In electronic components chip marking, jewelry, artwork production, fine processing has occupied an important position. UV laser marking, as one of the high-efficiency, high-quality and high-precision marking methods, has been increasingly used because of its excellent performance. In this article, we provide a comprehensive introduction to the best UV laser marking machine, provide detailed introduction and application, and help users to better choose the right marking machine for business.

What is UV Laser Marking?

UV laser marking is a process of using a high-powered laser beam to create a permanent and highly readable mark on a variety of materials, such as plastics, metals, glass, and ceramics. The process involves using a high-frequency laser to deliver a concentrated beam of light that vaporizes or removes a very thin layer of material from the surface of the material being marked. It can be used for ultra-fine marking and special material marking.

What is Application of UV Laser Marker?

UV laser marking, known as “cold marking,” is characterized by its exceptional absorption rates on diverse materials and its capacity to accomplish marking and processing while minimizing thermal damage. By harnessing the high absorption rate, UV laser marking ensures minimal thermal damage, even on materials like gold, silver, and copper, which possess high reflectivity. This approach reduces the formation of soot and burrs while safeguarding the integrity of the surface, enabling corrosion-resistant marking and processing. UV laser marking is especially well-suited for applications that demand high contrast or necessitate minimal product damage.

UV laser marking is commonly used in the following manufacturing industries:

