In recent years, the rapid development of laser welding has attracted attention. With its high precision, high efficiency and versatility, laser welding is gradually becoming one of the preferred technologies for enterprises to improve production efficiency and quality. This article will discuss the advantages and disadvantages between laser welding and traditional welding, and focus on the advantages of lightweight handheld laser welding machine, welding methods and how it can help small business improve productivity.

Handheld Laser Welding vs. Traditional Welding

What is Traditional Argon Arc Welding?

Arc welding processes like MIG, TIG or SAW welding. Traditional Argon Arc Welding is a welding process that uses an electric arc between a tungsten electrode and the work piece to produce the weld. During the welding process, a flow of inert gas, typically Argon, is used to shield the weld area from atmospheric gases. This prevents oxidation and contamination of the weld, resulting in a stronger, more precise joint.

Advantages of Traditional Argon Arc Welding include:

1. High-quality: The precision and control that this process offers make it an ideal choice for welding critical components and structures.

2. Versatility: Traditional Argon Arc Welding can be used to weld a wide variety of metals, including aluminum, stainless steel, nickel alloys, and titanium. This makes it a versatile process that is well-suited for a range of applications.

3. The welding thickness is relatively thick, suitable for thick welding plates above 4mm.

4. Traditional argon arc welding also has a comparative price advantage. The price is low, generally ranging from $3000 to 8000.

Disadvantages:

1. Although the processing is relatively rough, the power is stronger than others. It is suitable for load-bearing steel structures with slow welding speeds.

2. It generates extreme heat that deforms thin materials, makes it difficult to weld copper, and is limited in welding metals of different thicknesses.

3. High technical requirements for welders.

Excellent Alternative to Traditional: Laser Welding

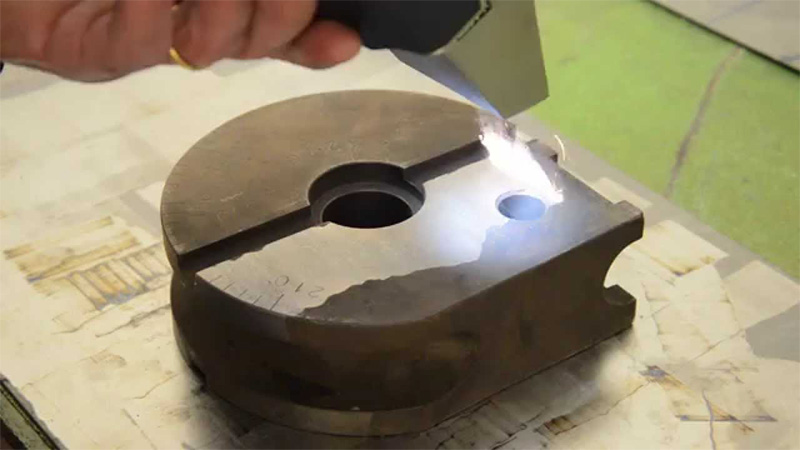

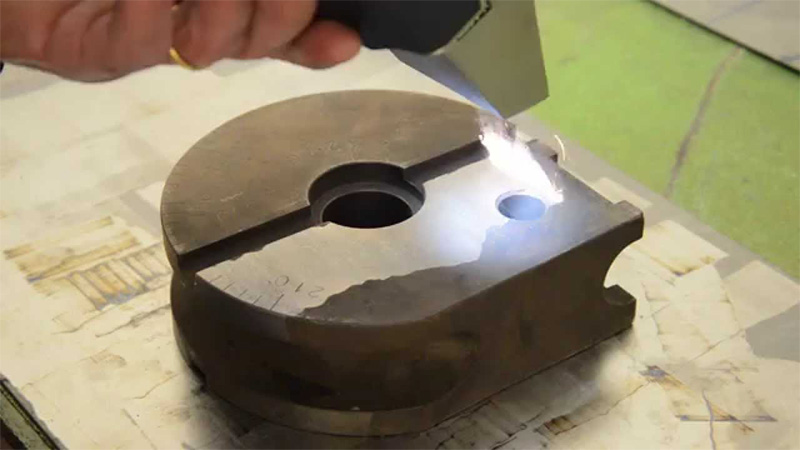

Laser welding is a welding process that uses a highly focused laser beam to melt and merge the edges of two materials. The laser beam heats and melts the surface of the materials in a much localized area, creating a narrow and deep weld.

