Welding, the art of fusing metals together, has played an indispensable role in the world of manufacturing and construction. This article is your comprehensive guide to navigating the advantages of laser welding vs mig welding, offering insights that will help you choose the most suitable welding approach based on your processing requirements. In the quest to understand the ideal welding methods for your specific needs, we embark on an exploration the unique applications that set them apart.

Laser Welding vs Arc Welding

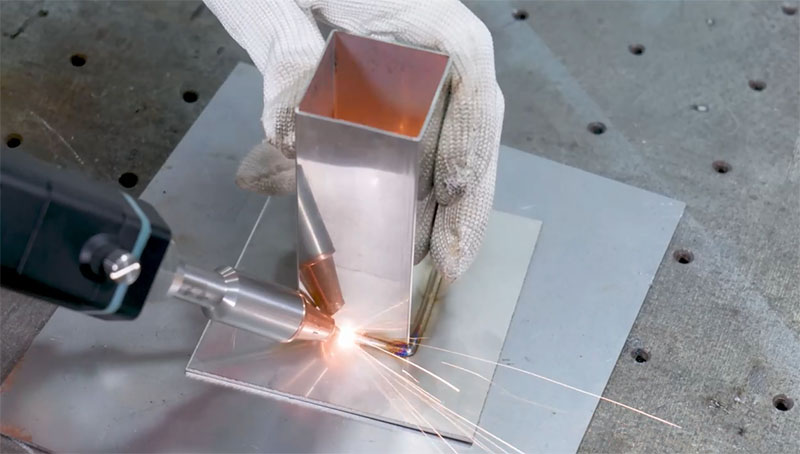

Laser welding is an efficient and precise welding method that utilizes a high-energy density laser beam as a heat source. It allows for precise energy control, enabling the welding of intricate components. By controlling parameters such as laser pulse width, energy, peak power, and repetition frequency, the workpiece is melted to form a specific weld pool.

The handheld laser welding machine, in particular, stands out for its simplicity in structure, quick setup, welding flexibility, and strong penetration capability, making it suitable for welding at various complex angles. It offers high flexibility and scalability. Automatic laser welding machines can be equipped with robotic arms or other CNC welding machine beds, and can switch between standard handheld heads or oscillating handheld heads to meet more automated welding needs. Laser welding can be applied to a wide range of metals, especially excelling in welding challenging materials and dissimilar metals.

Pulsed Laser Welding VS CW Laser Welding

Laser welder can be categorized into two working modes: pulsed laser welding and continuous wave laser welding. Pulse laser welding is mainly used for spot welding and seam welding of thin-walled metal materials with a thickness of up to 1mm. Continuous fiber laser welding offers a greater depth-to-width ratio and faster welding speeds.

Traditional Argon Arc Welding

Traditional welding methods encompass a variety of techniques, including arc welding, gas shielded welding, TIG welding, MIG welding, and resistance welding. These methods differ in their applications, processes, and performance, but they all share the common principle of melting metal materials using a heat source and subsequently allowing them to cool and join together.

Argon arc welding is a commonly used metal welding technique. Its principle involves applying high voltage between two metal surfaces that need to be joined, heating the metal surfaces through an electric arc to melt and mix them, and introducing argon gas for protection to prevent negative effects such as oxidation and corrosion. Argon arc welding can be applied to most major metals, including carbon steel and alloy steel.

Melting inert gas shielded welding is suitable for materials such as aluminum, magnesium, copper, titanium, zirconium, and nickel alloys. It is widely used in mold repair welding due to its cost-effectiveness, but it has drawbacks such as a large heat-affected zone and large weld joints. Currently, in the precision mold repair, it is gradually being replaced by laser welding.

Laser Welding vs. MIG Welding for Beginners

What is MIG Welding?

MIG welding, also known as Metal Inert Gas Welding, is a commonly used arc welding method. It is a semi-automatic or fully automatic welding process that utilizes a continuous wire electrode (welding wire) and an inert gas (such as carbon dioxide or a mixture of inert gases) for welding.

What are the advantages of MIG Welding?

