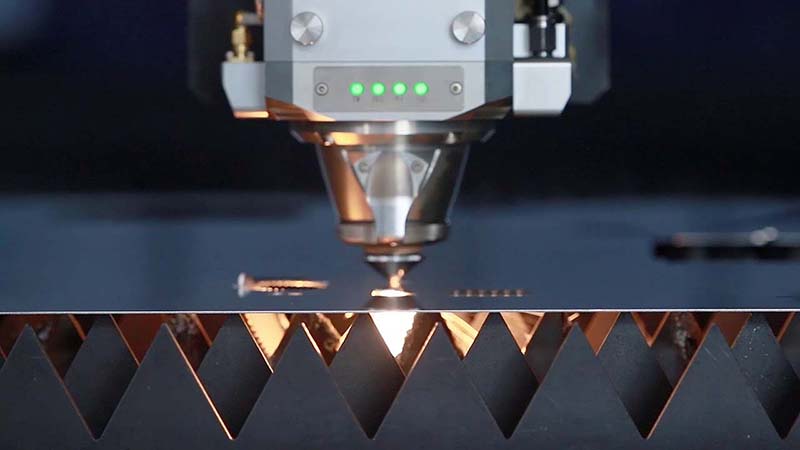

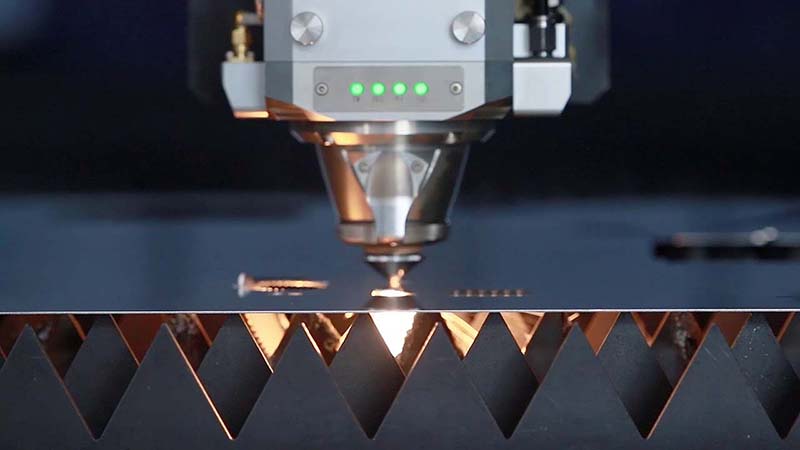

In the metal sheet processing, fiber laser cutting machines have become the mainstream equipment, gradually replacing traditional methods due to their advantages of non-contact cutting, such as high cutting quality, fast speed, and no tool wear. However, fiber laser cutting machines face challenges in processing medium to thick plates. Firstly, thick plates require high power laser cutter, leading to increased costs and initial investment. Secondly, issues in thick plate processing limit the improvement of cutting efficiency. The development and application of fiber lasers have progressed towards higher power, and particularly in the laser cutting field, the use of high-power lasers has become a major trend. What are the advantages of the best high power laser cutting machine?

1. Significant Increase in Maximum Cutting Thickness

The cutting limit of a 12kW fiber laser reaches up to 40mm for stainless steel and 50mm for carbon steel, with excellent cut surface quality. With the introduction of 12kW, 15kW, and 20kW high power laser cutting machine for metal, the maximum cutting thickness continues to be surpassed, thereby reducing the cost of thick plate processing and promoting the application of laser cutting in more thick plate fields. The enhanced cutting capabilities allow for easy handling of various materials, including metal, plastic, and wood, providing a broader range of applications.

2. Improvement in Cutting Speed

When selecting the power of laser cutting equipment, the cutting speed for different materials is a crucial factor. Fiber laser cutting exhibits significant advantages in processing medium and low-thickness plates, with the increase in laser power enabling a substantial boost in cutting speed.

