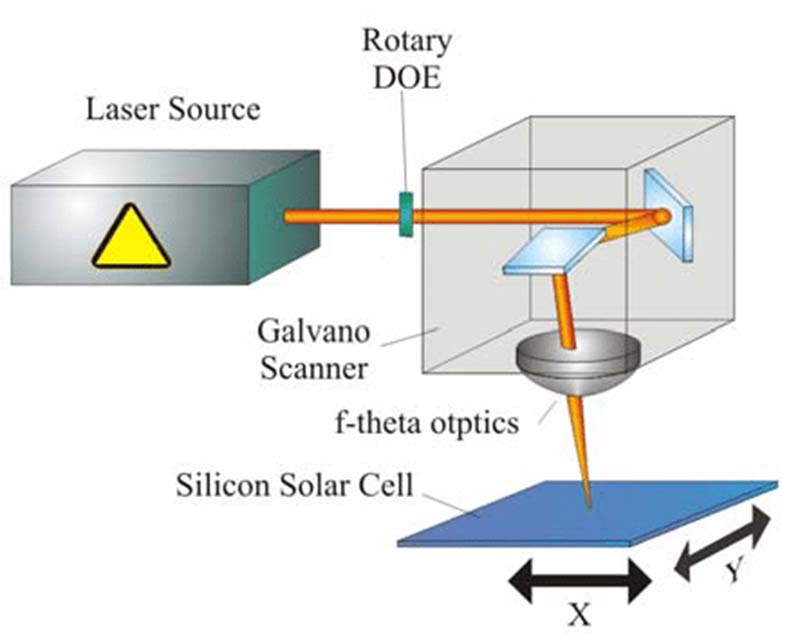

The galvo laser welding machine utilizes the galvanometer’s rapid adjustment and focusing of the laser beam to enable the joining of materials with complex configurations for fast and precise welding.

What is galvo laser? Laser galvanometer is used in the laser industry a high-speed scanning galvo scanning system. Galvanometer scanning marking head note by XY scanning mirrors, field mirrors, galvanometers and computer software and other components. Simply speaking galvo system is a kind of high precision, high speed servo control system composed of drive plate and high speed oscillating motor. Very high precision in practical applications, especially in the field of fine micromachining.

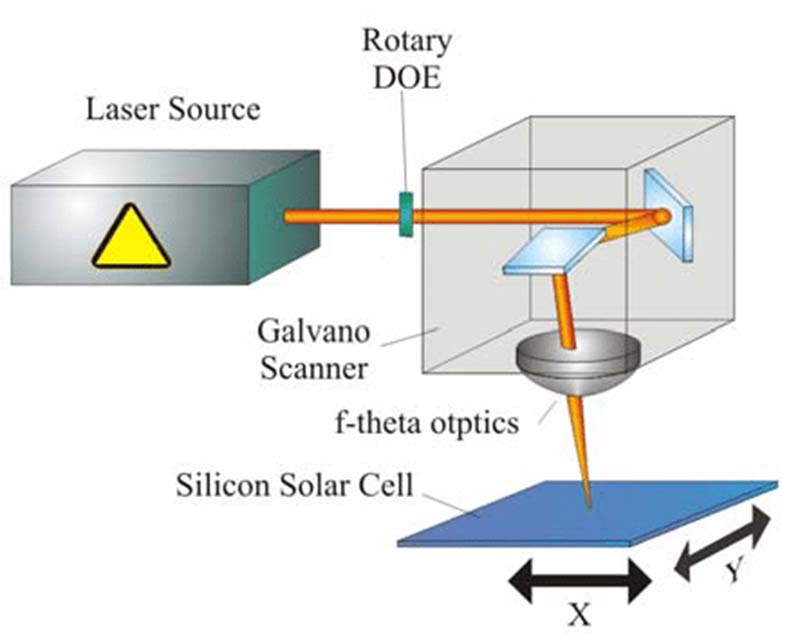

How Does a Galvo Laser Work?

The galvanometer laser welding machine adopts galvanometer technology to control the direction and focal length of the laser beam by adjusting the galvanometer. The galvanometer enables rapid adjustment and high-frequency scanning, allowing the laser beam to be precisely focused in the welding area. By fine-tuning the focal length and scanning speed, the galvanometer laser welding machine can achieve high-speed and precise welding. This technology is not only suitable for flat welding but also applicable to welding three-dimensional complex shapes, improving welding quality and efficiency.