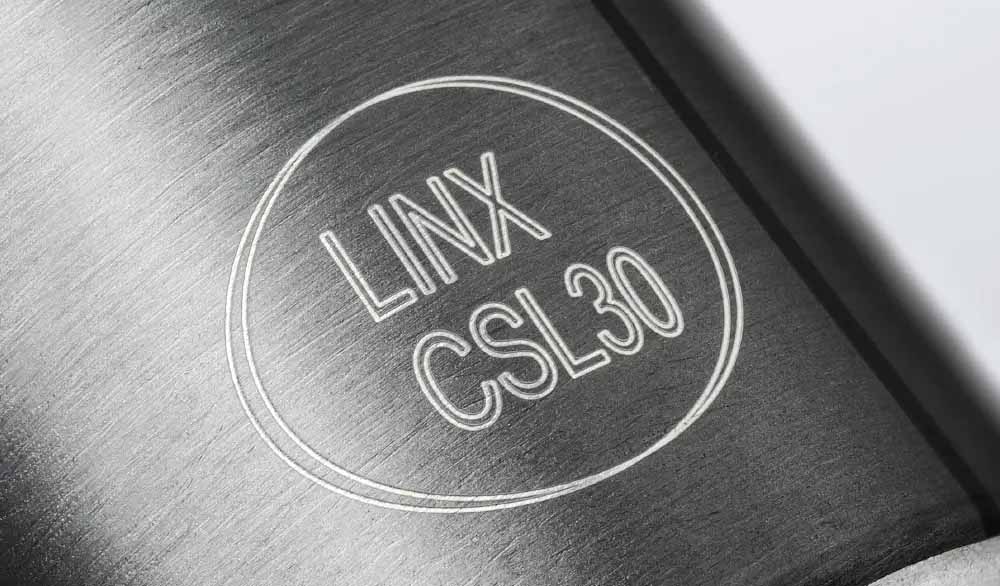

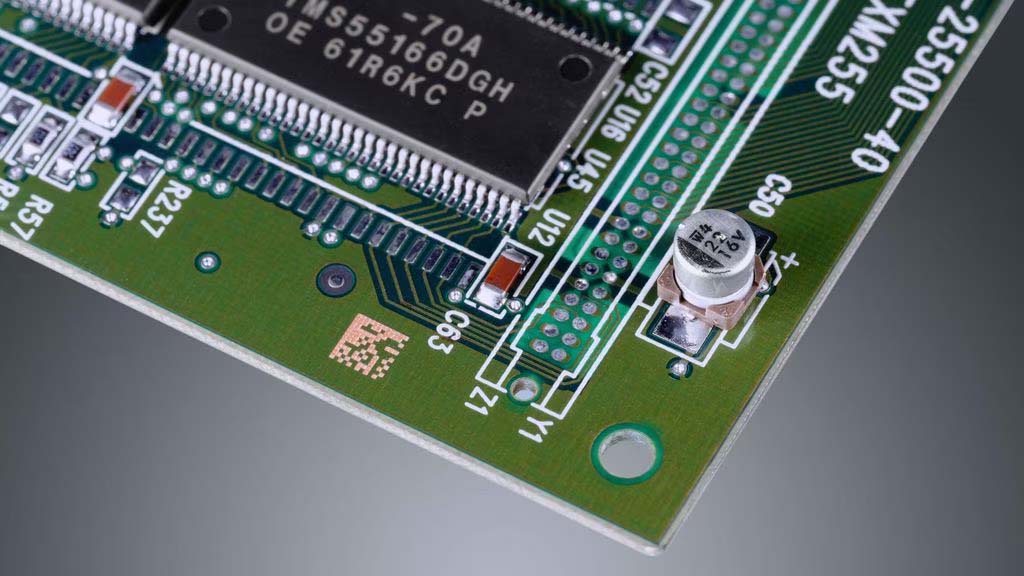

1. Electronics industry:

UV laser can be used for fine marking on electronic components, printed circuit boards (PCBs) and semiconductor devices for identification, tracking and anti-counterfeiting.

2. Medical devices:

Medical device manufacturers use UV laser marking technology to put permanent marks on medical devices, including product information, batch numbers, and serial numbers and company logos.

3. Automotive industry:

UV laser marking can be used to mark automotive parts, engine components and chassis components for tracking and identification, such as driveline, engine parts, EV batteries, etc.

4. Packaging industry:

UV laser marking on packaging materials can be used to achieve anti-counterfeiting and traceability functions, such as markings on food and pharmaceutical packaging.

5. Tableware:

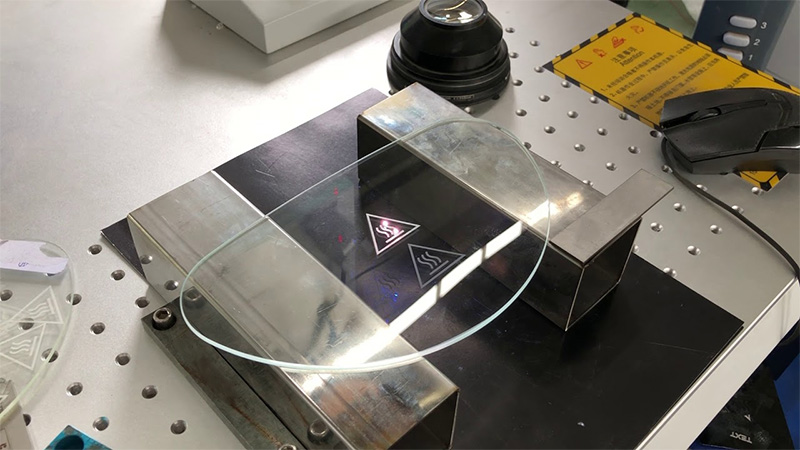

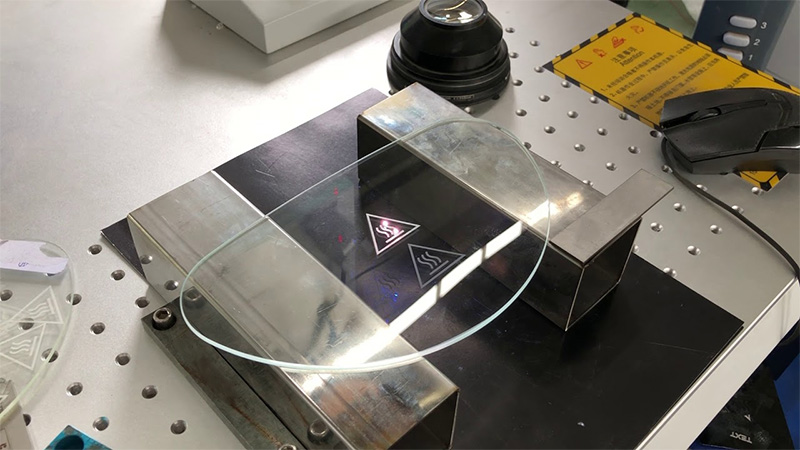

UV laser marking can engrave patterns, text or logos on glass surfaces, which are commonly used on wine glassware, glass containers and glass decorative products.