3. Precise and Efficient Cutting Quality

Utilizing high-power laser beams, large-format high-power laser cutting machines achieve high-precision cutting with smooth, burr-free lines. Their high-speed cutting and automated operation enhance production efficiency, reduce labor costs, and meet the demands of modern industrial mass production.

4. Large-Format Cutting Capability

Large-format laser cutting machines possess a wide cutting range, enabling the completion of large-size product cutting tasks and significantly improving work efficiency.

5. Flexible and Diverse Cutting Modes

Large-format laser cutting machines can adjust parameters to achieve different cutting modes, including continuous cutting and pulse cutting. This versatility allows them to adapt to the cutting needs of various materials and thicknesses, offering more flexible and diverse cutting solutions.

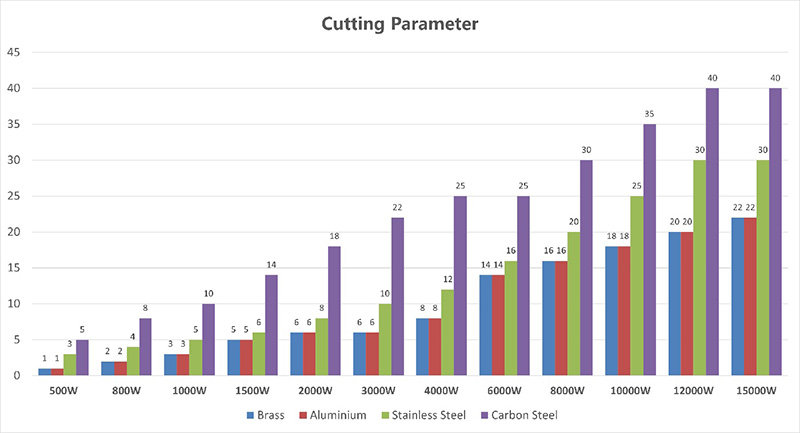

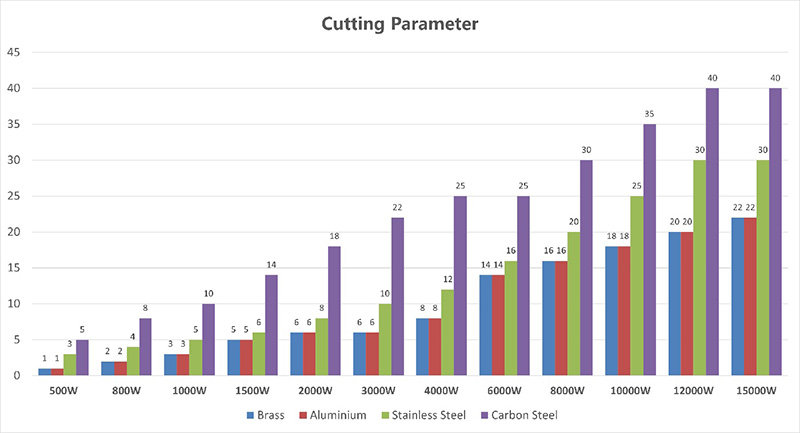

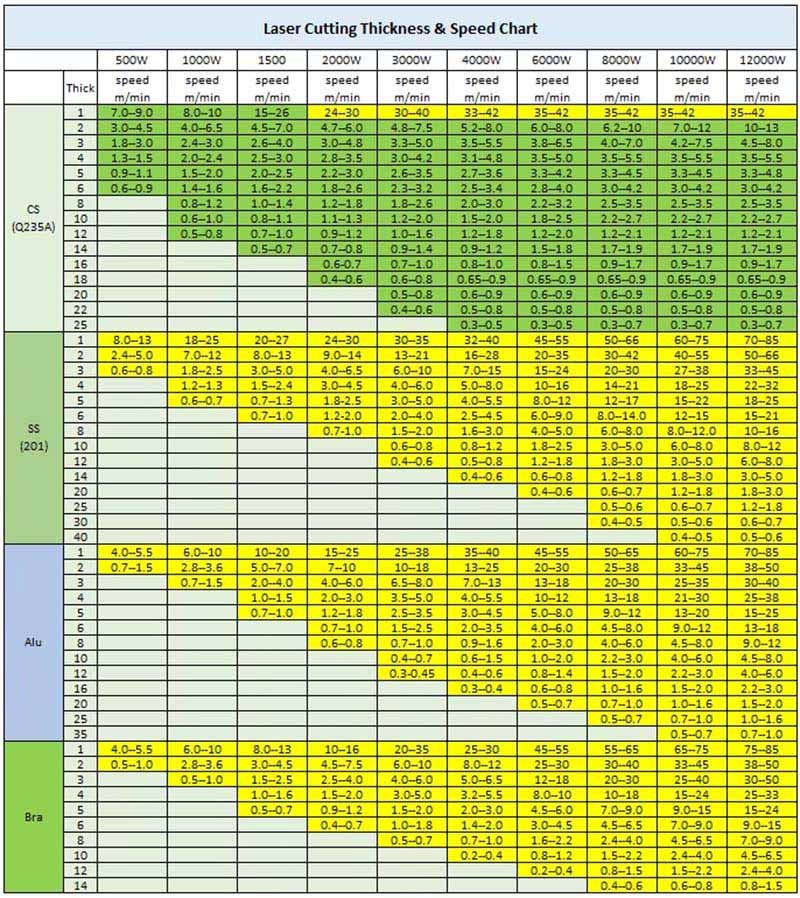

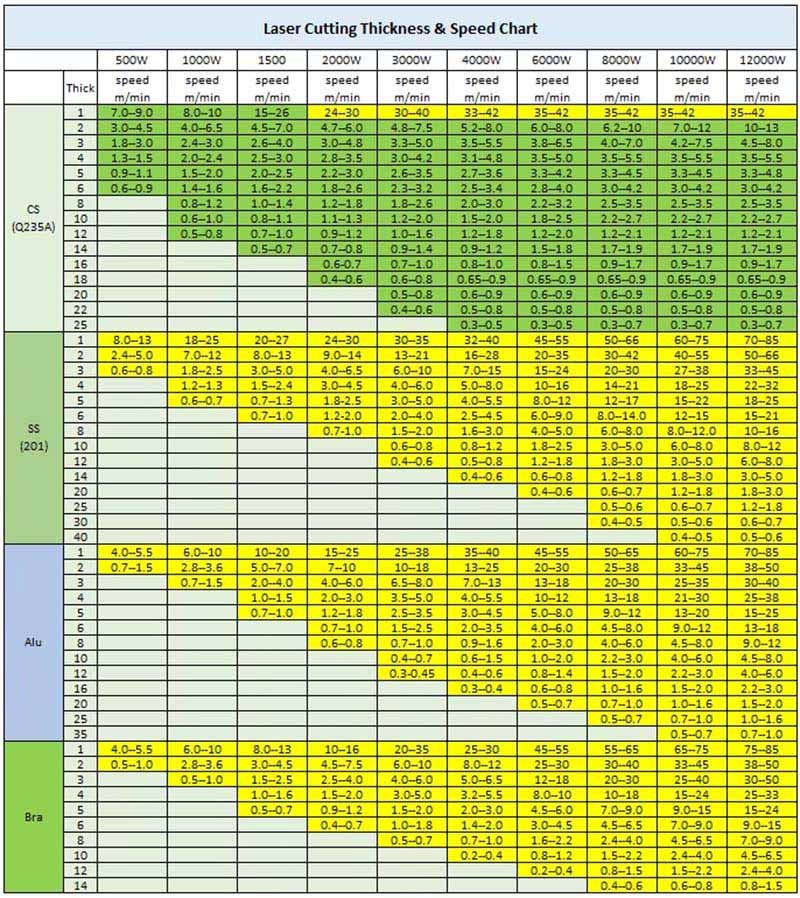

Laser Cutting Power vs Material

The choice of power is also related to the thickness of the material. For the same laser cut material, the thicker the material, the more power is needed to achieve the required depth. Therefore, if you want to strike a balance between power, speed and material, thickness is also an important factor to pay attention to.

