With the acceleration of technological progress, laser cutting technology has become a key technology in the field of steel cutting. Compared with traditional mechanical processing methods, laser cutting and engraving steel with its significant advantages – including high speed, high precision, high performance and excellent product quality – is being increasingly widely adopted in the steel processing. These features not only improve productivity, but also facilitate the transition to higher standards in manufacturing.

Can Fiber Lasers Cut Steel?

The answer is yes. Laser cutters for steel has long been recognized as one of the most efficient and accurate methods of CNC metal cutting. Both CO2 laser cutting machines and fiber laser cutting machines can be used for metal steel cutting. Steel is defined as an iron-carbon alloy with a carbon content of less than 2%. Based on its composition, steel is categorized into carbon steel and other alloy steels. The most common types of steel used in laser cutting are stainless steel and carbon steel.

Why Use Laser Cutters for Steel?

Fiber laser steel cutting has the advantages of good cutting quality, high cutting efficiency, and non-contact cutting and so on.

The basic principle of fiber laser steel cutting is to use high power, high energy density laser beam irradiation to steel, so that the irradiated material rapidly melting, vaporization, ablation, or to reach the ignition point, and at the same time, with the help of coaxial high-speed airflow with the beam to blow away the molten material, so as to achieve the steel cut.

Features of Laser Cut Steel

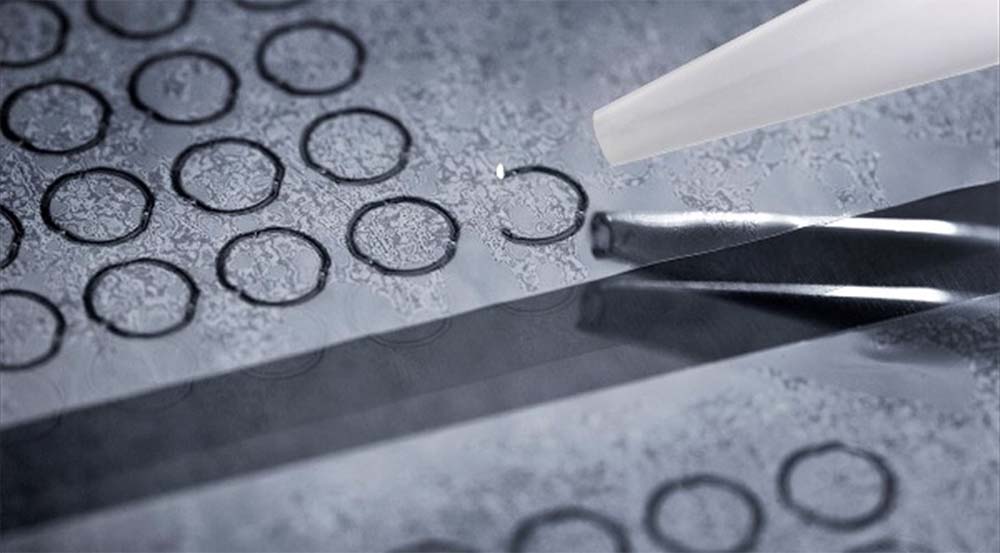

Narrow Kerf Width: The laser beam focuses to a tiny spot, generating high power density that rapidly heats the material until it vaporizes, forming a hole. As the beam moves linearly relative to the material, continuous holes form a narrow kerf with a typical width of 0.10~0.20 mm.

