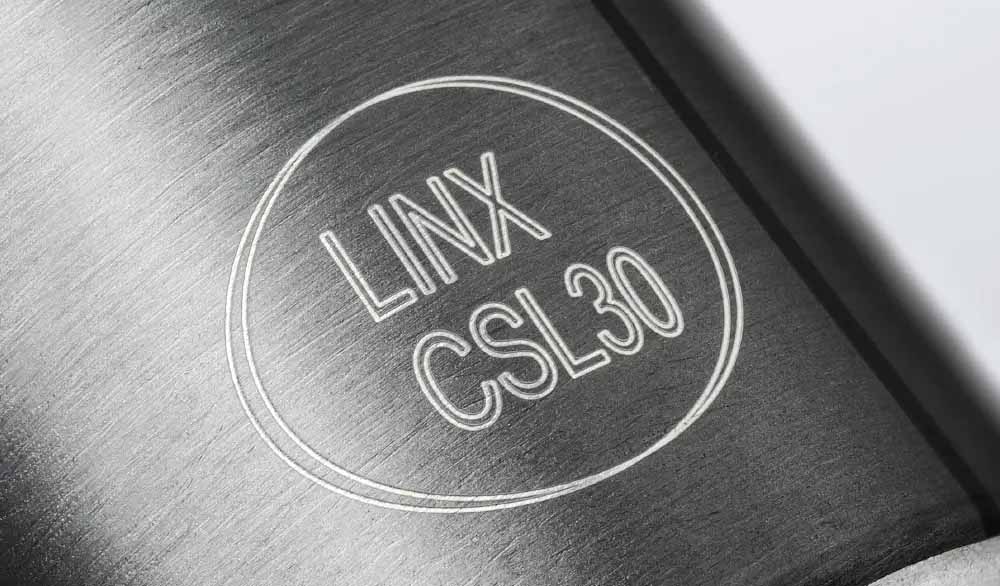

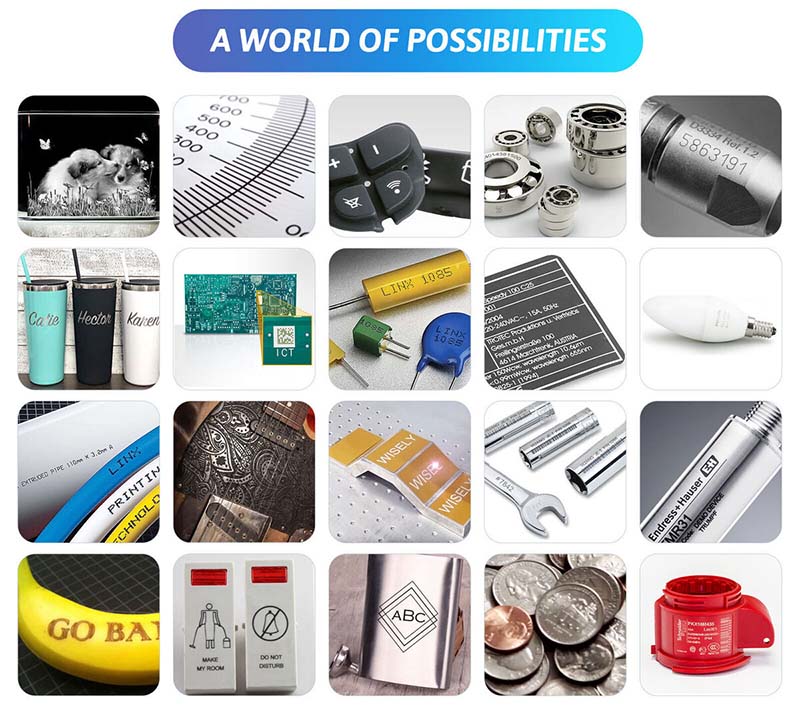

Laser marking is a versatile technology for contrast marking on a wide range of materials. Whether it’s engraving an intricate design on metal or etching a serial number on a micro-semiconductor, laser marking has become the preferred solution for precise, durable marking. DPLASER handheld laser marking machine for beginners utilize advanced optics to focus the beam on a sub-micron target location, resulting in a highly accurate and repeatable marking process.

Our handheld laser marking system are capable of deep engraving, etching, or marking the surface of a part, including marking graphics, text, logos, barcodes, and more.