These are the ranges of cutting thicknesses for common metal materials at different laser powers. It is important to note that these figures are based on conditions of normal cutting speeds and that the limiting cutting thickness may be slightly increased in specific cases. As you can see from the charts, for fast cutting needs or thick metal cutting, a high power laser cutter is the optimal choice.

Higher power lasers not only complete the cutting task in a shorter time, but also ensure cut quality and edge smoothness. Choosing the right power laser cutting machine not only improves productivity, but also reduces operating costs and maintenance frequency. Therefore, in practical applications, it is crucial to select the appropriate laser cutting power based on specific cutting needs and material characteristics.

High Power Fiber Laser Cutting Machine Application & Benefits

The laser cutting machine is capable of cutting various metal sheets and tubes, primarily used for materials such as stainless steel, carbon steel, manganese steel, galvanized sheets, various alloy plates, and rare metals. It finds wide application across numerous industries, including kitchen appliances, sheet metal cabinets, machinery, electrical equipment, lighting hardware, advertising signage, automotive parts, elevator panel cutting, metal crafts, and various metal products.

1. Kitchen Appliance

The fiber laser cutting machine offers fast cutting speeds and high precision, enhancing processing efficiency and enabling the development of customized and personalized products. It is highly favored by kitchen appliance manufacturers.

2. Automotive Manufacturing

High power laser cutting machine efficiently and accurately cut automotive parts, such as brake pads, enhancing vehicle safety. The process produces burr-free, one-time molded parts, making it an ideal choice for the automotive industry.

3. Fitness Equipment

The laser tube cutting machine is capable of efficiently processing shaped metal tubes of all shapes and sizes, adapting to the complex design needs of fitness equipment and ensuring high precision cuts and quality edges. Its level of flexibility and automation makes it ideal for meeting complex design needs.

4. Sheet Metal Processing

Professional laser cutting machines are highly accurate and efficient in sheet metal processing, and the flexibility of cutting makes it possible to handle materials of complex shapes and thicknesses, which is greatly superior to traditional cutting methods. The advanced CNC control system effectively reduces scrap and improves product quality and productivity.

5. Chassis & Cabinet

For the standardized production of thin sheets used in power distribution cabinets, file cabinets, and other enclosures, laser cutting machines improve production efficiency, making them ideal for the cabinet and enclosure industry.

6. Agricultural Machinery

Laser cutting machines reduce the manufacturing costs of agricultural machinery equipment and enhance economic benefits. They meet the diverse and specialized needs of agricultural machinery products.

7. Shipbuilding

In shipbuilding, CNC laser cutting machines provide high cutting precision, good seam quality, minimal thermal deformation, and eliminate the need for secondary processing. The parts can be directly welded, improving production efficiency.

How to Get Started With Laser Cutting?

High power laser cutting is a complex and precise process. Laser cutting machine manufacturers provide high-quality equipment and technical support to help users achieve efficient, accurate and stable cutting processing.

1. Preparation

Before starting cutting, the operator needs to complete the following preparations:

Check the equipment: make sure that all parts of the laser cutting machine are running normally and free from faults.

Prepare the material: clean and fix the material to be processed, make sure its surface is free of dust and oil.

2. Setting parameters

According to the type and thickness of the material to be processed, as well as the required cutting quality and efficiency, set the cutting parameters, including:

Laser power

Cutting speed

Spot diameter

3. Commissioning equipment

Debug the laser cutting machine to ensure its normal operation, specific operations include:

Adjusting the focus and position of the laser beam

Calibrating the position and trajectory of the cutting head.

