In modern manufacturing, laser technology is undoubtedly a shining star, and laser power is one of the keys to its brilliant performance. We will discuss in depth what is laser power and bring you into the wonderful world of laser power. Laser power is the core parameter of laser technology in welding, cutting, engraving and marking applications. By popularizing the concept of laser power, we will reveal how this parameter affects the performance of laser technology and delve into how to set the optimal parameter for laser equipment and applications.

What Does Laser Power Mean?

The energy delivered per unit of time by a fiber laser. The power of a laser cutting machine determines its cutting or engraving speed, as well as its ability to penetrate or heat materials. Laser power is a physical quantity that measures the output energy per unit time, and it shares the same unit of measurement as electrical power, using watts. It is a crucial parameter in laser systems, playing a significant role in determining the cutting, engraving, or marking capabilities.

Other critical parameters of the laser:

Peak Power: This is a specific term for pulsed lasers and an important performance indicator for pulse lasers. It represents the highest power that can be achieved by a single pulse. The unit is watt (W).

Pulse Width: Also known as pulse duration, it refers to the duration of a single pulse. Therefore, it is a unit of time measured in milliseconds (ms), microseconds (us), nanoseconds (ns), picoseconds (ps), femtoseconds (fs), etc.

Max Pulse Energy: Refers to the laser energy carried by a single pulse and is the product of peak power and pulse width. The unit is joule (J). For example, if the peak power is 10 kilowatts and the pulse width is 100 nanoseconds, the pulse energy E = peak power * pulse width.

Pulse Repetition Rate: Equivalent to the number of pulses repeated within one second, measured in hertz (Hz).

Average power: It is the laser energy output per unit time in one repetition cycle, unit is Watt (W). Output power = pulse repetition frequency * pulse energy.

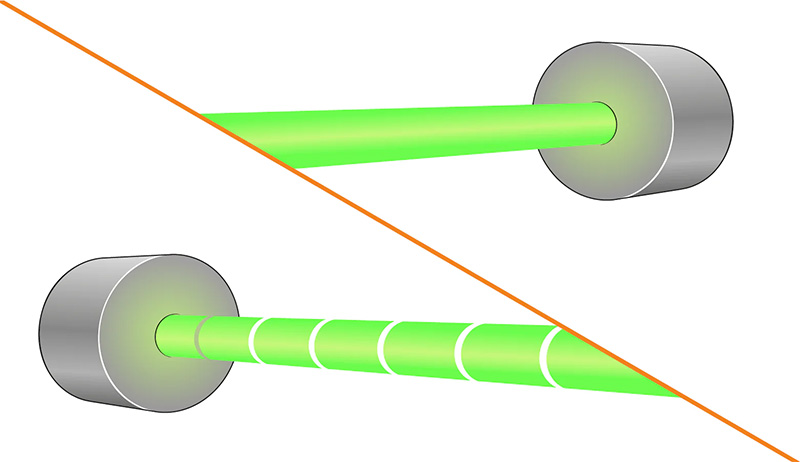

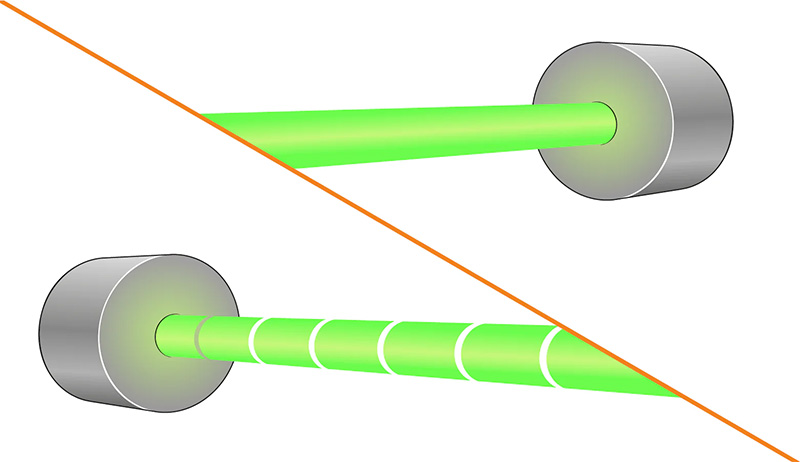

Continuous Wave Lasers vs. Pulsed Lasers

Pulsed lasers release energy in pulses, with a short pause between each release of energy to allow energy to build up before the next pulse is fired. This allows pulsed lasers to reach higher peaks of energy. It is characterized by high peak power, short pulse width and high frequency repetition. It is used for laser cleaning, material cutting, marking and microfabrication.

Continuous lasers output the laser beam in a continuous stream rather than by pulsing. The energy of the laser beam is continuously and steadily output. Used for laser descaling, metal cutting, laser welding, etc.

Laser Pulse Duty Cycle: The percentage of time that a pulsed laser is continuously on in a cycle is directly proportional to the laser power. When the duty cycle is 100%, i.e. fully open in one cycle, it is a continuous laser.

How to set the parameters for laser welding, cutting, engraving and marking?

Laser engraving, marking, cutting and welding applications have their own unique requirements for laser power, pulse frequency, pulse width and pulse repetition frequency. An in-depth understanding of laser power will help you more quickly configure the parameters of your laser equipment to achieve optimal processing results. This understanding laser power not only improves productivity, but also ensures excellent results in a variety of application scenarios.

1. Laser Welding:

– Laser Power: Depends on the material type and thickness to be welded, typically requiring higher power.

– Pulse Frequency: Higher pulse frequencies can be employed for finer welding.

– Pulse Width: Adjustable to accommodate different welding requirements, with shorter pulse widths often used for precision welding.

