With the continuous advancement of technology and the ever-growing manufacturing industry, the global 3D laser cutting machine market is undergoing significant transformation and expansion. This market has become increasingly vital in recent years, bringing innovation and competitiveness to various industries. 3D laser cutting technology not only achieves high precision and efficiency in material cutting but also provides designers and manufacturers with greater flexibility and creativity, driving the continuous evolution of products. This article will delve into the global 3D fiber laser cutting machine market size, analyzing its market share, key application areas, market trends, and potential investment opportunities.

Starting with the boom in electric vehicles, the automotive industry has been one of the most prolific fields for laser processing applications, primarily focusing on laser cutting and laser welding. Laser cutting encompasses plate tube cutting and three-dimensional cutting, and for high-strength steel structural components with complex contours, three-dimensional laser cutting is an extremely effective processing method, both from a technical and economic perspective. Three-dimensional laser cutting operations can be performed on flat, inclined, or curved surfaces. The application of 3D laser cutting machines reduces tooling investments, shortens development cycles for automotive manufacturers and component manufacturers, enhances processing efficiency, and improves the precision of cut workpieces. It stands as a powerful tool for automotive manufacturers and component manufacturers to enhance their competitiveness.

Laser Cutting Machine Market

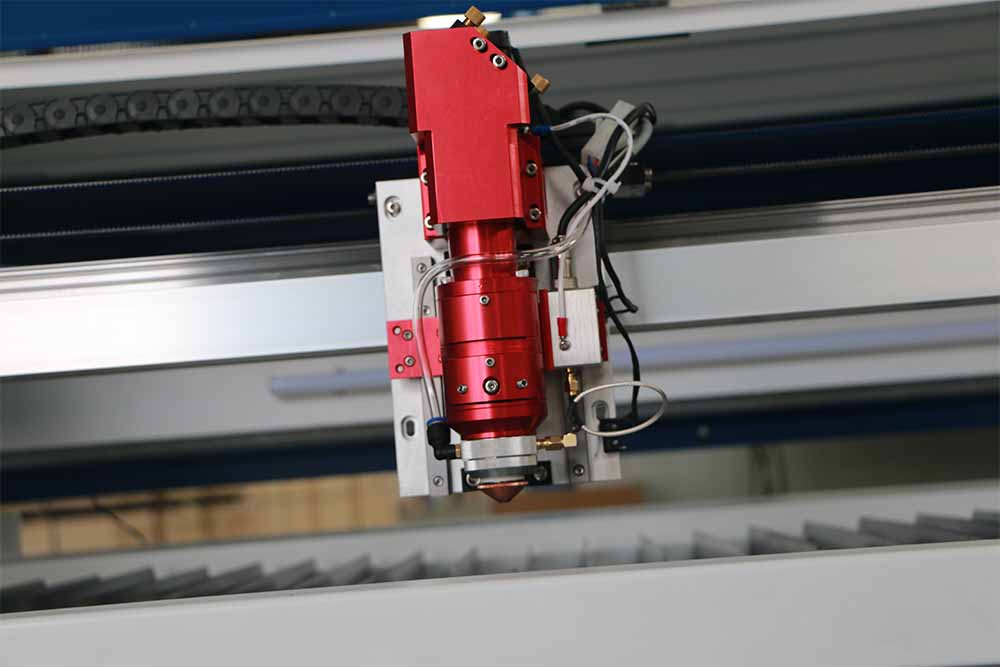

In many industries, traditional metal cutting cannot meet the needs due to variations in sheet thickness or spatial constraints, and this is where 3D laser cutting machines come into play. Utilizing fiber lasers as their working light source, these machines can cut three-dimensional shapes without the need for alterations to the laser system, offering high cutting precision and excellent quality.

3D fiber laser cutting machines are advanced CNC laser cutting devices that incorporate key technologies such as fiber laser sources, fiber scanning, numerical control systems, and control systems. They excel in high-precision laser cutting and find extensive applications in cutting three-dimensional shapes from metal alloys (such as titanium stainless steel and aluminum) as well as processing sheet metal parts with varying thicknesses and complex geometries.

Using CO2 or fiber lasers as their working light source, 3d fiber laser cutting machine achieve rapid scanning through devices like scanning mirrors and lenses, enabling three-dimensional cutting or engraving of target shapes.

