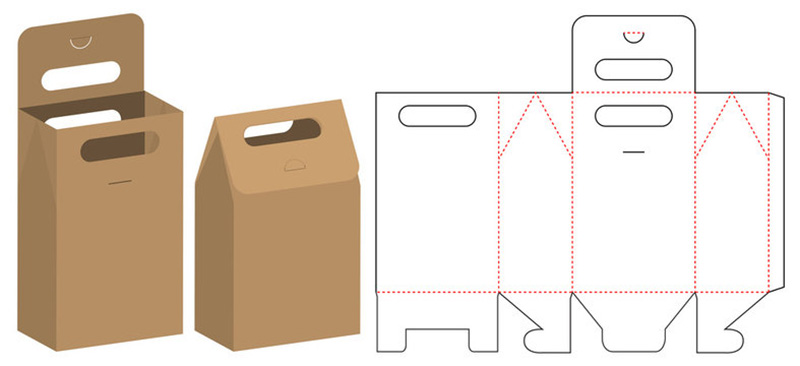

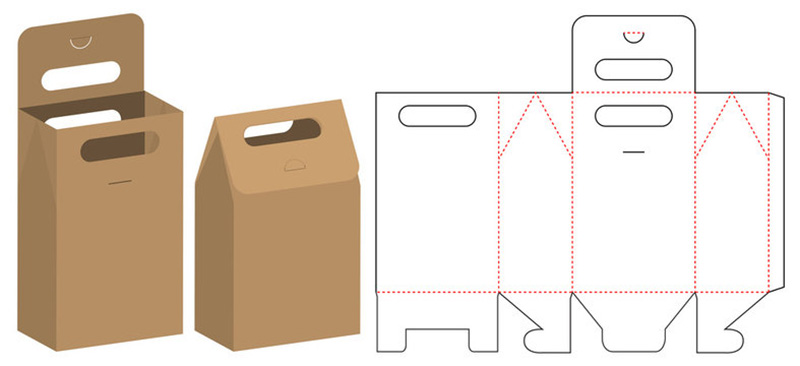

Cardboard as a material has many advantages over other materials. One of the main advantages is its cheapness; cardboard is relatively inexpensive. In addition, cardboard is easy to use and can be cut, folded and assembled, offering a wide range of flexible design possibilities. Laser cutting technology makes it easier to realize various cuts and engravings on cardboard. Laser cutting paper board is widely used to customize a variety of paper products. For example, cardboard can be used to make greeting cards, toys, boxes, decorations, and more. The high precision and clean of laser cut cardboard ensures that the results are as designed and the cutting process is more efficient and convenient.

Laser Cutting of Cardboard and Paperboard

Laser cutters are highly effective in cutting cardboard with precision. Cardboard is a versatile material widely used in applications like packaging, prototyping, and arts and crafts. The use of laser cutters ensures accurate and clean cuts on cardboard, enabling the creation of complex designs and shapes with ease.

Advantages of Laser Cutting in the Cardboard Industry

Laser cut cardboard has high quality processing results, improves productivity, reduces waste, and is suitable for cardboard products of various shapes and sizes. It has become a widely used technology in the field of cardboard processing and packaging.

1. High precision: laser cutting technology has very high precision and accuracy. It can realize very fine cutting, engraving and punching on cardboard, and can cut out complex shapes and patterns.

2. Non-contact processing: Laser cutting is a non-contact processing method where the laser beam acts directly on the cardboard surface. Compared with traditional tool cutting, laser cutting reduces mechanical stress and deformation, and avoids contamination and wear caused by contact.

3. Flexibility: The laser cutting machine can be adjusted on-the-fly to meet design requirements and can easily cut cardboard products of various shapes and sizes without the need to change tools. This provides greater flexibility and productivity.

4. Automation and high efficiency: Laser cutting allows for automated production, capable of batch processing and continuous operation through computer programs. It has high processing speed and productivity, which can significantly increase production capacity and output.

