Are you a small business owner seeking to add a touch of personalization and precision to your products? With its ability to etch intricate designs and logos on various materials, a CO2 laser cutter can revolutionize your business and set you apart from the competition. How do you choose the best one for your small business? In this article, we will guide you the best laser cutter for beginners.

When looking for the best laser cutter for your small studio or home business, there are a few things you need to consider.

Part 1: Types of Laser Cutters

CO2 laser cutting machine is a CNC machine that uses laser technology to cut and engrave materials. Since CO2 laser cutting machines can also use for engraving, they are also known as CO2 laser engraving machines.

What Are the Advantages & Disadvantages of Laser Cutting?

Advantages of CO2 laser cutting machine:

1. Fast cutting speed

2. High cutting efficiency

3. Small heat-affected zone

4. Narrow cutting kerf

5. Suitable for cutting non-metallic materials

6. Unaffected by the shape of the workpiece

7. Material and labor saving

Disadvantages of CO2 laser cutting machines:

1. Low photoelectric conversion rate

2. High energy consumption

3. Various consumables that need frequent maintenance.

CO2 vs. Fiber Laser

Fiber laser cutting machine are also among the most commonly used metal laser cutting machine. Unlike CO2 lasers with gas laser tubes and optical transmission, fiber laser cutting machines use a fiber laser generator and cable to transmit the laser beam. The wavelength of the fiber laser beam is only 1/10th of the wavelength produced by CO2 lasers. Compared to CO2 laser cutting machines, fiber laser cutting machines offer better consistency and reliability, allowing for the production of finer patterns.

1. Laser Source

CO2 laser engraving machines use CO2 gas laser tubes to generate the laser beam. The primary gas used is CO2, with auxiliary gases such as O2, He, Xe. The CO2 laser beam is reflected and focused by mirrors and lenses onto the laser cutting head. Fiber laser cutting machines generate the laser beam through multiple diode pumps. The laser beam is then transmitted to the laser cutting head through flexible fiber optic cables.

2. Material Processing

The wavelength of a CO2 laser beam is 10.64 µm, which is more easily absorbed by non-metallic materials. However, the wavelength of a fiber laser beam is 1.064 µm, which is 10 times shorter. Due to this shorter focal length, fiber laser cutting machines have an intensity nearly 100 times higher than CO2 laser cutting machines with the same power output. Therefore, fiber laser cutting machines are highly suitable for cutting metal materials.

3. Cutting Quality

CO2 lasers provide excellent cutting quality and can achieve intricate details on non-metallic materials. Fiber lasers provide excellent cutting quality on metals, offering smooth edges and high precision.

4. Initial Cost

CO2 laser machines are generally less expensive compared to fiber lasers. Fiber laser machines are typically more expensive than CO2 lasers due to their advanced technology and capabilities.

