In an era of rapid development in manufacturing and sheet metal processing, we have continually sought more efficient and precise manufacturing methods. Coil fed laser blanking is one such technology with the potential to completely transform the way we shape and mold sheet metal. In this article, we will elaborate on the applications, principles, and advantages of coil fed laser blanking system. Furthermore, we will explore the customization of coil fed laser cutting machine to meet the specific sheet metal production requirements of manufacturer.

What is Coil Fed Laser Blanking?

To facilitate storage and transportation, many sheet materials are harvested in coil form, which presents certain challenges for sheet processing. The coil-fed laser blanking line uncoils and levels the coil material before feeding it into the laser cutting machine for cutting. The coil-fed laser cutting production line primarily consists of a CAD/CAM programming system, automatic uncoiling and leveling system, servo automatic feeding, and laser cutting system, enabling a series of automated production processes such as uncoiling, feeding, cutting, and unloading of coil materials.

The sheet metal leveling machine can correct and level metal coil materials, ensuring that the material is straightened, whether it was previously bent upwards, downwards, or flat. It produces stress-free, dimensionally accurate sheet metal parts, making automated welding smoother and resulting in perfectly fitting finished components. This is the preferred choice for manufacturing aluminum sheets, steel sheets, circuit boards, home and kitchen appliances, automotive metal parts, elevators, and cabinet manufacturing, meeting the requirements of high air tightness, high precision, and high quality. More and more industries are able to economically process sheet metal in small batch situations.

What is Coil Fed Laser Blanking Used For?

Sheet metal cutting may encounter deformation, warping, or twisting, which can affect subsequent welding and riveting processes. The flatness of the product, the perpendicularity of the enclosure, tolerances of diagonals, surface and structural quality, and sealing are all impacted. To reduce defective products and produce high-precision sheet metal components, it is necessary to level the material before cutting and level the parts with a leveling machine after cutting to eliminate stress.

Coil fed fiber laser cutting machine feature an open cutting bed that allows continuous metal sheets to be uniformly fed into the cutting machine through a straightening machine. The continuous supply of metal plates enables the laser cutting machine to continuously feed material until the coil is depleted. Therefore, automatic coil fed laser blanking line are the preferred choice for large-scale production.

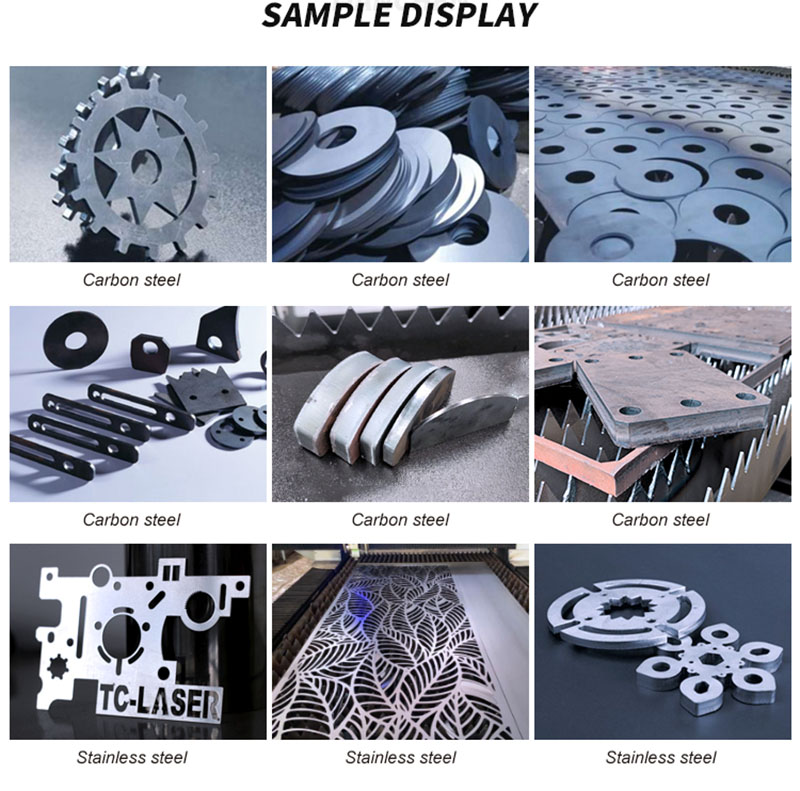

The laser cutting technology provide a viable alternative for mechanically cutting blank coils, making it suitable for both large scale applications and the ever-changing demands of small-batch sheet metal fabrication. Laser blanking lines are suitable for various metal materials, including iron, aluminum, copper, titanium alloys, cold-rolled sheets, galvanized sheets, Q235 steel sheets, 304 stainless steel sheets, alloy sheets, and high hardness metals. Any task that can be accomplished using a fiber laser cutting machine can be more efficiently executed with coil fed laser blanking line & cutting system.