Can You Cut Cardboard With a Laser Cutter

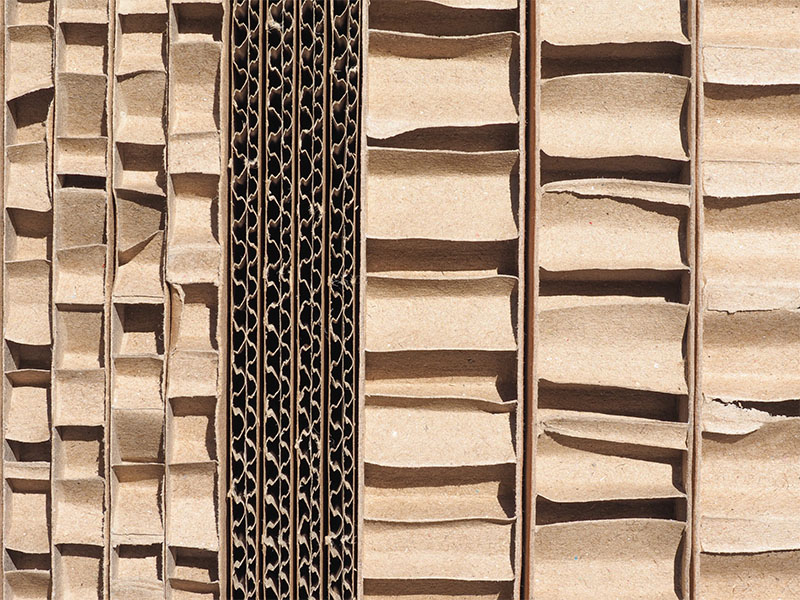

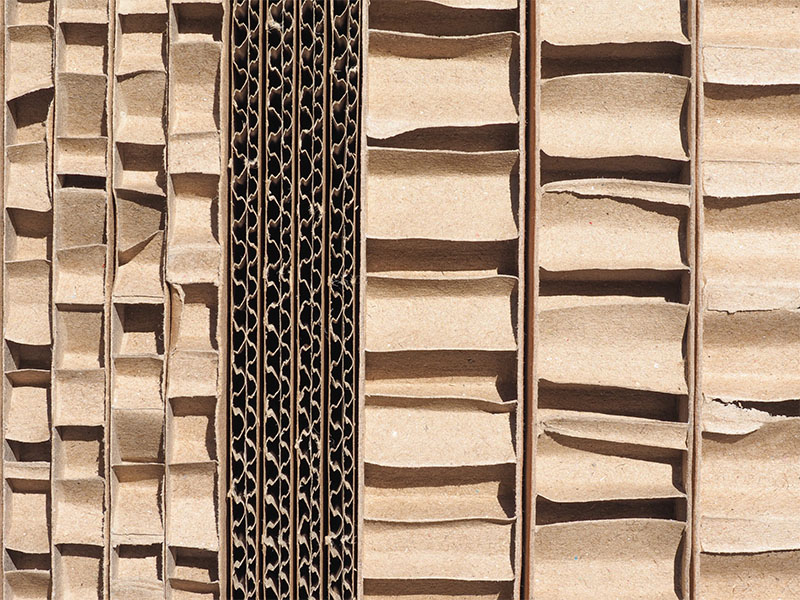

What types of cardboard can be laser cut? Different types of cardboard have different densities, thicknesses and materials, so the cutting characteristics and requirements are also different, so the power and parameters of the laser cutting machine need to be adjusted and adapted according to the actual situation.

Hardboard:

Laser cutting can effectively cut hardboard, such as cardboard, color paperboard, packaging cardboard and so on. Due to the relatively high density of cardboard, laser cutting machine needs corresponding power and energy to cut.

Acrylic cardboard:

Acrylic cardboard is a kind of cardboard made of paper pulp and latex, which is commonly used in display racks, furniture and decoration. Laser cutting can accurately cut and engrave acrylic cardboard to achieve complex patterns and shapes.

Honeycomb paperboard:

Honeycomb paperboard is lightweight and structurally stable, and is commonly used for packaging and protective materials. Laser cutting can cut and engrave on honeycomb paperboard to realize various shapes and structures.

