Laser cleaning technology is rapidly becoming a popular method in industrial production. Its efficiency, environmental friendliness, and non-contact nature are quickly replacing traditional methods like chemical and mechanical cleaning. This article provides an in-depth analysis of the effectiveness of laser cleaning machine for metals, plastics, glass and stone, effectively removing surface contaminants without damaging the material.

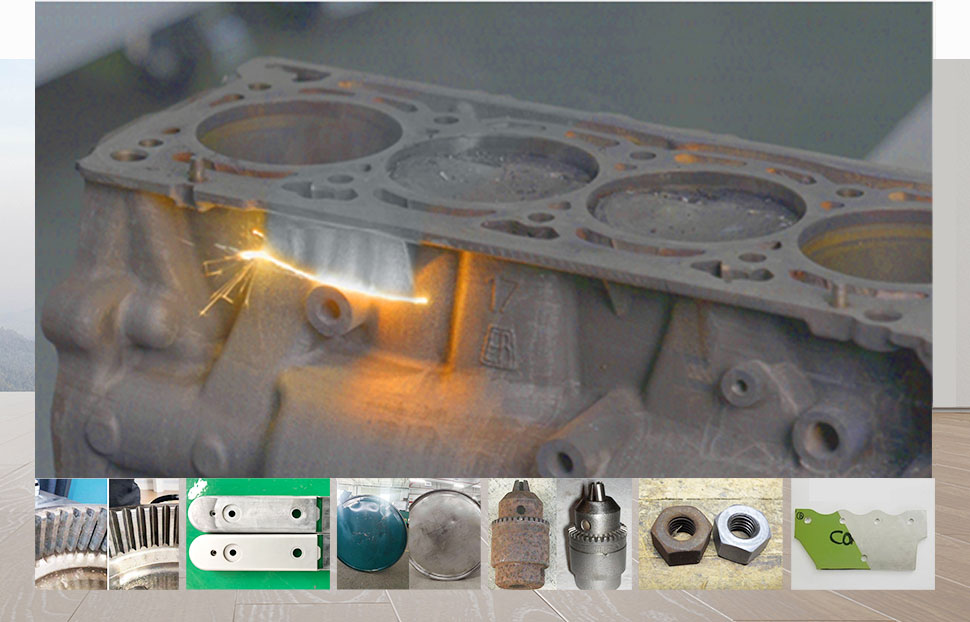

Laser cleaning uses a high-energy density laser beam to irradiate the surface of a workpiece, causing surface contaminants, oxide layers, coatings, or films to instantly melt, ablate, evaporate, or peel off. This process cleans the workpiece surface without damaging the base material.

Laser cleaning is suitable for cleaning metal substrates and other materials in industrial production. It is especially effective for irregular and uneven surfaces, making it an ideal solution where traditional cleaning methods fall short.

Advantages of Laser Cleaning

- Removes oxides and other impurities, enhancing metal corrosion resistance

- Optimizes surface conditions before welding

- Intelligent, controllable, and precise laser beam ensures a stable substrate fusion line interface

- No need for media or chemical reagents; operation is dry and clean

- Can be used immediately before welding

- Expands the capability for surface texturing

What Types of Materials Can Laser Cleaning Machines Clean?

Laser cleaning technology has become an indispensable cleaning method in high-end manufacturing fields such as industry, shipbuilding, and aerospace. It is widely used to remove rubber contaminants from tire molds, silicone oil contaminants from metal films, and for high-precision cleaning in the microelectronics industry.

While laser cleaning is less common in traditional manufacturing, its application is rapidly increasing in high-end fields such as lithium batteries, aircraft blades, precision instruments, rail tracks, and ships. In industrial applications, laser cleaning effectively removes contaminant layers from various substrates, including metals, semiconductor wafers, ceramics, magnetic materials, plastics, and optical components.

Laser Cleaning Machine for What Material?

