In the modern industrial manufacturing, the widespread use of carbon steel has established it as a cornerstone material in manufacturing. In the precise processing of carbon steel, fiber laser cutting machines are gaining prominence, becoming a focal point due to their efficiency and precision. This article will unveil the distinctive features of fiber laser cutting in carbon steel processing, discuss solutions to common issues, and delve into the details concerning material thickness and cutting accuracy. We aim to assist you in understanding how to choose the best carbon steel sheet laser cutting machine for your business.

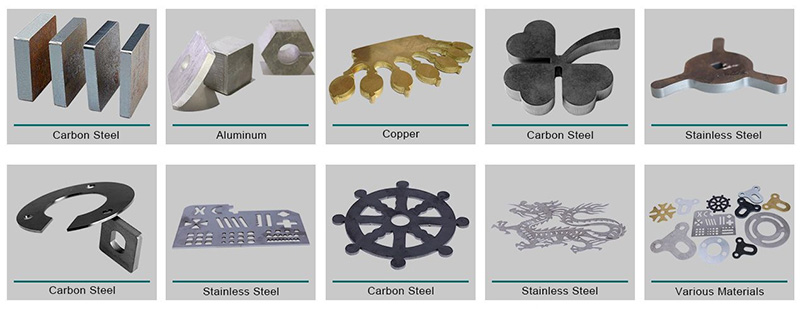

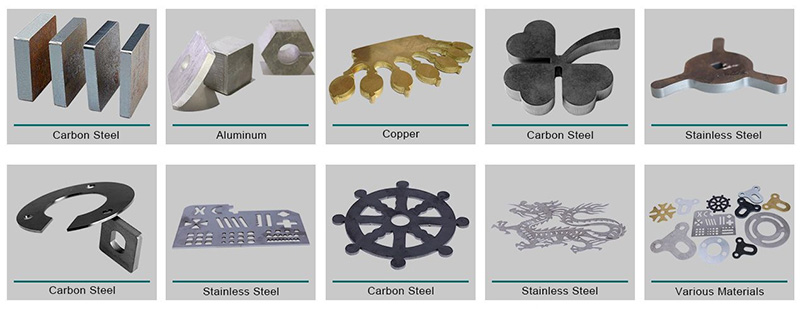

What Materials Can a Fiber Laser Cut?

Fiber laser cutter are widely used for cutting various metal materials, including carbon steel, stainless steel, aluminum alloy, copper alloy, and more.

Can You Laser Cut Carbon Steel?

Yes, laser cutting is particularly effective on carbon steel due to its good absorption of laser energy. The process involves using a laser beam to melt, burn, or vaporize the material, resulting in a precise and clean cut.

Absorption Characteristics: Carbon steel exhibits good absorption of laser energy due to its primary component being carbon. The absorption of laser energy on carbon steel is converted into heat, contributing to a more efficient cutting process.

Cutting Speed: The cutting speed of carbon steel is typically relatively fast, attributed to the favorable cutting effect of laser on carbon steel. It enables swift penetration and completion of the cutting process.

Thermal Conductivity: Carbon steel has a relatively low thermal conductivity, meaning that laser energy is more easily concentrated and generates high temperatures in carbon steel. This is advantageous for achieving higher quality cutting.

Fiber laser cutting carbon steel is characterized by its relatively high absorption and conversion efficiency on carbon steel, thus enabling a more efficient and higher quality cutting process. This makes fiber laser cutting machines more widely used in carbon steel applications, including the fabrication of automotive components, structural steel, machinery parts, and more.

Advantages of Carbon Steel Cutting with Fiber Laser Cutting Machine

Applicability:

Laser cutting machines can be widely used for processing carbon steel materials. Problems that may occur in traditional carbon steel processing, such as scarring, cracking, delamination, white spots, impurities, and looseness, are improved in laser cutting.

Efficient Processing:

Due to the presence of carbon in carbon steel, which has a weak reflection to light, it readily absorbs the laser beam. This high energy conversion efficiency on carbon steel facilitates efficient cutting.