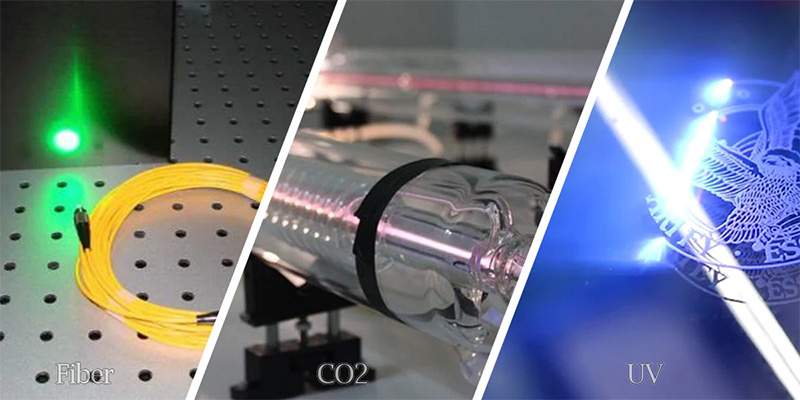

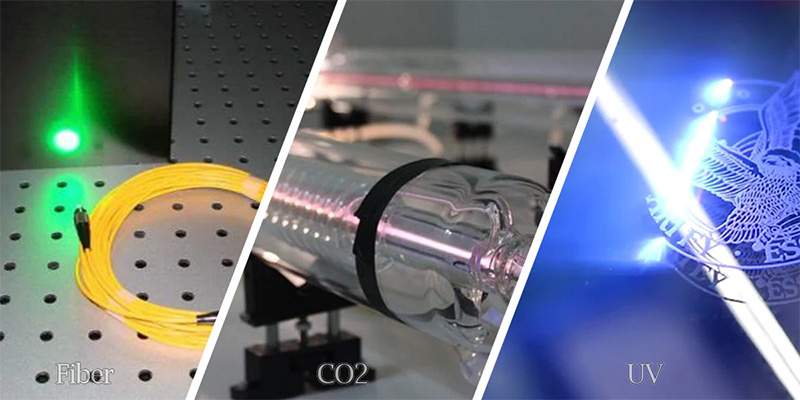

Compared with fiber laser marking and carbon dioxide (CO2) laser marking, UV laser marking has some unique features. Compared to fiber laser marking, UV laser has a shorter wavelength and therefore can achieve higher resolution and finer markings. It can achieve finer patterns and text for application scenarios that require high precision. Therefore, the price of UV laser marking machine price with the same configuration will be more expensive than other laser source marking machine.

Ultraviolet laser marking can be used on more types of materials, including plastics, glass, ceramics and semiconductor materials. UV marking is smooth to the touch and 100 times more accurate than CO2 laser marking machine. This is due to the smaller spot size and higher repetition rate of the UV laser. Marking results in a clean appearance with no cracks or chips.

Therefore, when choosing an engraving technology, it is important to consider the type of material, the desired marking effect and the accuracy required. UV laser marking is suitable for scenarios requiring high precision, durability and multi-material applications, while fiber laser marking and CO2 laser marking are suitable for other different application scenarios.

What Materials Can Be Marked with a UV Laser Machine?

Whether you want to apply a custom design to a metal or plastic product, laser marking is the preferred method. Laser marking is the preferred choice for customizing products, company logos, and marking medical and aerospace components due to its minimal destructive impact.