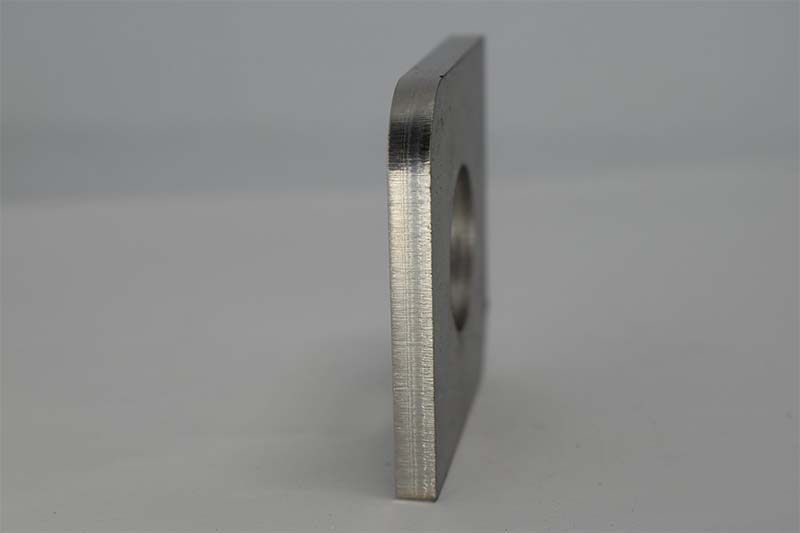

Smooth Cutting Edge: The cut edges are burr-free, and the surface roughness is generally controlled within Ra 6.3~12.5μm.

High Cutting Speed: For example, when using a 2,500W laser to cut 1mm thick cold-rolled carbon steel plate, the cutting speed can reach 10~16 meters/minute.

Non-Contact Cutting: The laser does not touch the workpiece, eliminating tool wear and preventing damage to the workpiece.

Efficient Material Utilization: Using computer programming, different shapes can be optimally nested on a sheet, maximizing material usage.

Improve New Product Development: The entire cutting process is controlled by a numerical control system, allowing for immediate laser processing once the product drawings are ready, shortening the time from design to physical prototype.

Broad Material Compatibility: Laser cutting technology can be applied to various materials, including metals, non-metals, and metal and non-metal composite materials, although different materials have varying absorption rates, affecting their suitability for laser cutting.

High Quality and Efficiency: For steel, using high-power lasers and effective cooling systems ensures both quality and efficiency in cutting.

However, laser cutting steel also has some limitations, such as high equipment costs, large one-time investment, as well as the limitation of laser power and equipment size, can only cut medium and small thickness of plates and tubes. As the thickness of the workpiece increases, the cutting speed decreases significantly.

How to Cut 8mm Steel Plate?

Steel plate cutting is a common metal fabrication requirement. Choosing the right cutting method can improve cutting efficiency and quality, and reduce cutting costs and risks.

Flame Cutting

Flame cutting is a cutting method that uses a high-temperature oxygen flame to preheat the steel plate to the ignition point, and then injects a high-pressure oxygen gas stream to oxidize the steel plate violently in the flame and blow away the slag to form an incision. Flame cutting technology is low cost and simple to operate. But the disadvantages of flame cutting are slow speed, low precision, large heat-affected zone, easy to produce deformation and oxidized layer, not suitable for cutting stainless steel and other difficult to melt materials.

Plasma Cutting

Plasma cutting is the use of high-temperature plasma arc heat to make the workpiece at the incision of the metal local melting (and evaporation), and high-speed plasma momentum to exclude the molten metal to form the incision of a processing method. Plasma cutting machine has excellent performance, high speed, high precision, small heat-affected zone, and can realize automation and numerical control. Plasma cutting is suitable for cutting a variety of metal materials with a thickness between 0.5-160mm, including stainless steel, aluminum, copper and so on. However, the disadvantages of plasma cutting are high cost of equipment, high noise, and the arc is harmful to human body, which requires good ventilation and protective measures.

Laser Cutting

Laser cutting is the use of high-energy laser beam to heat, local melting, vaporization of metal, complete the cutting of the material, usually used for thin steel plate (<30mm) efficient precision cutting. Laser cutting equipment with very high precision (up to ± 0.05mm), fast speed, good quality, small heat-affected zone, can realize the cutting of complex graphics. Laser cutting is suitable for cutting all kinds of metal steel with thickness between 0.5-20mm, especially for highly reflective materials such as stainless steel and aluminum alloys. 8mm steel laser cutting is undoubtedly the optimal choice.