Global 3d Laser Cutting Machine Market 2023

Prospects for Laser Cutting

With the continuous development of modern mechanical processing industries, there is a constant demand for higher quality and precision in cutting sheet and pipe materials. Simultaneously, the requirement for improved production efficiency, reduced production costs, and the integration of highly intelligent automatic cutting capabilities is on the rise. CNC laser cutting machine adapted to the needs of the modern machining industry, has become one of the most popular means of processing, rapid growth in recent years.

Development Trend of 3D Laser Cutting Technology

Higher Cutting Speed: With the intensification of market competition, production speed becomes crucial. Future developments will focus on enhancing the speed of laser cutting equipment to increase production efficiency.

Higher Accuracy and Precision: Components in 3C products are becoming increasingly smaller, demanding higher levels of accuracy and precision. Laser cutting technology will continue to evolve to meet these requirements, ensuring high-quality cutting and processing.

Wider Range of Application: 3D laser cutting system will find applications in more diverse fields, including medical, electronics, textiles, and more, offering various cutting solutions to industries. 3D laser cutting technology fosters personalized product design, enabling engineering designers to unleash their creativity and craft more intricate products without the limitations of traditional machining methods.

Expanded Material Cutting Capabilities: Future 3D laser cutting machines will be capable of cutting a broader range of materials, including metals, plastics, ceramics, and more, providing increased choices and flexibility.

More Intelligent Control Systems: With the development of artificial intelligence and automation technologies, 3D laser cutter will feature more intelligent control systems that can automatically adjust parameters and optimize the cutting process, enhancing efficiency and quality. High levels of intelligence simplify the operation of machine equipment technology, reduce the dependence on personnel skills, make operations simple and easy to learn, and can also reduce costs.

3d Laser Cutting Machine Regional Development

Growing industrial production in emerging countries is one of the factors driving the growth of the 3D laser cutting equipment market. The global industry is experiencing a shift towards automation. This has led to higher demand for advanced machinery including laser cutting machines. Due to increasing use of laser equipment for cutting, welding, and cleaning components and molds throughout the manufacturing process. The consumer electronics industry is expected to grow at the highest CAGR between 2023 and 2030. High precision laser cutting machines are mostly used for cutting of consumer electronics and mechanical production parts.

3D laser cutting machine market size of nearly $6 billion in 2023, low power laser cutting equipment is still the mainstream of the market.

Fiber laser cutting system are categorized based on the materials, with distinctions between metal material cutting machines and non-metal material cutting machines. They can also be classified based on their control methods, into CNC (Computer Numerical Control) cutting machines and manual cutting machines. CNC cutting machines are driven by digital programs that control the movement of the machine tool, and during this movement, a cutting tool attached to the machine is used to cut objects. Among them, CNC fiber laser cutting machines are known for their high efficiency and precision, typically suitable for cutting thinner materials.

As the global economy recovers and traditional manufacturing industries undergo technological updates, the demand for laser cutting equipment continues to rise. Laser cutting technology is gradually replacing traditional cutting methods, becoming the mainstream processing technology. It is estimated that by 2023, the laser cutting market, including sheet metal cutting, precision cutting, and other non-metal material cutting, will reach a market size of approximately 6 billion USD.

