Laser cutters are widely used in various industries, including manufacturing, art, and design, architecture, and engineering. The guide for the best laser cutter engraver 2023 may cover various factors to consider when choosing a laser cutting machine, such as the type of materials to be cut or engraved, the desired cutting speed and precision, the available budget. This post help individuals or businesses select the best laser cutting machine for their specific needs and requirements.

What is Laser Cutting Machine?

Laser cutting machine is a type of industrial cutting equipment that uses a high-powered laser beam to cut or engrave various materials such as metal, wood, plastics, fabrics, and leather with a high degree of precision.

In laser cutting, the laser beam is directed onto the material surface using mirrors, lenses, and other optical components. The intense heat generated by the laser melts, burns, or vaporizes the material along a specific cutting path, creating a clean and precise cut edge. Laser cutting machines can also be used for engraving, etching, marking, and other surface treatments on various materials.

Laser cutting technology has the characteristics of high precision, faster cutting speed, automation, saving raw materials, stable laser cutting, and low cost. Metal laser cutting machine is mainly used for cutting alloy steel, ferrite core, stainless steel, aluminum alloy profiles, galvanized sheet, copper and other metal composite materials, which can be cut quickly.

Laser cutting machines also can be used to cut a wide variety of Non-metal materials, including: Acrylic, Wood, Paper, Fabric, Leather, Glass, Plastic, Foam, Rubber, and Ceramics. It can offer high precision and accuracy when cutting these materials, making them ideal for a range of applications in various industries such as signage, advertising, fashion, and industrial manufacturing.

Applications and Industrial Benefits of Laser Cutting Machine?

Manufacturing:

Laser cutting machines are used for cutting and shaping materials such as metals, plastics, and composites in various manufacturing applications. This includes the fabrication of automotive parts, aerospace components, medical devices, and consumer electronics.

Art and design:

Laser cutting machines are used to create intricate designs and patterns in various materials, including paper, fabric, leather, and acrylic. This includes creating art installations, sculptures, and fashion accessories.

Kitchenware:

Many sheet metal panels are generally used in kitchen utensils. When manufacturing with traditional methods, it faces the problems of low efficiency, large consumption of mold, and high costs. The metal laser cutting machine perfectly solves this kind of difficulty. Faster laser cutting speed, high precision, high manufacturing efficiency, customized and personalized product development, and improved compliance rate.

Machinery manufacturing:

Laser cutting can be mass-produced and processed quickly, with high precision, high efficiency, no burrs, and one-time molding. This is why laser cutting machines are commonly used in machinery manufacturing.

As one of the most intelligent industrial chains at present, the automobile industry integrates various manufacturing processes. As one of the most important specialties, the sheet metal laser cutting machine has completed 70% of the intelligent production.

Construction materials:

Construction projects need to laser cut many round holes and special-shaped holes on various thick and thin plates, and the high precision requirements. Holes can be drilled quickly by laser cutting, and the ideal shape can be cut by laser cutting, which further improves production efficiency and quality.

Laser cutting machines offer high precision, accuracy, and versatility, making them ideal for a wide range of industries and applications.

What are the Types of Laser Cutting Machines?

Learn about the types of laser cutters to help you easily find the laser engraver that fits your needs and budget.

There are many types of laser cutting machines, and there are also different classification standards. Below are some common types of laser cutters.

By Cutting Material

There are metal laser cutting machines and non-metal laser cutting machines. In the application field of sheet hardware industry, metal laser cutting machines are used.

By Laser

There are fiber laser cutting machines, CO2 gas laser cutting machines, and YAG laser cutting machines. Fiber laser cutting machines on the market are increasingly replacing CO2 gas laser cutting machines and becoming the mainstream of market applications.

By Laser Output Power

There are high-power laser cutting machines, medium-power laser cutting machines, and low-power laser cutting machines. The lasers used in the sheet metal processing are mainly high-power fiber laser cutting machines.

By Cutting Area

There are standard format laser cutting machines and large format laser cutting machines. The former such as 3000mm × 1500mm, 4000mm × 2000mm, 6000mm × 2000mm, 8000mm × 2000mm and so on. The cutting length of the latter machine tool in the X-axis is more than 8000mm, and the cutting width in the Y-axis is mostly 2500mm. Of course other sizes can also be customized.

By Workbench Structure

There are single table laser cutting machines and exchange table laser cutting machines. Due to the exchange table structure, it is convenient to load and unload the board, shorten the standby time for loading and unloading, and can be matched with automatic loading and unloading equipment to realize unmanned laser cutting operations.

How to Choose the Right Laser Cutting Machine?

