisite and beautiful.

The fiber laser color marking machine can cooperate with assembly line for production, and can be customized as a CCD visual positioning system. The work piece can be placed on the assembly line at will, and the marking machine can accurately identify and mark accurately, improving production greatly.

1. Advertising and Promotions: Color marking are commonly used in the advertising and promotions industry to create colorful and eye-catching signage, displays, promotional items, and branded merchandise.

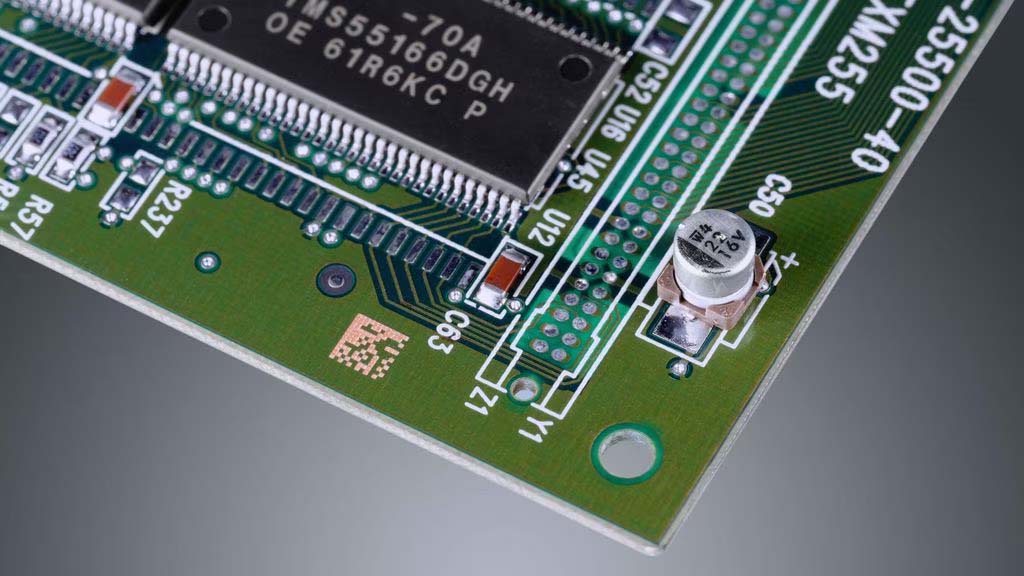

2. Automotive: The automotive industry utilizes laser color marking machine for marking and branding components, such as logos, serial numbers, part identification, and decorative elements on various automotive parts, including engines, chassis, interiors, and more.

3. Personalized Gifts and Customization: Color fiber laser marking machine are popular in industries that provide personalized gifts and customization services, such as engraving names, images, messages, and designs on various items like jewelry, accessories, trophies, awards, and novelty items.

4. Art and Craft: Colour laser marking machine are also utilized in the art and craft industry for creative and intricate designs, artwork, engravings, and personalization on various materials such as wood, acrylic, glass, leather, and more.

Color marking machines are suitable for a wide range of industries that require high-quality and visually appealing markings on various materials.

Laser Color Marking for Different Materials

Not every material is suitable for color laser engraving. Here are some common industrial applications and materials that require color marking.

The visible color of the final mark may vary depending on the material and configuration parameters. Some experimentation and adjustments are necessary to obtain the highest color quality for marking situations. For specific effects, please contact DPLASER to obtain your proofing effect.

Glass/Ceramic

Industrial products: logos and markings on advertising, decoration and branding of products

Crafts: glass trophies and awards, designs on tableware, personalization of cups, tile patterns

Metal Laser Engraving

The shiny surface and oxidizing properties of the metal make it the best choice for different applications. Stainless steel is the most widely used material in color laser engraving. Color laser engraving changes the outer layer of the metal and introduces a range of colors on the engraved part. Raw or untreated metal surfaces are especially suitable as you have a wide range of colors to choose from. Actual color marking engraving on metal depends on laser frequency, focal length, speed and power. Other metals that can be laser marking in color include chrome, titanium and steel.

Plastic ABS Glass

Unlike metal, there aren’t many options for laser etching in color on plastic yet. Plastic engraving mainly adopts the same color series as the base material, except for light and dark changes. Some plastic materials that can be laser engraved in color include polyethylene plastic, ABS plastic, glass-filled plastic, and others.

Acrylic

Color laser engraving on acrylic present a different angle than previous materials. Once you have your laser engraved part, all you need to do is fill it with colored paint, then use wet porous paint thinner to scratch and wipe to add color permanently.

Color laser engraving on non-metallic materials such as plastic and acrylic unlike metal, there is no way to oxidize non-metals to achieve the desired color. To introduce an artificial color into the engraving for better results, colorants are required for color engraving on plastic. You need to apply it to the surface of the material. You can choose the color you want according to your project. You can see the color immediately after the laser beam hits the surface of the material.

Color laser engraving is a useful technique that can enhance the customization of any material. It can take your business to the next level and allows you to be more creative and make unique and extraordinary products. If you want to power marking production business, you should take advantage of the color laser engraving technology.

The Bottom Line

You may not be able to make color laser engravings on all materials, but you can still create great color laser engraving on metal, stainless steel, plastic and acrylic. What color do you want to draw on what material? Or have you encountered any problems with color carving? Welcome to leave a message, by configuration and selecting materials, we are willing to find the right color laser engraving solution for you.