Laser welding technology has brought about a transformative impact on the manufacturing industry, introducing unparalleled precision and efficiency in material welding processes. The ability to create strong and seamless welds with exceptional accuracy has revolutionized the way products are made. In this article, we will delve into the various factors that influence the CNC laser welding machine price. By gaining a comprehensive understanding of these factors, individuals and businesses can make informed decisions when investing in a laser welder, ensuring optimal results and cost-effectiveness in their manufacturing operations.

How Much is a small laser welding machine price?

The answer to the question of what is the price of a laser welding machine can vary greatly depending on a number of factors, including the type of laser source, power output, configuration parameters and additional features.

1. Laser Source Type: Different types of lasers, such as fiber lasers, CO2 lasers, or solid-state lasers, have different price ranges based on their technology and capabilities.

2. Power Output: The power output of a laser welding machine affects its price. Higher power lasers generally come with a higher price tag due to their increased performance and versatility.

3. Configuration Parameters: The specific configuration parameters of the laser welding machine, such as beam quality, pulse duration, and spot size, can influence the cost.

4. Additional Features: Some laser welding machines come with advanced features and capabilities, such as integrated robotics, automated systems, or specialized control software. These additional features can impact the overall cost.

5. Brand and Supplier: The reputation, brand value, and service support of the manufacturer or supplier can influence the price of the laser welding machine.

Before choosing a laser welding machine, it is recommended to consult with laser equipment suppliers, compare different models, and evaluate the specific requirements of your application to get an accurate price quote for a laser welding machine.

What is Laser Welding Machine?

Laser welding machine is a type of equipment that utilizes laser technology to join or weld materials together. It employs a high-energy laser beam to melt and fuse the workpieces, creating a strong and precise weld seam. Laser welding machines offer several advantages over traditional welding methods, such as arc welding or gas welding.