Optical Characteristics Advantage:

Under laser beam, carbon steel undergoes a high-temperature reaction. With the assistance of auxiliary gases, reactions occur with elements such as silicon, manganese, sulfur, and phosphorus contained in carbon steel, leading to oxidation, melting, and vaporization, allowing rapid penetration of carbon steel.

Excellent Cutting Effect:

Laser cutting carbon steel can realize high-quality processing effect. The cutting surface is flat, smooth and beautiful, which not only improves the appearance quality of the workpiece, but also facilitates subsequent processing procedures.

Cost Savings:

Laser cutting machines are convenient and safe to use, contributing to cost savings in carbon steel processing. The efficient cutting speed and quality reduce production costs and increase productivity.

Cutting Thickness:

When cutting carbon steel, laser cutting machines can handle relatively thick materials, with a maximum thickness of up to 50mm of carbon steel. This convenience is beneficial for processing thicker carbon steel workpieces.

What Materials Cannot be cut on a Fiber Laser?

Non-Metallic Materials: Fiber laser cutter are mostly used for cutting metals. For non-metallic materials such as stone, glass, etc., they cannot be cut because they cannot absorb the wavelength of the laser cutting machine.

Flammable Materials: Fiber laser cutting system involve thermal processing. For flammable materials such as wood, paper, etc., the material surface is prone to spontaneous combustion due to heating, leading to an uncontrollable cutting process and rendering it unsuitable for cutting requirements.

Transparent Materials: The working principle of fiber laser cutting machines relies on the absorption of laser beams by materials and their conversion into thermal energy. Transparent materials such as transparent plastic, acrylic, etc., cannot effectively absorb laser energy and, therefore, cannot be cut.

The primary application of fiber laser cutting machines is metallic materials. For non-metallic and flammable materials, alternative cutting processes or equipment need to be considered to achieve the desired processing effects.

Common Problems in Laser Cutting Carbon Steel Plate

When laser cutting carbon steel, the most common problem with carbon steel cutting is that it doesn’t cut through, resulting in burrs.

1. Cutting speed is too fast. When the cutting speed is too fast, it is easy to cut the phenomenon of impermeability.

2. Improper choice of nozzle. The aperture of the nozzle does not match the thickness of the plate, and more nozzles are needed. In the absence of a new nozzle replacement, should increase the cutting gas pressure

3. Loose threads at the connection between the nozzle and the laser head. At this time, you should immediately pause the cutting, check the laser head connection status, re-apply the thread.

Burrs appear at the bottom of the cut surface of the material

1. Focus problem. This problem can be solved by adjusting the focus.

2. Laser output power problem. Under the premise of determining the normal operation of the laser, further check whether the output power of the laser matches the demanded power of the plate.

3. Cutting speed problem. Cutting speed is too slow will also cause the phenomenon of burrs at the bottom of the cutting surface, this time you need to speed up the cutting speed.

4. Auxiliary Gas. The purity of the gas can also affect the quality of the cut, you need to replace the gas with higher purity to cut.

5. Machine working hours. When the machine works continuously for more than a certain time, you need to restart the machine.

The Cutting Thickness of Industrial Laser Cutting Machine for Carbon Steel

1000W power laser cutting machine cutting carbon steel thickness: 0.8-10mm, cutting speed 1~3.2m/min

1500W power laser cutting machine cutting carbon steel thickness: 1-16mm, cutting speed 0.8-3.2m/min

2000W power laser cutting machine cutting carbon steel thickness: 1-20mm, cutting speed 0.8~3.6m/min

6000W power laser cutting machine cutting carbon steel thickness: 1-30mm, cutting speed 0.55~3.8m/min

12000W power laser cutting machine cutting carbon steel thickness: 1-50mm, cutting speed 0.35 ~ 2.8m/min

Generally speaking, compared with other materials, carbon steel can be laser cut at a higher speed. The laser cutting speed of carbon steel can be from 0.5m/min to more than 60m/min. Of course the thicknesses cut at different powers are at cutting speeds that are acceptable for routine production. For the same thickness of material, higher cutting speeds require higher laser power.