Laser Cleaning Machine for Metals

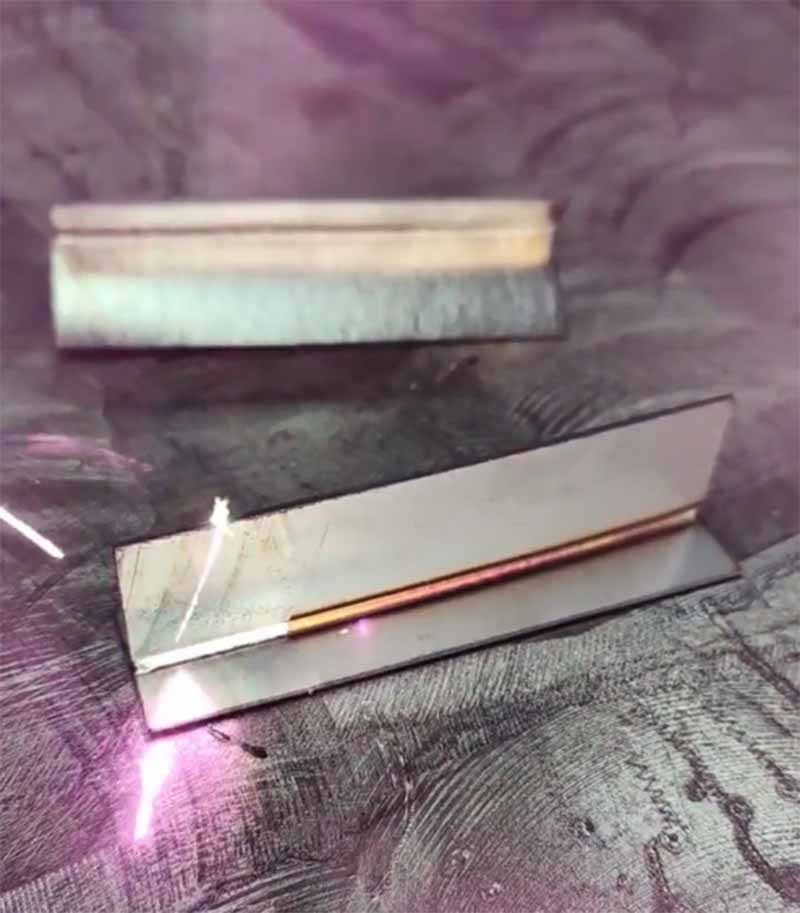

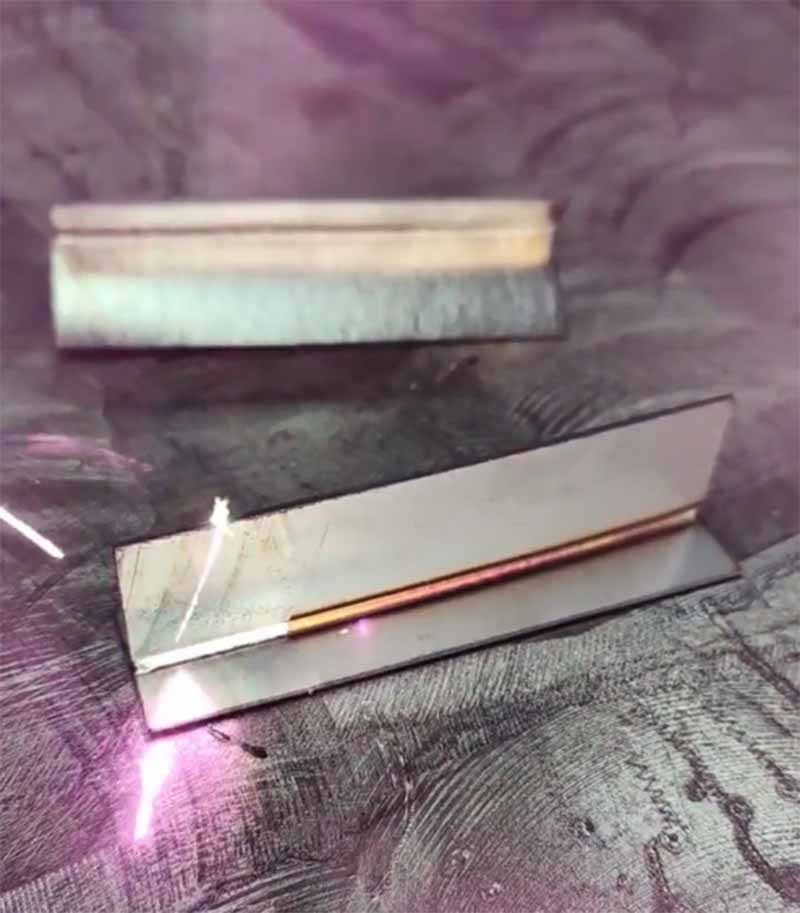

Common contaminants on metal surfaces include greasy organic substances, surface oxide films, and scale. Oxide films (commonly known as rust) can affect the performance of steel and should be removed promptly. Laser cleaning technology is a recommended solution, proving highly practical for cleaning oxides before welding or cleaning surfaces before painting.

