CO2 laser cutting machine is an efficient and widely used cutting equipment, suitable for fine processing of various materials. This article will introduce what is co2 laser cutting machine and what can a co2 laser cut, explore its advantages and limitations in depth, and show examples of its application in different industries.

What is a CO2 Laser Cutter?

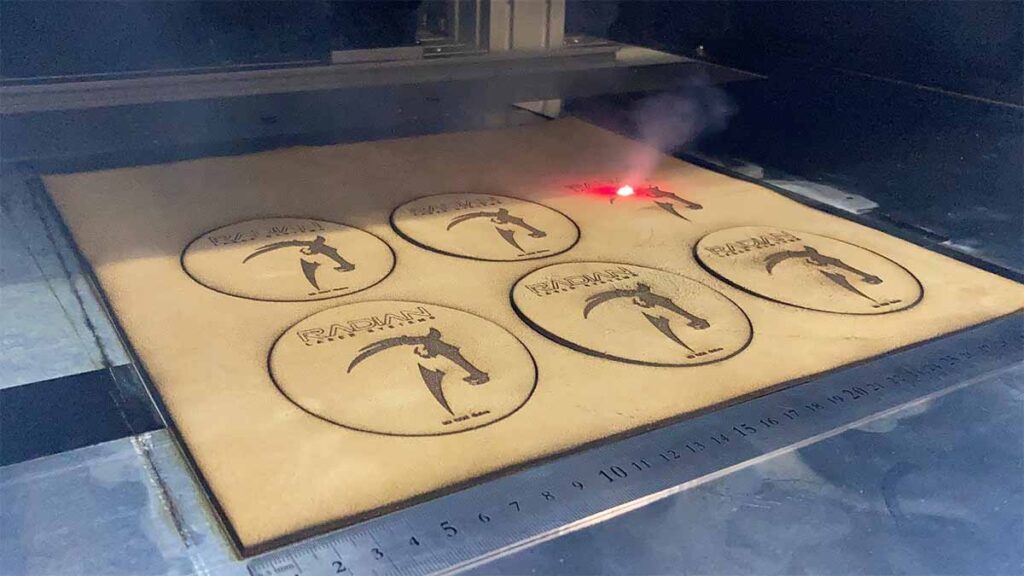

The CO2 laser cutting machine is often referred to as a CO2 laser engraver due to its capability to perform engraving operations. Additionally, some people call it a wood laser cutter or acrylic laser cutter. It is a type of machine that uses a carbon dioxide laser to cut, engrave, or mark various materials. These cutters are commonly used in various industries for manufacturing, prototyping, signage, and art.