One of the main advantages of laser welding is its high level of precision and accuracy. The narrowness of the laser beam allows for precise control over the welding process, resulting in high-quality welds with minimal distortion or heat-affected zones. Additionally, laser welding can be performed without direct contact between the laser and the materials being welded, which reduces the risk of contamination or damage to the materials.

Types of laser welding

There are two types of laser welding: conduction welding and keyhole welding. In conduction welding, the laser beam heats the surface of the two materials until they melt and fuse together. This type of welding is typically used for metals with low melting points. In keyhole welding, the laser beam creates a deep, narrow hole in the material, which is then filled with molten material. This type of welding is used for thicker materials or materials with high melting points.

The Advantages of Laser Welding Over Arc Welding

1. Welder certification is not necessary, resulting in reduced labor costs.

2. The welding speed is fast, thus boosting efficiency by 3-8 times.

3. Laser welding is highly accurate, with generally narrow weld seam widths and sub-millimeter welding accuracy, allowing for high-precision part assembly and traceability.

4. Exquisite weld seams are produced, eliminating the need for secondary processing.

5. It generates moderate indirect radiation, necessitating only the use of goggles.

Argon arc welding

1. The workpiece is prone to deformation, making it challenging to weld properly.

2. The welding process produces environmental pollution and may harm the ecosystem.

3. It is complicated to weld metals with low melting points and high evaporation rates.

Compared to laser welding, argon arc welding is more suitable for certain specific situations:

1. Larger size workpieces: traditional welding can be used to weld metal workpieces of various sizes, including large metal parts and thicker sheet metal.

2. Thicker sheet metal: because argon arc welding uses high power, it is often better suited for thicker sheet metal than laser welding.

3. Some metal types: argon arc welding is suitable for metals that are difficult to weld with a laser, such as titanium, nickel and aluminum, because it does not require highly reflective materials to transmit energy.

Although laser welding can provide higher efficiency and greater accuracy, argon arc welding is still a better choice in some specific scenarios, especially for large workpieces and thick metal plates.

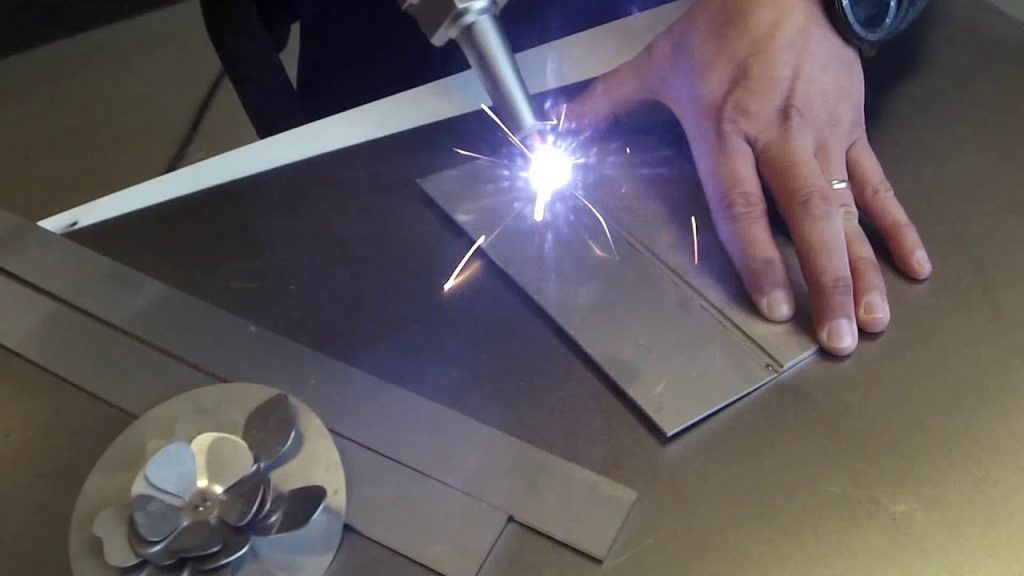

Hand-Held Laser Welding for Metal Welding

1. The handheld laser welding equipment is powerful:

Ergonomically designed and suitable for various working environments. It has a unique laser safety operation protection function. And it can ensure the operator’s safety when working.