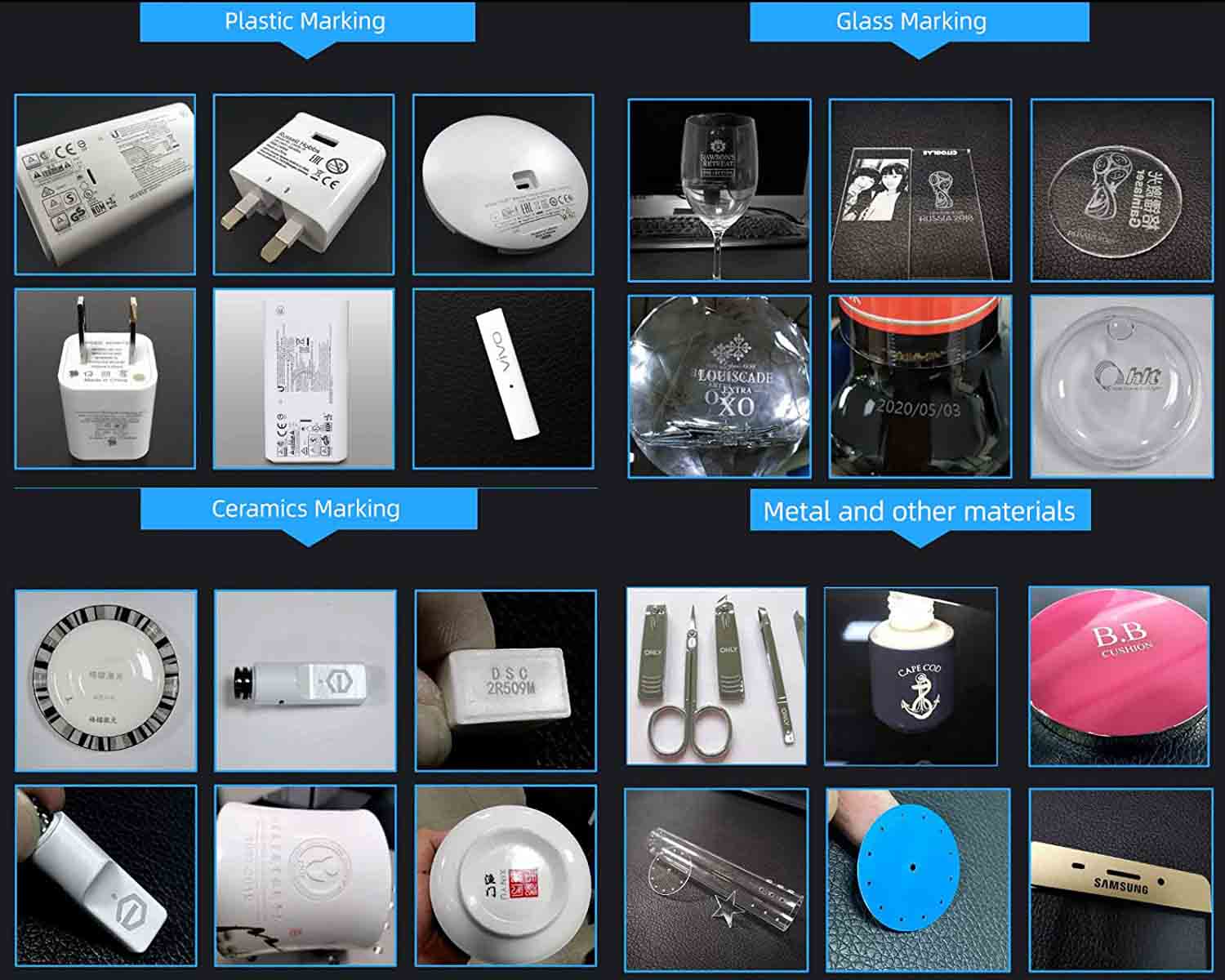

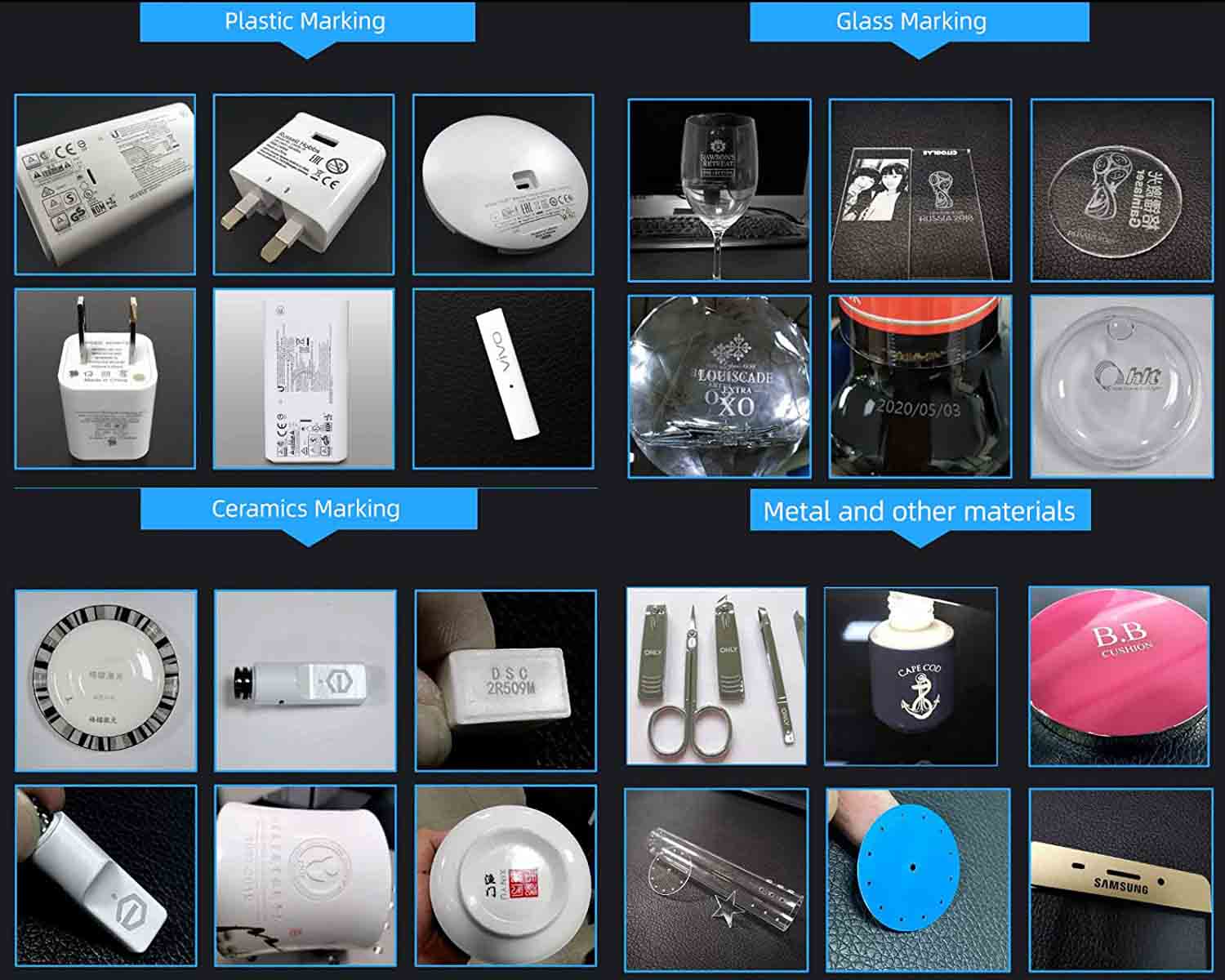

UV laser marking is mainly applicable to the following materials:

UV laser marking is applicable to a wide range of materials, the following are some of the main applicable materials.

1. Plastics:

UV laser marking performs well on a variety of plastic products. Compared with other types of laser marking, UV laser has shorter wavelength and higher energy density, so it is better for marking many plastic materials, such as polyurethane, polyethylene, polypropylene, etc. It can achieve high contrast marking without causing melting or deformation of the material.

2. Metal:

Compared to other types of laser marking, UV laser marking on metal materials is more effective. The short wavelength of the UV laser enables it to overcome the high reflectivity of metals and achieve high-resolution marking without excessive thermal impact on the material.

3. Glass:

UV laser marking for glass allows for high precision and high contrast marking. Compared to other laser types, UV lasers are able to interact better with glass materials to create clear and durable markings. This makes UV laser marking widely used in the production of glass products such as displays, glassware and glass decorations.

4. Ceramics:

Due to the short wavelength and high energy density of the UV laser, it is able to achieve fine marking on ceramic materials. Whether it is ceramic tiles, ceramic tableware or ceramic decorations, UV laser marking is able to create long-lasting and clear patterns or text on the surface.

