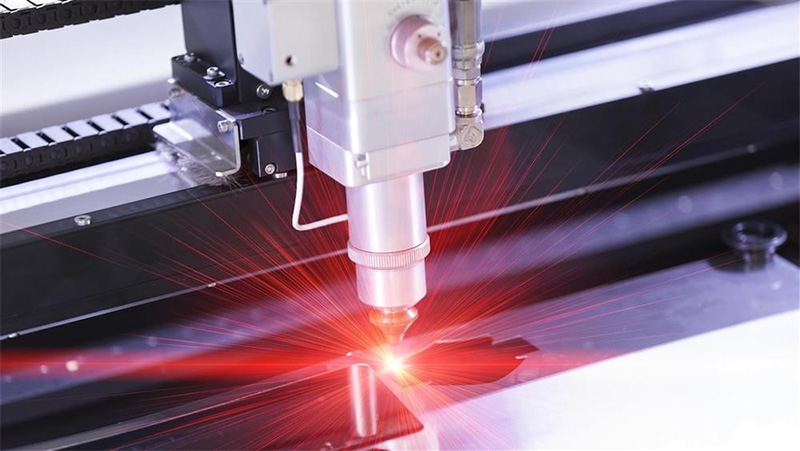

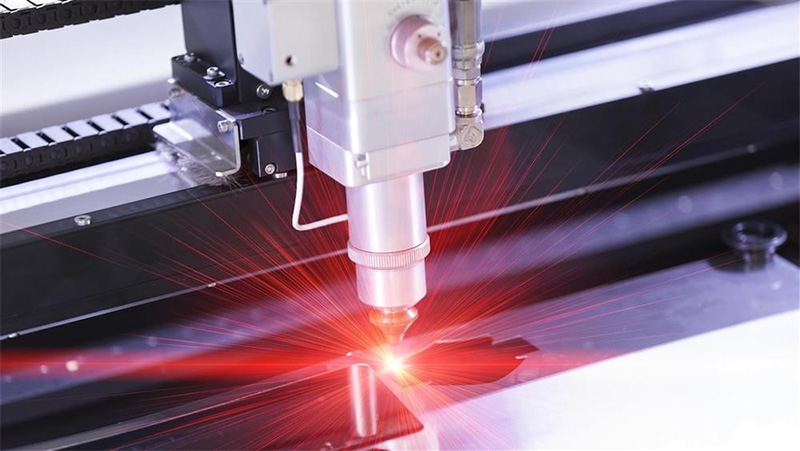

Currently, the manufacturing industry is rapidly growing, and industrial fiber laser cutting machines are standing out as a powerful tool in technological advancements, serving various sectors. This article explores the laser cutting industrial applications such as mechanical manufacturing, advertising, kitchenware production, PCB fabrication, and construction. We will discuss why laser cutting technology excels in high-precision cutting and forming. This technology not only enhances efficiency and accuracy in manufacturing but also shapes a new era in manufacturing processes across different industries.

What Industries Use Laser Cutting?

Mechanical Manufacturing – Laser Precision Cutting for Parts

In the realm of mechanical manufacturing, the production of precise components like shafts, gears, and molds is essential. Industrial metal laser cutting machines excel in precisely cutting these parts, enhancing manufacturing precision and quality. Simultaneously, the swift processing speed of laser cutting machines significantly reduces production cycles, elevating overall production efficiency.

Agricultural Machinery Manufacturing

With its exceptional speed, precision, and adaptable customization capabilities, laser cutting machines play a transformative role in agricultural machinery manufacturing. They not only enhance production efficiency and decrease manufacturing costs but also drive technological innovation in this sector.

Agricultural machinery often involves metal components, and conventional cutting methods often rely on intricate molds, leading to increased manufacturing expenses. Laser cutting machines, through high-precision cutting, swiftly adapt to diverse design requirements, boosting productivity and reducing the need for molds, thereby lowering overall manufacturing costs.

The flexibility of CNC industrial laser cutting machines allows them to handle a broad spectrum of agricultural machinery components, including knives, brackets, and connectors. This flexibility extends to managing complex structures, while the precision of laser cutting improves part quality and assembly accuracy, ultimately enhancing the longevity and reliability of agricultural machinery.

Laser cutting technology is gradually supplanting traditional mechanical knife cutting methods. While traditional cutting machines are efficient for thinner materials, they face challenges with thicker or harder materials, leading to reduced efficiency and increased time and effort requirements. CNC fiber laser cutting machine utilizing an invisible beam of light, offers high precision, rapid cutting, pattern flexibility, automatic nesting, material conservation, smooth cutting, and cost-effectiveness. This shift positions laser cutting as the evolving trend for improving or replacing traditional metal cutting tools.

