In the flourishing development of modern laser cutting technology, understanding the 2D and 3D laser cutter technology is a crucial aspect of guiding business success. We will explore the distinctive features of these two laser cutting methods and their applications in various fields. By delving into the differences of these two laser cutting technologies, we are committed to guiding you to the best choices for your business.

What is 3d Laser Cutting?

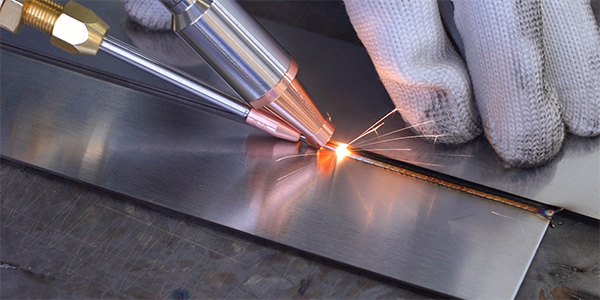

Traditional metal processing usually uses manual arc welding or plasma cutting to cut plates. However, due to the inconsistency of plate thickness or space constraints, the traditional methods cannot meet the diverse material cutting needs of various industries. In this case, 3D laser cutting machine becomes a solution.

With excellent flexibility and adaptability, 3D laser cutting can efficiently cut different types of tubes, angles and I-beams. This approach gives fabricators greater design freedom, allowing the creation of parts with diverse shapes and complex structures.

Difference between 2D and 3D Laser Cutting

While 2D laser cutting machines specialize in processing flat products, 3D laser cutting machines can easily handle three-dimensional products in space in comparison.

Difference between 2d and 3d cutters, 2D laser cutting machines are simple and affordable, suitable for smaller shops due to their lower complexity and more economical price. Secondly, 2D laser cutting machines achieve high precision and accuracy for applications that require tight tolerances, and are able to perform fine cutting tasks with minimal distortion and machining accuracy of ±0.02 mm. At last, 2D laser cutting machines are often used for workpieces that are simple in structure, and therefore have faster cutting speeds.

In terms of the working mechanism of 3D laser cutting, compared to 2D laser cutting, 3D laser cutting requires constant adjustment of the laser cutting head’s posture to ensure that it is perpendicular to the surface of the workpiece, in order to maintain the superiority of cutting quality. The 3D laser cutting machine is able to effectively deal with challenges such as uneven plate thickness or space constraints. It offers greater flexibility and adaptability than traditional methods. Through laser technology, 3D laser cutting machines are able to cut accurately in all three axes, overcoming the difficulties of traditional methods when dealing with spatially curved structural plates or shaped tubes. Fiber laser cutting can be applied to different materials and workpiece’s of different thicknesses, ensuring that the cutting surface is flat, free of burrs and burrs.

Flexibility: Three-dimensional laser cutting has excellent flexibility, can adapt to a variety of different shapes of workpieces for cutting processing, outstanding performance, especially when dealing with complex structures and shaped workpieces.

High precision: Its high-precision cutting technology can satisfy products requiring high manufacturing precision, such as aluminum alloy rolling stock and stainless steel subway, ensuring high precision of cutting quality.

Economic benefits: In terms of economic benefits, 3D laser cutting can replace the traditional trimming and punching molds with its simple process, short manufacturing cycle, fast cutting speed, small slit width and high processing quality. By reducing cost and shortening the development cycle of new models, it brings significant economic benefits to the manufacturing enterprises.

| Items | 2D Laser Cutting | 3D Laser Cutting |

| Cutting dimensions | Cutting of flat sheets only along the X- and Y-axis | Cutting and drilling for 3D shapes and complex spatial forms |

| Application areas | Suitable for parts with relatively simple structures, such as signs, panels, gaskets, etc. Suitable for small shops and mass production due to its ease of operation and relatively low cost. | 3D laser cutting is suitable for complex parts that need to be cut in multiple axes. It allows for greater flexibility and adaptability for, for example, tubes, angles, I-beams, etc. |

| Control system requirements | Relatively simple process with easy path planning. | More complex cutting processes and precise motion control are required. |

| Cost | Cheaper than 3d laser cutters | Advanced technology and wide range of applications are more expensive. |

Applications of 2D&3D Laser Cutting Machine

2D laser cutting machines are crucial in the production of detailed signage for advertising, and their precision is valued in the processing of metal components, circuit boards and machinery manufacturing. The automotive industry extensively utilizes 2D laser cutting for shaping chassis parts, brackets, and panels. Moreover, in the textile industry, these machines contribute to the accurate cutting of fabric for custom-designed clothing and textiles.

Three-dimensional laser cutting systems are widely used in a number of industries, covering areas including but not limited to sheet metal processing, metal processing, advertising production, kitchenware manufacturing, automobile manufacturing, lamp production, saw blade manufacturing, elevator manufacturing, metal handicrafts manufacturing, machinery manufacturing, glasses manufacturing, medical equipment and instrumentation and so on. Especially in the field of sheet metal processing, three-dimensional laser cutting technology has successfully replaced the traditional processing methods, favored by users in the manufacturing industry.

