Sheet Metal Laser Cutting Machines

Fiber laser cutter for steels and aluminum metalworking by focusing a high-powered laser beam onto the surface of the metal, which melts or vaporizes the material in the path of the beam. The laser beam is guided by mirrors and lenses, and the cutting process is controlled by computer numerical control (CNC) software that precisely directs the laser beam’s movements.

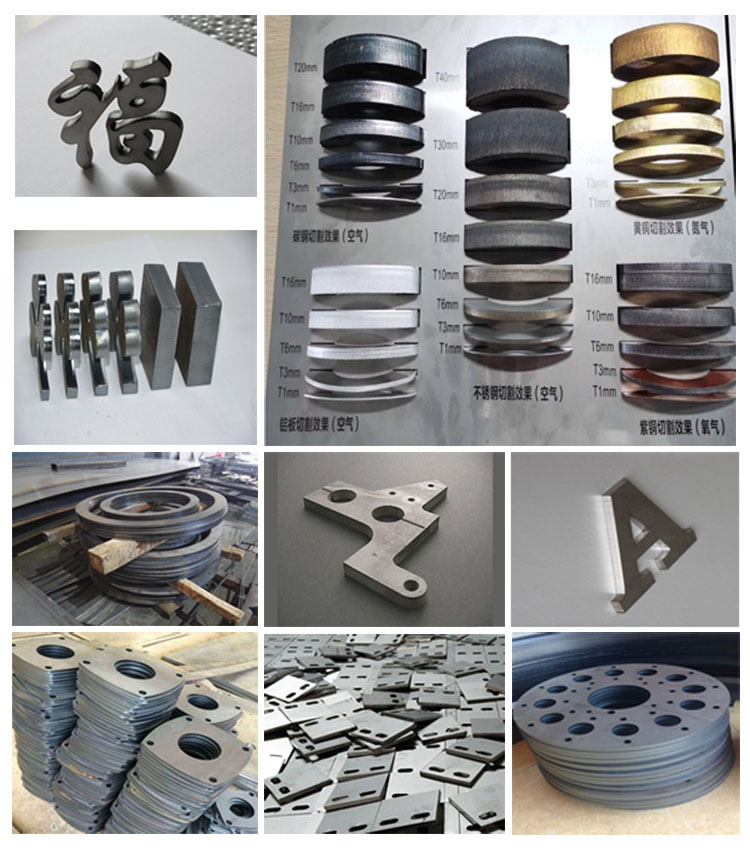

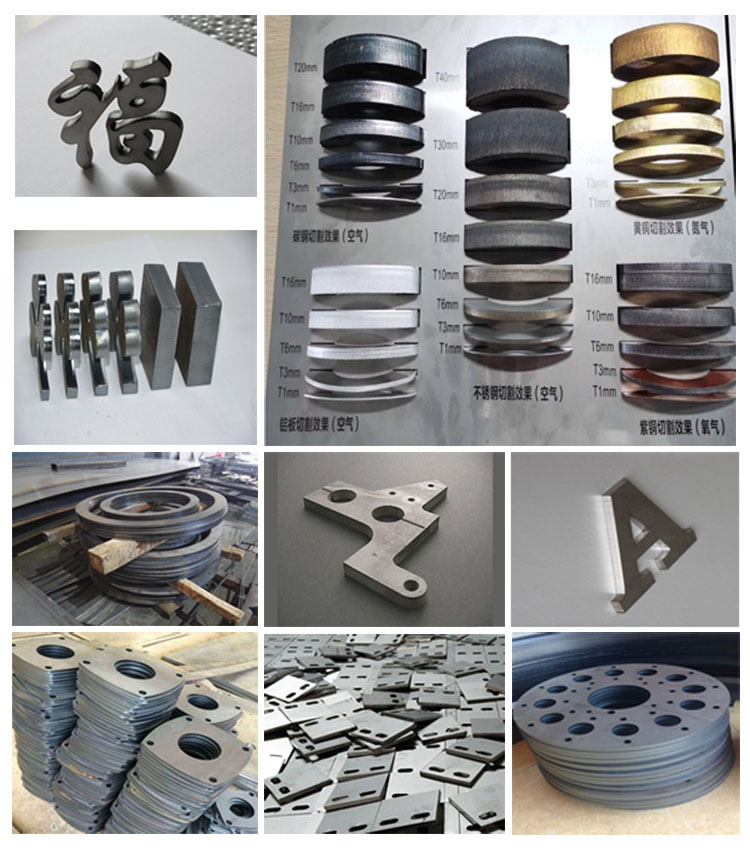

The laser sheet cutting machine are high precision, speed, and ability to cut through a wide range of metal plate materials, including steel, stainless steel, aluminum, copper, brass, and more. They offer superior cutting quality with minimal heat-affected zones, resulting in clean and accurate cuts. Additionally, fiber laser cutters are more energy-efficient and require lower maintenance compared to traditional CO2 laser cutters.

- High rigidity machine bed, exclusively treated with high-temperature CNC electric furnace annealing process, ensuring Long-term stability of machine accuracy.

- Imported original packaged fber laser, with good beam quality and stable performance, no reflective mirrors, no need for optical adjustment, virtually maintenance-free, with a service Life of over 100,000 hours.

- High electro-optical conversion efficiency of the fiber Laser, reaching an eficiency of 30%, which significantly saves power consumption during operation and results in extremely low operating costs.

- Fast cutting speed and Low operating costs, providing a quick return on investment.

Product Features:

1. This cutting head is suitable for power levels of 3000W and below.

2. The internal structure of the laser head is completely sealed, preventing contamination of optical lenses.

3. The laser head employs a two-point centering adjustment, and the focusing mechanism is driven by a servo motor, significantly improving perforation efficiency.

4. The protective mirror structure is drawer-type, allowing for easy and convenient replacement.

5. Compatible with various lasers equipped with QBH fiber connectors.

Capable of cutting various metal sheets and pipes (additional pipe cutting device requred), primarily suitable for rapid cutting of materials such as stainless steel, carbon steel, galvanized sheet, electrolytic plate, brass, aluminum, manganese steel, various alloy sheets, and rare metals.

OSPRI Cutting Head:

Suitable for 3000W and below medium power fiber laser cutting. Adopt ultra-precision and ultra-smooth lens processing technology, with excellent cutting quality and speed. Realize seamless connection and deep integration with the system to further improve production and processing efficiency. Modular component design, rapid on-site maintenance of equipment, customers can quickly restore production capacity and realize 24-hour uninterrupted production. The localization of service and maintenance further reduces user costs.

Product Features:

1. This cutting head is suitable for 3000W and below power band.

2. The internal structure of the laser head is completely sealed, which can avoid the contamination of the optical lens.

3. The laser head adopts two-point centering adjustment, and the focusing mechanism is driven by servo motor, which can significantly improve the piercing efficiency.

4. Protective mirror structure adopts drawer type, easy and simple to replace.

5. It can be used in various lasers with QBH fiber connector.

| Maximum Atmospheric Pressure | 25 Bar | Horizontal Focus Range | ±1.5mm |

| Collimated focal length | F75-F100 | Vertical Focus Range | ±8mm |

| Focusing focal length | F125/F150/F190 | Applicable power | ≤3000W |

| Effective aperture | 25 mm | Weight | 5.5kg |

Reviews

There are no reviews yet.