How Does CO2 Laser Cutting Work

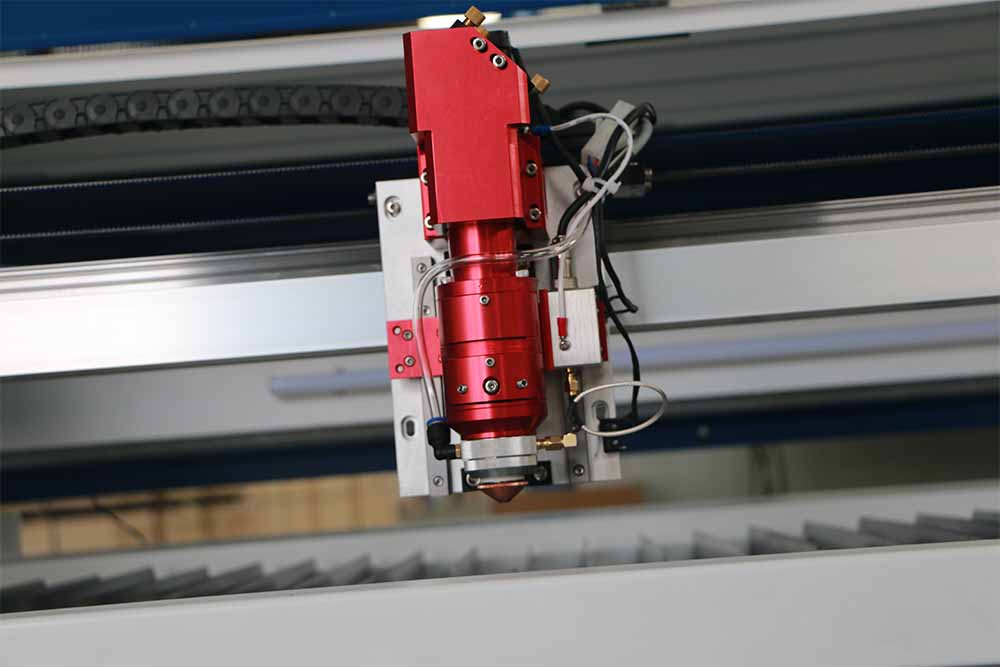

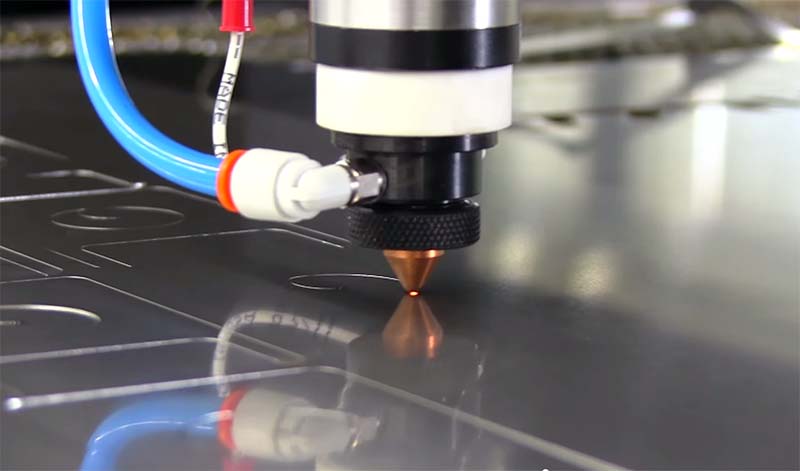

The CO2 laser is a type of gas molecular laser, which generates laser light by utilizing the transitions between vibrational and rotational energy levels of CO2 molecules. A focusing lens concentrates the CO2 laser beam onto the material’s surface, forming an extremely small spot. This spot is then focused at the cutting point, producing a high-temperature, high-energy spot that instantly melts or vaporizes the material. The molten material is blown away by coaxial compressed gas. The laser beam moves along a specific path, creating the cutting shape and achieving precise cutting.

Advantages of co2 Laser Cutting

Fast cutting speed: CO2 laser cutting machines can complete cutting tasks at high speeds, increasing productivity.

High cutting efficiency: The high energy density of the laser allows the material to be quickly cut into precise shapes and sizes, saving time and labor costs.

Small heat-affected zone: The laser cutting process has a small heat-affected zone, reducing the possibility of material deformation.

Narrow kerf: The kerf produced by laser cutting is usually very narrow and highly accurate, making it suitable for applications that require high precision.

Suitable for cutting non-metallic materials: Especially suitable for cutting non-metallic materials such as wood, acrylic, rubber and plastics.

Independent of the shape of the workpiece: The CNC system of the laser cutting machine is able to cut according to the preset path and shape, independent of the shape of the workpiece, with less waste of material on the cutting edge.

No need to make molds: Plastic products can be processed without molds by using CO2 laser cutting systems, thus largely saving production costs and shortening the production cycle.

Saving material and labor: no need to touch the workpiece during the cutting process, reducing material loss and tool wear, saving production costs and manpower.

Limitations of CO2 Laser Cutter

Low photoelectric conversion rate: The energy utilization rate of CO2 laser cutters is relatively low, with some energy being lost as heat.

High energy consumption: A large amount of electrical energy is required during operation, leading to high costs.

High operating costs: This includes equipment maintenance, energy costs, and consumable expenses, resulting in relatively high overall operating costs.

Frequent maintenance of consumables: Consumables such as lenses and gases need to be regularly replaced and maintained, increasing the complexity and cost of operation management.

What Materials Can a CO2 Laser Engrave?

