With the rapid development of industrial manufacturing, the demand for raw materials has increased significantly, fuelling the widespread use of heavy metal tubes. These tubes are widely used in heavy machinery, steel buildings, building construction, machine building, bridge construction, greenhouses and communication towers. The processing of special sizes and large diameter tubes has always been a challenge for the manufacturing industry. Heavy duty laser cutting machine is able to accurately process oversized diameter and thickness tubes, providing highly customized solutions for a wide range of industries and driving manufacturing to greater excellence and scale.

The Best Laser Cutting Machine for Heavy-Duty Pipe

Heavy-duty pipes are steel pipe products with wall thicknesses typically exceeding 3mm, offering high load-bearing capacity along with exceptional strength and stiffness. These pipes not only possess excellent compressive properties but can also endure significant bending and torsional forces, making them reliable structural supports for various complex projects. Traditional cutting methods, however, suffer from low efficiency and poor processing quality, making it challenging to meet the demands for high-precision and intricate cutting.

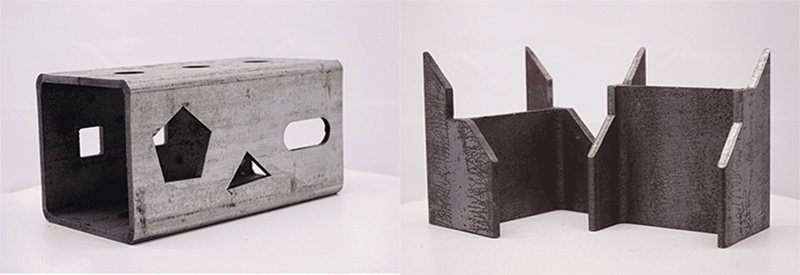

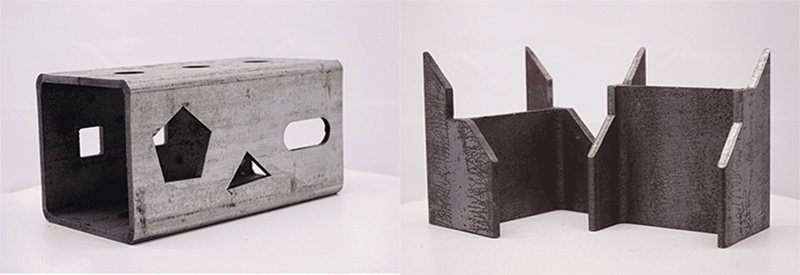

In contrast, laser cutting for heavy tube provides notable advantages. It eliminates the need for molds, significantly reducing new product development time, and features fast cutting speeds and high precision. Laser tube cutting machines can precisely cut open holes, achieve broken cuts, create coherent lines, and handle complex shapes, meeting increasingly stringent process requirements.

Applicable pipes include round pipes, rectangular pipes, profiled pipes, oval pipes, OB pipes, angle iron, channel steel, and other metal pipe fittings and profiles of various materials and specifications. This technology serves multiple industries such as engineering machinery, locomotive manufacturing, petroleum pipelines, agricultural and forestry machinery, ladder fences, smart homes, fitness equipment, metal furniture, office desks and chairs, and bus manufacturing.

Traditional laser tube cutting machines are often limited by the length, diameter, weight, and metal type of the pipes when processing heavy-duty pipes. Conventional laser tube cutting machines can only handle round and square pipes up to 6 meters in length, and the weight of individual pipes is also restricted, making them unsuitable for cutting heavy-duty pipes effectively. To address these limitations, Dapeng Laser has developed a specialized heavy industrial metal laser cutting machine.