2. Good welding effect:

Fast welding speed, flat and beautiful weld seam after welding. Small heat-affected zone during welding, which will not cause deformation of workpiece, blackening, back alignment and other problems. And the welding depth is large, the welding is firm and the melting is sufficient.

3. Compact & portable:

The compact and portable nature of hand-held laser welding equipment makes it ideal for use in confined spaces and in the field, where large-scale welding equipment may be impractical.

4. Reduce additional processes:

Hand held laser welding is known for its ability to produce welds with excellent cosmetic appearance, minimizing the need for additional cleaning or finishing processes.

5. Cost saving:

Good welding effect reduces the subsequent grinding process and saves time and cost (2-10 times faster than traditional welding, one machine can save at least 2 welders a year and less consumables). Less consumables, long life, low equipment maintenance costs.

6. Easy to operate:

Manual welding, quick to get started, flexible and convenient, and long welding distance.

7. High flexibility:

Suitable for a variety of complex welds, easy to weld any part of the workpiece at any angle. Further broaden the scope of application of laser welding. Can weld ceramics, organic glass and other non-metallic materials as well as shaped materials, good results, good flexibility. Flexible drive non-contact welding of difficult welding parts. Laser beam can achieve time and energy shunt, can process multiple beams at the same time, providing conditions for more precise welding.

8. Difficult-to-weld materials:

Laser welding is the use of very high energy density of the laser beam to melt the material. Laser welding can weld not only ordinary carbon and stainless steel, but also materials that are difficult to weld with conventional welding, such as structural steel, aluminum, copper and other metals.

The initial investment in a laser welding machine is certainly expensive, but the quality and characteristics of laser welding are unmatched. Laser welding offers several advantages that are often not found in other welding methods.

The Defining Characteristics of Laser Welding Are

- The whole welding process can be easily automated using a CAD/CAM setup

- No form of tool wear occurs

- Laser welding is highly specific in targeting

Compared with desktop laser welding machines, handheld fiber laser welding machines are mainly aimed at laser welding of long-distance and large workpieces. Welding on thin stainless steel metal plates, iron plates, galvanized plates and other metal materials can perfectly replace the traditional argon arc welding and electric welding processes.

Top Applications of Handheld Welding Machine

various sheet metal processing materials, molds, water tank welding, hardware lighting, advertising signs, cabinets, kitchens and bathrooms, stair lifts, shelves, ovens, stainless steel doors, window guardrails, distribution boxes etc.

Shielding Gas for Laser Welding

Auxiliary gas (usually argon or helium) helps to displace the atmosphere around the weld zone, preventing oxidation and contamination of the metal surfaces during welding. It can also help control the temperature around the weld zone, reducing the risk of thermal distortion and cracking. In some cases, the use of auxiliary gas can also enhance the visual clarity of the weld area, making it easier for the operator to monitor the welding and ensuring a consistent and high-quality weld.

How to Choose Auxiliary Gas for Laser Welding?

Argon or nitrogen both ok. It is recommended to use argon for welding and nitrogen for cutting

Choosing the right auxiliary gas for laser welding depends on several factors, including the type of material being welded, the thickness of the material, and the desired characteristics of the weld.

Here are some guides you to select shielding gas for laser welding:

1. Material type: Some materials, such as aluminum and copper, require different gases than steel. For example, argon is commonly used for welding steel, while helium is often used for welding aluminum.

2. Thickness: The thickness of the material being welded can affect the choice of gas. For thicker materials, a higher flow rate of gas may be required to displace the atmosphere effectively around the weld zone.

3. Mixing gases: In some cases, mixing different gases can help achieve specific welding characteristics. For example, adding a small percentage of oxygen or nitrogen to argon can improve weld penetration and control spatter.

4. Cost: Finally, the cost of the gas should also be factored in when choosing an auxiliary gas. Some gases, such as helium, can be more expensive than others and may not be cost-effective for all applications.

In general, it is recommended to consult with a welding expert or the equipment manufacturer to determine the most suitable gas for specific applications. They can provide valuable insights and advice on the best auxiliary gas for the intended use.