3D Laser Cutting Machine Application Trend

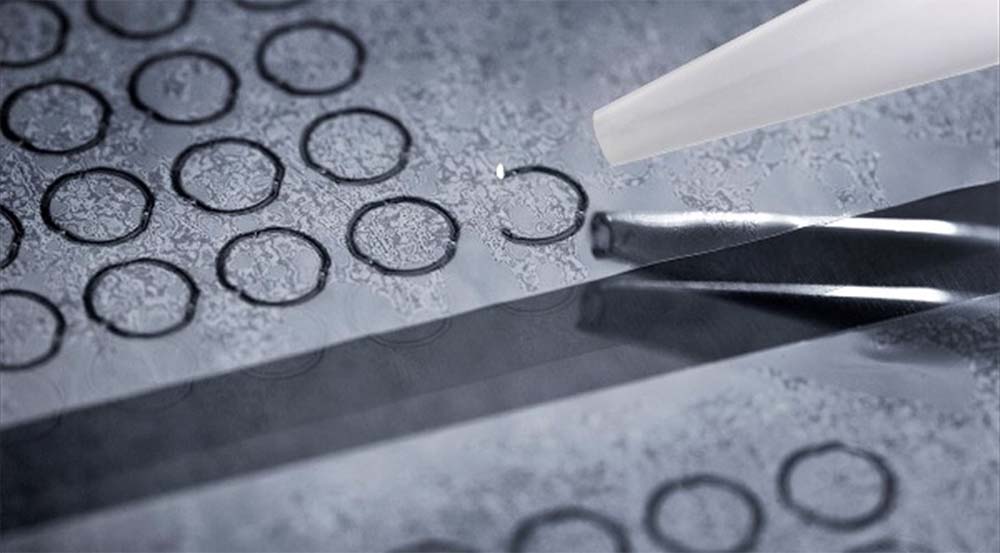

3D laser cutting machine is a laser processing equipment used for cutting complex, three-dimensional parts with irregular surfaces. It is primarily used for cutting, drilling, punching, milling, remove burrs, and edge trimming of components on three-dimensional and irregular surfaces.

Manufacturing Industry

Advanced industrial tools like 3D laser cutting system employ laser technology to cut, etching, and engrave various materials in three dimensions. These 3D laser cutting equipment are capable of executing complex and precise cuts on three-dimensional objects at impressive speeds and with high precision, resulting in intricate shapes and patterns. These machines find wide applications in model manufacturing, producing metal parts for the automotive and aerospace industries, creating custom signage and artwork, as well as manufacturing complex electronic components.

CNC laser cutting machine in automotive manufacturing, elevator manufacturing, packaging machinery, textile machinery, electrical switchgear, aerospace and other industrial sheet metal processing areas have achieved more successful applications. But in shipbuilding, construction machinery and other industries that require medium and thick metal plates and other cutting applications are very few. So excellent performance, competitive price, and can be competent in medium and thick plate cutting high power, large-scale CNC laser cutting machine in the future market potential is huge.

Emerging Industry

In recent years set off the national fitness, green travel and other hot trend, fitness equipment, electric bicycle are highly favored. The 3D pipe laser cutting machine is precisely suitable for fitness equipment, bicycles, electric cars and other metal pipe processing industry professional equipment. Professional 3D laser cutting machine tools for cutting different specifications and graphics on pipes and profiled tubes will surely produce a great enhancement for their manufacturing. Three-dimensional laser cutting equipment occupies a very important social position, this kind of laser equipment power is suitable for cutting shaped plates, shaped pipe fittings and so on.

In the past ten years, the laser cutting industry has undergone a series of changes, including the improvement of the quality and thickness of cutting materials, the improvement of machine power and efficiency, so that today’s laser cutting machines can be used at higher speed, precision and better cutting quality. Efficiently process countless component products including automotive, aerospace, shipbuilding, medical equipment, electrical and electronics, textiles, woodworking, kitchenware and more.

The application field of 3D laser cutting machine is expanding, and the downstream demand shows a diversified trend. In order to meet the multi-dimensional market demand, 3d CNC laser cutting machine is gradually upgrading to the direction of intelligence, automation, lightweight, high efficiency and low energy consumption.

Should You Invest in a Laser Cutter?

Compared to traditional cutting methods, a significant advantage of 3D laser cutting is time and cost savings. Large projects that need to be completed in a short timeframe can achieve higher efficiency through 3D laser cutting. With 3D laser technology, projects that would typically take around a month to complete can be shortened to just a few days.

Small and medium-sized enterprises may face a substantial initial investment when purchasing 3D laser cutting equipment, including the cost of acquiring and setting up the machines, as well as the expenses associated with necessary software and training. These high costs might give some startup pause. However, these machines are recognized for their efficient and precise assembly line cutting capabilities. Compared to traditional cutting techniques, they can quickly accomplish complex and precise batch cutting tasks, enhancing production efficiency, reducing turnaround times, and minimizing material wastage.

In the long run, investing in a laser cutter can be a wise decision if it aligns with your project requirements, budget, and workspace capabilities.

Summary

3D laser cutting technology is rapidly transforming the global manufacturing landscape at an astounding pace. The prospects for this technology appear boundless, offering not only efficient solutions but also unprecedented creative possibilities for manufacturers and designers alike.

With the rise of automation, intelligence, and green manufacturing, the 3D laser cutting machine market will continue to thrive, infusing new vitality into the global manufacturing market. Investors and manufacturing managers should pay close attention to 3d laser cutting machine application to catch the business opportunities it brings. Whether it is improving production efficiency, improving product quality, production security or enabling a more environmentally friendly manufacturing process, 3D fiber laser cutting technology holds great potential for the future of manufacturing.