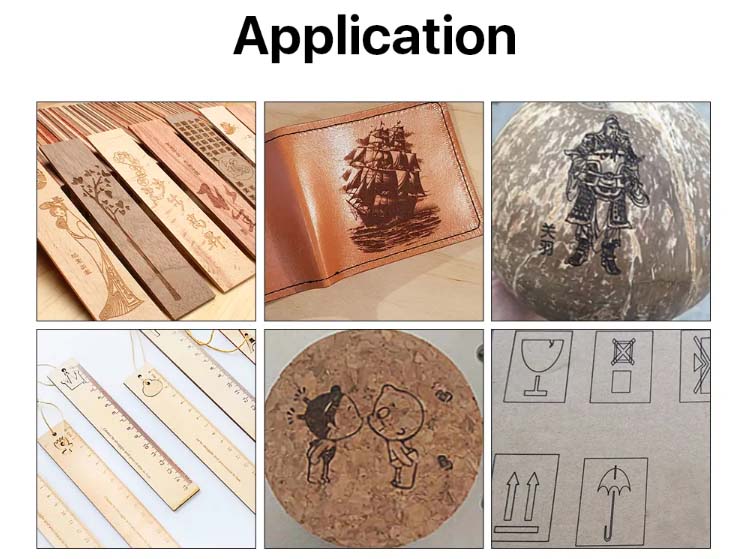

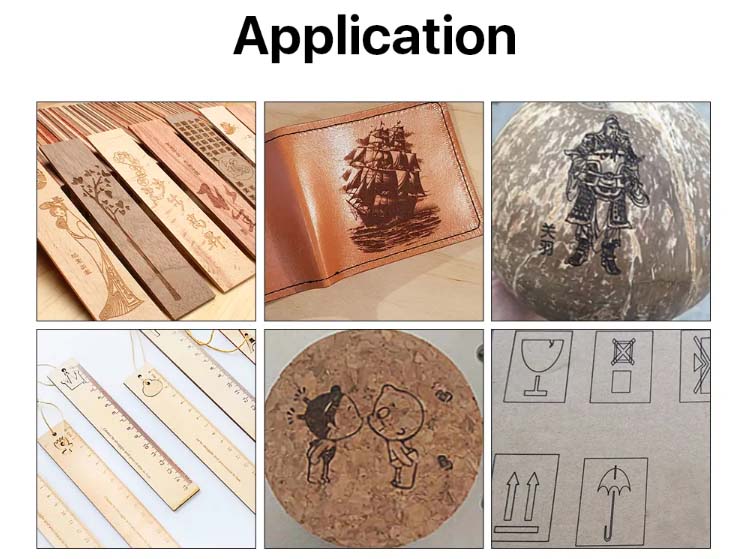

Part 2: What Materials are Suitable for CO₂ Laser Cutting

Although CO2 laser cutting machines can process low carbon steel, aluminum, titanium, and other alloys, they have lower cutting efficiency in comparison. However, they excel in cutting and engraving non-metallic materials. CO2 laser engraving machines can cut and engrave various non-metal materials such as wood, acrylic, paper, fabric, epoxy resin, plastic, rubber, crystal, etc. CO2 laser cutting machines find wide applications in industries such as apparel, leather, fabric toys, embroidery cutting, electronics, models, crafts, advertising, as well as in industries like decoration, packaging printing, and paper products.

A 40W CO2 wood laser cutting machine can mark on steel, while a 90W CO2 laser engraving machine can engrave on the surface of steel. With oxygen as an assist gas, 150W CO2 CNC laser cutting machine can cut 1mm thick steel sheets.

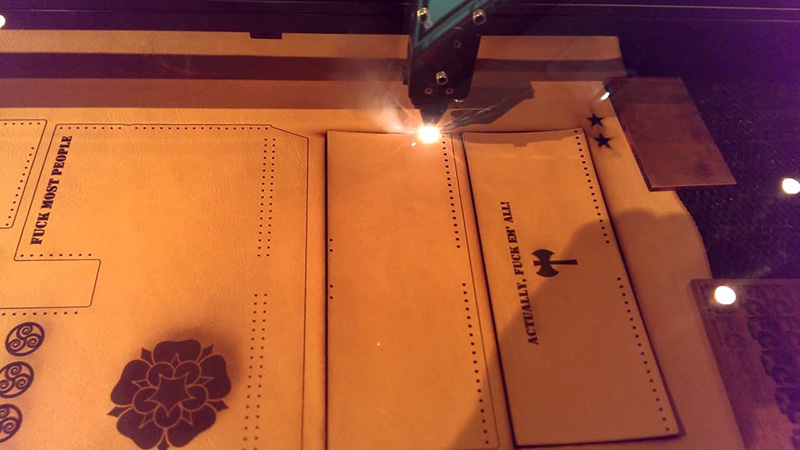

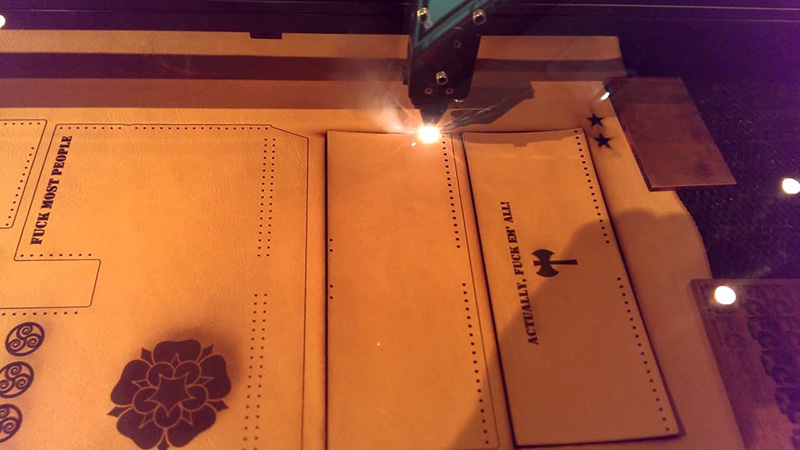

Laser Cutting and Engraving Leather

You can laser cut leather very easily with a CO2 laser machine. Using laser cutting on leather adds intricate patterns and a sense of design to the products. Laser cutting provides high precision, clean-cut edges, and imparts a delicate texture to the overall product. Traditional cutting machines often result in flaws along the edges when cutting panels, with slower speeds, less smoothness, and lower accuracy.

