Laser cleaning machines have become a popular technology for industrial cleaning applications. Unlike traditional methods that rely on chemicals or abrasive materials, laser cleaning machines use laser beams to remove rust and contaminants from surfaces. This process is highly efficient, precise, and environmentally friendly. In this article, we’ll analyze what is laser cleaning machine and their benefits.

How Does Laser Cleaner Work?

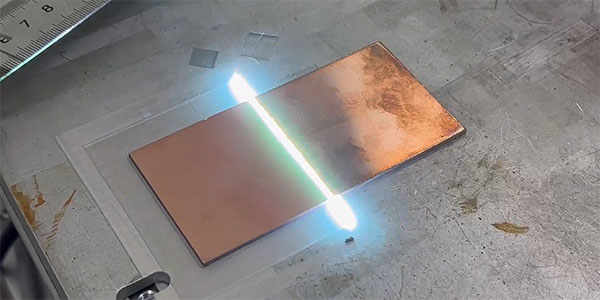

Laser cleaning machine uses a high-powered laser beam to remove impurities and contaminants from the surface of a material. The laser beam is directed at the surface to be cleaned, where it generates a burst of energy that vaporizes or ablates the impurities. This process, known as laser ablation, is highly precise and efficient, and does not require the use of chemicals or abrasive materials. The laser beam is delivered to the surface of the material using a delivery system that includes mirrors, lenses, and other optical components, and the removed material can be captured and collected using a vacuum or extraction system.

Traditional industrial cleaning methods can be time and labor intensive. Oxide removal may involve certain hazardous chemicals. Laser cleaning is an environmentally friendly process used to remove rust, paint, oxides and other contaminants from metal and non-metal surfaces.

What are the Advantages of Laser Cleaning Machine?

There are several advantages to using a laser cleaning machine for metal and non-metal surface cleaning.

1. Precision: Laser cleaning machines can be programmed to deliver precise amounts of energy to the surface being cleaned, ensuring that only the contaminants or unwanted material are removed, while leaving the underlying material intact. This precision makes laser cleaning ideal for delicate or complex surfaces.

2. Efficiency: Laser cleaning machines are highly efficient and can clean surfaces much faster than traditional cleaning methods. This increased speed and efficiency result in increased productivity and reduced cleaning time.

3. Environmentally friendly: Laser cleaning is a non-contact, non-abrasive, and chemical-free cleaning method. This makes it an environmentally friendly alternative to traditional cleaning methods that use harsh chemicals and produce harmful waste.

4. Versatility: Laser cleaning machines can be used on a wide range of surfaces, including metals, plastics, ceramics, and more. This versatility makes them suitable for a variety of applications and industries.

5. Reduced maintenance: Since laser cleaning machines do not require the use of abrasive materials or chemicals, they produce less waste and require less maintenance compared to traditional cleaning methods.

6. Increased safety: Laser cleaning machines are safe to use and reduce the risk of injury or damage to equipment or surfaces. This makes them ideal for use in industrial and manufacturing settings.

These benefits make laser cleaning an attractive option for a wide range of industries and applications. Especially portable hand-held laser cleaning machines are also widely used in small industrial production.

Laser cleaning is a non-contact cleaning, with little damage to the substrate, good stability, automation, good cleaning quality, high precision, and environmental protection. It is a “green” cleaning equipment. Laser cleaning replaces traditional cleaning methods and is a technological revolution that is environmentally friendly and cost-saving. Due to its high efficiency and easy to use, it is used in more and more applications. It can clean the surface of metal or non-metal parts. When processing the corresponding work piece, it is only necessary to adjust the interface parameters of the laser cleaning machine.

Industrial Laser Cleaning Applications

Laser cleaning has been widely used in many industrial fields, including automobile manufacturing, semiconductor cleaning, precision parts processing and manufacturing, aerospace, building wall cleaning, cultural relic protection, circuit board cleaning, precision parts processing and manufacturing, liquid crystal displays, molds , nuclear power and new energy. Primarily for rust, paint, oil, film, scale, resin, glue, dust and slag removal.

Laser paint removal can be applied to surface paint removal and some precision paint removal applications in the maintenance process of aircraft and railways. In the application of paint removal on the surface of aviation aluminum alloy, it is also necessary to ensure that the anodic oxide film on the surface of the aluminum alloy is protected during laser paint removal.