How Thick a Laser Cutting Can Cut Steel?

The thickness of laser cutting steel frame is not only dependent on the type and power of the laser source but also influenced by factors such as the focusing lens, beam mode, choice of auxiliary gas, cutting speed, nozzle design, and quality of optical components. To achieve optimal cutting results, these parameters need to be considered and adjusted accordingly.

500W Laser Cutting Machine

For Stainless steel: 0-3 mm

For Carbon steel: 0-6 mm

1,000W Laser Cutting Machine

For Stainless steel: 0-5 mm

For Carbon steel: 0-10 mm

2,000W Laser Cutting Machine

For Stainless steel: 0-8 mm

For Carbon steel: 0-16 mm

3,000W Laser Cutting Machine

For Stainless steel: 0-10 mm

For Carbon steel: 0-20 mm

In the case of the same laser power, increasing the thickness of the material being cut can potentially affect the quality of the cut section and the cutting speed. Steel plates with a thickness of less than 20 mm are generally well-suited for laser cutting. For plates thicker than 20 mm, water jet cutting might be a more appropriate option.

Laser Cut Steel Applications

Configured with different laser powers and optical systems, laser cutting machines can cut thin and thick steel plates with high speed and high precision. This is incomparable to traditional cutting methods. At the same time, due to the high precision of the laser cutting machine, it can handle various shapes of steel plates well, thus providing greater design flexibility for steel structure construction.

Laser cutting can be implemented in commonly used steel metal materials, including carbon steel, stainless steel, alloy steel, aluminum and aluminum alloys, titanium and titanium alloys, and most nickel alloys. Laser cut steel plates are used in a wide range of applications covering machinery manufacturing, construction, home appliances, marine, aerospace and many other fields.

Cutting precise small parts: In structural steel construction, there is sometimes a need to manufacture a large number of precise small parts, which can be accomplished using laser cutting machines.

Mechanical manufacturing sector: Laser cutting of steel plates can be used to manufacture various mechanical components, such as automotive parts and construction machinery components. The application of this technology improves the precision and efficiency of parts, providing strong support for the development of the mechanical manufacturing industry.

Automotive manufacturing: In the automotive manufacturing process, laser cutting is used to cut body panels and produce other metal parts. Its high precision and rapid cutting capabilities allow automakers to produce complex-shaped parts while maintaining consistent quality.

Construction field: In the construction industry, laser cutting of steel plates can be used to make steel structures and steel frames, enhancing the stability and safety of building structures.

Household appliance sector: Laser cutting of steel plates is used in the production of metal furniture and casings, brackets, and other components for household appliances. It provides clean cutting edges and high-quality surface finishes, reducing the need for additional processing.

Electronics manufacturing: In electronics manufacturing, laser cutting is used to cut precise metal casings and other tiny components. It enables high-precision micro-processing, meeting the high demands of electronic devices.

Shipbuilding sector: In shipbuilding, laser cutting of steel plate technology is used to manufacture hull structural components, improving the strength and safety of ships.

Steel plate laser cutting is an efficient, precise, and flexible metalworking technology that is widely applied across many industries to meet diverse material needs. For bulk production of steel plates and tubes, we recommend using fiber laser cutting machines. Our fiber laser cutting sheet metal machines primarily cut various steel plates. For example, sheet metal laser cutting machines can cut stainless steel, carbon steel, alloy steel, as well as aluminum, copper, and other metal plates and tubes. These processed steels can be used for mechanical manufacturing, railroads, metal doors and windows, construction, infrastructure, and other purposes.

Sheet & Tube Laser Cutting Machine

Features of Metal Sheet & Tube Laser Cutting Machine

One machine for two purposes: Integrated design provides dual cutting functions for sheet and tube.