MIG welding machine is widely used for welding materials like steel, stainless steel, and aluminum alloys. It offers the advantages of high efficiency, quick welding, and relatively high welding speeds, making it suitable for industrial manufacturing and repair applications. MIG welding uses inert gas for shielding, which effectively reduces spattering and melt loss. This results in a more stable welding process and higher welding quality.

What is Arc Welding?

TIG for Tungsten Inert Gas Welding, sometimes referred to as Gas Tungsten Arc Welding (GTAW). In TIG welding, a tungsten electrode is used as the electrode to create a high-temperature arc that melts the workpiece and the welding wire. Simultaneously, an inert gas, typically argon, is used for shielding to prevent contamination of the weld pool by oxygen and nitrogen from the surrounding air.

TIG welding is known for its high weld quality, low melt rate, and slower welding speed, making it suitable for lightweight and highly reflective materials.

For saving labor, laser welding equipment offers strong functionality and is adaptable to various working environments. It is designed with ergonomic considerations and provides proprietary laser safety features to ensure the safety of operators during work. Laser welding is easy to learn and quick to master, with a low technical threshold for operators, resulting in reduced labor costs.

Argon arc welding labor costs: Argon arc welding requires skilled welders. In contrast, handheld welding is easy to learn, and regular operators can become proficient in half a day. Therefore, when considering labor costs alone, using fiber laser welding machine instead of traditional argon arc welding can lead to cost savings.

Laser Welding vs. Traditional Welding

Advantages of Argon Arc Welding

1. One of the advantages of arc welding is its ability to join thicker metal components together. Additionally, arc welding is often more cost-effective than laser welding and can be used to weld larger areas in a single pass.

2. Argon gas protection can isolate the adverse effects of oxygen, nitrogen, and hydrogen in the air on the arc and weld pool, reducing the burn-off of alloying elements. This results in dense, spatter-free, and high-quality weld joints.

3. Arc welding offers a stable arc combustion, concentrated heat, high arc temperature, high welding production efficiency, a narrow heat-affected zone, and reduced tendencies for stress, deformation, and cracking in the welded workpiece.

4. Argon arc welding machine can weld virtually all metals, especially challenging-to-melt and easily oxidized metals such as magnesium, titanium, molybdenum, zirconium, aluminum, and their alloys.

Benefits of Fiber Laser Welding Machine

- Laser welding can achieve spot welding, butt welding, overlap welding, and seal welding for thin-walled materials and precision components. The concentrated heat source of a laser welding machine results in minimal material deformation, making it advantageous for welding thin-walled materials. It is suitable for processing complex-shaped parts and micro components.

- Thanks to its high laser power, laser welding offers an excellent depth-to-width ratio, minimal distortion, and fast welding speeds. It delivers high-quality welds with smooth surfaces, no porosity, and increased material toughness.

- Laser welding provides higher precision, aesthetically pleasing weld seams, no weld scars, no discoloration, and eliminates the need for post-weld grinding. The user-friendly design with an LCD display and keypad operation makes it easier for operators to complete their tasks.

- Laser welding can not only achieve spot welding but also perform automated straight-line welding, circumferential welding, and is suitable for various welding scenarios like lap welding, stack welding, inside and outside corner welding, circular welding, and welding irregular shapes.

- When combined with automatic robotic arms, laser welding enables process automation and is capable of filler wire welding, making it ideal for improving existing product structures and materials.

- Widely used in various industries:

Laser welding is employed in automotive body welding, mechanical components, mold welding, and pipe components welding. It is suitable for all metal materials, including copper, aluminum, stainless steel, and some special alloy steels, making it versatile for applications in automotive body manufacturing and industrial components.

Limitations of Fiber Laser Welding

High Initial Costs

Compared to other machines, the initial cost of purchasing a handheld fiber laser welding machine is relatively high. It’s a significant investment that requires some planning.

Porosity and Embrittlement Concerns

Due to the rapid solidification of weld seams, there is a concern that the welds may have high porosity, become brittle, and potentially develop cracks in certain metals.

Altered Welding of Materials

When using a handheld laser welding machine, the Welding of materials with high thermal conductivity and reflectivity, such as copper, aluminum, and their alloys, may be altered.