The precision and stability of the cut can be improved through accurate commissioning.

4. Start cutting

Place the prepared material on the working table and start the laser cutting machine. The laser beam will cut according to the set parameters and predetermined trajectory, and accurately complete the cutting task.

5. Follow-up processing

After cutting is completed, the operator needs to carry out the following processing:

6. Cleaning of waste and residue

Grind and polish the cut edges: ensure that the cut edges achieve the required surface quality.

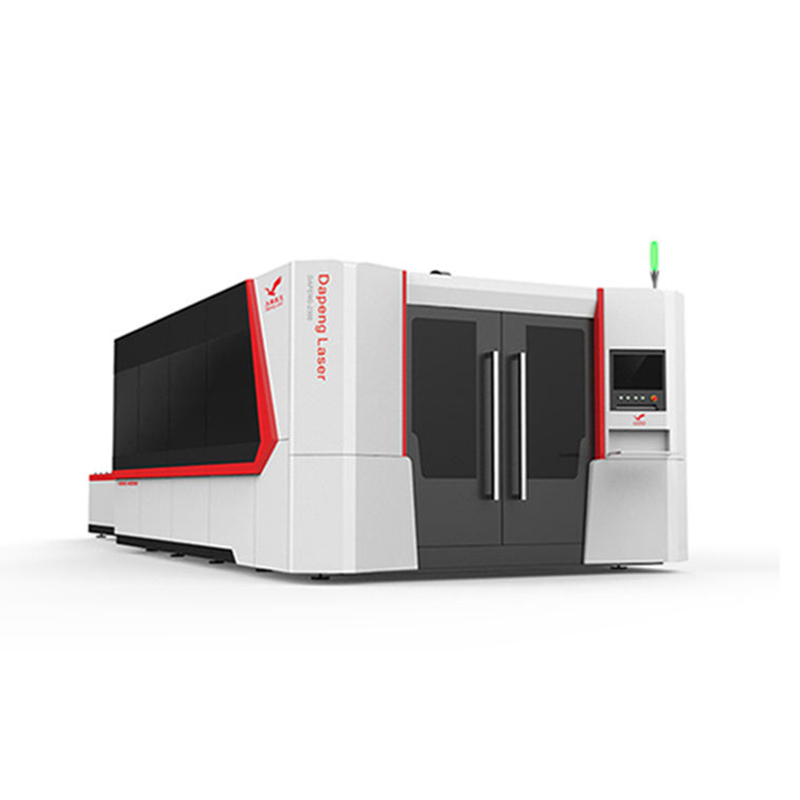

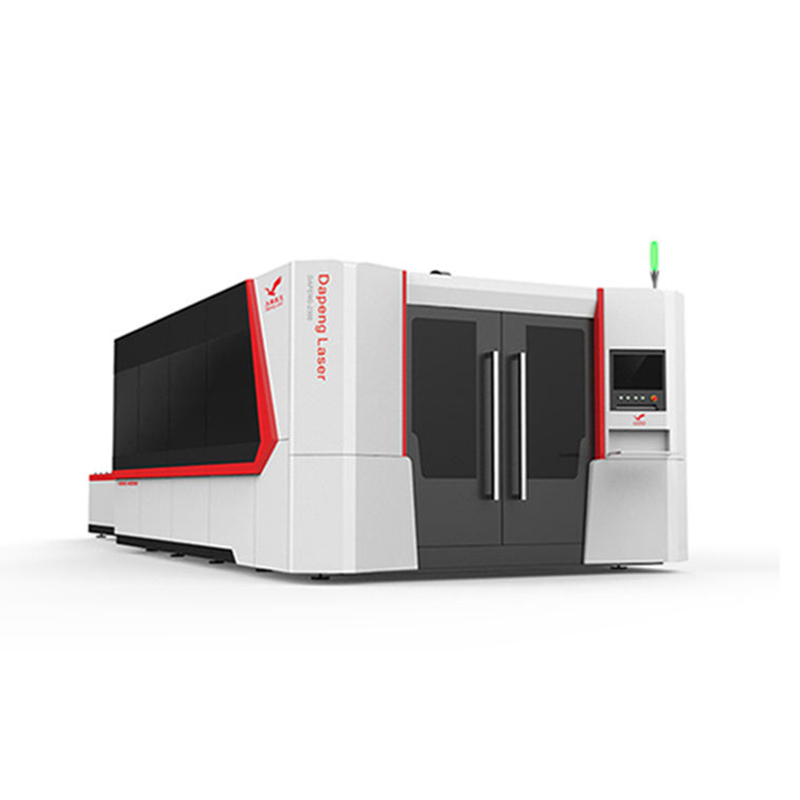

K Series High Power Fiber Laser Cutting Machine

The K Series high-power laser cutting machine is the main laser cutting system of Dapeng Laser, specializing in ten-thousand-watt laser cutting and stable cutting of thick plates, meeting the needs of ultra-high-power cutting.

Features

High Speed and Efficiency: Can cut thin plates at speeds of tens of meters per minute, greatly improving production efficiency.

Excellent Cutting Quality: Ensures high edge quality, minimal deformation, and a smooth, aesthetically pleasing appearance.

High Precision: Equipped with imported guiding transmission systems and servo motors, ensuring high cutting precision.

Strong Flexibility: Allows for the design and immediate cutting of various shapes or text, making operation simple, flexible, and convenient.

The laser cutting machine not only enhances cutting efficiency and quality but also significantly reduces production costs, meeting the high-precision and high-efficiency cutting requirements of various industries.

Advanced Cutting Technology

Ten-kilowatt Level Cutting Expert Process Database: Includes unique process technologies such as zero-second piercing, stable cutting of thick plates, low-pressure cutting, and clean cutting.

High Cutting Precision and Efficiency: Overall performance surpasses other Chinese laser equipment manufacturers.

Integrated Bed Structure

Integrated High-Rigidity Aluminum Beam: Utilizing advanced manufacturing techniques, the structure is fully welded and undergoes annealing and vibration aging treatments to effectively eliminate internal stress. This improves machine stability and prevents thermal deformation under high power. The machine runs at high speeds without deformation and is unaffected by the high heat of the plates. It boasts light weight, good rigidity, high adaptability, and stability.