Perforation and Engraving

Mechanical manufacturing requires perforating and engraving sheet metal to meet the needs of different customers. Laser cutting machine can complete these jobs quickly and accurately, and improve the manufacturing precision and quality. At the same time, the non-contact processing method of laser cutting machine can effectively avoid the problems brought by the traditional processing method, such as tool wear and thermal deformation.

PCB Industry

In the PCB industry, the wide application of laser cutting machines significantly improves production efficiency, reduces scrap and labor costs, and at the same time realizes high-precision cutting and reduces the adverse effects on the environment and products.

Specific applications of laser cutting machines in PCB manufacturing

- Circuit board cutting: Utilizing the high energy and high precision of the laser, the circuit board is finely cut to ensure that the cutting edges are neat and the accuracy of the line is maintained.

- Metal Hole Cutting: For PCBs that need to be drilled, laser cutting can be done quickly and accurately without causing damage to the surrounding area.

- Shaped structure cutting: Laser cutting machine can easily cope with a variety of complex shapes cutting needs, to meet the personalized needs of different products.

The successful laser cutting industrial applications in PCB manufacturing has injected new momentum into the industry, promoting the modernization and intelligence of the manufacturing process. Its high efficiency, precision and environmentally friendly features make it an important tool for PCB manufacturing, pushing the industrial manufacturing to a higher level.

Advertising Production

In the dynamic realm of advertising production, the demand for processing both metal and non-metal materials is pervasive. The laser cutting system has emerged as an indispensable tool, showcasing remarkable versatility across various industries. The introduction of laser cutting machines marks a substantial leap forward for the advertising industry, surpassing the capabilities of traditional processing equipment.

Traditional CNC billboard cutting machines often grapple with challenges in achieving optimal processing precision and cutting surfaces, particularly when handling materials like advertising fonts. This dilemma results in high rework rates and cost inefficiencies, significantly hampering overall work efficiency. The introduction of fiber laser cutters effectively mitigates these challenges. Leveraging high-precision laser cutting technology, coupled with pure auxiliary gas processing, the cutting surface achieves a flawless finish, markedly reducing rework probabilities, cutting production costs, and elevating work efficiency.

Moreover, laser cutting machines demonstrate proficiency in handling intricate graphics, transcending the constraints of traditional technology. This opens avenues for advertising companies to diversify their product offerings, cater to a broader spectrum of client demands, and thereby bolster their market competitiveness. For small-scale enterprises, the industrial application of laser cutting not only enhances production efficiency but also generates additional profit margins.

Kitchenware Manufacturing

Laser cutting technology plays a pivotal role in revolutionizing kitchenware manufacturing. Traditional methods grapple with inefficiencies, substantial mold consumption, and increased costs, particularly when working with sheet metal panels for items like range hoods and gas appliances, impeding the introduction of innovative products. Laser cutting machines, through high-speed and high-precision cutting of panels, significantly amplify production efficiency and product yield. The adaptability of laser cutting machines to irregular shapes further enhances their utility.

In comparison to traditional manual or electric shearing machines, laser cutting machines not only surmount issues of slow speed and complex structural but also comprehensively enhance efficiency and material utilization. With a straightforward operation, users can input graphics and dimensions into the computer, facilitating rapid and precise cutting of the entire material. The non-contact processing feature of laser cutting eliminates the need for tools or molds, streamlining the manufacturing process for enhanced convenience and swifter results.

Cabinet Manufacturing Industry

In the traditional metal cabinet manufacturing process, the use of conventional machining methods, such as mechanical cutting or stamping, is usually limited by high tooling costs and low efficiency. This constraint limits the production of metal cabinets for complex designs and high precision requirements. However, laser cutting machine technology brings a new solution to metal cabinet manufacturing through its high-speed, high-precision features and flexible, customized production processing.

Distribution boxes and computer enclosures are often made of metal materials that require precise cutting and intricate designs, which is exactly what laser cutting machines specialize in. Laser cutting machines easily create clean, straight and perfectly round holes that are difficult to achieve with other methods. Their high-precision cutting ensures the accuracy of metal casework components, which improves the overall product assembly quality. At the same time, the flexibility of laser cutting machines allows manufacturers to highly customize production to fit the needs of metal cabinets of different shapes and sizes based on design requirements.