Galvo Laser Welding

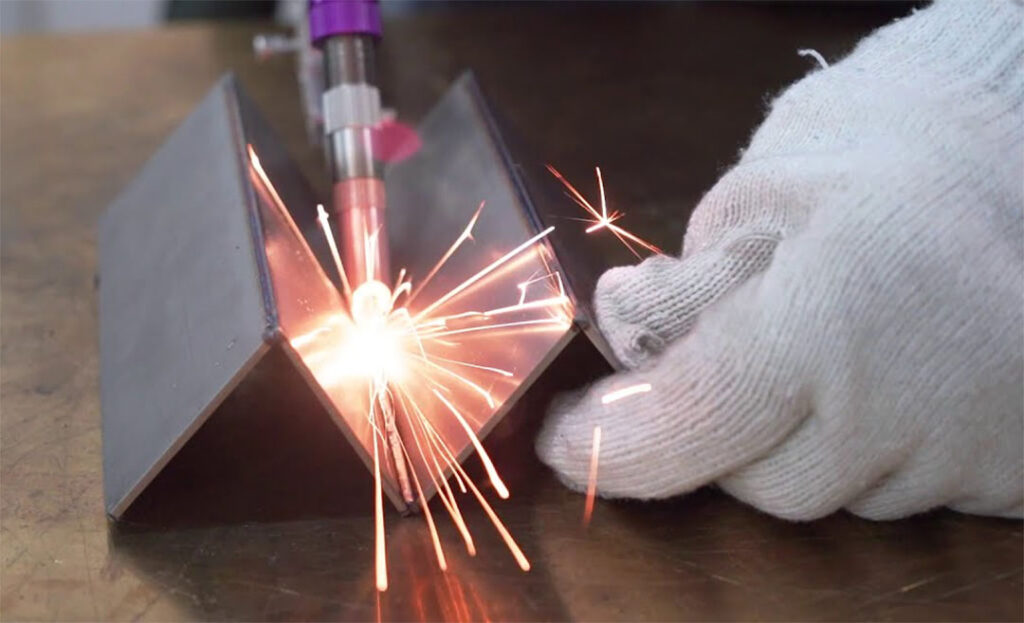

1. Laser emission: The machine first generates a high-energy laser beam through a laser emitter.

2. Galvanometer adjustment: The laser beam is reflected and adjusted by one or more vibrating mirrors, causing rapid changes in its direction.

3. Focused welding: The adjusted laser beam is focused within the welding area, generating high temperature to instantly melt the welding material.

4. High-speed movement: The vibrating mirror oscillates at a high frequency, causing the laser beam to move rapidly within the welding area, completing the welding process.

Advantages of Galvo in Laser Welding

1. High Efficiency

The galvanometer positions the laser beam at a very high speed and precision, thus dramatically increasing the welding speed and significantly improving productivity.

2. Precision Welding

By setting the output energy waveform and performing waveform control, more ideal welding results can be achieved. Using a mirror or lens controlled by a current detector, the laser beam can be redirected to a specific area with sub-millimeter accuracy, enabling complex and precise welding operations.

3. Miniature Welding

Focusing the laser enables miniature welding with a high depth-to-width ratio, making it ideal for precision welding of high-power devices.

4. Powerful Adaptability

The ability of the galvanometer to adjust the focal length allows the welding to be adapted to different depths and configurations of the material to be joined. Whether you are welding thin or thick plates, the weld quality is stable and the weld seam is beautiful, without the need for follow-up treatment.

5. Real-time Beam Tracking

The ability of the galvanometer to realize real-time beam tracking ensures accurate alignment and position control even when dealing with complex or irregular joint geometries. This feature compensates for any deviations or variations in the welding process and helps maintain consistent weld quality.

6. Bulk Production

The light guide system of the galvanometer laser welding machine enables effective and stable laser spot welding through the rapid movement of the galvanometer. With high stability and reliability, it can work stably for a long time and is suitable for mass production.

Application of the Galvo Scanner Laser Welding Systems

The galvanometer laser welding technology has been widely applied in scenarios where components exhibit complex shapes, demand high welding precision, and necessitate flexible manipulation of the laser beam path. The introduction of three-axis galvanometer laser welding machines, built upon the foundation of traditional two-dimensional systems, adds the capability of Z-axis movement while incorporating pre-focusing lenses. This innovation enables the laser focal point to move smoothly and freely in the x, y, and z directions of the workpiece. Such advancement significantly enhances welding flexibility and efficiency, rendering it suitable for welding 3D or multi-dimensional products. Customization options, including 3-axis or 5-axis configurations, are available to meet specific production requirements.

Automobile Manufacturing

Achieve high-speed welding processes for automotive components (including but not limited to body, engine parts, and interior components).