Dual Motor Parallel Exchange Workbench

Efficient Cutting Workbench: Can be independently or synchronously exchanged to prevent plate wobbling, enabling quick non-stop switching and enhancing processing efficiency.

High-Strength Chain Drag Structure: Enhances the workbench’s load-bearing capacity, making it suitable for high-power thick plate processing.

Automated Loading and Unloading System

Enables automated material switching, improving production efficiency.

How to Choose the High Power Laser Cutting Machine Price?

When considering the purchase of a high-power laser cutting machine, it’s essential to evaluate not only the initial investment but also the long-term value it offers. While price is a crucial factor, it should be weighed against the machine’s capabilities, reliability, and potential return on investment.

High-power laser cutting machines come with varying price points depending on factors such as laser power, cutting bed size, cutting speed, and additional features like automation and software capabilities. Investing in a high-quality machine may initially require a higher upfront cost but can result in lower operating costs, reduced downtime, and higher productivity in the long run.

DPLaser Ultra high power fiber laser cutting machine provides customers with stable cutting of metals in batch by virtue of its excellent characteristics such as stability, precision and speed. Our products can not only meet the stringent requirements for high quality, but also increase the processing efficiency by several times, significantly shorten the product delivery cycle, thus bringing more significant economic benefits.

ultra high power cnc fiber laser cutting machine With more than ten years of experience in laser equipment production and strong resource integration, Dapeng Laser has dozens of branches in China. We can offer you the cheap laser cutting machine price and excellent quality beyond the level of the same industry. Please get a high power laser cutting machine price online now.