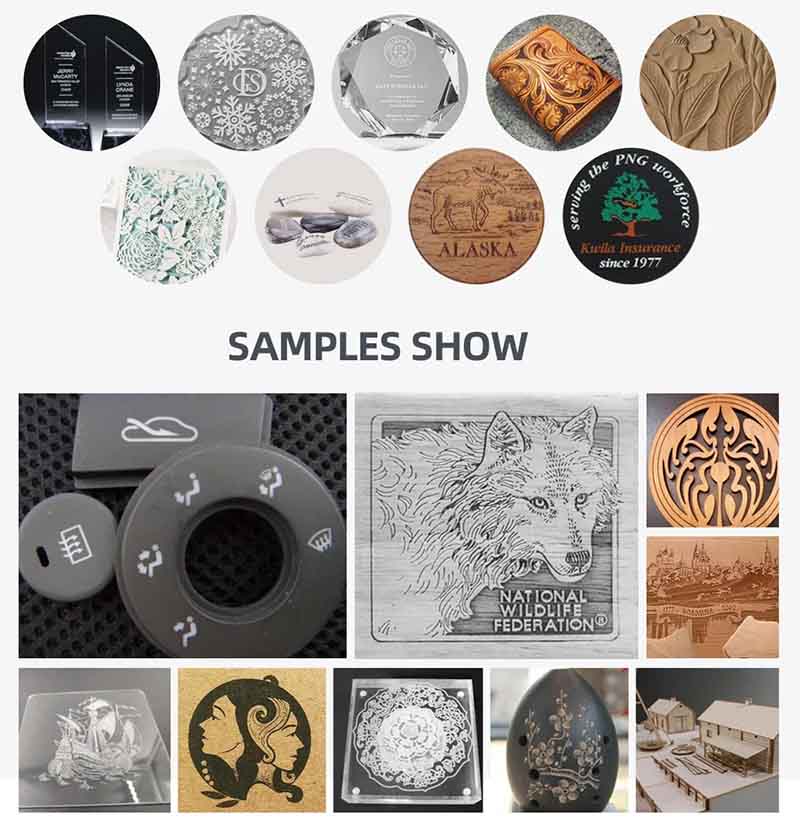

CO2 lasers are less effective at cutting and drilling metal materials, but they can be used for surface treatments such as engraving on metal surfaces.

CO₂ Laser for Metals Engraving

Ferrous Metals: Low carbon steel

Non-ferrous Metals: Aluminum, titanium alloy

Due to its good stability, CO2 laser cutting is particularly advantageous for cutting non-metallic materials. It can cut non-metallic materials such as wood, acrylic, PP, and Plexiglas with high quality.

CO2 lasers can cut and engrave most non-metallic materials, including:

Plastics: acrylic, ABS, PVC, plastic films, etc.

Wood: MDF, plywood, solid wood, etc.

Paper: cardboard, paperboard, thermal paper, etc.

Fabrics: leather, cotton fabric, nylon fabric, etc.

CO2 laser cutters are widely used for various non-metallic materials such as wood, acrylic, paper, fabric, epoxy resin, plastic, rubber, and crystal. They have significant applications in industries such as clothing, leather, fabric toys, computer embroidery cutting, electronics, models, crafts, and advertising. Additionally, they are extensively used in decoration, packaging printing, and paper products industries due to their high precision cutting capabilities and flexible operation characteristics, meeting the demands for design complexity and production efficiency in different industries.

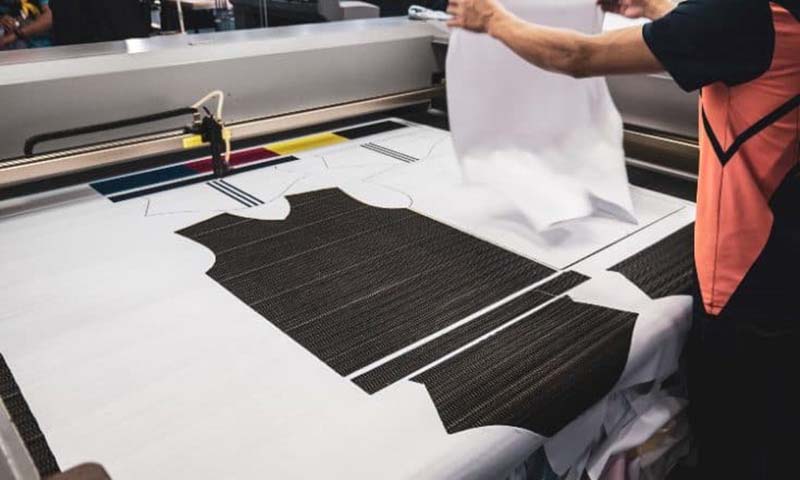

Cutting Textile Fabrics

Flexible fabrics have long been using laser cutting machines to replace traditional manual cutting and other mold cutting methods. The recommended laser power for most types of fabric is 100W. However, for cutting thicker plush, composite fabrics, or leather, a laser tube with 130W or 150W can be used. The shape of the pattern designed on the fabric, the thickness of the material, and the laser power used will affect the cutting speed of the fabric. If you want faster cutting productivity, you can equip the machine with dual laser heads.