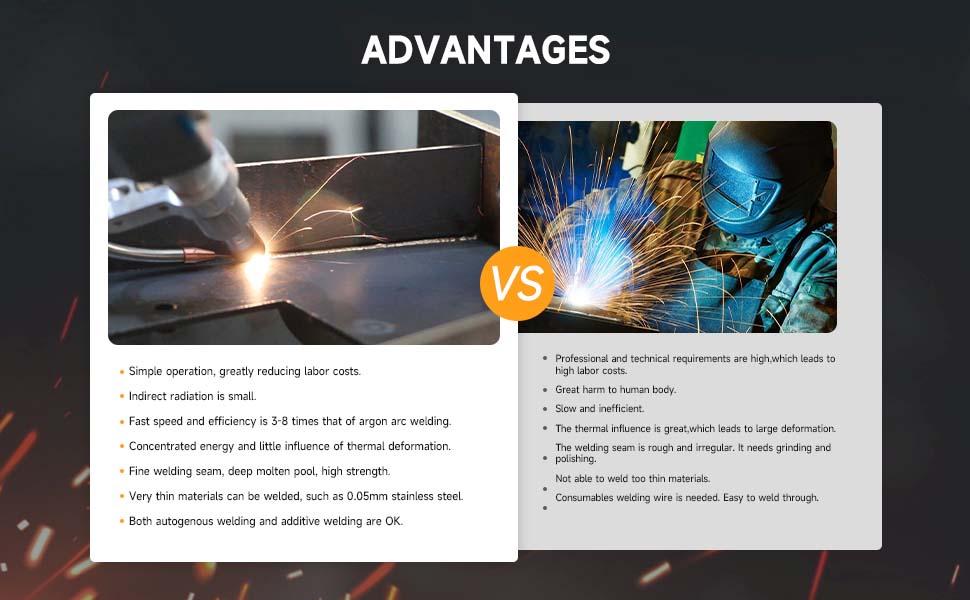

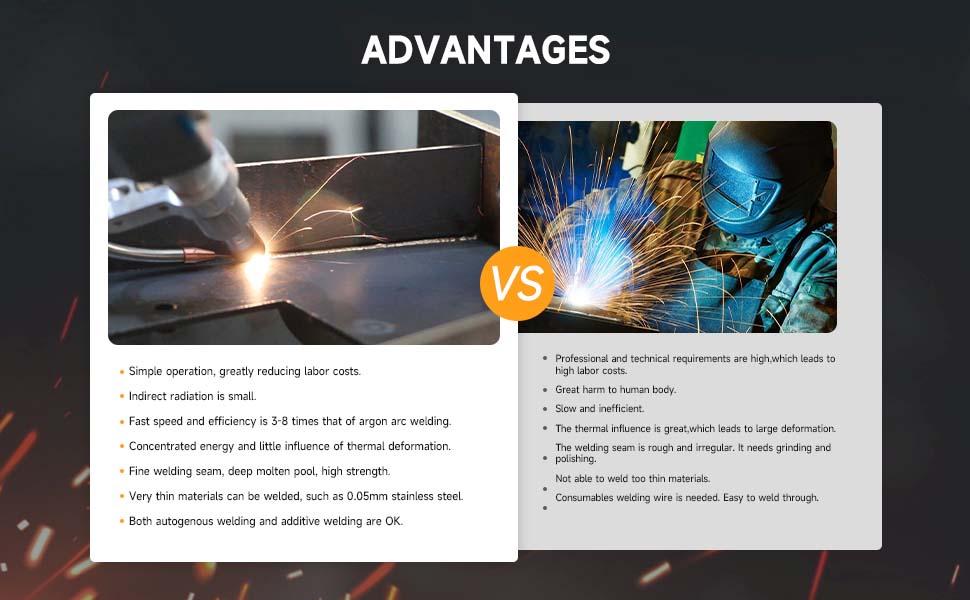

What are the Benefits of Laser Welding Machines vs. Traditional Welding Methods?

1. High precision and accuracy

Laser welding utilizes a high energy laser beam for welding and can provide very fine control of the weld. The focus of the laser beam can be very small, resulting in highly precise welding operations. This makes laser welding suitable for applications that require high precision welding, especially micro fine welding such as electronic components, automotive aerospace parts, jewelry, etc…

2. Small heat affected area

The heat generated by laser welding is highly concentrated and affects only a small area around the weld area, thus reducing the thermal impact on the work piece. In contrast, conventional welding methods typically require higher welding temperatures and longer welding times, resulting in larger heat affected areas that can cause distortion and material damage.

3. Fast welding speed:

Laser welding has a fast welding speed and can complete the welding task in a short time. The high energy density of the laser beam allows the material to melt and solidify quickly, thus increasing productivity and making it especially suitable for mass welding and automated production lines.

4. High-intensity welding

Laser welding provides a high-energy heat source that enables a high temperature and cooling rate in the weld area, resulting in a high-intensity welded joint. The melting and solidification process in the weld area is very fast, resulting in a fine grain weld, which enhances the strength and durability of the welded joint.

5. Suitable for a wide range of materials

Laser welding is suitable for welding a wide range of materials, both metallic and non-metallic. It can weld thin plates, pipes, complex shaped workpieces, etc. Whereas traditional welding methods may have limitations for certain materials, such as challenges for welding heat sensitive materials or highly reflective materials.

6. Contactless welding

Laser welding is a non-contact welding method where the laser beam acts directly on the surface of the work piece without contact, thus avoiding contamination, wear or heat transfer problems caused by contact. This is important for the welding of certain special materials and precision components.

What is the Difference between an Expensive and a Cheap Laser Machine?

“What is the difference between an expensive laser machine and a cheap laser machine?”

Laser welding machines have been widely used in the manufacturing industry for their high welding efficiency, quality, speed and ease of operation. Laser welding machines are available in various types by configuration parameters, ranging from $500 to $20,000. The price is hundreds of times higher than that of TIG welding equipment. Such a disparity is really unacceptable. Why laser welding machine prices so high?

The main reasons for an expensive laser machine and cheapest laser welding machine is the configuration of the machine, the functional accuracy and the power level. Expensive laser machines usually have higher precision and more powerful laser beams, which allow them to weld materials with greater precision and speed. They also typically have more advanced features and functions, such as the ability to handle a wider range of materials or a broader range of manufacturing applications.

On the other hand, inexpensive laser machines may not offer the same level of accuracy, but for general manufacturing without too high welding requirements, it is sufficient.

Laser Welding Applications

Laser welding technology is versatile and adaptable. This makes it effective in many industries, enabling high-quality welding of small and large parts.

| New energy vehicles | Battery cells and modules, body, motors, frame, transmission system |

| Aircraft | Turbine blades, frames, fuselage sections |

| Electronics | Printed circuit boards, batteries and modules, housings, lugs, etc. |

| Medical | Medical instruments, devices and implants |

| Construction | Metal sheets, pipes |

| Kitchen Utensils | water pipe fittings, water tanks, reducer fittings, tees, valves, nozzles |

| Lithium Battery | Lithium battery case, battery pack, electrode |

| Decoration | Stainless steel, titanium, glass doors and windows, billboards |

| Hardware Industry | Welding of complex stampings and castings, such as impellers, kettles, handles |

