Laser rust removal technology, as an efficient and environmentally friendly method for metal surface treatment, is increasingly gaining attention. We will delve into the superiority, wide-ranging applications, pricing information, and noteworthy features of best laser rust removal machine. In this article, we aim to provide you with comprehensive insights into laser rust cleaning machine and how they can contribute to the growth of your business.

According to market research reports, the global laser cleaning market was valued at $589 million in 2018, and it is projected to reach $724 million by 2023, with a Compound Annual Growth Rate (CAGR) of 4.22% between 2018 and 2023. The economic and social benefits generated by the application of laser cleaning technology in key industries of the national economy are substantial. Under the current state of laser technology, the practical and industrial adoption of laser rust removal and cleaning technology holds significant importance in driving the development of high-tech industries in a short period of time.

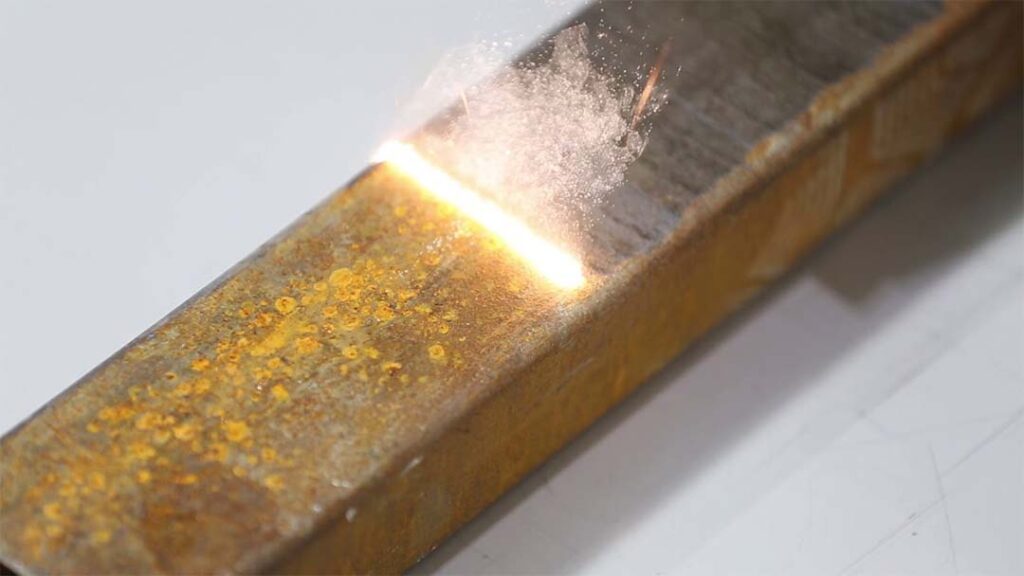

How Does Laser Rust Removal Work?

Handheld laser rust removal machine are primarily used for cleaning various metal materials, including rust layers, paint coatings, oil residues, and more on metal surfaces. By adjusting the focusing system, the laser beam’s energy density can be controlled at the focal point, where appropriate laser energy density causes heating and evaporation of absorbed dirt. This process effectively removes oil, stains, and rust layers from the surface of objects.

How does laser rust removal differ from traditional cleaning? Whether it’s rust removal or paint and oil stain cleaning, laser cleaning offers a significant advantage over traditional methods: it does not harm the underlying material. This makes laser cleaning equipment particularly suitable for cultural heritage conservation and treating precious items.

Laser Cleaning VS. Traditional Methods

| Item | Cleaning method | Damage | Cleaning efficiency | Cleaning effect | Cleaning accuracy | Environmental protection |

| Chemical cleaning | Chemical cleaner | Damaged | Low | General, Uneven | Uncontrollable, poor precision | Heavy Chemical Contamination |

| Mechanical Polishing | Mechanical/Abrasive, Contact | Damaged | Low | General, Uneven | Uncontrollable, poor precision | Polluting The Environment |

| Dry Ice Cleaning | Dry Ice, Non-Contact | No Damage | Middle | Excellent, Uneven | Uncontrollable, poor precision | Non-Polluting |

| Ultrasonic Cleaning | Cleaning Agent, Contact | No Damage | Middle | Excellent, small clean range | Unspecified range cleaning | Non-Polluting |

| Laser Cleaning | Laser, Non-Contact | No Damage | High | Good cleaning effect | Precise and controllable, high precision | Non-Polluting |

Advantages of Handheld Laser Cleaner for Rust Removal

1. Efficient Cleaning:

Handheld laser rust cleaning machine utilize high-energy laser beams for efficient and rapid rust removal. The high-energy laser beam effectively breaks down and removes rust layers. Compared to traditional cleaning methods, laser cleaning saves significant time and labor costs.

2. Non-contact Cleaning:

It is a non-contact cleaning technique, ensuring that the laser beam does not physically touch the object’s surface during the cleaning process. This means that the cleaning process does not cause damage or deformation to the object, making it particularly suitable for applications with stringent surface requirements.