You can choose to configure a laser cutting machine with a CCD camera, which has a fast recognition speed and high cutting accuracy. This setup is mainly suitable for mass continuous cutting of small embroidery appliqués, labels, woven labels, and embroidery patches.

Electronics Manufacturing

In the electronics manufacturing field, CO2 lasers are used for cutting printed circuit boards (PCBs) or drilling holes in metal electrodes. Using CO2 laser cutting can significantly improve the processing precision and quality of electronic components.

Product Packaging

In packaging production, laser cutting machines can precisely die-cut boxes and containers. They can also perform laser engraving to achieve complex designs and patterns.

Can CO2 laser cutting machines be used for industrial?

CO2 laser cutting can be applied to sheet cutting, but its performance and precision are generally average, and it has significant limitations on the thickness of the sheets. However, using a high-power CO2 laser cutter can meet the requirements, achieving ideal precision and efficiency when cutting thin sheets.

Can a CO2 Laser Machine Engrave Curved Objects?

Most materials cut with a CO2 laser machine are flat, but this does not mean they must remain flat. By adding a rotary attachment, you can engrave on curved objects. When the rotary attachment is connected to the CO2 laser machine and enabled in the software, it replaces the Y-axis on the gantry, allowing it to rotate instead of moving back and forth. The rotary device opens up new creative possibilities, enabling engraving on items such as glass cups, wine bottles, cans, and spheres.

How to Choose the Right CO2 Laser Cutter?

CO2 lasers have excellent cutting capabilities, able to handle complex designs with very high precision. The power of the laser and the thickness of the material determine the cutting depth, allowing for different degrees of customization in various projects. Choosing the right CO2 laser cutter requires considering the required power, material thickness, and specific project requirements.

Materials and Cutting Range:

Firstly, it is crucial to determine the specific type of material you plan to cut or engrave, such as non-metal materials like plastic, wood, rubber, etc. Additionally, understanding the thickness range of the materials to be processed and the specific size of the workpieces is essential. These factors directly impact the size and specifications of the CO2 laser cutter you ultimately choose. Larger worktables for CO2 CNC laser cutters require special customization. Common worktable sizes include 600*900mm, 1300*900mm, 1400*1200mm, etc., with larger worktable sizes typically correlating to higher prices for CO2 laser cutters.

Laser Power and Speed:

The power of a CO2 laser cutter directly affects its cutting ability and speed. Typically, powers ranging from 40W to around 100W are suitable for cutting and engraving non-metal materials. Higher power levels may result in faster cutting speeds, especially for thicker materials. Choosing the appropriate power based on your production needs is crucial.

Price:

When considering the price of CO2 laser cutting machines, it’s important to take into account the machine’s configuration, quality, and performance. Rather than focusing solely on price, consider the long-term return on investment. Cheaper machines may use inferior components, leading to higher maintenance costs in the future and potentially affecting production efficiency and product quality. When planning to purchase a CO2 laser cutting machine, you might wonder about the price range. Depending on different specifications and configurations, CO2 laser cutting machines can range from $3,000 to $20,000.

Accessories:

Depending on your specific application needs, specific configurations and accessories may be necessary. For instance, if you need to engrave on cylindrical workpieces, a machine equipped with a rotary attachment would be necessary. Additionally, if your work involves cutting fragile materials like glass, having a protective enclosure can ensure operator safety. If the objects you are engraving are small and you need high-speed assembly line, then online flying and conveyor belts may be what you need.

Before purchasing CO2 laser cutting equipment, thoroughly research the manufacturer’s background, including their expertise in CNC laser cutting machine manufacturing, production capacity, delivery capabilities, and after-sales service levels. Clearly defining rights and responsibilities for both parties before signing contracts helps protect everyone’s interests.

Last but not least, you now have a better understanding of CO2 laser cutting machines: from their working principles to what materials can a co2 laser engrave. CO2 laser cutting machines play an important role in modern manufacturing and creative industries thanks to their high precision, efficiency and multi-material suitability. Whether you are a manufacturer, designer or educational institution, a CO2 laser cutting system can open up new production and creative possibilities. For further enquiry or more information, please do not hesitate to contact us and we will be happy to provide you with customized CO2 laser cutting solutions.