The 3D fiber laser cutting machine is capable of processing a variety of materials, including stainless steel, carbon steel, alloy steel, silicon steel, aluminum, aluminum alloy, galvanized sheet, aluminum zinc plated plate, pickled plate, copper, silver, gold, titanium and other metal plates and tubes. This multi-material processing capability makes it suitable for a wide range of industries, providing greater flexibility and efficiency while meeting different production needs. Widely used 3D laser cutting technology brings higher production quality and efficiency to these industries.

Trimming and punching processes have always been difficult in the mold making process. For the production of parts extruded and formed by molds, the use of industrial 3D laser cutting machines for nesting and eyelet processing is considered a more suitable choice due to the high design and manufacturing cost of drop dies, long manufacturing lead time and poor punching quality. This method helps to reduce costs, shorten the manufacturing cycle time and improve the machining quality of the parts.

3D Laser Cutting Machine for Automotive Manufacturing

In the automotive industry, furniture manufacturing, home furnishing industry and toy manufacturing, etc., there is an increasing demand for cutting steel plate and stainless steel type raw materials. In automobile manufacturing, generally steel plate needs to be cut after stamping and forming, and in the cutting work after stamping and forming, 3D fiber laser cutting machine is widely used.

Three-dimensional laser cutting technology is widely used in automobile manufacturing, which is especially suitable for dealing with key structural parts, such as longitudinal roof beams, roof side beams, window reinforcement bars, door panel reinforcement bars, transverse support frames, suspension mounts, longitudinal bearing beams and so on. Compared to 2D laser cutting, 3D laser cutting not only involves more complex machine tools and programming, but also requires auxiliary equipment such as body stamping. The introduction of this innovative technology brings significant advantages to automotive manufacturing.

First of all, 3D laser cutting guarantees a high level of cut quality and precision. Through precision laser cutting technology, automotive structural components can be cut to precise dimensions and shapes while maintaining high quality, ensuring the consistency and reliability of automotive parts.

Secondly, 3D laser cutting significantly improves cutting efficiency. Compared with traditional 2D cutting methods, 3D laser cutting can handle complex structural parts more flexibly, reduce material waste, and complete cutting tasks more efficiently, thus improving production efficiency and reducing manufacturing costs. The application of this technology has brought innovation and benefits to several industries.

How to Choose a Fiber Laser Metal Cutting Machine

C3015 CNC Metal Sheet Laser Cutter

Fiber laser cutting machine for metal sheet utilizes a computer numerical control system to make precision cuts on sheet metal by means of a high-energy laser beam. Features include superior cutting accuracy, high speed and high efficiency production capabilities for a wide range of metal materials such as stainless steel, aluminum, carbon steel, etc. The machine has the flexibility to cut complex shapes and patterns, which are designed and controlled through CAD/CAM software.

3D 5 Axis Metal Tube Laser Cutting Machine

The 3D laser cutting machine is a high-performance device known for its processing flexibility, cost-effectiveness, stable quality, and user-friendly operation. Its key components utilize cutting-edge international fiber laser technology, coupled with a precise numerical control system, ensuring heightened precision, faster speed, and superior cutting quality. This machine is ideal for welding three-dimensional carbon steel and stainless steel materials, catering to a wide spectrum of metal and non-metal cutting needs.

Furthermore, the machine can be equipped with a fully enclosed casing and dust filtration device to effectively control dust, particles, and smoke. Dapeng New fiber laser cutting machine, with upgrades in over ten components such as bed structure, cutting head, and control system, has increased overall cutting efficiency by 20%, maintaining its leading market share in China.

The 3D Metal Laser Cutting Machine is tailored for industries like metal processing, power, electronics, technology, and medical instruments. It processes various metal materials, including carbon steel, stainless steel, galvanized steel, electrolytic galvanized steel, aluminum, brass, and copper. The system is characterized by stability, reliability, easy deployment, simple debugging, production safety, rich functionality, and outstanding performance. It supports modular, personalized, automated, and information-based solutions, facilitating memory caching and possessing a robust cutting process database to meet diverse thickness and spatial structure cutting requirements.

6 Axis Laser Cutting Robot System

The robotic 3D laser cutting machine consists of robot arm, fiber laser, cutting head, cutting stand, standard worktable, and chiller and so on. The whole system is highly integrated, easy to operate, maintain and repair, with excellent product stability. The welding speed is faster and the processing precision is higher.

For small workpieces, dual-station operation can be realized to improve cutting efficiency. For large workpieces, single-station operation is realized, which is flexible and convenient. PLC control system is adopted to realize real-time communication among robot, machine tool, and cutting head and other equipment’s as well as timing sequence of cutting process action. The operation interface adopts touch screen, which is convenient for setting cutting parameters, obtaining and clearing alarm information, monitoring I/O status, etc., realizing a high degree of automation.

The Bottom Line:

Understanding the features of 2d and 3d laser cutting not only helps you make informed decisions in design and manufacturing, but also opens up innovative possibilities for your business. When choosing a laser cutting machine, we offer recommendations that will support your business decisions. If you have any needs or questions about cutting plates and tubes please feel free to contact our team of professionals.