3. Precise Positioning and Cleaning:

Handheld laser rust cleaner offer precise positioning and control capabilities. Operators can use the handheld device to precisely position and control the laser beam, focusing it on the rusted areas that require cleaning. This enables localized cleaning while avoiding unnecessary cleaning of surrounding areas.

4. Environmentally Friendly:

Fiber laser rust removal machine eliminate the need for chemical cleaning agents or solvents, reducing environmental pollution. The laser cleaning process does not generate wastewater, emissions, or waste materials, aligning with environmental protection and sustainable development requirements.

5. Versatility Materials:

Handheld laser rust removal machine are suitable for cleaning various materials, including metals, plastics, and stone. Laser beam parameters can be adjusted based on the characteristics of different materials, ensuring efficient cleaning results.

6. Safety:

Handheld laser rust remover are designed to be safe and reliable, with user-friendly operation. They are typically equipped with safety features such as protective eyewear and safety switches on the handheld device, ensuring the safety of operators and the surrounding environment.

These advantages make handheld laser rust removal machine an ideal choice for rust removal, enhancing cleaning efficiency, reducing costs, and meeting the demands of high-quality cleaning requirements.

How to Operate the Handheld Laser Descale Machine?

1. Turn on the button switch on the laser rust cleaning machine. After the self-check is completed, the machine can be used normally.

2. Before cleaning, adjust the laser cleaning parameters according to the actual situation, such as cleaning power, scanning speed, and focus, to ensure optimal cleaning results.

3. Put on laser safety goggles, use your hand to remove the handheld laser rust cleaning gun from the insertion box, and align the handheld laser rust cleaning machine with the object to be cleaned.

4. To achieve a better cleaning effect, it is recommended to use a back-and-forth scanning method to ensure that every detail is covered.

5. After use, turn off the laser rust cleaning machine, place the laser rust cleaning gun back into the storage box, and unplug the power plug.

You can visit our YouTube handheld laser machine channel and will get a wealth of video tutorials with information to help you better understand and use your handheld laser equipment.

These tutorials will show you how to properly operate your handheld laser cleaning machine, including how to use the device, adjust device parameters, and properly install and replace laser device parts. Our channel also offers video tutorials that address common questions and troubleshooting. You can learn about common problems associated with handheld laser machines and get practical tips and advice on how to solve them.

Whether you are a beginner or an advanced user, we are committed to providing you with valuable content that will give you the best possible experience.

7 Basics Safety of Laser Rust Removing Tool

1. Pay attention to the safety guidelines and maintain a safe distance. Before operation, make sure to wear appropriate protective gear.

2. Ensure that the surface of the object is flat and smooth, and try to eliminate surface damage as much as possible to achieve the best cleaning effect.

3. During cleaning, be aware of the surrounding environment, avoid direct eye contact with the laser beam, and protect the environment from the hazards of exhaust gases and residues.

4. Emergency Stop: The machine should be equipped with an easily accessible emergency stop button that can quickly shut down the laser in case of any unexpected situations.

5. Maintenance and Inspection: Regularly inspect the machine for any signs of wear, damage, or malfunction. Perform routine maintenance and calibration as recommended by the manufacturer.

6. Power and Electrical Safety: Ensure that the machine is properly grounded, and all electrical connections are secure. Avoid exposing the machine to water or moisture.

7. Operational Guidelines: Follow the manufacturer’s guidelines for operating the laser rust removal machine. Adhere to recommended power levels, scanning speeds, and other settings to ensure safe and effective operation.

Application of Handheld Laser Rust Removing Cleaning Machine

Steel Structures:

Laser rust cleaner can easily eliminate rust and oil stains on the surface of steel, significantly extending the lifespan of steel structures. It also activates the surface, enhancing the adhesion capability for subsequent coatings.

Automotive and Marine Bodies:

Laser rust removal machine effectively removes oil residue from areas such as the engine compartment, wheel hubs, and chassis. It also targets debris and dust in hard-to-reach corners, achieving a thorough automotive cleaning. Laser descale machine tackles issues that traditional methods may struggle with.

Electronic Components:

The technology can remove oxidation layers from the surfaces of electronic components, enhancing their conductivity and energy efficiency, thereby extending their lifespan.

Aluminum Products:

Laser rust removal swiftly eliminates oxidation, rust spots, and burrs from the surface of aluminum products, resulting in improved polishing effects and enhanced surface quality.

Pre-welding with Laser Cleaning

Utilizing a laser descaling apparatus has the potential to enhance the caliber of welded components. Following the laser rust removal process, the presence of pores in the welded joints substantially reduces. Consequently, the welded joints exhibit elevated levels of yield strength, tensile strength, ductility, and resistance to fatigue.

Pre-coating with Laser cleaning

If you are welding the components until you paint them, the oxides must be cleaned to protect the coating from weakening over time.

Even irregular-shaped metal components can undergo rust removal with a laser rust remover. Anywhere the laser can reach, it can remove surface rust, oil stains, paint layers, or oxidation. Therefore, in areas where tight spaces or difficult-to-reach tools pose challenges, hand held laser cleaning offers unparalleled advantages. As laser technology is most effective for cleaning small, cleaning larger surface areas may take more time and might not yield optimal results.