How Thick Can DPLASER Handheld Fiber Laser Welding Machine Weld?

| Material | Gas used | Thickness(mm) | Laser power(W) | Wire diameter(mm) | Wire speed(mm/s) | Scanning speed(mm/s) | Scan width(mm) | Welding frequency(HZ) | Duty cycle | Barometric pressure(bar) | Welding method |

| Stainless steel | Argon | 1 | 1000 | 1 | 90 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding |

| 1.5 | 1000 | 1 | 90 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding | ||

| 2 | 1500 | 1.2 | 75 | 300 | 3 | 1000Hz | 100 | 10 | Flat welding | ||

| 2.5 | 2000 | 1.2 | 75 | 300 | 3 | 1000Hz | 100 | 10 | Flat welding | ||

| 3 | 2000 | 1.6 | 60 | 300 | 3.5 | 1000Hz | 100 | 10 | Flat welding | ||

| 4 | 3000 | 1.6 | 60 | 300 | 3.5 | 1000Hz | 100 | 10 | Flat welding | ||

| Carbon steel | Argon | 1 | 1000 | 1 | 90 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding |

| 1.5 | 1000 | 1 | 90 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding | ||

| 2 | 1500 | 1.2 | 75 | 300 | 3 | 1000Hz | 100 | 10 | Flat welding | ||

| 2.5 | 2000 | 1.2 | 75 | 300 | 3 | 1000Hz | 100 | 10 | Flat welding | ||

| 3 | 2000 | 1.6 | 60 | 300 | 3.5 | 1000Hz | 100 | 10 | Flat welding | ||

| 4 | 3000 | 1.6 | 60 | 300 | 3.5 | 1000Hz | 100 | 10 | Flat welding | ||

| Galvanized sheet | Argon | 1 | 1000 | 1 | 90 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding |

| 1.5 | 1500 | 1 | 90 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding | ||

| 2 | 2000 | 1.2 | 75 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding | ||

| 2.5 | 2000 | 1.6 | 60 | 300 | 3 | 1000Hz | 100 | 10 | Flat welding | ||

| 3 | 3000 | 1.6 | 60 | 300 | 3.5 | 1000Hz | 100 | 10 | Flat welding | ||

| Aluminum | Nitrogen(N2) | 1 | 1000 | 1 | 90 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding |

| 1.5 | 1500 | 1 | 90 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding | ||

| 2 | 2000 | 1.2 | 75 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding | ||

| 2.5 | 2000 | 1.6 | 60 | 300 | 3 | 1000Hz | 100 | 10 | Flat welding | ||

| 3 | 3000 | 1.6 | 60 | 300 | 3.5 | 1000Hz | 100 | 10 | Flat welding |

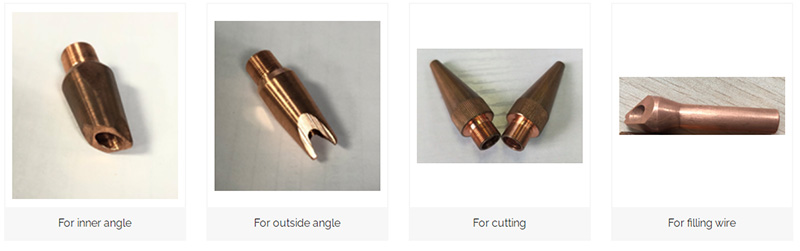

Nozzles for Laser Welding Machines?

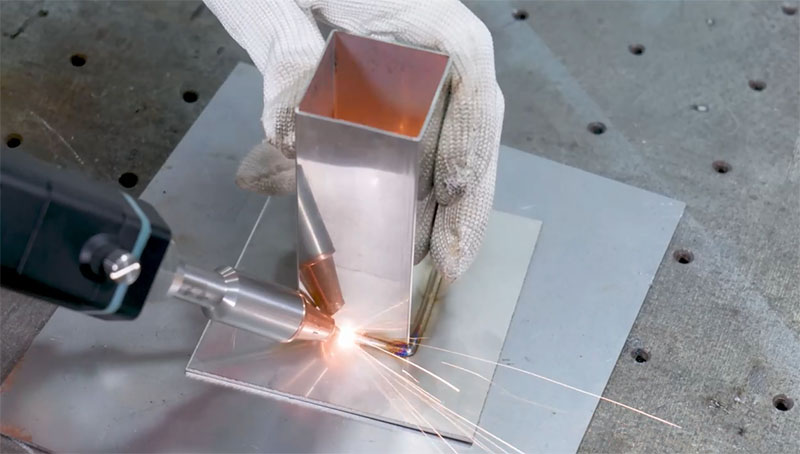

Handheld laser welding equipment can support a variety of welding, such as tailor welding, stitch welding, internal and external fillet welding, arc welding, and special-shaped welding.