Generally, when purchasing a laser cutting machine, you must first consider your business, the thickness of the material, and which materials need to be cut. Secondly, in order to better complete the cutting effect, determine the power of the laser equipment and the size of the worktable.

Power and Size

At present, the application of laser cutting equipment is divided into two types: metal and non-metal: the thickness of the plate generally ranges from 1~30mm, and the laser cutting machine with a laser cutting machine power of 1000W-20000W can achieve cutting.

Non-metal laser cutting machine is to cut plastic (polymer), rubber, wood, paper products, leather and natural or synthetic organic materials. It is best to use a CO2 laser cutting machine for cutting.

Therefore, when choosing a laser cutting machine, the first thing to distinguish is the type of metal and non-metal, and then choose according to the type and thickness of the specific cutting material.

Laser Cutting Machine Configuration

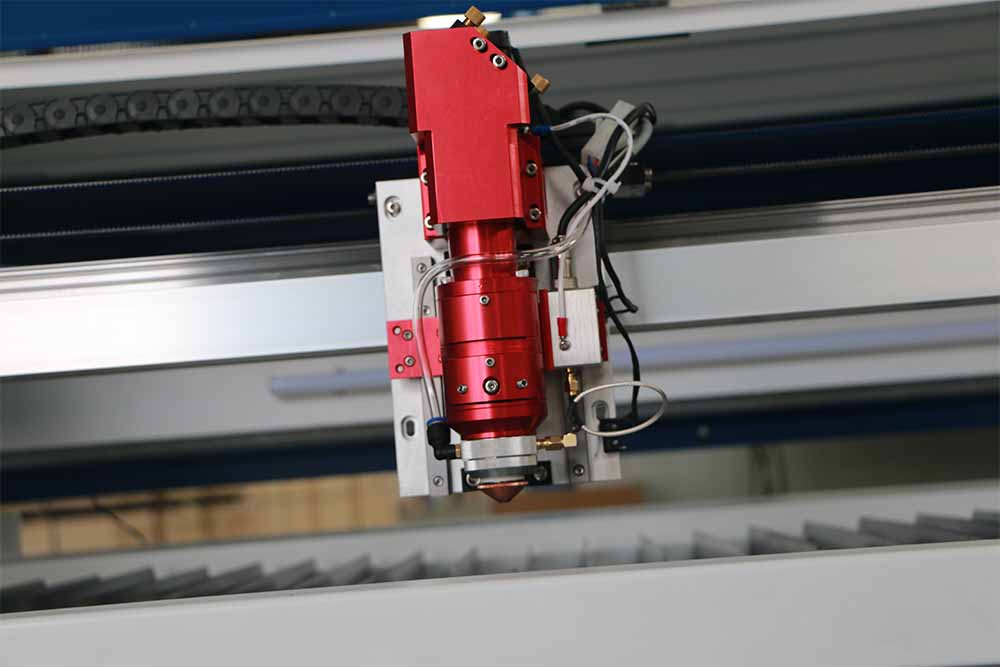

The configuration of the laser cutting machine greatly affects the price, especially some core part of the laser cutting equipment: laser source, laser head, and servo motor, guide rail, cooling cabinet and machine bed, etc., which ultimately determine the cutting quality and accuracy.

Of course, if you don’t know how to choose the best laser cutter for any budget, you can always leave a message at the bottom of the article or contact our experts to help you make a decision. We can make free proofing for you when needed.

The Best Laser Engraver for Small Business

The Best Laser Cutting Engraving Machines for Beginners

The best budget laser engraver for metal should offer you ease of use, versatility to engrave any material you want, and value for your small cutting application.