Surface cleaning

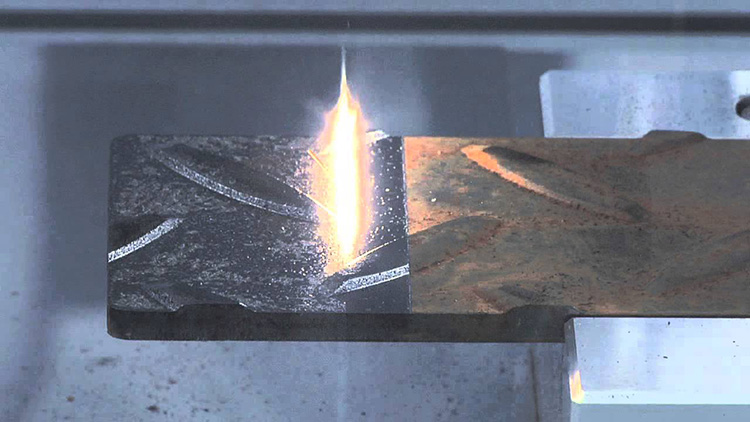

This type of cleaning is done to remove rust from the top surface of the material. Generally, surface cleaning is the most widely used application of laser cleaners. Cleaning activities such as paint removal, degreasing and material restoration are all types of surface cleaning. Laser rust removal machines is widely used in heavy metal manufacturing. Remove rusting or deoxidizing is often required in most heavy metal and manufacturing industries.

Rust removal

In the manufacturing process of many large steel structures, equipment, and infrastructure, a large amount of steel is used. During the transportation and storage of steel, it is easy to rust on the surface due to contact with humid environment, contact with sweat or contact with other corrosive media. For metal rust removal, laser cleaning technology is a good choice.

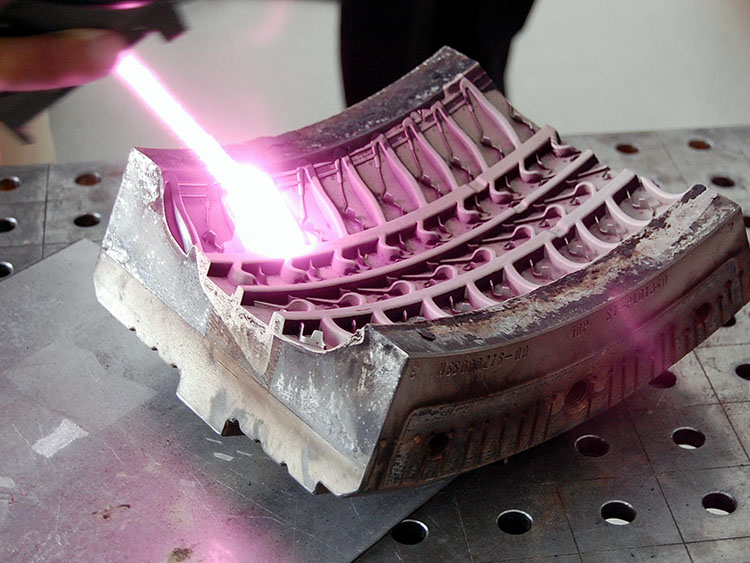

Mold cleaning

Regular cleaning of composite material molds, tire molds and other rubber product molds during use can use laser cleaning machine to replace traditional manual grinding, dry ice cleaning or sandblasting cleaning, etc., to improve efficiency or reduce costs. Taking tire mold cleaning as an example, the use of laser cleaning can make it cost 1/10 of dry ice cleaning.

Automotive

Laser cleaning machines are used in the automotive industry for paint stripping and surface preparation, as well as for cleaning engine parts and components.

Medical equipment

Laser cleaning machines are used in the medical industry for cleaning surgical instruments, medical devices, and dental equipment. The precision and cleanliness of laser cleaning help to maintain a sterile environment, essential for medical procedures.

Laser cleaning technology is used in many processes such as welding pretreatment, coating removal, oil cleaning and so on. They offer efficient, precise, and environmentally friendly cleaning solutions, making them a valuable asset for many businesses and organizations. Using a laser rust remover in your industry, not only help you speed up the production/repair process, but also provide you with a cost-effective solution.