Corrugated Cardboard:

Corrugated cardboard is a structure made up of multiple layers of cardboard and is commonly used in cardboard boxes and packaging materials. Laser cutting can be performed on corrugated board to create cartons and packaging in a variety of shapes and sizes.

Cardstock:

Cardstock is a thicker and sturdier type of cardboard often used for crafts, card making, and scrapbooking. Laser cutting is suitable for precise and intricate designs on cardstock.

Chipboard:

Chipboard is a dense and rigid type of cardboard composed of pressed paper particles. It is commonly used for items like book covers and puzzles. Laser cutting can be used to achieve clean and accurate cuts on chipboard.

What is the Maximum Cutting Thickness of Laser Cut Cardboard?

The maximum thickness of laser cut cardboard depends on the power and characteristics of the laser cutting machine, as well as the density and quality of the cardboard. Generally speaking, the maximum thickness of laser cut cardboard is between 2 and 10 millimeters.

For low power laser cutting machines, such as CO2 laser cutting machines, which are suitable for thin cardboard, such as cardboard, paper boxes, etc., the maximum cutting thickness is usually around 2-6 mm.

High power laser cutting machines, such as fiber laser cutting machines, can handle thicker cardboard. In general, the maximum cutting thickness can reach more than 10 millimeters.

It should be noted that the maximum thickness of the laser cutting machine for cardboard is also affected by other factors, such as the density of the cardboard, the type of impregnated material and so on. In addition, different settings of laser cutting machine parameters will also have an impact on the maximum cutting thickness.

It is recommended to test and adjust according to the specific type of cardboard and the specifications of the laser cutting machine in order to determine the best cutting results and maximum cutting thickness in actual operation. If you don’t have the condition to debug and choose the most suitable cardboard laser cutting machine for production, you are very welcome to contact the laser cutting machine manufacturer at any time, according to the samples you provide, we can help you test and make free samples.

How to Laser Cut Cardboard

Laser engraver for cardboard can be a precise and efficient way to create complex designs or accurate shapes. The following will provide some basic steps on how to use a laser cutter to cut cardboard. These steps will include preparing the cardboard material, preparing the laser cutter, setting the cutting parameters, and making the actual cut.

1. Preparation:

Get the cardboard material ready and make sure its surface is clean. Check the working condition of the laser cutting machine to ensure its normal operation.

2. Design pattern:

Create or import a design file for the cardboard using computer-aided design (CAD) software. Make sure the design file contains the desired cutting path, size and shape.

3. Set cutting parameters:

Set the appropriate laser cutting parameters based on the type of material and thickness of the cardboard. These parameters include laser power, cutting speed and focusing distance. Refer to the operation manual of the laser cutting machine or consult professional technicians to get the best parameter settings.

4. Position the cardboard:

Place the cardboard material on the working table of the laser cutting machine and fix it in place using clamps or magnetic positioning system. Make sure the cardboard is flat and will not move to ensure the accuracy of cutting.

5. Adjust the focus:

Adjust the focus of the laser cutter according to the thickness of the cardboard to ensure that the laser beam can be accurately focused on the surface of the cardboard.

6. Cutting operation:

Start the laser cutter and follow the cutting path set in the design file. The laser beam will move on the cardboard and cut according to the set parameters. Ensure that there is sufficient ventilation during the operation of the laser cutting machine to remove the smoke and gas generated.

7. Completion and inspection:

After completing the cutting, turn off the laser cutter and remove the cut cardboard. Check the cutting result to ensure that it meets the design requirements and expected accuracy.

Please note that laser cutting is a technical operation and requires appropriate knowledge and experience. Before operating the laser cutter, be sure to familiarize yourself with the relevant safety regulations and follow the instructions and recommendations provided by the laser cutter manufacturer.

Precautions and Guide for Laser Cutting Paper Packaging

Safety is crucial when operating with a cardboard laser cutter. Here are some safety precautions for cardboard laser cutting. These precautions are designed to ensure the safety of the operator and the proper use of the machine.