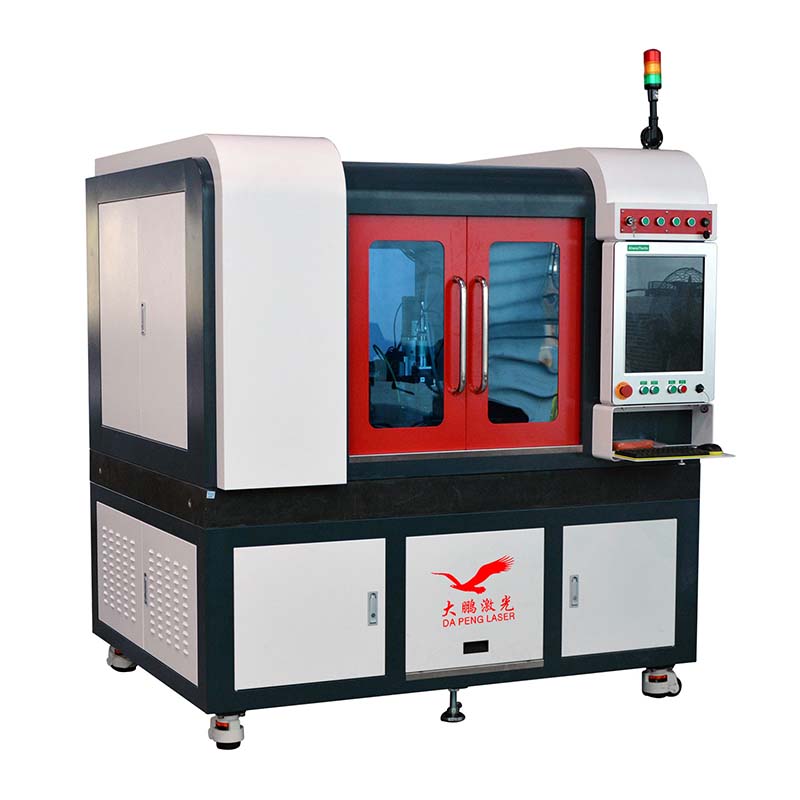

DPLASER single table Fiber Laser Cutting Machine is designed for high precision sheet metal processing. It provide efficient cutting at optimal speed using a fiber laser.

DPE-F3015 is a CNC laser metal cutting machine professional for metal plate. It is simple designed, with open bed single working platform, so this laser machine price is economical and saving space. It is easy to control and the best choice for beginner to start fiber laser cutting.

Advantage:

- High-rigidity machine bed, exclusive high-temperature numerical control furnace annealing process, can guarantee the stability of the machine tool for a long time.

- Imported original packaged fiber laser, good beam quality, stable performance, non-reflective lenses, no need to adjust the optical path, basic maintenance-free, and the service lite of up to more than 100,000 hours.

- The fiber laser has high electro-optical conversion efficiency and conversion efficiency can reach 30%,which can greatly save power consumption during operation and has extremely low operating costs.

- Fast cutting speed and low operating costs, rapid return on investment.

CNC Fiber Laser Cutting Machine for Metal Sheet and Pipe

Metal sheet pipe tube laser cutting machine is industrial cutting equipment, designed for circular square, metal pipe tube and sheets cutting. It adopts strong steel bed, rack drive system, professional pipe laser cutting CNC system, which ensure good cutting accuracy and efficiency of the CNC laser cutting machine.

The machine can be controlled by a computerized numerical control (CNC) system that allows for precise and repeatable cutting of complex shapes and designs.

Fiber laser cutting machine for metal plate and pipe is a versatile and efficient cutting tool that can meet the demands of various industrial applications.

Precision Fiber Laser Cutting Machine

Precision fiber laser cutting machines are advanced laser machines used to cut and engrave various materials with high precision and accuracy. It use for materials such as metals, plastics, ceramics, and composites with a high degree of accuracy.

Precision laser cutting is widely used in the manufacture and processing of precision components including aerospace, automotive, electronics and medical devices.

Laser processing is a non-contact flexible processing, not affected by the shape of the work piece, can process arbitrary graphic.

Double drive linear ultra-precision fiber laser cutting machine DPE-0606L adopt gantry type structure, linear motor, guide rails adopt fully enclosed protection, reduce dust pollution. Double-side drive with linear motor, high precision, high acceleration, fast speed.

Professional Fiber Laser Cutting Machine for Pipe

Professional exchange table fiber laser cutting machine for metal tube aim to increase the productivity, flexibility and cutting quality of tubes and profiles finishing with more precise fiber laser cutting.

Professional fiber laser cutting machine for pipe is a highly versatile and efficient cutting tool that can meet the demands of various industrial applications. It is designed to handle pipes of different shapes and sizes, including round, square, rectangular, triangular, d-shaped, custom-shaped tube and oval pipes.

In addition, the laser pipe cutting machine can provide a good cutting section, and no secondary treatment is required for subsequent welding and other processing, which is equally applicable to thin-walled and thick-walled pipes.

Laser tube cutting machine can cut a variety of metal materials, including steel, aluminum, copper, brass, and titanium. This makes them ideal for a range of industrial applications, including automotive, aerospace, construction, and manufacturing.

We aim to help small and medium size enterprises produce and improve manufacturing efficiency. For more cutting machine guides, please refer to 12 Best Laser Cutters for Small Businesses in 2023.

Last but not least, when choosing a best laser cutter for beginners, its R&D team, professional technical support, and after-sales service system are all factors that need to be considered. In order to better improve customer experience, DPLASER has established a complete market service system, and its sales and service network covers the world, which can quickly respond to various needs of customers.