The parameters of fiber laser cutting machine for carbon steel can be found on this page, however, due to space limitations, we are unable to present all machine parameters. If you do not find the information you need on this page, please feel free to contact us and we will provide you with more detailed parameter information.

How Precise Is Laser Cutting Carbon Steel?

The kerf width is the narrow kerf created by the laser beam during the laser cutting process. The size of this width is influenced by the diameter of the laser beam and the focal length of the lens. Laser cutting is capable of achieving relatively narrow kerf widths, particularly for carbon steel, typically in the range of 0.1~ 0.4 mm.

Tolerance is the range of acceptable cutting errors. Achievable tolerances depend on a number of factors, including material thickness, the specific laser cutter model, and the desired cut quality. For carbon steel, typical tolerances typically range from ±0.05mm~±0.2mm.

Laser cutting machines are designed to provide a high degree of repeatability, meaning that they are able to maintain a consistent and accurate cut from job to job. Repeatability is affected by a number of factors, including the stability of the machine, the performance of the motion control system and the quality of the laser beam. By ensuring the stability of the laser cutting system, repeatability within a few hundredths of a millimeter can be achieved. This contributes to consistent, high-quality cutting results across a large number of cutting tasks.

Factors Affecting Quality Fiber Laser Cutting Carbon Steel

Carbon Content: The carbon content in carbon steel has a significant impact on the absorption of laser energy. Carbon steel with higher carbon content exhibits better absorption capabilities for laser energy. Therefore, it may be necessary to adjust laser power and cutting parameters to achieve optimal cutting results.

Oxidation Sensitivity: Carbon steel is sensitive to oxidation, and measures need to be taken to prevent oxidation during cutting. This might involve adjusting the cutting gas composition or employing a protective atmosphere to reduce the impact of oxidation on cutting quality.

Cutting Speed: Compared to other metals, carbon steel may require a higher cutting speed to ensure sufficient melting and vaporization while maintaining a high cutting quality.

Focus Position: For carbon steel, the choice of focus position may have a greater impact on cutting quality. Careful optimization of the focus position is necessary to achieve clear and smooth cutting edges.

F3015 Carbon Steel Sheet Laser Cutting Machine

This fiber laser sheet cutter stands out with its unique single-table design, which is designed to minimize initial investment costs while optimizing space utilization for more efficient operations in the work environment. With this smart and compact layout, users are not only able to flexibly deploy the machine in limited space, but also increase productivity without compromising on performance. Its outstanding performance has made it warmly welcomed by customers in a wide range of industries, including metalworking, construction, furniture manufacturing, and equipment manufacturing.

3015 Fiber Laser Cutting Machine for Carbon Steel Sheets and Pipes

This fiber metal laser cutting machine, integrating plate and tube cutting functions, stands out as an exceptional cutting device. By ingeniously combining the cutting capabilities for both plates and tubes, this laser cutting machine not only reduces investment costs but also achieves a highly integrated functionality in its clever design. Furthermore, it gains a significant advantage in space utilization, effectively saving workspace. The uniqueness of this versatile cutting machine lies in its ability to efficiently cut both plates and tubes on the same equipment, greatly enhancing work efficiency and streamlining the production process.

There is a question in reddit: “I have recently started playing with laser cutting carbon steel and am having trouble finding the sweet spot to cut 8mm and 10mm thick steel plates. Just wondering if anyone has a settings guide?”

Please do not allow yourself to encounter such problems, it is vital that you choose a professional and experienced laser cutting machine manufacturer. A reliable manufacturer will provide you with comprehensive support to ensure that you are able to take full advantage of carbon steel and iron laser cutting machines to upgrade your business. On-site installation and training is the most basic service we offer to help you get into production quickly and ensure optimal performance of your equipment.

Summary, we dissected the prominent advantages of fiber laser cutting in carbon steel processing. Whether for manufacturers or designers, carbon steel sheet laser cutting machine offer a more precise and efficient method for carbon steel treatment, opening up new possibilities for the industry. As a cornerstone in carbon steel processing, metal fiber laser cutting machine will continue to drive innovation, enhance production efficiency, and create broader development opportunities for the manufacturing sector.