What is the difference between Laser Engraving vs. Laser Etching vs. Laser Marking?

Laser engraving, laser etching and laser marking are common metal processing methods that utilize a laser beam to accurately process and mark metal surfaces. While they can be used interchangeably, there are some differences and applications between them.

Compared to traditional desktop laser engraving machines, the flexibility, portability, ease of operation, wide range of applications, high precision marking and low cost of handheld laser marking machines make them ideal for use in a variety of industries. Whether for mass production or individual production, handheld portable laser marking machine can meet the needs of users and provide excellent marking results.

8 Benefits of the Portable Handheld Laser Marker?

The portable handheld laser marker offers several benefits that make it a versatile and valuable tool in various industries and applications.

1. Portability:

The handheld laser marker is designed to be lightweight and easy to carry, allowing users to bring it to different locations or work in confined spaces.

2. Compact and Ergonomic Design:

These devices are typically ergonomically designed, fitting comfortably in the hand for extended use without causing fatigue. Their compact size enables easy maneuverability and precise marking even in intricate or hard-to-reach areas.

3. Versatile Marking Capabilities:

Laser markers can create high-quality, permanent markings on a wide range of materials, including metals, plastics, glass, ceramics, and more. They can produce precise, detailed designs, alphanumeric codes, logos, barcodes, serial numbers, or other custom markings as per the user’s requirements.

4. Non-Contact Marking:

The laser marker operates in a non-contact manner, meaning it does not physically touch the material being marked. This eliminates the risk of damage or deformation of delicate or sensitive surfaces.

5. High Precision and Speed:

Handheld laser markers utilize advanced laser technology, providing exceptional precision and accuracy. They can create fine lines, small characters, or intricate patterns with ease. Additionally, they offer fast marking speeds, enabling efficient production processes and minimizing downtime.

6. Permanent and Durable Markings:

Laser markings are typically permanent and highly resistant to wear, fading, or smudging. This ensures the longevity and traceability of the marked items, making them suitable for applications that require long-lasting identification or branding.

7. Low Cost:

Handheld laser marking machines usually have a simpler structure and design, which makes them relatively inexpensive. In addition, compared to traditional marking equipment, handheld laser markers do not require additional equipment or consumables, such as the ink and supplies needed for inkjet printers. This reduces operating costs and avoids additional fees.

8. Wide Applicability:

Handheld laser markers are also suitable for large workpieces. Thanks to its flexible maneuverability and portability, marking on the surface of large workpieces can be done easily without having to move the workpiece to a fixed marking position.

Overall, the portable handheld laser marker provides a convenient, versatile, and reliable solution for high-quality marking, identification, and customization requirements across different industries, including manufacturing, electronics, packing, handicrafts, jewelry and stationery.

What Can You Do with a Hand held Laser Marking Machine?