Nozzles used in laser welding machines serve several important functions, such as focusing the laser beam, protecting the optics, shielding the welding zone and protect the laser focusing lens from spatter and debris during the welding process. Different types of nozzles are designed to accommodate specific welding applications and laser systems. These nozzles are typically made of durable materials such as copper or brass, and are available in a variety of sizes and shapes to accommodate different welding applications.

Here are some common types of nozzles used in laser welding machines:

1. Straight Nozzles – These are the most common type of copper nozzle used for laser welding and are straight and cylindrical in shape.

2. Tapered Nozzles – These nozzles have a tapered shape that helps to focus the flow of gas and provide better shielding for the weld.

3. Swiveling Nozzles – These nozzles can be rotated to direct the flow of gas in the desired direction and are particularly useful for welding in tight spaces.

4. Coaxial Nozzles – These nozzles are used for coaxial welding and incorporate a second gas stream that assists in controlling the weld puddle.

The choice of nozzle will depend on the specific requirements of the welding application, such as the type of material being welded, the thickness of the material, and the desired welding speed and quality.

Handheld Fiber Laser Welding Solution Features for Enterprises Manufacturing:

- Hand-held welding head is flexible and convenient for outdoor welding.

- The hand-held welding machine works in such a way that the workpiece can be welded at any position and at any angle.

- Suitable for spot welding of various complex joints and various materials.

- Large welding area and high welding efficiency are required.

- Plate thickness is above 0.5mm.

- Solve the problem of aesthetic and deformation of weld seam.

- Applicable materials are made of stainless steel, iron plate and aluminum.

For precision laser welding and welding of extremely thin materials, there are other types of welding machines available, such as fiber galvo laser welding machines, energy feedback laser welding machines and automatic welding machines, etc.

Handheld laser welder has the advantages of simple operation, beautiful welding seam, fast welding speed and no consumables. It can perfectly replace traditional argon arc welding, electric welding and other processes when welding stainless steel plate, iron plate, galvanized plate and other metal materials.

You don’t need to be a Laser Equipment Expert

Handheld laser welding systems offer presets for common material types and thicknesses. Simple sets allow you to select the correct preset parameters by selecting the material type and thickness. If a more unique material weld is required, our laser equipment experts are also available to assist you in adjusting the equipment parameters to fit any of your production sessions.

The hand-held laser welding system can also be designed as an all-in-one type for simple laser cutting and laser cleaning. This may help with part preparation to remove any stains, oil or rust from the workpiece. The compact design of the DPLASER 3-in-1 Handheld Laser Welding Machine greatly enhances its flexibility and portability. In addition to the laser welding function, it has two additional functions, laser cutting and laser cleaning, making it a cost-effective choice for improving manufacturing efficiency.

In practical applications, the 3-in-1 Handheld Fiber Laser Welder can be widely used in metal processing, automotive manufacturing, electronics manufacturing, jewelry mold repair and many other fields.

The extremely rapid growth of cobot technology has allowed many production plants to achieve a basic level of factory automation. The flexibility of this robot welding combined with the capabilities of laser welding technology makes it suitable for precise, high-efficiency mass production. You further increase laser welding productivity by pre-loading the part fixture while the collaborative robot performs the weld on a separate fixture. Last but no leas, handheld laser welding enables fast welding, easy to learn and operate; and provides high quality, consistent results across a wider range of materials and thicknesses with minimal distortion, distortion. If you are looking handheld laser welding price to reduce enterprise manufacturing costs, improve workmanship quality and simplify your welding process, DPLASER fiber handheld laser welding offers the best solutions to success and increased profitability.