Steel and Stainless Steel

Laser cleaning technology excels in the metal industry, particularly for removing rust, oxide scales, welding residues, and coatings from steel and stainless steel surfaces, efficiently restoring the metal’s original bright appearance.

Aluminum

Since aluminum easily forms surface oxide layers, laser technology can effortlessly remove these oxides, maintaining the material’s cleanliness.

Copper and Brass

For copper and brass, laser cleaning effectively removes oxide layers and accumulated dirt, enhancing appearance and ensuring good electrical conductivity.

Cast Iron

For the common roughness and oxidation issues on cast iron surfaces, laser treatment precisely removes oxides and impurities, significantly improving the overall quality of cast iron components.

Alloy Products

Laser cleaning can safely and effectively remove oxides, excess coatings, and contaminants from various metal alloys, including titanium, nickel, and chromium alloys, ensuring the material’s performance and appearance remain intact.

Non-Ferrous Metals

Different non-ferrous metals have varying cleaning characteristics. For example, copper, copper alloys, and silver generally have weak acid resistance. Aluminum, with its protective oxide film, has better acid resistance, but other metals are prone to corrosion during acid cleaning. Additionally, waste liquid from acid cleaning is difficult to manage. Therefore, laser cleaning is also the recommended method for cleaning non-ferrous metals.

Laser Cleaning Machine for Non-Metals

Plastics and Composites

While laser energy might risk damaging some plastics, it is suitable for cleaning specific types such as ABS, PVC, and PET. This method is commonly used in industrial applications for cleaning molds, plastic components, composite surfaces, and for the fine cleaning of 3D printed objects.

Glass and Ceramics

Glass is widely used for its transparency and aesthetic appeal but can lose these qualities over time due to dirt and contamination. Sandblasting or mechanical cleaning can degrade quality, making laser surface cleaning the best solution for restoring glass. Ceramics can also benefit from laser cleaning without surface damage.

Stone Maintenance

Over time, stone surfaces can accumulate dirt and graffiti. Laser cleaning is an ideal solution, being a non-contact process that effectively cleans stone without damage. It can reach into small cracks and detailed designs, ensuring thorough cleaning.

Wood Refinishing

In the restoration or maintenance of wooden furniture, lasers can precisely remove stains, old paint layers, and coatings from wood surfaces, achieving detailed refinishing effects.

Carbon Fiber Composites

Carbon fiber and its composites have high strength-to-weight ratios, high modulus, heat resistance, and corrosion resistance. In the air, carbon fiber oxidizes above 350℃, and in an inert atmosphere, it does not melt at high temperatures but sublimates above 3500℃. To clean contaminants from carbon fiber surfaces without damaging the material, laser cleaning is the most suitable method. It is convenient and quick, and with proper parameter adjustments, it causes no harm to the composites.

What Can You Clean With Laser

Cleaning materials mainly include rust, metal particles, paint, dirt, oil, oxidized layers of metal, as well as resins, gums and dust.

Surface Cleaning

Surface cleaning aims to remove rust and dirt from material surfaces. Laser cleaning machines are widely used for tasks such as paint stripping, degreasing, and material restoration. In heavy metal manufacturing industries, laser rust removal machines are extensively used to eliminate rust and oxide layers from metal surfaces. Most heavy metals and manufacturing industries frequently require rust removal or oxide removal, making laser rust removal technology an ideal choice for these applications.

Rubber Mold Cleaning

Cleaning rubber molds is often one of the most challenging tasks due to the soft and dirt-absorbent nature of rubber. With a laser cleaning machine, it’s possible to thoroughly clean every corner of the mold and remove any impurities without damaging the rubber itself. Laser cleaning technology provides the best solution for cleaning rubber molds, preserving their chemical properties and ensuring long-lasting cleanliness.

