What is Laser Marking on the Fly?

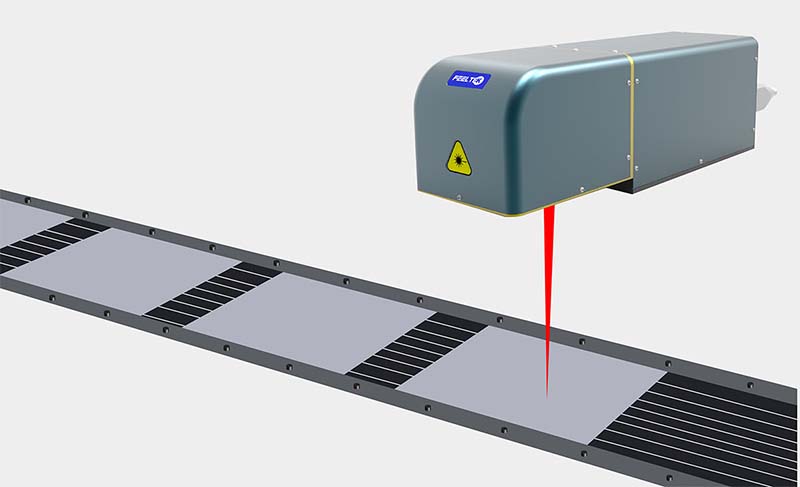

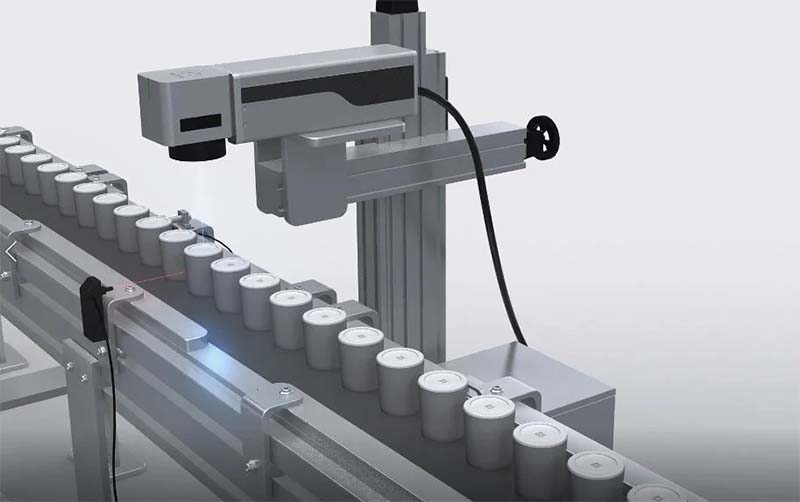

Flying laser marking technology combined with a conveyor belt enables automatic positioning and continuous marking of products without human intervention, resulting in significant productivity gains.

Designed for mass production environments, the flying laser marking machine is suitable for all types of assembly line items such as parts, tools, crafts, pens, knives, labels, wires and tags. The system utilizes assembly line operations and industrial automation technology, blending high speed and integration, eliminating the need for additional labor costs and effectively shortening production cycle times.

The flying laser engraving system has powerful text and graphic marking capabilities that automatically generate lot and serial numbers, providing traceable identification of products. Especially in scenarios that require high-speed, dynamic marking, such as on continuous production lines, the flying laser marking system enables efficient and seamless marking operations, further enhancing work efficiency and product quality.

How Does Laser Marking On The Fly (MOTF) Work?

Workpiece Arrangement and Loading:

Firstly, the objects to be marked are placed in an orderly manner on the conveyor belt, which may also replace with an automated feeding system to further reduce manual intervention.

System Initialization and Calibration:

Prior to startup, the marking control system completes a series of initialization settings, including adjustments to laser parameters and calibration of the vision system, ensuring marking accuracy and quality.

Automatic Conveyance:

As the conveyor belt starts, the workpieces are conveyed one by one to the predetermined marking positions. During this process, the speed and positioning accuracy of the conveyor belt are crucial to ensure that each product arrives at the marking area within the appropriate time window.

Marking on the Fly:

When the workpiece reaches the designated position, the fiber laser marking machine quickly activates and, based on precise coordinates provided by the vision system, performs rapid and accurate marking on the workpiece. Thanks to the high speed and energy efficiency of the fiber laser, the marking process is completed swiftly as if “flying”.

Automatic Ejection and Next Process:

Upon completion of marking, the conveyor belt continues to convey the workpieces to the next station, which may involve inspection, packaging, or other subsequent processes. The entire process is seamlessly connected, greatly enhancing production efficiency.

Components of Online Flying Laser Marking Machine

Control system:

As the command center of the equipment, it manages the delivery of marking tasks, the precise control of laser and scanning head, and implements system monitoring and fault diagnosis to ensure stable operation through the collaboration of computer, laser control card and motion control card.

Laser Generator:

The laser generator converts the high energy laser into a laser beam that can be used for marking. Commonly used lasers include CO2 lasers, fiber lasers and semiconductor lasers. As different lasers have different characteristics and application materials, users can choose different types of lasers according to their needs.