1. Safety protection: Always wear appropriate personal protective equipment, such as safety glasses and gloves, before operating the laser cutter. Ensure the work area is well ventilated and place the laser cutter on a stable surface.

2. Material: Different types and thicknesses of cardboard may require different cutting parameters and settings.

3. Cutting parameters: According to the type and thickness of cardboard and the desired cutting effect, set the cutting parameters of the laser cutting machine correctly, such as power, speed and frequency. Conduct sufficient tests and adjustments to ensure accurate and high quality cutting results.

4. Design and layout: In order to maximize the utilization of cardboard and reduce waste, design the cutting pattern and layout reasonably. Consider the size, shape and cutting path of the cardboard to ensure high efficiency of the cutting process and good cutting quality.

5. Keep the cutting area clean: Keep the cutting area clean and tidy, and clean up cardboard debris and dust in time. This helps to ensure the accuracy and stability of the laser beam, as well as improve the cutting effect and precision.

6. Monitor and operate: During the cutting process, closely monitor the running status of the laser cutting machine. Avoid long periods of continuous operation and take appropriate breaks to avoid overheating or malfunctioning of the equipment. Follow the instructions and operating requirements of the laser cutting machine.

7. Regular maintenance: Maintain and clean the laser cutting machine regularly to ensure its normal operation and safety. Clean the optical path system and lenses of the cutter, as well as clean up waste and dust accumulation.

Safety Tips:

- When operating the laser cutter, strictly follow the manufacturer’s safety procedures and guidelines.

- Keep fingers or other objects away from the laser beam to avoid accidental injury.

- Stay focused and alert during the cutting process and be ready to handle emergencies.

- If you find that the laser cutting machine is malfunctioning or working abnormally, stop operating it immediately and find professional to check and repair.

The Best Laser Engraver for Cardboard

3D Large Format Dynamic Focus Laser Marking Machine

3D dynamic large format laser marking machine is a powerful tool used for engraving and cutting various materials with precision and accuracy. This advanced machine utilizes dynamic and 3D engraving technology, allowing for the creation of intricate and detailed designs on large surfaces.

The large format capability of this laser engraver machine means that it can accommodate larger workpieces, making it ideal for engraving on furniture, signage, architectural elements, and other sizable objects. Whether it’s paper, cardboard, acrylic, leather, fabric, this laser engraver machine can handle a wide range of materials, opening up endless possibilities for creative and industrial applications.

Features:

1. Dynamic 3D Engraving: The machine employs dynamic focusing technology, allowing it to automatically adjust the focal distance during the engraving process. This enables consistent and accurate engraving, even on curved or irregular surfaces.

2. Large Working Area: The machine offers a spacious working area, accommodating large and bulky materials with ease. It provides ample space for engraving extensive designs, making it suitable for applications like signage, displays, and architectural models.

3. High Precision and Detail: Equipped with advanced laser technology, the engraver delivers intricate and detailed engravings, capable of capturing complex designs, fine text, and delicate patterns on cardboard surfaces.

4. Wide Material Compatibility: Apart from cardboard, the machine can also engrave various other materials, including wood, acrylic, glass, leather, and more, making it a versatile tool for multiple creative and industrial applications.

3D dynamic large format laser engraver machines can be utilized across various industries for cutting cardboard. Such as packaging industry, boxes, displays, trays, and inserts, printing industry, arts and crafts, design and DIY.

The adoption of laser cutting machines has not only streamlined production processes but has also unleashed a new wave of creativity for designers and manufacturers alike. From custom packaging solutions to innovative paperboard structures and artistic displays, the possibilities are limited only by imagination.

In conclusion, cutting cardboard with laser cutter has emerged as a transformative force in the paper packaging & manufacturing industry, offering unparalleled precision, versatility, and efficiency. As we have explored in this article, the technology’s ability to create intricate designs and deliver consistent, high-quality results has revolutionized the way we approach cardboard processing.