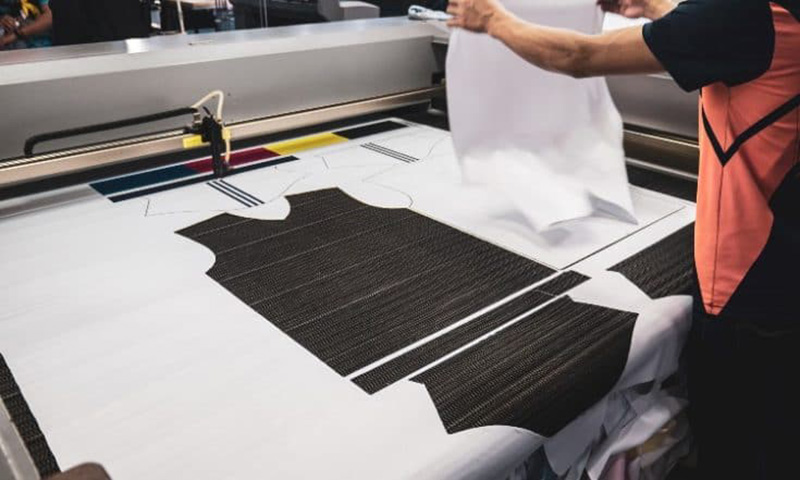

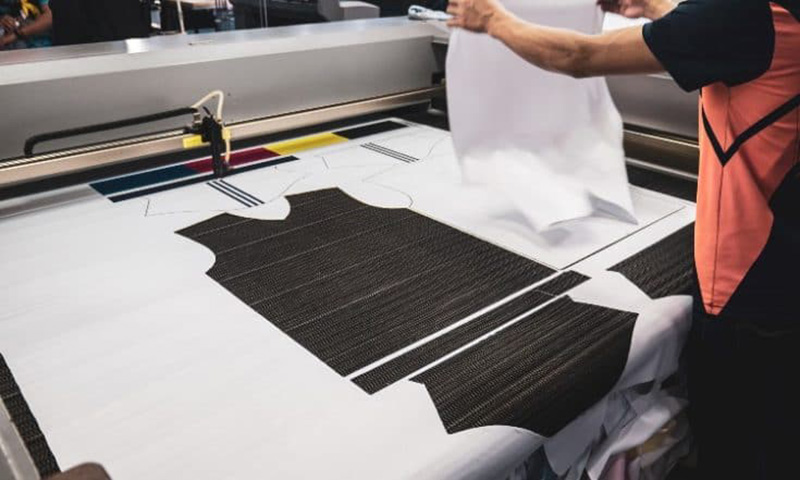

CO2 Machines for Laser Cutting Textiles

Fabric Panels and Pieces: CO2 lasers can efficiently cut fabric panels and pieces of various shapes and sizes with clean and sealed edges. This is beneficial for manufacturing clothing, upholstery, and other fabric-based products.

Textile Marking: CO2 lasers can perform marking and engraving on fabric, allowing for the addition of logos, branding, labels, and other information directly onto the fabric surface. This provides a permanent and professional marking solution.

CO2 laser cutting also allows for much greater flexibility in design and pattern-making. Unlike traditional cutting methods which require manual labor and specialized tools, CO2 laser cutting can easily execute complex designs, curves and even intricate details

Laser Wood Cutting Machine

CO2 Laser wood cutting machine are commonly used in industries such as woodworking, furniture manufacturing, and crafts to create intricate wooden designs. The machines are suitable for both thick and thin wood materials and can cut through solid wood, MDF, plywood, and more.

Another benefit of laser wood cutting machines is the ability to engrave designs onto the wood surface. This can include logos, text, and other custom designs that add value to the finished wood product.

CO2 laser cutting offers versatile and precise cutting capabilities for wood, enabling creativity and intricate designs in various woodworking applications.

Laser Cut Paper Art

Laser cutting allows for more intricate patterns on paper, moving away from the traditional shapes. Whether it’s cutting delicate outlines or creating three-dimensional greeting cards, the desired effects can be achieved with a laser cutting machine. Even in complex and fine paper art pieces, the current laser cutting machines can quickly deliver the desired results.