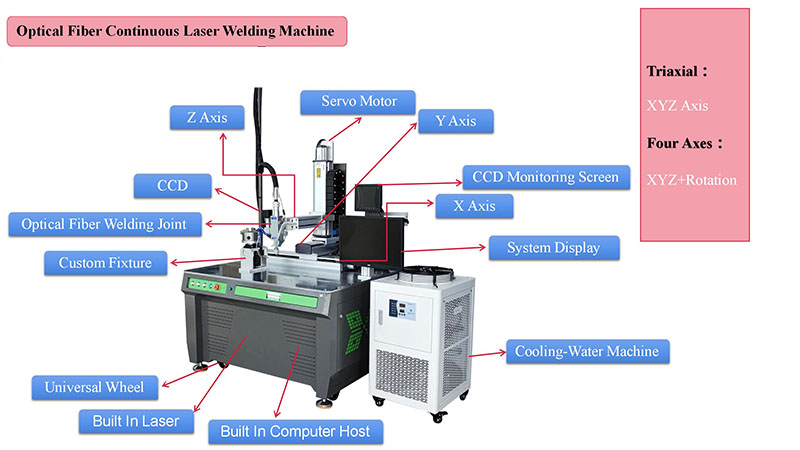

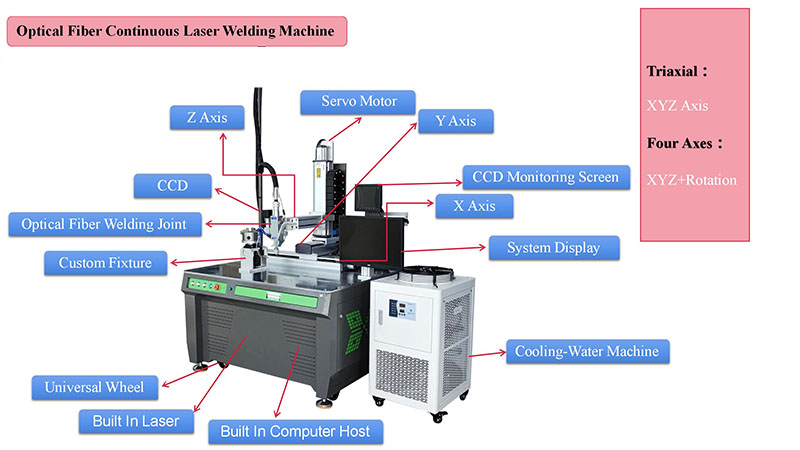

The prices of handheld laser welding machines and automatic welding machines also differ greatly due to their technical complexity, functionality, and automated production.

There are two types of laser welding machines: automatic welding machines and hang held welding machines. Automatic welding machines require automated configurations such as CCD monitoring systems, control systems, and automatic fixtures or tables. Therefore, automatic welding machines are more expensive than manual welding machines.

Handheld vs. Automatic Laser Welding Machines

The advantages of automated welding over handheld welding include higher efficiency, better quality control, lower error rates, increased safety, and reduced costs. These advantages make automated welding widely used in bulk and precision welding applications.

1. Improved production efficiency: Automated welding systems enable continuous and high-speed welding operations, surpassing the speed and efficiency of manual welding. They can complete a large volume of welding tasks in a short period, thereby increasing productivity.

2. Enhanced welding quality and consistency: Automated welding systems achieve higher welding quality and consistency through precise control and stable welding processes. In contrast, manual welding is susceptible to variations in welding quality and consistency due to factors such as operator skill and fatigue.

3. Reduced human errors: Automated welding systems, controlled by computers, minimize human intervention, thereby reducing the potential for human errors. This improves welding accuracy, reliability, and reduces the occurrence of defects and the need for rework caused by human factors.

4. Increased safety: Welding is a hazardous task involving high temperatures, sparks, and harmful gases. Automated welding systems reduce the time and risk of human operators being exposed to hazardous environments, enhancing workplace safety.

5. Cost savings: While the initial investment in automated welding systems may be higher, they can result in long-term cost savings through improved production efficiency, reduced defects and rework, and lower labor costs.

The price of laser welding machines is primarily influenced by factors such as the type of laser source, power and output energy, system configuration and features, welding range and application requirements, as well as the brand and supplier. When choosing a laser welding machine that suits your specific needs, it is important to consider these factors and strike a balance between price and performance.

There are numerous brands in the laser welding machine, and the cost of the machines can vary. If you have specific functional requirements, you can seek custom laser welding machines from laser equipment manufacturers.

How to Choose the Right Laser Welder for Your Business

Determine budget: Determine your laser welder based on your limited budget. Knowing your budget will help you narrow it down and find a laser welder that meets your needs.

Consider application: Different types of metal laser welders are suitable for different applications, so choose the laser welder that meets your specific needs. Generally you need to provide the material you want to weld, thickness, accuracy or other welding requirements.

Summary:

The laser welding machine price made in china is related to the brand, model, power, configuration and other factors. Buyers need to choose the right equipment according to their actual needs when buying laser welding machines. If you are looking for a China laser welding machine manufacturer, DPLASER is a good choice. Our worldwide sales network allows us to provide door-to-door product and service, which is very important for large industrial equipment. We hope this post will satisfy you to choose the best laser welding machine. If you have any questions or need more information, please feel free to contact us.