Automatic Coil Fed Laser Blanking Line & Cutting System – Sheet Metal Coil Cutting Solution

The DPLASER coil fed laser cutting solution is primarily designed for automated uncoiling, leveling, feeding, cutting, and unloading services for metal sheets ranging from 1500 to 3000 mm in width and with a thickness of 3mm (optionally 6 to 10mm). Once the stack of material is unwound and subjected to the leveling process, most of the internal stresses in the material are relieved. The three-dimensional cutting on the laser cutting machine and then automatic unloading of the metal products.

Automatic loading and unloading coil fiber laser cutting machine efficiently cut and blank sheet metal or coils into specific shapes and sizes.

1. Coil Feeding: The system starts by feeding a coil of raw material (usually sheet metal) into the machine. This coil could be made of materials like steel, aluminum, or other metals.

2. Uncoiling: The coil is unwound, and the material is pulled through the system for further processing.

3. Straightening and Leveling: In many cases, the material may need to be straightened and leveled to ensure it is flat and free from deformities before the cutting process.

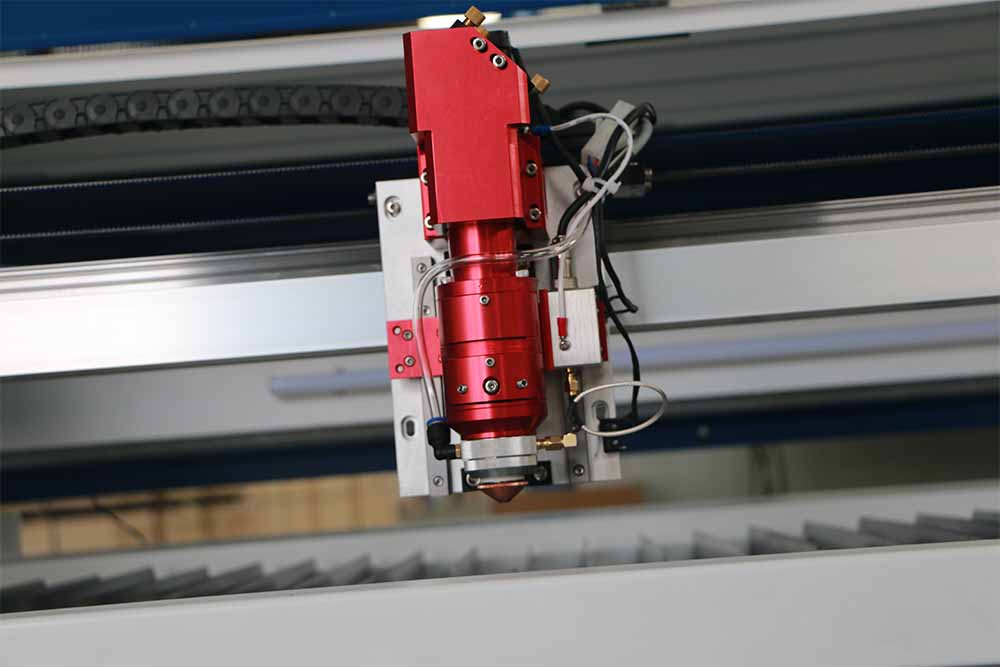

4. Laser Cutting: One of the core features of this system is the use of a laser cutting unit. High-powered lasers are used to precisely cut the material into the desired shape and size. Laser cutting is highly accurate and can cut a wide range of materials.