Galvanometer Scanning Head:

Controls the precise guidance and movement of the laser beam, utilizing the reflector set to control the beam path and speed, with auto-focus and dynamic flight marking capability to adapt to the fine marking of diverse workpieces.

Conveyor:

Provide power transmission to make the material move quickly along the set track to realize continuous high-speed processing. Equipped with automatic sorting, positioning and alignment functions to ensure high efficiency and low error rate in mass production.

Flexible & Reliable Production Solutions of On-The-Fly Laser Marker

a. Enhancing Production Efficiency

The online flying laser marking system possesses the ability to rapidly track moving targets, adapting to the rapid movement of products on the conveyor belt. Through advanced real-time positioning and tracking technology, the laser beam can accurately follow the trajectory of the product’s movement, achieving precise marking. Regardless of the speed at which products move on the conveyor belt, the flying laser marking system can maintain stable marking quality and high efficiency.

b. Ensuring Product Quality

The flying laser marking system employs high-speed laser scanning technology, capable of completing complex marking tasks in extremely short timeframes. With its fast marking speed, the system meets the demands of high-volume production lines, greatly enhancing production efficiency. The CNC laser marking system is capable of continuously and accurately marking clear characters, numbers, batch numbers, production dates, logos, as well as complex patterns and anti-counterfeiting marks on various materials. Through program control, the system significantly reduces the need for manual operation, thus lowering the error rate caused by human mistakes.

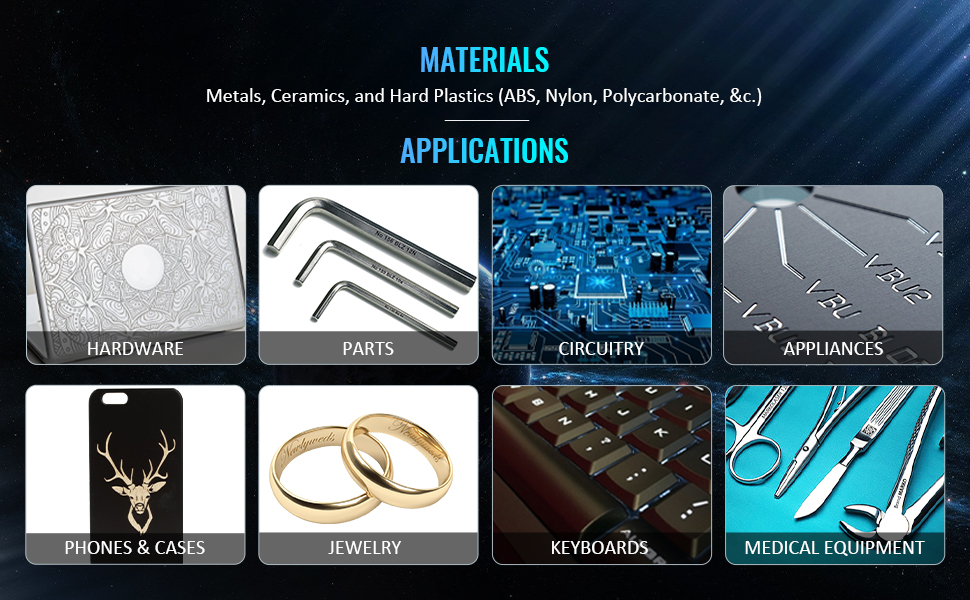

c. Suitable for Various Materials

The laser marking on the fly exhibits wide applicability, capable of handling products made of various materials. Whether it’s metal, plastic, glass, ceramics, or other high-hardness materials, the laser can easily cope with them, achieving precise marking.

Visual Positioning on the Fly Laser Marking Machine

Marking on the flying technology is an advanced laser processing technology, especially suitable for high-speed, high-precision marking needs in industrial production. It realizes precise marking during object movement by mounting the laser marking head on a robotic arm or a high-speed moving conveyor belt. One of the core advantages of this technology is its close integration with vision positioning systems.

Vision positioning system can capture and analyze the position of the object in real time, direction and other information, even if the object is placed irregularly or in the dynamic, can quickly and accurately identify the marking position, so as to guide the laser marking head to make the corresponding path adjustment and focus positioning, to ensure that the marking accuracy is not affected by the object movement.

Marking positioning:

For non-fixed position or randomly placed objects, the vision positioning system can automatically identify and position them without manual presetting, which greatly improves the degree of flexibility and automation. For batch irregular marking, fixture, feeding difficult, poor positioning, slow, CCD camera marking by using an external camera real-time shooting to capture the characteristics of the point of the way to be solved.

Improve precision:

Especially for small or complex shaped objects, the vision system with precise algorithms can achieve micron-level positioning accuracy, ensure the marking position is accurate and improve product quality.

Improve efficiency:

CCD vision laser marking machine can mark multiple products at a time, can also be carried out in the assembly line automatic loading, rough positioning and then visual positioning marking, not only to save labor, but also improve production efficiency, and at the same time has the function of error prevention. Easy to realize the automated production line compatible with multiple products, saving a lot of cost for the factory.