Limited Welding Thickness

Not all thicknesses can be welded using a handheld laser welding machine. Materials with a melt depth exceeding 19mm are not suitable for this type of welding.

The selection of laser welding parameters is material dependent and involves considerations of the material type and thickness. Common materials such as carbon steel, stainless steel, and aluminum alloys require adjustments to the welding parameters such as laser pulse width, energy, peak power, and repetition frequency through the control system panel before laser welding. The laser power needs to be determined earlier based on the welding application,

1. 300W Laser Welding Equipment

Suitable for stack welding with a thickness not exceeding 1.5mm. While it is sometimes possible to slightly increase the parameters to handle greater thickness, this is generally not recommended as it may affect welding strength and lead to excessive heat deformation.

2. 600W Laser Welder

Applicable for laser welding of kitchen equipment, household appliances, and high-speed stainless steel with a thickness less than 1mm and a melt depth less than 1mm. It can also be used for welding 1.5mm-thick steel plates.

3. 1000W Laser Welding System

Ideal for fully welding 2mm thick stainless steel plates with finer weld seams being preferred. It is recommended to use a 1000W fiber laser welding machine, which can achieve welding speeds of 1m/min or more. While a 500W machine can be used, it will result in slower welding speeds.

4. 1500W Fiber Laser Welding Machine

Suitable for welding stainless steel with a thickness not exceeding 5mm. A 2000W laser welding machine is applicable for welding stainless steel with a thickness not exceeding 8mm.

What Metals Can Be Weld?

Not all metals can be welded using the same welding method, and some metals may pose more challenges during welding. Most common metals, such as steel, stainless steel, aluminum, copper, and cast iron, can be welded. Different metals require different welding methods. For example, arc welding, gas shielded welding (such as TIG and MIG welding), spot welding, laser welding, and other methods are suitable for different types of metals and applications.

How to Choose Welding Methods for Different Metals?

Carbon Steel: Carbon steel is suitable for various welding methods, including arc welding, MIG welding, TIG welding, and laser welding. Laser welding is often used in high-precision applications, as it can achieve a smaller heat-affected zone and reduce deformation.

Stainless Steel: Stainless steel can be welded using MIG welding, TIG welding, and laser welding. Laser welding is also commonly used in stainless steel welding for detailed work and high precision requirements.

Aluminum: Aluminum is typically welded using TIG welding, MIG welding, and laser welding. Laser welding excels in controlling weld seams in aluminum welding.

Copper: Copper is usually welded using TIG welding, but laser welding can be used for high-precision applications, such as in the manufacturing of electronic components.

Cast Iron: Cast iron is typically welded using arc welding or gas shielded arc welding. In certain situations, laser welding can also be used for repair work, especially for intricate cast iron parts.

Chromium Alloys and Nickel Alloys: These metals typically require the use of TIG welding or MIG welding, along with special alloy wires and gases to ensure high-temperature performance and corrosion resistance.

Titanium Alloys: TIG welding is a common method for welding titanium alloys and requires the use of pure titanium materials and pure argon gas.

Laser welding and MIG welding are two different types of welding methods, each with its own advantages and disadvantages. The choice between them depends on factors such as the type of material, thickness, joint design, quality requirements, budget constraints, production volume, and more. In general, laser welding is better suited for thin or delicate materials that require high precision, low heat input, no filler metal, minimal spattering, and no contact. MIG welding is better suited for thicker or robust materials that require high speed, high strength, versatility and ease of use.

Metal welding technology is crucial for various industries and applications, and I’m happy to discuss any questions or topics related to metal material welding at any time. If you need more information on metal welding processing, feel free to reach out, and I’ll do my best to provide efficient and useful solutions regarding metal material processing.

Finally:

Whether you are in the manufacturing industry, automotive, mold repair field, or any other domain, understanding the laser welding vs arc welding pros and cons and knowing how to select the appropriate welding technology based on specific needs will have a profound impact on the success of your projects. The continuous development and innovation in metal welding technology offer various industries more possibilities, driving us to delve deeper into research and exploration to meet changing demands.