Fiber Laser Cutter for Metal Sheet

F3015 single table fiber metal laser cutting machine is designed for high precision sheet metal processing. It provide efficient cutting at optimal speed using a fiber laser.

CNC laser metal cutting machine is professional for metal plate. It is simple designed, with open bed single working platform, so this laser machine price is economical and saving space. It is easy to control and the best choice for beginner to start fiber laser cutting.

Advantage:

- High-rigidity machine bed, exclusive high-temperature numerical control furnace annealing process, can guarantee the stability of the machine tool for a long time.

- Imported original packaged fiber laser, good beam quality, stable performance, non-reflective lenses, no need to adjust the optical path, basic maintenance-free, the service lite of up to more than 100,000 hours.

- The fiber laser has high electro-optical conversion efficiency and conversion efficiency can reach 30%,which can greatly save power consumption during operation and has extremely low operating costs.

- Fast cutting speed and low operating costs, rapid return on investment.

Features:

- Safe and environment friendly

- All-in-one design, easy to move and space saving

- High performance qualified fiber source, which is high reliability and longevity of service.

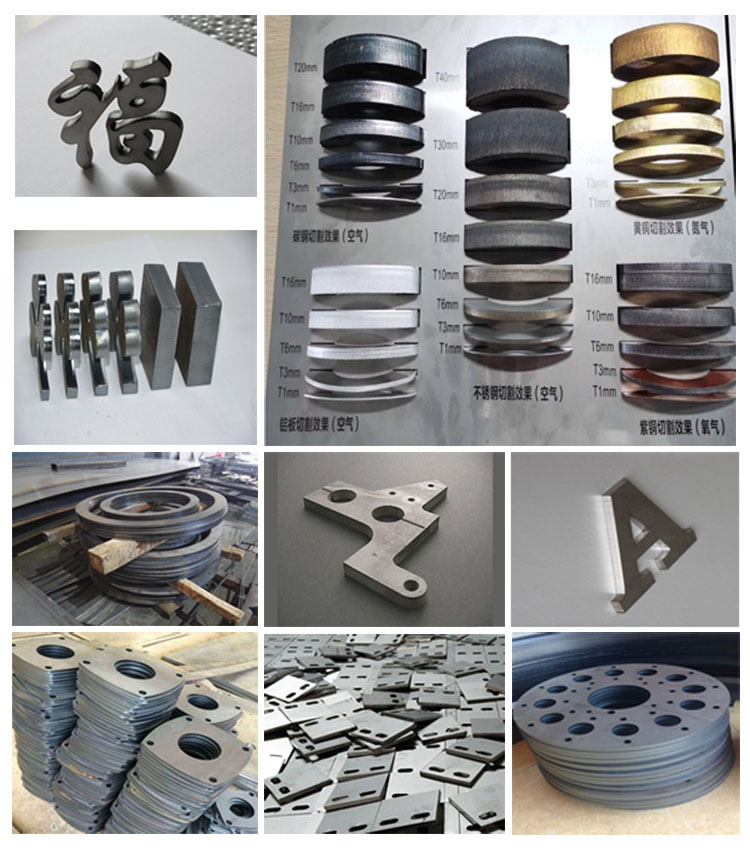

- Smooth cutting surface, little deformation, pretty leveling appearance.

- Import transmission parts and servo motor, high dynamic movement performance, high cutting precision.

Application:

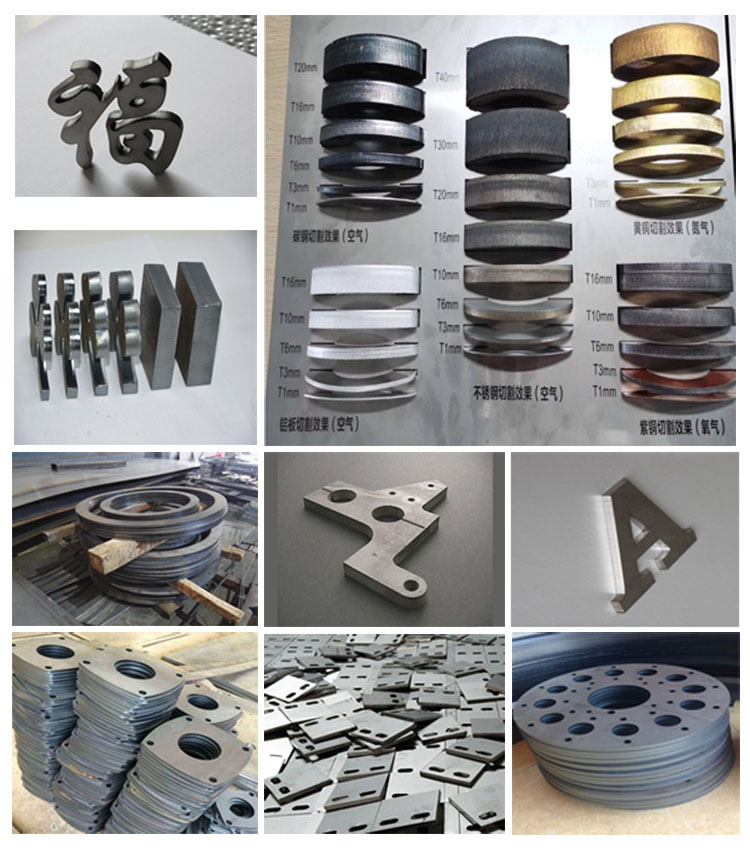

CNC single table fiber laser engraving & cutting machine for a variety of metal sheet, pipe (if need cut pipe, plus pipe cutting device additional), mainly aplies to stainless steel, carbon steel, galvanized sheet, electrolytic plate, brass plate, aluminum plate, manganese steel, various alloy plate s, rare Rapid cutting of metal and other materials. Fiber laser cutting is are capable of processing various metal types and play an essential part in industrial and commercial activities.