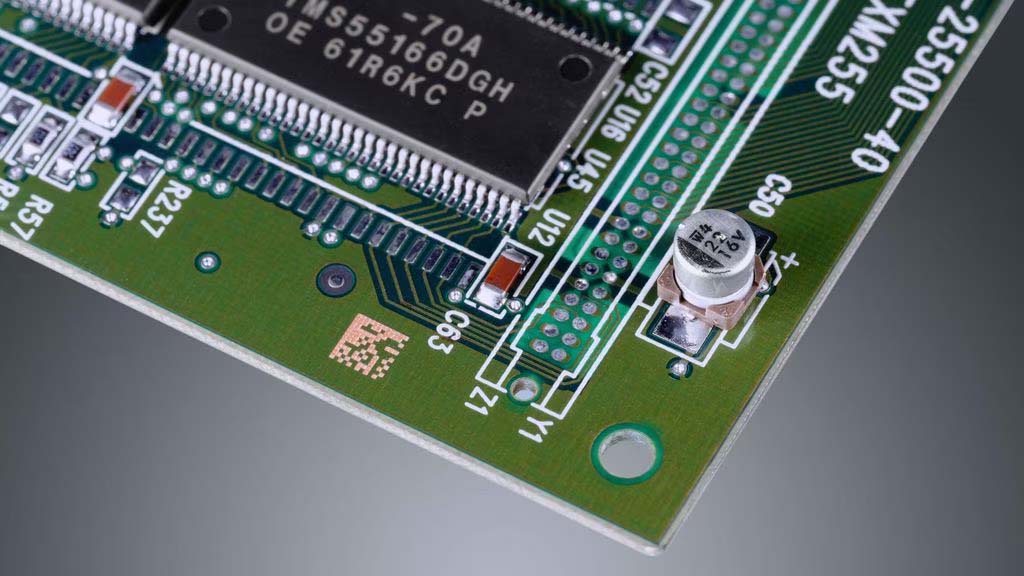

Handheld fiber laser marking machine are also suitable for many other work areas such as electronics manufacturing, packaging industry, electronic communications, clothing logo marking and many more. Because of their portability, flexibility and suitability for different materials and surfaces, handheld laser markers are the ideal tool for improving the efficiency and quality in many industries.

1. Manufacturing:

Hand held laser marking can be used to permanently mark a wide range of materials, such as metals, plastics, ceramics, and so on. It can be used to mark product serial numbers, batch numbers, dates, trademarks, graphics and other information for product traceability and identification.

2. Retail packing:

Handheld portable laser marking machine can be used for marking on merchandising packages, such as barcodes, QR codes, price tags, etc. It can also be used to engrave personalized information to increase the attractiveness of products.

3. Medical industry:

Handheld portable laser engraver for marking medical equipment, pharmaceutical packaging, medical devices and so on. These markings can include information such as product batch numbers, production dates, safety warnings, etc. to ensure product traceability and compliance.

4. Nameplate making:

Handheld laser marker to make nameplates, labels and signs. It can provide long-lasting marking on metal, plastic, wood and other materials for a variety of indoor and outdoor marking needs.

5. Arts and Crafts:

Handheld laser marking equipment for lettering, engraving and decorating on artwork, crafts, jewelry and other items. It can perform fine marking on a variety of materials to add unique character and value to the items.

How to Use the Latest Handheld Laser Engraving Machine?

When using a handheld fiber laser marker, it is important to follow the relevant safety regulations. It is recommended to read the manual of the equipment carefully before operation and strictly follow the manufacturer’s operating instructions and safety recommendations. The following is the routine use of the handheld laser marker, the specific operation and use steps may vary depending on the model and manufacturer.

1. Installation and preparation:

1.1 Place the Handheld Fiber Laser Marker on a stable workbench and connect the power cord.

1.2 Ensure that the work area is well ventilated and wear required safety equipment, such as laser safety goggles and gloves.

2. Turn on the equipment:

2.1 Turn on the power of the handheld fiber laser marking machine according to the operating instructions of the equipment and wait for its self-test to complete.

2.2 Verify that the equipment is in working condition and check that all safety features are functioning properly.

3. Set parameters:

3.1 Through the control interface or software of the equipment, set appropriate laser parameters, such as power, frequency and marking speed.

3.2 According to the type of material to be marked and requirements, adjust the laser parameters to ensure the best marking effect.

4. Prepare the marking material:

4.1 Place the material to be marked on the equipment table and secure it to prevent movement or shaking.

4.2 Make sure the material surface is clean and flat to obtain clear marking results.

5. Focus the laser beam:

5.1 Using the focusing aid provided with the equipment (e.g., red light indicator or camera system), accurately focus the laser beam on the surface of the marked material.

5.2 Adjust the focus for optimal marking results.

6. Begin marking:

6.1 After confirming that the focus is accurate, start the marking process through the control interface of the device.

6.2 Take care to maintain a stable handhold position and consistent movement speed to ensure uniform marking results.

7. Monitor the marking process:

7.1 During the marking, pay attention to observe the marking results to ensure the marking quality and accuracy.

7.2 If necessary, adjust the laser parameters or refocus according to the actual situation.

8. Finish marking:

8.1 After marking is completed, turn off the equipment and disconnect the power supply in time.

8.2 Wait for the equipment to cool down and store the handheld fiber laser marker properly.

9. Cleaning and maintenance:

9.1 Clean the unit’s lenses and parts regularly to ensure that the unit maintains optimal performance.

9.2 Inspect and maintain the handheld fiber laser marker regularly according to the equipment manufacturer’s maintenance schedule.

What should be considered When Buying a Handheld Laser Marking?

Laser Beam Power

For fiber, CO2, and diode lasers, the higher the laser power, the better the performance and marking capabilities. When you use a 50W fiber laser marker, you get a greater depth of engraving compared to using a 30W model. This is because higher power means that the laser beam has a higher energy density, which heats and removes material from the metal surface more efficiently.