Features of the Heavy Tube Laser Cutting Machine

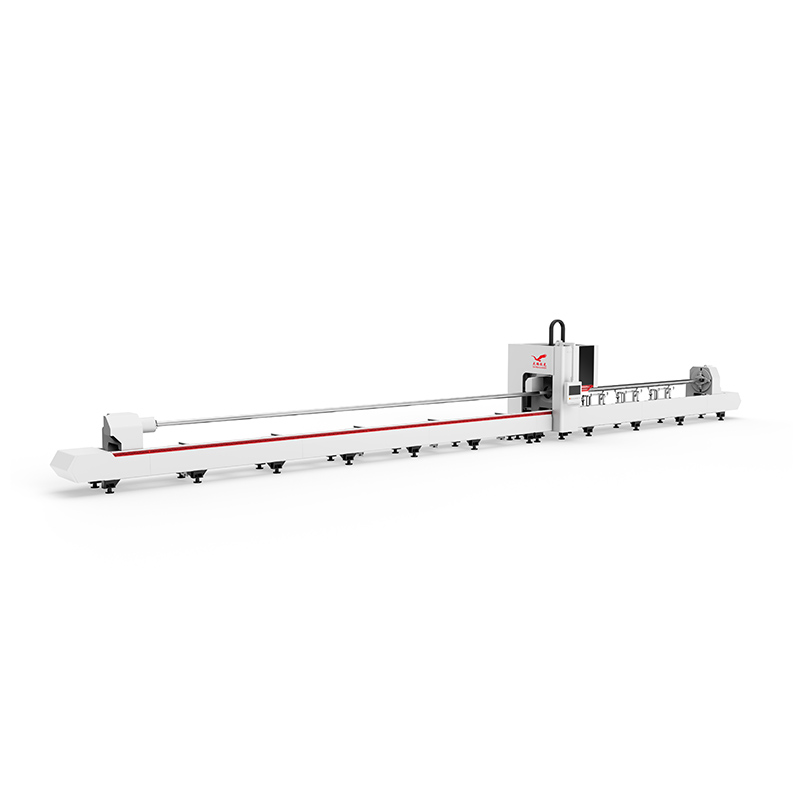

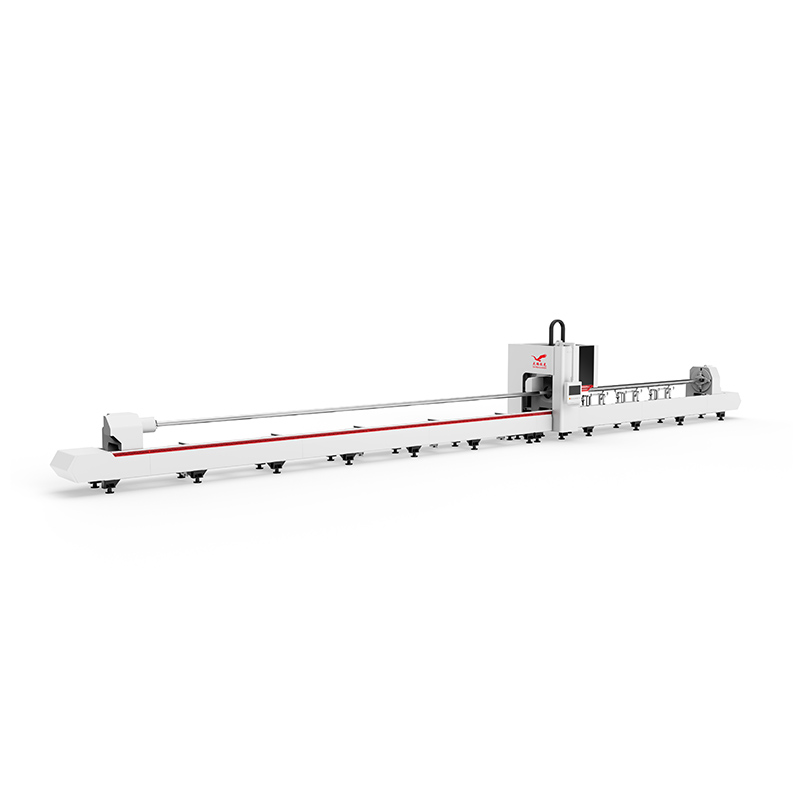

Designed specifically for the heavy-duty pipe processing, this laser tube cutting machine perfectly meets the precision cutting requirements for heavy, extra-long, and uniquely shaped pipes, setting new standards for high precision and intelligent cutting. With its exceptional sensing accuracy and rapid response speed, the machine maximizes material utilization through zero-waste cutting, significantly saving metal materials. It excels in handling round and square pipes with diameters ranging from 15mm to 350mm and metal pipes up to 12 meters in length, while maintaining a single-load capacity of up to 900kg, significantly enhancing production efficiency.

The heavy three-chuck tube laser cutting machine features an innovative three-chuck automatic clamping system, revolutionizing loading and unloading intervals. This effectively reduces pipe wastage and ensures efficient, zero-waste cutting operations every time. The built-in bus real-time control system, integrated with a follow-up control design, enables smoother and more agile bending and cutting processes, resulting in superior and reliable product quality.

Accompanied by professional 3D nesting software, which integrates intelligent nesting and automatic layout optimization functions, the machine greatly simplifies operational procedures. This allows for easy handling of even complex tasks, significantly boosting efficiency while reducing costs. It provides an ideal one-stop solution for the metal pipe processing industry.

Laser Sources

BWT: A leader in high-power fiber lasers, known for stable performance.

MAX: Renowned fiber laser manufacturer, offering high cost-effectiveness.

Raycus: A company specializing in the R&D, mass production, and sales of fiber lasers. Their performance rivals IPG, with low maintenance costs and backup laser services.

Laser Head

Modular Design: Easy to replace and maintain, ensuring high cutting efficiency.