Higher cutting quality and efficiency, cutting speed is up to 120m/min with appearance and beautiful cutting edge.

- Heavy bed: Integrated design ideas with a heavy-duty carbon machine bed, stress relief annealing treatment, and gantry milling machining ensure the stability of the bed during operation, resulting in the best cutting effect.

- Aluminum beam: Using heavy-duty steel mold pressure casting, the aluminum water is uniformly dense, providing high strength to the protective casting surface.

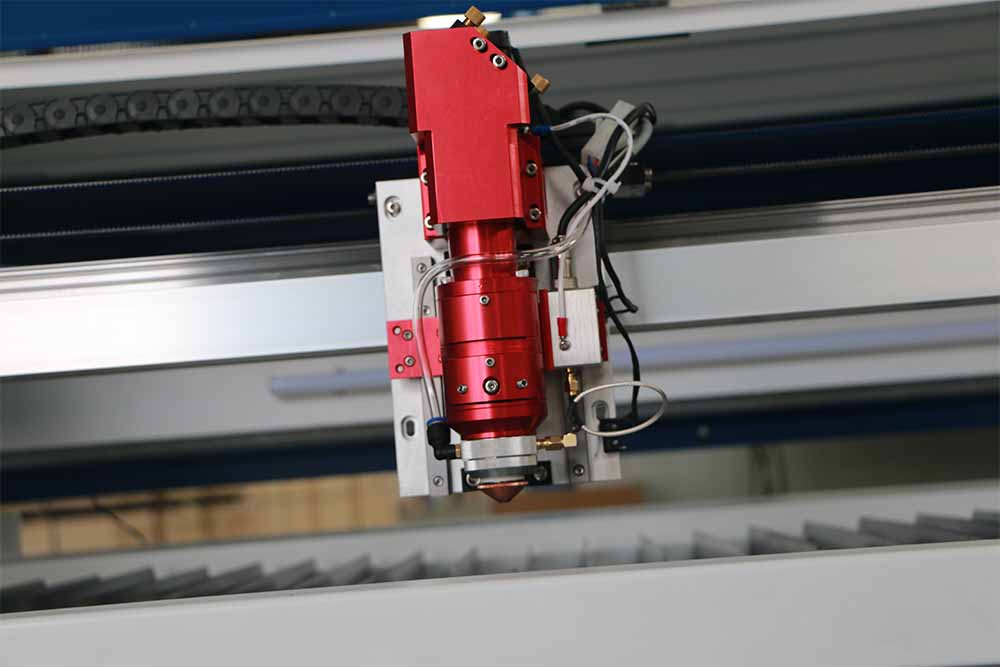

- Auto-Focus laser head: The laser cutter automatically adjusts its focus when working with varying materials and thicknesses, ensuring maximum efficiency and effectiveness.

- Precision and speed: The fiber laser cutting machine is equipped with a Taiwan YYC rack and Taiwan Shangyin guide rail to ensure cutting precision.

- The new human-computer interaction interface on the CNC system cuts and simulates the CAM software to track and dis-play in real time.

- Imported servo drive system, high-precision imported screw drive system.

When a high-density laser beam precisely hits the surface of steel, the energy is sufficient to rapidly melt or vaporize the material at the focal point. This process allows operators to cut customized parts and specific shapes from different types of steel with extreme precision. Laser cutting technology is critical to improving the smoothness and reliability of metal parts in machinery and equipment manufacturing.

The Bottom Line

In the field of steel processing for industry, laser cutting technology has become the preferred industry solution due to its high precision, efficiency and flexibility. It not only significantly improves productivity and product quality, but also offers manufacturers a wider range of design freedom and processing possibilities. This article is to provide the basics of fiber laser steel cutting and to offer some guidance for those seeking the best laser cutting solutions for metal. We hope this information will help you make informed choices when developing your laser cut steel designs and projects.