Reduce costs:

Automated process reduces the dependence on labor, not only reduces labor costs, but also reduces can the rate of scrap due to human error, in the long run significantly reduce production costs.

Strong adaptability:

Allows users to quickly adapt to various product design needs, and handle marking patterns, text, serial numbers and visual positioning templates through a simple import and editing process. Easily adjust the content layout to meet diverse marking requirements, significantly enhancing the ability to adapt to products of different sizes and shapes. Whether it is a large number of standardized production, or small quantities of diversified customization, industrial online flying laser marking machine combined with visual positioning can be a flexible response to meet the individual needs of different industries and products.

Industrial Online Flying Laser Marking Machine Applications

Production lines for electronic products require marking of electronic device serial numbers and identification codes, as well as date coding for food, pharmaceuticals, and cosmetics. Additionally, automotive components and various metal and non-metal materials in other industries require marking of parts and components.

Automotive Mechanical Industry: Bearings, steel sleeves, piston rings, engines, vehicle nameplates, and machine tools, etc.;

Electronic Communication Industry: Mobile phones, keyboards, electronic components, home appliance panels, optical cables, cables, etc.

Hardware Equipment Industry: Tools, measuring tools, cutting tools, sanitary ware, tableware, locks, knives, medical instruments, fitness equipment, stainless steel products, etc.;

Buckle and Badge Industry: Buttons, luggage buckles, belt buckles, gold and silver jewelry, signs, badges, attendance cards, business cards, photos, bags, belts, pens and pen holders, collectibles, art pieces, etc.;

Instrument and Eyewear Industry: Metal watch cases, watch backs, eyeglass frames, instrument panels, etc.

Wood Craft Industry: Wooden crafts, replica and mounting of calligraphy and paintings, furniture decoration, etc.

Packaging and Bottle Industry: Tobacco, food, pharmaceuticals, cosmetics, and other internal and external packaging, metal bottle caps, furniture decoration, buckle badges, plastic products, etc.;

Wire Stripping.

Fly Laser Marking Machines Material Adaptability

Mainly depends on the laser source. Common laser sources for laser marking include fiber CO2 and UV.

Fiber: Particularly suit flying laser marking machine for metal, including but not limited to stainless steel, carbon steel, aluminum alloys, copper, gold, silver, titanium, and their alloys. It also works with some plastics (such as ABS) and can mark surfaces with paint or anodized treatment. Ideal for high-speed, high-precision metal marking needs.

CO2: Widely used for non-metal materials, including wood, fabrics, acrylic (PMMA), paper, various plastics (such as PVC, PET, HDPE), leather, glass (etching), stone, ceramics, etc. It is more suitable for non-metal absorption, capable of deep engraving and cutting, making it the preferred choice for processing non-metal materials.

UV: Covers almost all materials and excels in fine processing, including but not limited to plastics (especially transparent or sensitive materials), glass, ceramics, metals (especially thin metal sheets or metals sensitive to thermal effects), silicone, PCB boards, films, jade, etc. Suitable for marking applications requiring extremely high precision and minimal thermal effects, such as electronic components and medical devices in high-end industries.

What Can DPLASER Flying Laser Marker Do?

The flying fiber laser marking machine is designed for large quantities marking tasks in fiber laser marking production lines. Industrial fiber laser marking machines with conveyor belts feature permanent marking capabilities and reliable operation in harsh conditions, meeting the needs of various packaging materials. Particularly suitable for mass production environments, it is one of the excellent etching/marking solutions in the industrial sector. The perfect integration of laser technology and production lines enables efficient marking on fast-moving products. The machine is mainly used for marking Chinese characters, English characters, numbers, batch numbers, production dates, logos, real-time clock information, and anti-counterfeiting marks, especially widely used in fields such as pharmaceuticals, food, packaging, and electronic components.

- Fine engraving: The laser beam quality is excellent, making it ideal for fine engraving.

- Fastest engraving: High pulse repetition rate, stable power output, and less than 1% single pulse energy surge enable high-speed engraving while controlling the depth and shape of the beam spot.

- Fast processing speed: Marking speed is 2-3 times faster than traditional marking machines.

- Compact structure: The machine has a very small footprint, making it easy to carry and suitable for both mobile and fixed operations.

- 10-year lifespan with ultra-low operating costs. Long lifespan, low power consumption, conversion efficiency greater than 30%, and the unit power of the whole machine does not exceed 0.5KW.

- Wide applicability: The laser machine can mark on all metal materials and some non-metal materials.

- Simple operation: Equipped with dedicated engraving software based on Windows, allowing real-time adjustment of laser power and pulse frequency. You can edit in specific engraving software and software such as AutoCAD, CorelDraw, or Photoshop, and input and output through computers.

The flying laser marking machine price varies depending on your specific application, business productivity, and the desired applications you want to achieve from the machine. However, our company offers material prices that are among the most competitive in the market. The price for a flying laser engraving machine starts at US$1500. For professional industrial flying laser marking machines, prices are typically higher due to advanced features such as high-speed dynamic marking capability, vision positioning systems or multiple marking heads and assembly lines for increased production., etc., to meet the strict requirements for speed and precision on continuous production lines.