It is important to note that while UV lasers perform well on many materials, they may not be suitable for some materials. For example, organic materials such as wood and paper are better suited for CO2 laser marking, while metal materials are better suited for fiber laser marking.

Fiber lasers have broad applicability and are particularly effective for achieving high contrast when marking metals. However, they are not suitable for marking transparent materials, and the use of high power can occasionally cause damage to the marking surface.

Ultraviolet lasers excel in creating high contrast marks on plastics materials, including PP (polypropylene), PC (polycarbonate), PE (polyethylene), ABS, PA, PMMA, silicon. Additionally, UV lasers offer the advantage of generating non-damaging marks, ensuring the integrity of the marked surface.

CO2 lasers utilize heat to burn and mark various materials. This makes them well-suited for marking wood, paper, ceramics, and transparent targets, allowing for clear and precise marks.

In summary, it is necessary to choose in the appropriate laser marker according to the characteristics of the material and marking requirements. Of course you have any ideas and questions, our laser marking equipment experts are willing to communicate with you, just to leave a message to contact us.

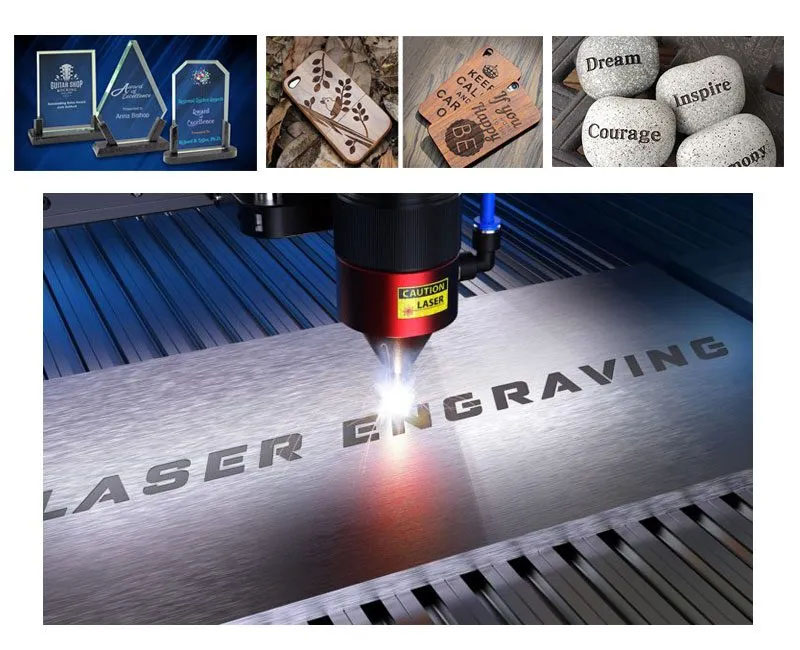

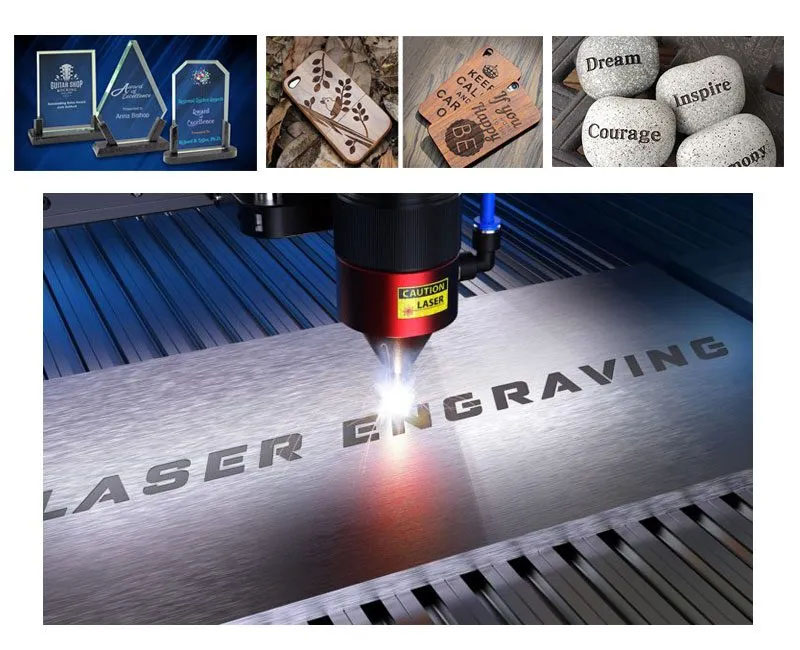

Laser Marking VS Laser Engraving: Differences

Laser marking and laser engraving are two different processes that use similar laser technology.

Laser marking involves using a laser beam to change the surface of a material, leaving a visible mark. The laser beam heats the material to a point where it oxidizes or vaporizes, creating a contrast to the unaffected surface. Laser marking is commonly used to create barcodes, serial numbers, and logos, among other things.

Laser engraving, on the other hand, involves using a laser to remove material from a surface to create a deeper cavity that can be seen and felt. This process is usually used to create permanent markings, such as nameplates, plaques, and signage.

- Laser engraving removes material to create deep marks

- Laser marking discolors the surface but does not remove material like etching and engraving

All processes will leave permanent marks on the part.

The main difference between the two processes is the depth of the mark. Laser engraving creates a much deeper cavity in the material, which means the mark is permanent and can be felt with fingers. Laser marking creates a shallower mark that can be seen but not felt. Additionally, laser engraving is typically more time-consuming due to the material removal required.

A marking machine is able to mark, etch, and engrave by simply adjusting the laser power, which affects the depth of the laser’s penetration and the resulting appearance.

What Are the Advantages of UV Laser Marking Machine?

1. UV laser beam quality, and focus spot is smaller, can achieve ultra-fine marking;