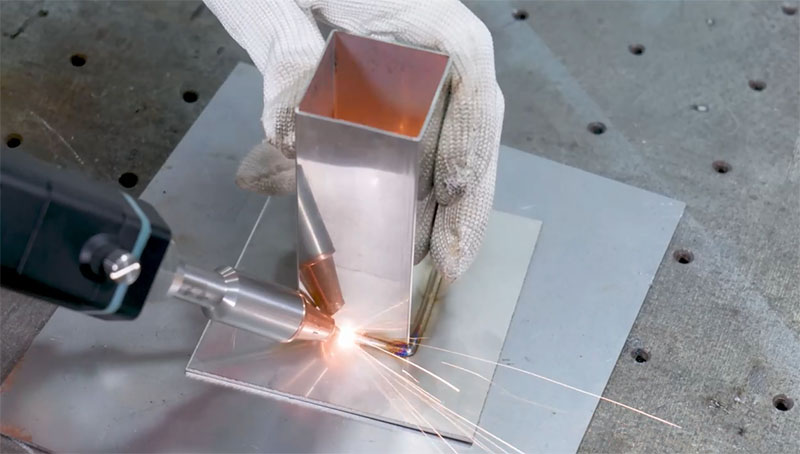

Weld Seam Cleaning

Welding often leaves deposits on material surfaces that need to be removed to ensure the quality of the final product. Laser cleaning technology is effective for treating weld seams on almost all types of metal alloys, particularly aluminum alloys, stainless steel, and other hard metal alloys. Laser cleaning allows you to easily remove weld residues and prepare surfaces to the highest standards.

What Materials Are Not Suitable for Laser Cleaning?

Transparent materials: e.g. glass, acrylic, etc. These materials have low absorption of laser light and cannot absorb laser energy effectively, so the cleaning effect is not good.

Reflective materials: e.g. mirrors, metals, etc. As the laser energy is reflected, the cleaning effect is not ideal. Such materials are more suitable for other cleaning methods.

Heat-sensitive materials: e.g. plastics, waxes, etc. Laser cleaning generates high temperatures, which may cause deformation, melting or damage to these materials, and it is recommended to use a lower temperature cleaning method.

Coated materials: e.g. with paint, coated film, etc. Laser cleaning may damage or strip the coating. It is more appropriate to choose other cleaning methods suitable for the coating to avoid irreversible damage to the material.

Types of Laser Cleaning System

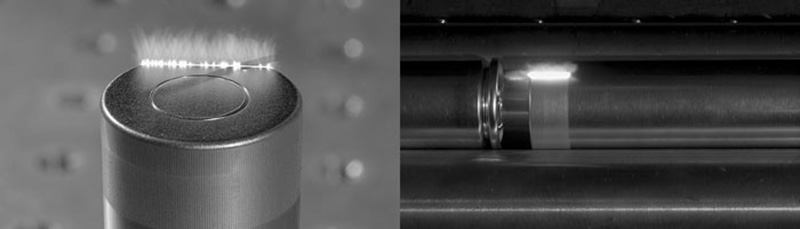

Handheld Fiber Laser Cleaning Machine

The handheld fiber laser cleaning machine is renowned for its portability and flexibility, designed with a focus on convenient handheld operation. It typically features a compact laser head that allows prolonged handheld use, integrated with buttons on the handle for easy operation. Equipped with a responsive scanning system and a robust, dust-resistant structure, it ensures stable durability. The handheld design enables precise cleaning of targeted areas, particularly suitable for complex shapes and hard-to-reach spots. It may also include a red light assist for precise focusing during cleaning.

Platform Laser Cleaning Machine

Platform-based laser cleaning machines are usually mounted on a fixed platform, ideal for automating cleaning tasks on large or batched workpieces. These machines utilize precise control systems for accurate positioning of workpieces and extensive, continuous cleaning operations. Workpieces on the platform can be loaded automatically or manually, ensuring systematic and standardized cleaning processes suitable for production line environments. Platform machines typically feature higher power and sophisticated optical systems to meet the demands of industrial-scale cleaning.

Robot Fiber Laser Cleaning Machine

Combining advanced robot technology with laser cleaning, this type of cleaning machine employs a laser head mounted on a robotic arm to execute cleaning tasks, significantly enhancing cleaning flexibility and automation. Robots can perform three-dimensional cleaning on various shapes and sizes of workpieces based on preset programs or complex path planning. This system offers highly customized cleaning solutions, reduces manual intervention, and improves production efficiency and safety. It is commonly found in high-end manufacturing sectors such as automotive and aerospace industries.

The application of lasers for polishing, surface cleaning, and coating removal is rapidly expanding. Depending on the application, precise selection of laser pulse frequency, energy, and wavelength is crucial to effectively clean, polish, or ablate target materials while preventing any damage to the substrate. Currently, laser cleaning technology is primarily used for cleaning small parts but can also be applied to clean large surfaces and equipment, although efficiency may vary.

Summary

What can laser cleaning remove? Laser cleaning is not limited to the removal of surface contaminants; it can also handle complex cleaning challenges such as paint removal, oxide cleaning, and coating removal. Whether in manufacturing, aerospace, or cultural heritage preservation, laser cleaning demonstrates its unique advantages and promising applications. With continuous technological advancements and growing market demand, laser cleaning technology will continue to be a significant tool in the fields of cleaning. Choosing the right laser cleaning machine not only improves work efficiency but also get better cleaning results than expected.