Improve welding quality and precision, reduce welding distortion, thereby increasing the overall fatigue life and safety of automotive structures.

Adopting uneven thickness laser welding plate technology helps to reduce vehicle weight, optimize component structure, and lower costs.

Kitchen Appliances

Laser galvanometer welding technology, with its high-precision motion control system, can achieve micron-level positioning. It is especially suitable for welding precision kitchen components such as stainless steel cookware, knives, cutlery, and other complex structures and delicate parts, greatly enhancing welding accuracy and efficiency.

The automation production line has been significantly improved, meeting the demands of high-volume, continuous production while ensuring high-quality product output. The large depth-to-width ratio of welds, small heat-affected zone, and minimal contamination and deformation effectively enhance the overall structural strength and aesthetic appeal of kitchenware.

Laser galvanometer welding demonstrates excellent adaptability to aluminum and stainless steel materials and can flexibly handle various specifications and models of kitchenware products, achieving automated welding of complex weld seams through programming.

Electronic Components

Used for welding small-sized components and precision circuit boards, particularly suitable for high-precision, small-space welding operations. Examples include electronic components, cards, PCB circuit boards, etc. Galvanometer welding machines not only boast fast welding speeds, high quality, and low costs but also avoid defects such as thermal deformation and metal impact present in traditional welding techniques.

Aerospace

For complex geometric components in the aerospace field, galvanometer laser welding machines can accomplish high-difficulty, high-precision welding tasks.

Meet the stringent requirements of various components on welding strength, sealing, and lightweight structures on spacecraft and aircraft.

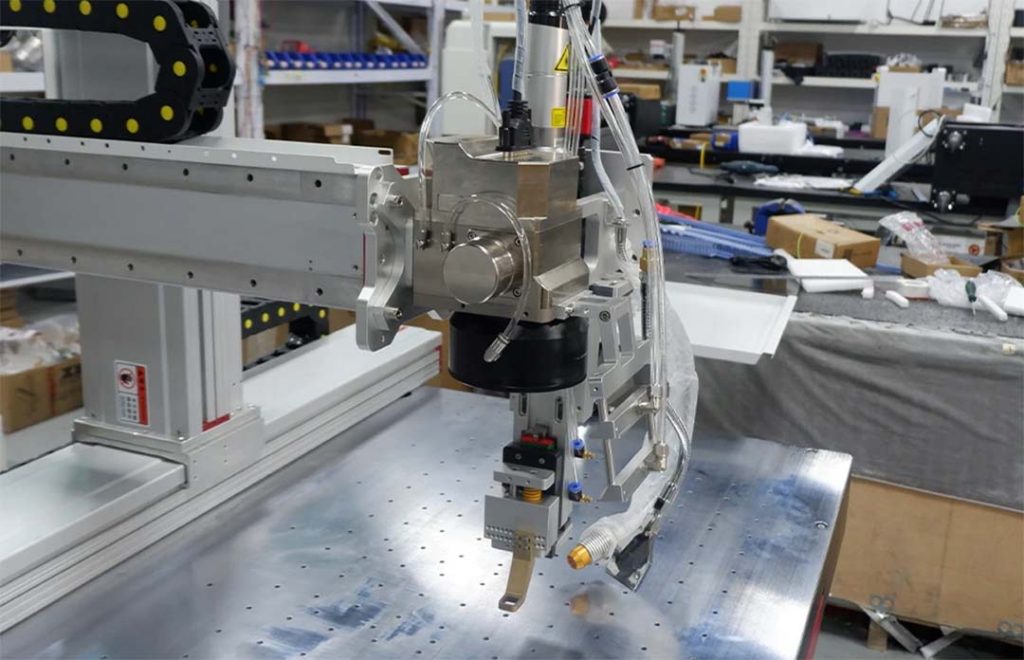

Galvanometer scanning QCW laser welding machine

The automatic galvo laser welding system integrates industrial-grade computer and high-performance PLC dual control system, realizing a high degree of synergistic operation of high-speed galvanometer and CNC workstations, which improves the working efficiency by more than ten times compared with the traditional stepping motor-driven, fixed optical path continuous welding method and realizes the whole unattended on-line laser welding automation. The galvanometer scanning laser welding machine utilizes high-speed galvanometer technology to accurately position at a rate of 7,000 millimeters per second, resulting in fast welding speeds and overall performance that far exceeds that of conventional laser spot welding equipment, and is particularly suitable for precision laser spot welding of small, thin-walled parts.