How much is Laser Rust Removal Machine?

The prices of laser rust removal machines vary from thousands to tens of thousands dollar. The price of a rust remover is related to its power, with higher laser power resulting in a higher price. However, when purchasing a laser rust removing machine, it’s important to consider your specific needs rather than just opting for higher power. For example, simple removal of thin rust can be achieved with lower power.

Generally, a 1000W portable laser rust remover starts at $3000. The price range for a 1500W handheld laser rust remover starts at $3500. The minimum cost for a 2000W high-power laser rust remover is $4800. A 3000W laser rust removal gun is priced from $7500. Of course, the price of robot-operated laser rust removers will be higher. Of course, the specific price also depends on the brand and parameter selection of the core components.

Manual portable CW fiber laser cleaning machine, with power options of 1000W, 1500W, 2000W (continuous wave mainly for rust removal, able to remove thin oxide layers), and 3000W (able to remove oxide layers), can be used to remove rust from surfaces of materials such as iron, steel, bronze, copper, brass, aluminum, and more.

Difference Between CW Laser Rust Cleaner And Pulsed Laser Rust Cleaning Machine?

CW Fiber Laser Cleaner:

1. Continuous Wave (CW) laser cleaning machines use lasers that emit a constant beam of light without interruption.

2. The laser beam is focused on the surface to be cleaned, vaporizing and removing contaminants through ablation.

3. It is effective for removing thin layers of surface contaminants like dust, dirt, rust, or paint.

4. CW laser cleaning is a gentle process that generates minimal heat, reducing the risk of damaging the substrate.

5. It is suitable for cleaning delicate materials, such as electronics, artwork, or historical artifacts.

6. CW laser cleaners are more commonly used for precision cleaning applications.

Pulsed Laser Cleaning Machine:

1. Pulsed laser cleaning machines utilize lasers that emit short-duration, high-energy pulses of light.

2. The laser pulse is absorbed by the contaminant, causing it to rapidly heat and expand, resulting in explosive removal or decomposition.

3. Pulsed laser cleaning is effective for removing tough or thick layers of contaminants like heavy rust, coatings, or oxides.

4. The rapid energy release during pulsed cleaning can generate higher temperatures, which may require cooling systems to prevent damage to the substrate.

5. It is often used for industrial cleaning applications, such as metal surface preparation, rust removal, or weld cleaning.

6. Pulsed laser cleaning machines offer higher cleaning speeds and efficiency for more demanding tasks.

The choice between a CW laser rust cleaner and a pulsed laser rust cleaning machine depends on the specific application, the level of rust or contamination, the material being cleaned, and the desired results. CW lasers are often favored for more controlled and precise cleaning tasks, while pulsed lasers are chosen for more aggressive and rapid rust removal.

Where to Buy Laser Rust Removal Machine?

You can buy a fiber laser rust removal machine from various sources, including specialized industrial equipment suppliers, online marketplaces, and directly from manufacturers. One reputable option is DPLASER, a leading manufacturer of laser equipment, including laser rust removal system.

DPLASER offers a range of high-quality and innovative laser rust removal machines designed to meet different cleaning needs. Their machines are known for their efficiency, reliability, and advanced technology.

The Best Fiber Laser Rust Remover

- Using a handheld laser rust removal gun design allows for flexible adaptation to various objects and angles.

- Lightweight Design: The handheld and portable design is well-suited for prolonged manual operation and is easy to use in any scenario.

- Dustproof and Sealed Design: The optical path features an independent modular design with sealing to prevent dust.

- Standard Fiber Optic Length is 10m, with longer options available for selection.

- A robust and stable water cooling system ensures optimal performance of the fiber laser generator.

- With low power consumption, maintenance-free operation, and easy assembly, this laser source is highly suitable for industrial laser cleaning applications.

Why Choose DPLASER Handheld Portable Laser Rust Removal Machine

DPLASER is a leading Chinese manufacturer of laser equipment, encompassing research and development, sales, production, and service. We offer customizable component and parameter configuration, auxiliary tools, etc. 500W, 1000W, 1500W, 2000W, and 3000W laser rust removal machines to cater to diverse manufacturing needs.

Our professional technical team can customize laser rust removal solutions based on your specific requirements.

With 12 years of experience in the laser industry, we provide reliable machine quality and efficient service.

Own production facility enables us to offer competitive prices for laser rust removal machines.

Our products are exported to more than 80 countries across Asia, North and South America, Europe, and various industries.

Finally: The laser rust removing tool is bound to bring forth increased opportunities and possibilities across various industries, empowering the continuous growth of your endeavors. If you aspire to gain further insights into laser rust removal technology and where to buy laser rust removal machine, we invite you to follow DPLASER YouTube channel or stay updated with our latest product information. Through these platforms, we will present a wealth of in-depth laser equipment applications, thereby enhancing your production and manufacturing capabilities.