The fast processing speeds and automation features of laser cutting machines help increase the productivity of metal cabinets. This is a critical advantage for situations that require mass production or a quick response to market demand. In addition, the industrial applications of laser cutting can also reduce production costs, reduce scrap generation and improve material utilization.

Construction industry

Sheet and tube laser cutting machine have been widely used in many areas of the construction industry. Among them, the laser cutting machine is especially widely used in steel structure manufacturing. Its ability to cut thick metal plates and tube perforation quickly and accurately makes it ideal for use in all types of construction projects.

Metal laser cutting machines can be used to cut thick metal plates and pipes, making them ideal for construction machinery manufacturing. In addition, laser cutters can be used to efficiently weld metal parts together to ensure they are strong and durable. In the construction industry, the application of laser cutting technology provides efficient and precise solutions for projects, driving technological innovation and productivity improvements in the construction sector.

Lighting Fixtures

As people’s lighting product design and quality continue to improve, traditional processing methods appear inefficient when dealing with complex designs and high precision requirements. Laser cutting machine with its high-speed, high-precision features and flexible customized production processing, for lighting fixtures and lanterns manufacturing has brought a new solution.

In the manufacturing of lighting fixtures, the shells and structures of various lamps and lanterns are usually made of metal or non-metallic materials, and traditional processing methods are often constrained by high mold costs and low efficiency. In contrast, laser cutting machine technology through high-precision laser cutting, not only can quickly adapt to a variety of design and material cutting needs, but also improve production efficiency and reduce production costs.

Compared with the traditional process, the laser cutting machine has a more flexible processing capability, able to deal with a variety of complex shapes and details, for the lamps and lanterns design to bring more possibilities. Its non-contact processing method avoids physical contact damage to the material, ensuring the quality and precision of the finished product. This feature is especially important for some lighting products with special designs and delicate structures.

Jewelry Design

In the jewelry industry, laser cutting is commonly used to create fine patterns and designs on metals and to cut gemstones. It can also be used to engrave text or images on jewelry. Traditional manual or mechanical cutting methods may face lack of precision and inefficiency. Laser cutting machine technology, on the other hand, with its very small cutting widths and high degree of customizability, provides manufacturers with more design freedom, enabling them to create more elaborate and unique jewelry designs.

Laser cutting has several advantages over other metal cutting methods, including:

- Fast cutting speed, good cutting quality and high precision.

- Narrow cutting slit, smooth cutting surface, will not damage the workpiece.

- Small cutting heat-affected zone, small sheet deformation, narrow kerf (0.1mm~0.3mm).

- No mechanical stress in the cut, no shear burr.

- In addition to processing metal materials, it can also cut non-metallic materials.

- Save investment in molds, save material and save cost more effectively.

- Simple operation, safety, stable performance, improve the speed of new product development, with a wide range of adaptability and flexibility.

2023 Best Fiber Laser Cutters

DPLASER F3015 series sheet metal laser cutting machine is an advanced product in metal cutting field, known for its high precision and high efficiency cutting ability. It is suitable for a wide range of metals, including carbon steel, stainless steel and aluminum. This series of cutting machines not only focuses on precision, but also excels in high efficiency, making it suitable for mass production. The innovative CNC system allows it to handle complex shapes and structures, providing users with more design freedom.

Metal Laser Cutting Machines for Industrial Manufacturing

High Precision

The F3015 fiber laser cutting machine is renowned for its exceptional precision, capable of achieving cuts down to the millimeter. This ensures the production of components meeting the most stringent standards, crucial for precision-demanding industries like metal working and automotive manufacturing.

High Efficiency

This laser cutting system series excels not only in precision but also in efficiency. Its advanced cutting technology and intelligent control system enable faster cutting, significantly boosting overall production efficiency. For enterprises focusing on large-scale production and rapid delivery, the F series laser cutter is an indispensable production tool.

Material Versatility

The F series fiber laser cutting machine effortlessly handles cutting requirements for various metals, including steel, stainless steel, and aluminum. Its material versatility makes it an ideal choice for diverse projects and industry needs, providing users with enhanced flexibility and production diversity.

Final Word:

Laser cutting machines showcase versatility and innovation across various industries such as machinery manufacturing, advertising, kitchenware production, electronic PCB, case manufacturing, lighting fixtures, and jewelry design. The F series laser cutting machine, known for its high precision, efficiency, and compatibility with diverse materials, offers revolutionary production solutions. Its successful implementation in precision-demanding fields like machinery parts and automobile manufacturing underscores the significant potential of industrial laser applications in advancing industrial processes. As technology continues to evolve, industrial laser cutting machine is poised to lead innovation and development in the manufacturing industry.