The Galvo fiber laser welder replaces the traditional two-dimensional table with a high-speed rotating scanning system, and a software program with advanced graphic processing capabilities to instantly complete multi-point welding tasks, significantly improving productivity and enhancing process flexibility. Compared to traditional automatic welding machines that rely on motor-driven workpiece movement, welding speeds are at least five times faster, with a maximum scanning speed of 7 meters per second, capable of completing 10 weld joints per second.

When using conventional automatic platform laser welding machines, it is common to encounter positional deviations and accuracy problems caused by material movement and changes in weld seam size. In this regard, when dealing with kitchen appliance parts with complex shapes, special standard fixtures are usually equipped to assist welding to ensure the stability and accuracy of the welding process.

Features of Galvo Fiber Laser Welding Machine

Efficient and precise welding: Utilizes a scanning system based on current meter control for fast and precise laser beam positioning, ensuring stable welding quality. The user-friendly interface makes the equipment easy to use and maintain, simplifying the entire welding process.

Fast processing speed: Due to the laser beam’s rapid and accurate movement, high-speed galvanometer laser welding operations can be achieved.

Welding of challenging materials: Computer-controlled galvanometer welding enables the welding of workpieces that are difficult to weld manually.

Fine control and resolution: Enables precise control of the laser beam, achieving high-resolution welding and minimizing the heat-affected zone.

Automation processing: Supports automated and programmable laser welding galvanometer processes, improving efficiency and repeatability.

Real-time monitoring: Ensures quality control during galvanometer laser welding processes through real-time monitoring systems.

Intelligent control and compatibility: Equipped with a dedicated intelligent control unit with powerful features and a user-friendly interface, supporting various graphic file formats for flexible programming and adaptation to different welding graphic requirements.

High production efficiency: Galvanometer laser welding machines significantly increase production efficiency compared to traditional laser spot welding equipment, with welding speeds increased by 4 to 10 times, greatly reducing production cycles.

Automation integration capability: Seamlessly integrates with various supporting production equipment to achieve online automated production processes, facilitating the establishment of intelligent manufacturing environments and enhancing overall line efficiency and consistency.

Application:

Galvanometer laser welding machines are widely used in industries such as mobile phones, computers, microelectronic components, precision parts, and components of smart terminal products. They are mainly utilized for laser welding between carbon steel, ordinary alloy steel, stainless steel, and different steel materials.

In the field of new energy, galvanometer laser welding systems for batteries are suitable for precision welding of batteries. This includes, but is not limited to, copper-aluminum connecting sheets, tabs, pole pieces, safety caps, and explosion-proof valve sheets, busbar connecting sheets, shell sealing, and PACK laser welding. Addressing the specific welding needs of different customers, these advanced galvanometer laser welding equipment can be designed into standard gantry structures according to specific production line requirements, offering solutions ranging from semi-automation to full automation. This ensures efficient and smooth production processes, as well as stable and reliable welding quality.

Custom Galvanometer Scanning Laser Welding Machine

Dapeng Laser, a professional manufacturer of laser equipment, offers design, production, and sales of automatic galvo fiber laser welders. These platform galvanometer welding machines are widely used in precision welding applications, such as in electronics, medical devices, jewelry, battery components, automotive parts, kitchenware, and bathroom industries, thanks to their high precision and speed.

Please share your production requirements with us, and we will tailor a laser solution for you:

Power selection: Depending on the thickness, shape, and welding speed requirements of the materials, we can customize laser generators of different power levels, such as 500W, 1000W, or 1500W.

Galvanometer system configuration: We adjust or design dedicated galvanometer scanning systems to meet specific welding trajectories and pattern requirements, thereby enhancing welding quality and production efficiency.

Control system integration: We integrate specialized control systems according to the automation production line requirements of customers, ensuring seamless integration with other production equipment and supporting functions such as multi-axis linkage and collaborative work with robotic arms.

Fixture design: Customized dedicated fixtures are designed for different workpiece shapes and sizes to ensure precise positioning and repeatability during the welding process.

Special application modules: For special materials or welding processes (such as non-contact remote welding, welding of transparent materials, etc.), special laser processing heads or additional functional modules may need to be developed and customized.

After-sales service: In addition to hardware equipment, Dapeng Laser also offers a comprehensive customized service package including installation and commissioning, operation training, and after-sales maintenance, ensuring that customers can smoothly use galvo fiber laser welder to drive economically beneficial production.

Conclusion:

The galvanometer not only controls the direction and position of the laser beam but also help high-speed, precise welding operations. Choosing the right galvo fiber laser welder is crucial for improving welding efficiency and quality. We hope this article provides you with a comprehensive understanding of galvanometer fiber laser welding machine and offers more reference and guidance for your project selection.