Gantry and Bed

Stable Gantry Structure: Constructed with high-strength aluminum alloy integrated cast beams and a welded steel bed.

Superior Heat Treatment and Processing: Ensures overall rigidity and long-term stability of the machine.

Servo Motors and Precision Gear Racks

High-Quality Imported Servo Motors: Combined with a high-precision double-drive gear and rack transmission structure, offering high precision and processing efficiency.

Three-Chuck Design

High-Power Laser Source and Three-Chuck Design: Ensures stability during the cutting process, especially important for ultra-heavy pipes, maintaining cutting accuracy and preventing material displacement during processing.

Intelligent Heavy-duty Chuck with Large Clamping Range

Zero-waste cutting capability can be achieved with just three chucks, whereas other brands require four or more. This helps to optimize your production in a precise and cost-effective way, reducing waste, and is particularly valuable for large diameter or heavy tubes, where material costs tend to be higher.

Pre-programmed drawing, nesting and undercutting segments on a computer through specialist tube cutting and nesting software to generate cutting programs, followed by full-stroke automated laser cutting and undercutting of heavy metal tubes and pipes. Professional tube nesting software can realize high volume, high efficiency and high quality cutting production of CNC laser tube cutting machine. Intelligent oscillating cutting head can cut bevels less than 45°, which is convenient for pipe splicing and welding, and easy to complete a variety of complex components.

Side-Rail Modular Mechanical Structure

Accommodating Larger Pipes: Large laser cutting machines feature a side-rail design with suspended chucks, allowing for the accommodation of larger pipes. The structure employs a modular design for sectional assembly and installation, making it easy to install and disassemble. This enhances machine stability and efficiency, particularly when processing heavy-duty pipes.

Auxiliary Gas for Heavy-duty Fiber Laser Tube Cutting Machine

When using a fiber laser tube cutting machine, auxiliary gases are required. The choice of auxiliary gases typically includes oxygen, nitrogen, and compressed air:

1. Compressed Air

– Suitable for cutting aluminum plates and galvanized steel plates, reducing oxide films, and saving costs.

– Generally used for thicker plates with less demanding surface cutting requirements.

2. Nitrogen

– As an inert gas, it prevents oxidation of the plate surface during cutting, especially useful for preventing scorching (common in cutting thicker plates).

3. Oxygen

– Primarily functions as an assist gas, accelerating cutting speed and increasing cutting thickness.

– Suitable for cutting thick plates, high-speed cutting, and thin plates, such as large carbon steel plates and thick carbon steel structural components.

While increasing gas pressure can enhance cutting speed, excessively high cutting speeds may lead to decreased efficiency. Therefore, when tuning the machine, attention should be paid to adjusting the gas pressure for optimal cutting performance.

Why Choose DPLASE Heavy Duty Laser Cutting Machine

1. Extensive Adaptability to Various Pipes

The laser tube cutting machine employs the FSCUT3000S system, specifically designed for pipe cutting. It can handle not only large-diameter round and square pipes but also various profiles (such as rectangular pipes, elliptical pipes, channel steel, angle iron, I-beams, slats, profiles, special-shaped pipes, etc.) with high precision and efficiency. This significantly expands the processing range, enhancing the versatility and application value of the equipment.

2. Precision and Efficient Cutting Technology

Addressing the low precision, low efficiency, and poor surface quality issues in traditional heavy-duty pipe cutting, the DP Laser’s ultra three-chuck laser cutting machine is equipped with an advanced chuck alignment system. This design ensures rapid center positioning of the pipe, achieving high precision and stability during cutting, effectively reducing kerf width and burr formation, and guaranteeing workpiece dimensional accuracy. As a result, processing efficiency is greatly improved, and the quality of the final products is enhanced.

3. Lean Production and Cost Optimization

By adopting non-contact laser cutting technology, this machine significantly reduces the heat-affected zone, making it particularly suitable for high-speed cutting of ultra-long and ultra-heavy pipes. Additionally, the three-chuck design enables zero-waste cutting, substantially reducing material wastage. These technological innovations not only shorten the processing cycle but also greatly reduce manual intervention, collectively leading to a significant reduction in overall production costs. Whether for small-batch customization or medium to large-scale production, it demonstrates outstanding cost-effectiveness, creating higher value returns for users.

DP Laser’s heavy three-chuck tube laser cutting machine is capable of efficiently and accurately completing the cutting task of super-heavy pipes through technological innovation. It meets the needs of various complex and demanding industrial applications and successfully solves the problems in the field of heavy pipe processing. The fiber laser cutter achieves all-round optimization from processing capacity, precision and efficiency to cost control, bringing revolutionary improvement to the metal pipe processing industry.