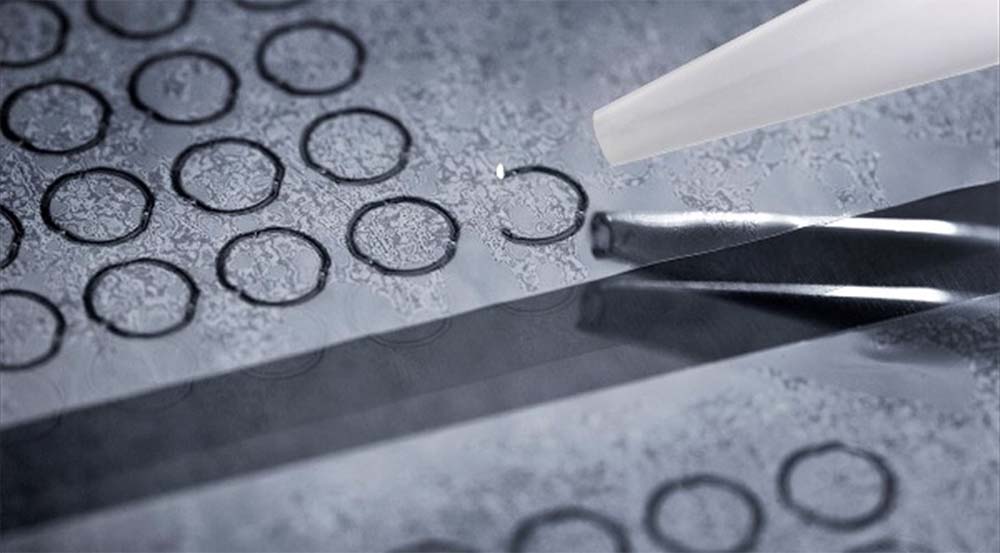

5. Blanking: Blanking are the cut pieces of material, which can vary in shape and size depending on the specific production requirements. These blanking can be used in various applications, such as automotive parts, appliance components, or construction materials.

6. Automation and Control: These systems are highly automated and can be controlled through computer programs and user interfaces. This automation ensures high precision, efficiency, and consistency in the production process.

The coil laser cutting production line offers several advantages, including high precision, fast processing, reduced material waste, and the ability to cut complex shapes with ease.

The industrial coil leveling linear laser cutting system can directly use various coil materials. The production line can automatically level and continuous cutting workpieces to the required dimensions, which greatly improves productivity and production efficiency.

Advantages of the Coil Fed Laser Cutting System

1. Efficient space savings: Integrating coils leveling, feeding, and laser cutting into a single device reduces equipment footprint and material handling between processes, thus improving production efficiency.

2. Flexible production: It can respond to changing production needs at any time. When required parts change, modifications can be made to two-dimensional graphics using programming software to cut the desired parts without any changes to the hardware structure of the equipment, allowing for the manufacture of different products.

3. Reduced material waste: Laser cutting directly from coil material eliminates the waste associated with end-of-sheet losses, leading to significant savings in raw materials. The cutting machine system itself features automatic nesting, allowing the production of spare parts as needed.

4. Lower defective rate: The sheet material, shaped by shearing, eliminates internal stresses and ensures flatness, reducing scrap.

5. Saving labor costs through automated operation: The system is equipped with an advanced automation control system that can automatically adjust leveling and feeding speed and force to ensure cutting precision and stability. Continuous coil cutting and batch processing reduce labor intensity.

6. User-friendly: Professional software is used for the timely processing of various graphics and text. It is easy to use, making it suitable for beginners.

Coil Fed Laser Cutting Machine Manufacturer

When selecting a fiber laser blanking system, it is essential to consider the material specifications provided by the customer, including material dimensions (length, width, and height), material type, elasticity, and the required flatness. Please provide detailed information about your materials, processing requirements, or design files, and we will customize the most suitable uncoiling and leveling fiber laser cutting machine for you.

What We Offer?

1. Free Sample Cutting: If you need samples cut and tested, simply send us your CAD files (.plt or .ai). We’ll handle the cutting in our facility and provide a video showcasing the process and results. Alternatively, we can send you the samples for quality inspection.

2. Customized Solutions: We can create tailored solutions to enhance production efficiency and processing quality based on your product processing requirements and applications.

3. After-Sales Support: Whenever you encounter installation, operational, or adjustment issues, we offer technical assistance through remote methods like Team Viewer, email, phone, mobile apps, WhatsApp, Skype, and 24/7 online chat. Additionally, we provide English training videos and user manuals for laser machine installation, operation, maintenance, and troubleshooting.

DPLASER offerings include a free sample cutting service to showcase our custom solutions designed to enhance efficiency and quality, and unwavering after-sales support. Our commitment is to provide you with top-notch service, ensuring your satisfaction and help your business develop.

In summary, the advancements in laser cutting technology have completely transformed how we approach metal sheet processing. Industrial coil fed laser cutting machine have emerged as a versatile and efficient solution, capable of processing various materials and delivering high-quality results. From automated uncoiling and leveling to precise cutting, these automatic processing systems have not only improved productivity but also reduced material wastage and lowered scrap rates, ultimately contributing to the cost-effectiveness of manufacturing processes. The fusion of innovative technology and customized laser solutions and support promises a brighter and more efficient future for the entire sheet metal processing and manufacturing industry.