2. UV laser marking heat-affected zone is extremely small, will not produce thermal effects, material scorching problems;

3. UV laser marking machine marking speed, high efficiency; the whole machine has the advantages of stable performance, small size, low power consumption, etc.

UV laser marking machine for PCB board, marking speed, a few minutes to etch the pattern on the circuit board. This makes UV laser engraving machine the fastest way to etch on PCB samples.

Precautions to Protect UV Laser Marking Machine

UV laser marking machines use UV lasers and therefore require special care in their use and maintenance.

Application Materials:

The UV laser marking machine power is much lower than fiber marking machine, which is not recommended for marking metal or products with hard materials and marking depth requirements.

Equipment Stability:

Place the UV laser marker on a smooth workbench to ensure equipment stability. Vibration and unstable working environment may affect the accuracy and quality of marking.

Parameter Setting:

Set the parameters of the UV laser marking machine correctly according to the characteristics and requirements of the material. This includes the selection of laser power, frequency, pulse width and other parameters. Different materials may require different parameter settings, so make adjustments as needed to get the best marking results.

Cleaning and Maintenance:

Keep the UV laser marking machine clean and perform regular maintenance. Clean the laser’s lens and lenses regularly to ensure its surface is clean and dust-free. Also, ensure that the cooling system is operating properly to maintain the stability and performance of the equipment.

Calibration and Alignment:

Periodic calibration and alignment of the equipment is performed to ensure accuracy and consistency of marking. This includes alignment of the laser beam and alignment of the optical path. If deviations or inaccuracies are found, they should be adjusted and corrected in a timely manner.

Training and Operation:

Operators should receive professional training and be familiar with the operation and safety requirements of the ultraviolet laser marking machine.

Environmental:

UV laser marking machines have more stringent requirements on the working environment than other laser sources. Maintain proper temperature and humidity (the machine working environment temperature should be kept at 16~28°C and humidity at 45~75%) to avoid dust and particles from entering inside the equipment to ensure marking quality and equipment life.

Finally:

UV laser marking machine for plastic has become an important application in the field of modern processing and manufacturing. Its high precision, high quality and permanent marking characteristics make it widely used in the manufacturing industry. By understanding the advantages and limitations of UV marking machines, small businesses can make informed decisions for production. DPLASER portable laser marking machine improves product identification, traceability and aesthetics, and precise and long-lasting marking effects help brand building.