DIY laser cut paper art can be used to create a wide range of objects, from greeting cards to decorative pieces, and more. Artists and designers can experiment with different paper types, textures, and finishes to add depth and dimension to their laser cut paper art projects.

Overall, laser cutting paper artwork is an incredible way to create detailed and delicate works of art. It’s a versatile technique with limitless possibilities and can be enjoyed by people of all skill levels looking to create unique, intricate designs from paper.

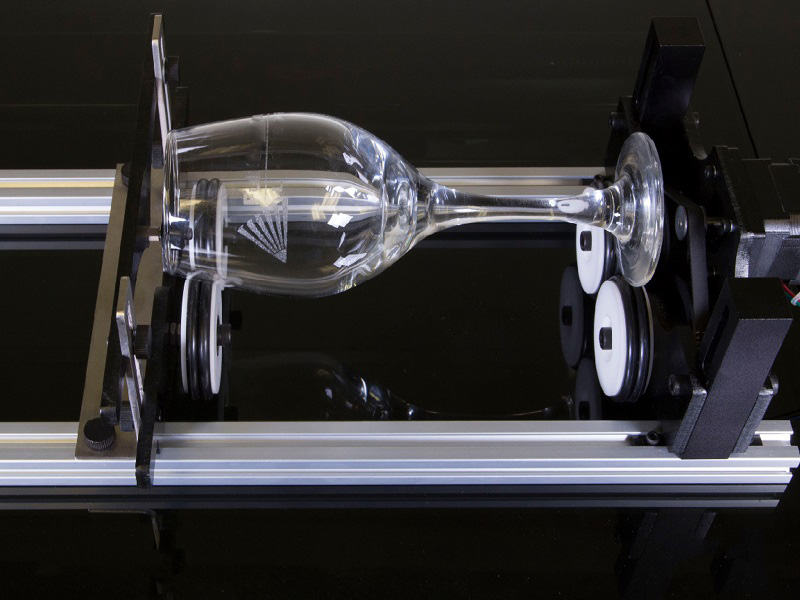

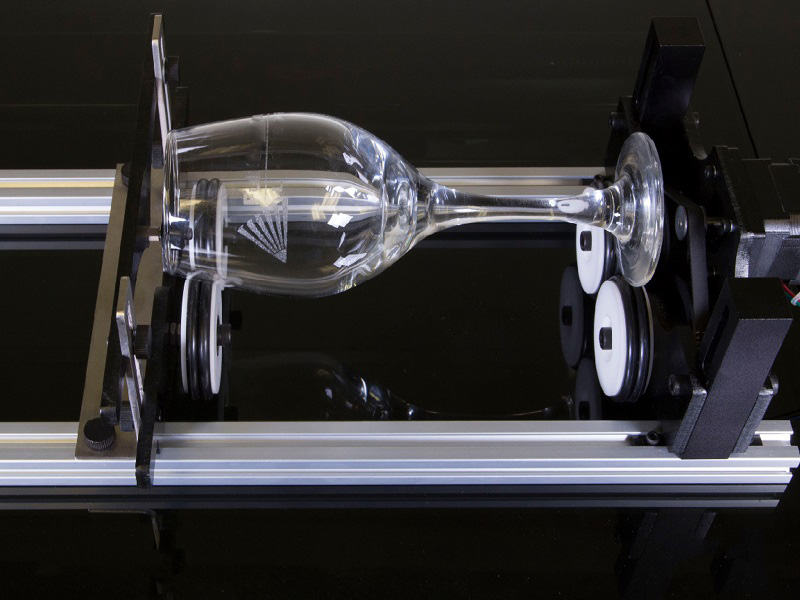

Laser Engraving Machine for Glass

With the utilization of a CO2 laser engraver, glass engraving and etching can achieve a captivating frosted effect, enabling the creation of personalized logos and designs on almost any glass item. The laser’s precision ensures meticulous detailing and control during the etching process. Laser engraving machine can be used for various applications in creating custom glass accessories, decorations, presents, awards, and plaques.

1. Custom Glass Accessories

– Personalized glassware: Etch names, initials, logos, or custom designs onto glassware such as wine glasses, mugs, tumblers, or shot glasses.

– Glass jewelry: Create intricate designs or patterns on glass pendants, earrings, bracelets, or key chains.

– Glass phone cases: Etch unique designs or text onto glass phone cases for a personalized touch.

2. Decorations & Presents for Home

– Glass ornaments: Etch festive designs, patterns, or personalized messages onto glass ornaments for holidays or special occasions.