What Type of Laser Cleaning Machine?

There are several types of laser cleaning machines available, each designed for specific applications.

1. Continuous wave (CW) fiber laser cleaning machine

This type of laser emits a continuous beam of energy, making it ideal for applications that require high-power output for long periods of time. The CW fiber laser cleaning machine adopts a hand-held cleaning head and a continuous laser source. The advantage of the CW washing machine is that it is cost-effective.

2. Pulsed laser cleaning machine

This type of laser emits energy in pulses, creating high-intensity bursts of energy that are ideal for high-value products need to clean and without harm the base materials. Pulsed lasers are often used in applications that require high precision and control.

3. Fiber laser cleaning machine

This type of laser uses fiber optic technology to deliver the laser beam to the surface being cleaned. Fiber lasers are highly efficient, have a longer lifespan, and require less maintenance compared to other types of lasers.

4. Handheld laser cleaning machine

Handheld laser cleaning machine is portable, making it ideal for cleaning small or hard-to-reach areas. Handheld laser cleaning machines are commonly used in automotive and restoration applications.

5. Automated laser cleaning machine

This type of laser cleaning machine is fully automated and can be programmed to clean surfaces without human intervention. Automated laser cleaning machines are often used in industrial applications where high throughput and consistency are required.

6. Robot laser cleaning machine

A laser cleaning system can be mounted on a robot to automate cleaning operations programmed by the robot. They are equipped with an advanced autofocus system for cleaning complex parts with high precision.

Our team offer a precise and efficient cleaning solution. Customized cleaning solutions tailored to your specific needs and requirements. We can clean a variety of materials, including metals, plastics, ceramics, and more.

At laser equipment factory, we have the expertise and equipment to handle a variety of laser cleaning projects, from small-scale to large-scale production runs. We are committed to providing high-quality services and delivering exceptional results.

The Basic Using Guide for Laser Cleaning Machine Beginners?

Using a laser cleaning machine may seem difficult for beginners, but it can be relatively simple with some basic steps. Please strictly abide by its usage steps to avoid unnecessary harm.

1. Take out the handheld laser gun from the cabinet and remove the lens dust cover at the front end of the laser cleaning gun.

2. Take out the external power cord and turn on the power, and turn on the key switch on the control panel of the laser cleaning host.

3. Turn on the green button switch, the green indicator light will be on after turning on, and the system will be powered on and initialized.

4. Use the laser control interface to set parameters. Click the pulse width, frequency, and power. Press the laser start button on the upper computer panel to start the cleaning operation.

5. Hold the gun head and turn the knobs to adjust the scanning speed and scanning range respectively. When moving and cleaning, please move the gun head.

6. After use, turn off the laser cleaning screen start button, the green physical button and the side power switch in sequence, insert the cleaning gun head back into the cabinet, and unplug the power.

Using Laser Cleaning Machine Precautions

1. Follow the switching sequence of the machine: when starting up, turn on the water cooler first, then turn on the power, and then turn on the laser switch. When shutting down, turn off the laser switch first, then turn off the power, and finally turn off the water cooler.

2. Clean the laser machine chiller once every half month, drain the internal water, and then fill up with new pure water.

3. Daily cleaning, remove the sundries on the table, limiter and guide rail.

4. The reflector and focusing lens should be scrubbed with a special cleaning solution every week. When scrubbing, use a cotton swab or cotton swab dipped in the cleaning solution to scrub counterclockwise from the center of the focusing lens to the edge, and be careful to prevent scratches lens.

5. Cleaning method of exhaust fan and smoke pipe: When there is a lot of smoke and dust during processing, it is necessary to clean the fan. Remove the outer cover of the fan, scrape off the dust on the fan blades and the air channel with a thin wood chip, and then blow it with a high-pressure gun.

Laser cleaning machines can be an effective and efficient solution for cleaning a wide range of surfaces. By following these basic steps and taking appropriate precautions, beginners can safely and effectively use a laser cleaning machine.

Summary

The article explains laser cleaning machine working principle, laser works and its advantages, including precision, efficiency, and environmental friendliness. You can get some industries and applications where laser cleaning machines are used and how does the laser cleaning machine improve production and manufacturing efficiency.