– Pulse Repetition Rate: Choose an appropriate pulse repetition rate based on the welding process to balance speed and quality.

2. Laser Cutting:

– Laser Power: Cutting requires higher power to ensure sufficient energy penetration through the material.

– Pulse Frequency: Typically uses lower pulse frequencies to provide enough energy for cutting materials.

– Pulse Width: Moderate pulse widths contribute to better cutting quality.

– Pulse Repetition Rate: Depends on the specific application, and an appropriate pulse repetition rate can be selected as needed.

3. Laser Engraving:

– Laser Power: Typically employs medium to low power, adjusted based on engraving depth and speed.

– Pulse Frequency: Moderate pulse frequencies yield good engraving results.

– Pulse Width: Uses shorter pulse widths for fine control and clear engraving lines.

– Pulse Repetition Rate: Higher pulse repetition rates can enhance processing speed, but adjustments should be made according to the specific application.

4. Laser Marking:

– Laser Power: Generally uses medium power, depending on the desired marking depth and material type.

– Pulse Frequency: Higher pulse frequencies are utilized for clear and intricate marking.

– Pulse Width: Typically employs shorter pulse widths for detailed marking.

– Pulse Repetition Rate: Can be moderately increased to improve production efficiency, but attention should be paid to quality and clarity.

How to Select the Right Power for Laser Cutting?

In laser cutting, the output power directly influences the energy density of the laser beam, thereby affecting the material’s melting and cutting quality. To achieve better cutting results, it is necessary to increase the output power to enhance processing capability. We can assess the appropriateness of laser power by examining the smoothness of the cut section of the workpiece and observing the spark conditions during cutting.

Smoothness of the Cut Section

Surface Smoothness: Appropriate power should result in a smooth and even cut section, rather than rough or uneven cutting. Observing a smooth and delicate surface on the cut section indicates that the power may be suitable.

Kerf Width: Adequate power should produce a kerf width in line with design requirements. If the cut is too wide or too narrow, it may be a sign of improper power settings.

When the laser power is too high, the upper and lower wave patterns during cutting appear linear, and the spacing between the waves increases. When the laser power is too low, the lower part of the cutting surface becomes very rough.

Spark Conditions during Cutting

Straight-Line Sparks: Under normal circumstances, appropriate laser power should result in sparks aligning in a straight line along the cutting direction.

Spark Diffusion: If sparks exhibit a diffused pattern, it may indicate that the laser power is set too low, leading to poor cutting quality. Insufficient power may prevent the metal from melting adequately, resulting in unstable sparks.

Sparks Ahead of the Cutting Direction: If sparks appear ahead of the cutting direction, it may indicate that the power is set too high. High power can cause excessive melting of the metal in the cutting area, leading to splattering and unstable sparks.

Laser Power for Metal Cutting

Selecting the appropriate laser cutting power requires several proofs and parameter adjustments to find the most suitable cutting parameters. This process involves continuously optimizing the laser power to meet specific material and cutting requirements. Through proofing, we are able to observe and evaluate the smoothness of the cut section, the width of the kerf and the state of the sparks, so that we can make precise power adjustments.

Many customers opt for laser cutting equipment with 10~30kW lasers due to large processing volumes. This choice is driven by the high power ability to balance cutting speed and section quality for thin, medium, and thick plates. It can significantly enhancing the processing efficiency of the factory, reduces operating costs and accelerates the return on investment. To meet diverse customer requirements for cutting thickness, speed, and processing efficiency, the selection of laser cutter power must be made while considering the practical processing needs of routine production, especially when dealing with significant quantities of plate cutting and varying thicknesses.

The choice of laser cutting machine power is determined by the workpiece. The best approach is to conduct sample production, allowing us to assist you in selecting the most suitable fiber laser cutting machine. It’s essential to note that higher output power doesn’t necessarily equate to better results.

How laser power is affected laser cutting?

It is affected by the material: Carbon steel with a thickness of 25mm can be easily cut with a 3KW laser, but for aluminum, it has limited cutting power, limited to 8mm thickness. To cut the same thickness of aluminum (25mm), you would need to increase the power of the laser to 8KW. This is because different materials require different levels of laser power, and thicker or denser materials usually require higher power lasers to cut effectively.

Theoretically, the power of the laser is a factor proportional to the thickness and density of the material being cut, so the choice of power is based on the material. If the material is thicker, or the density is higher, you need to use high power for cutting. Even if the material is relatively thin, the effect of long focal length cutting is not good, so if you want to make a good cutting effect, you must choose a reasonable power and focal length to be able to.

Brief summary:

- Higher power results in greater cutting and engraving depth. It also increases processing speed for the same workpiece.

- Higher power can be adjusted to lower power usage, but the reverse is not possible.

Laser power and speed are two key factors in the laser cutting. The laser power determines whether or not the material can be melted or vaporized efficiently, resulting in a clear, precise cut.

Higher power helps to handle thicker materials, while lower power may not achieve the desired cut. However, too much power may result in too much energy input, triggering material overheating and deformation problems.

Therefore, a balance needs to be struck between laser power and speed to achieve optimal cutting results. Efficient laser cutting can be achieved by considering power and speed together and selecting the appropriate parameters for the specific application requirements.

Last but not least, laser power is the engine that drives the superior performance of laser equipment, covering a wide range of critical applications from welding to cutting to engraving to marking. In the future, as technology continues to advance, we look forward to more innovations and technological breakthroughs that will open a new chapter in the development of laser technology. We hope that our sharing can provide useful guidance for your exploration path in the field of laser technology. If you have any questions about laser power definition and meaning or other related topics, please feel free to interact with us.