Additionally, if you want the same engraving depth, you can choose to engrave at a higher speed. Higher power is usually accompanied by increased speed, which can significantly reduce engraving time. This is especially useful in mass production business, helping you increase productivity and save time and costs.

Laser Types

Fiber laser markers are designed for metal processing, while CO2 lasers have a wide range of applications in cutting, engraving and marking of different materials.

The power for fiber lasers and CO2 lasers are not directly comparable. If you need to laser mark on metal, a 40W fiber laser marking equipment can provide better performance than a 100W CO2 laser marking machine. This is due to the higher energy density and smaller spot size of fiber lasers, which allows for finer and sharper metal marking results.

Lightweight Handheld Laser Marking Machine for Beginners

Portable handheld laser marking machine is capable of marking various types of content, including text, serial numbers, dates, logos, graphics, barcodes, and QR codes. It uses a fiber laser, which is known for its efficiency and accuracy in creating precise marks on different materials such as metals, plastics, ceramics, and more.

- Hand- held laser marking machine is specially designed to solve various marking difficulties.

- Advanced laser technology is used to realize fast focusing and high-precision marking.

- With highly integrated design, the body is small and light, and the battery is detachable, which can provide unlimited endurance and improve work efficiency.

- Hand- held laser equipment has a wider range of use and higher flexibility, which can meet the daily needs of customers.

Main features of Small Portable Fiber Laser Engraver

1. The whole machine adopts blow molding shell, the whole machine weight is only 6.5kg.

2. 220V plug-in version and battery charging version, to meet the different needs of customers.

3. Plug-in version plug-in that is, convenient and fast.

4. Rechargeable version of the battery removable design, charging offline or built-in, with a backup battery, you can infinite life.

The Portable Handheld Fiber Laser Marking Machine for Metal Plastic

Mini handheld laser engraving machine, ultra-fine marking effect. The portable fiber laser engraving machine is compact, pollution-free, no optical power coupling loss, air-cooled, highly efficient and stable, with a service life of more than 100,000 hours.

Fiber laser engraving machine output power can choose 20W, 30W, 50W, JPT/MAX/RAYCUS/IPG light source optional. The software is simple and easy to use, suitable for graphics, charts, letters, barcodes, 2D codes and any other content, and can be widely used to make permanent markings on a variety of metal and some non-metallic surfaces.

Features:

Portable design: Small size, suitable for many scenarios

Foldable design: Convenient to carry, does not occupy space

Wide range of marking materials: Suitable for non-metallic products of metal and its parts

Versatile: Capable of marking, engraving and cutting in a small area.

Long life and no consumables in use

The Best Cheap Laser Engravers for Beginners

The 20W portable laser marking machine for metal is one of the more affordable machines on the market. However, it is still very high quality, making it a good choice for beginners and fiber laser engravers on a budget.

The portable fiber laser marking machine adopts superior quality fiber laser and high precision digital scan head to enable stable output and high quality laser mode. It is manufactured from a modular aluminum structural framing system. The high-strength aluminum profiles provide the stability of an optical instrument with the rigidity and durability of a machine tool.

- The integrated design of the system makes it more convenient to use, and provides an ideal solution for various industrial applications.

- Using a pulsed fiber laser, when the pulse width is less than 30ns, it can output a peak power of up to 25KW.

- Long service life, small size, no need for water cooling system, just simple air cooling.

- High speed scanning galvanometer

It consists of an X-Y optical scanning head, an electronic drive amplifier and an optical reflective lens. The signal provided by the computer controller drives the optical s scanning head by driving the amplifying circuit to control the deflection of the laser beam in the X- Y plane.

- Laser field lens

In the same primary optical system, the additional field lens will reduce the area of the detector. If use the same detector area, it can expand the field of view and increase the incident flux.

This portable desktop fiber laser marking machine for metal and a variety of non-metal materials: high-hard alloys, oxides, electroplating, coating, ABS, epoxy resin, ink, engineering plastics, etc.

The Bottom Line:

Which laser marking machine is best? The portability and low purchase price of the DPLASER handheld laser marking system make them ideal for creative studio people such as small businesses and hobbyists. They provide laser marking at a lower cost and with greater flexibility, quickly adjusting and setting marking parameters to achieve the desired creative effect and create beautiful design.