– Glass vases: Create beautiful designs, floral patterns, or personalized messages on glass vases for gifts or home decor.

– Glass photo frames: Etch special dates, names, or custom designs onto glass photo frames for personalized gifts.

3. Awards & Plaques

– Recognition awards: Etch company logos, employee names, or achievement details onto glass awards for corporate recognition.

– Trophies: Create unique designs or text on glass trophies for sports events or competitions.

– Plaques: Etch memorial plaques, commemorative plaques, or dedication messages onto glass for special occasions or memorials.

Part 3: Workbench for CO2 Laser Engraving Cutting Machine

Compared to traditional cutting processing, laser cutting machines offer superior results in terms of product quality, precision, and cutting speed. The design patterns can be cut into any shape, pattern, or size of decorative edges, making laser cutting highly efficient and cost-effective.

Compact CO2 laser cutting machine can be used in homes or small business, but they may have limitations when it comes to handling larger objects. If you require a professional large size laser cutting equipment, it is advisable to contact the laser equipment manufacturer. They can customize to most common machine sizes.

Part 4: How Much Does a Laser Cutting Machine?

You may be interested in knowing the price of a CO2 laser cutting machine. Depending on the specifications and configurations, the price of CO2 laser cutting machines can range from a few thousand to tens of thousands of dollars.

Factors affecting the price of CO2 laser cutting machine

1. Brand: The brand of CO2 laser engraving machine reflects the quality, design, stability, and service of the machine. Well-known brands usually use high-quality components to ensure stable and reliable operation.

2. Components: The CO2 laser tube, as the primary device for generating the laser beam, is the most crucial component of a CO2 laser cutting machine. Other major components include optical lenses, guides, frames, stepper motors, and water chillers. High-quality components from reputable brands offer superior performance and durability, which results in higher prices.

3. CO2 Laser Tube Power: The thickness of materials that can be cut by a CO2 laser cutting machine varies depending on the CO2 laser power. Higher CO2 laser power allows for cutting thicker materials. Within the same brand, higher power CO2 laser tubes tend to have higher prices.

4. Working Bed Size: CO2 CNC laser cutting machines are typically equipped with different sizes of working beds. Common sizes include 600*900mm, 1300*900mm, 1400*1200mm, and 1300*2500mm. The larger the working bed size, the higher the price of the CO2 laser cutting machine.

5. Service: Comprehensive services provide customers with machine safety and timely maintenance for CO2 laser engraving machines. Reliable CO2 laser machine manufacturers offer complete and consistent pre-sales and after-sales services, which are reflected in higher prices. When purchasing laser cutting equipment, price is not the only factor to consider. For more, please refer to 5 factors affecting the price of fiber laser cutting machine.

DPLASER laser equipment manufacturer provides the following services:

1. Inquiry and consultation support.

2. Sample testing support.

3. Training for machine installation, commissioning, and usage.

4. On-site repair engineers.

5. 24/7 online support.

Which are the Right Laser Cutting Machine for Beginners?

Whatever the scope of your cutting project, DPLASER has a machine that will fit your needs, from entry-level systems to top-of-the line machines.

DPLASER CNC CO2 laser cutting machine adopt imported proprietary sliding guide, and equip with auxiliary facilities, such as blower, exhaust fan, infrared, foot pedal and other auxiliary facilities. Also, this series products integrate advanced high-speed continuous curve motion control card, and adopt self-developed high-speed laser engraving & cutting controlling software.

Power for CO2 laser cutting machine 60W, 80W, 100W, 130W, 150W, 180W, and 200W optional. Lower laser powers are used for engraving and carving, while higher laser powers are suitable for cutting thicker materials.

The water cooling system protects the laser tube from overheating during operation, ensuring stable laser output.

The high-precision laser head is designed with professional optical structures, providing high stability and allowing for extended continuous operation.

The retractable horizontal wheels are used for leveling heavy-duty laser engraving and cutting machines.

Electrical and control system: the electrical and control system serves as the central nervous system of the laser cutting machine, managing its operation, control, and safety features to ensure precise and reliable cutting performance.

Final word, if you want to purchase a co2 laser cutter for small business and home use, feel free to contact DPLASER at any time. Our expert team is always ready to assist you in finding the perfect laser machine. As a professional laser equipment manufacturer, we aim to provide powerful functionality and precision laser equipment! From engraving, cutting, marking and etching, our machines deliver professional production results.