Customized Industrial Laser Welding Machine

To be our partner

DPLASER is a company that specializes in the design, development, manufacturing, and sales of laser welding machines. We offer both OEM and ODM services, we provide customized fiber laser welding machines that meet the specific needs and requirements for our customers. We have a team of experienced engineers who can design and develop laser welding machines based on the customer’s requirements, including the type of laser source, power, welding speed, welding depth, and control system. Even the size, shape, and features of the machine to suit your workspace and application.

DPLASER has a reputation for providing high-quality laser welding machines that are reliable, efficient, and easy to use. We also offer a comprehensive after-sales system, ensuring prompt technical support and maintenance. This approach has earned the company trust from both domestic and international clients, establishing it as a rising leader in laser industry.

| Argon Arc Welding VS. Laser Welding | ||

| Items | Argon Arc Welding | Laser Welding |

| Heat | High heat | Low heat |

| Deformation | Prone to deformation | Minimal or no deformation |

| Weld Bead | Large weld bead | Smaller weld bead, adjustable spots |

| Aesthetics | Requires processing, high grinding costs | No need for post processing and low processing costs |

| Penetration | Susceptible to perforation | Not prone to perforation |

| Shielding Gas | Requires Argon gas | Requires Argon/Nitrogen gas |

| Precision | Traditional | High precision, Computer numerical control (CNC) |

| Efficiency | Traditional | 2-5 times faster |

| Safety | Intense ultraviolet radiation | Safe irradiation, almost no harm |

| Skill Requirements | Skilled welders | No technical requirements |

Yag Laser Welding Machine

CW Laser Welding Machine

Laser Welding Machine Customized Cases

6 Axis Robot Automatic Laser Welding Machine

The automatic robotic laser welding machine can move the laser head in multiple axes and can be programmed to follow a specific welding path. This enables the machine to weld complex geometries and parts that may be difficult or impossible to weld manually. The laser welding robot can be used to weld a wide range of materials, including metals, plastics, and ceramics.

The robot laser welding system can also be equipped with sensors and vision systems to detect the position of the parts and adjust the welding process to ensure consistent weld quality and accuracy.

Robot laser welding are often used in industrial manufacturing fields, such as automotive, aerospace, and medical instrument, where precision and efficiency are crucial.

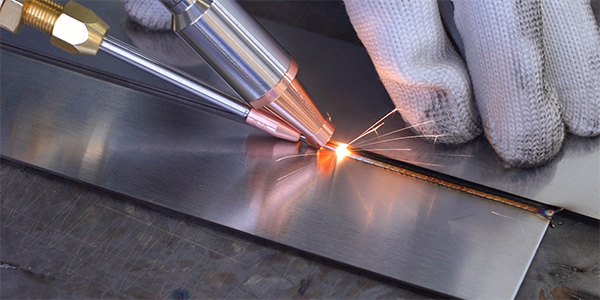

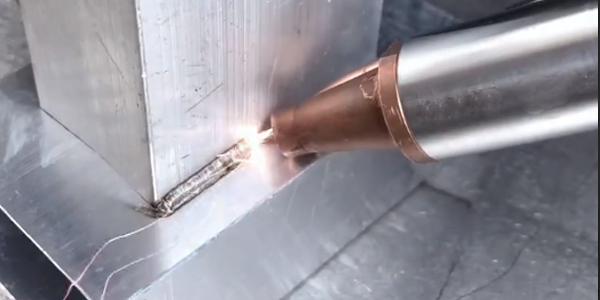

Handheld Fiber Laser Welding Machine

The hand-held laser welding system is a portable welding device that utilizes a fiber laser to perform welding operations. It is designed to be lightweight and easy to use, allowing for greater flexibility and maneuverability in various welding applications.

The hand-held design allows welders to access difficult-to-reach areas and perform welding tasks with greater dexterity. It is particularly useful for applications that require mobility or involve large and complex workpieces. The portability of the machine makes it suitable for on-site repairs, field operations, and various industrial sectors such as automotive, aerospace, and manufacturing.

Platform Automatic Fiber Laser Welding Machine

- The automatic fiber laser welding machine boasts intelligent design, enabling both auto and semi-automatic welding, making it suitable for 24-hour continuous operation, catering to the demands of industrial mass production.

- Controlled by a PC with specialized software assistance, it allows for easy learning and offers the flexibility to weld various flat shapes composed of seam welding, T-welding, overlap welding, edge welding, points, lines, circles, squares, or straight lines and arcs.

- Beautiful welding seam, fast welding speed, high welding speeds, and zero consumable requirements, effectively replacing traditional welding methods.

- Moreover, its user-friendly operation requires minimal operator skill, enhancing the quality, speed, and flexibility of welding applications while reducing overall costs.

- With a high depth-to-width ratio of weld seams, minimal heat input, and little impact on the heat-affected zone and part distortion, it ensures fast and efficient welding.

Non-standard Custom Cup Laser Welding Machine

Cup custom laser welding machine is designed to weld components of cups together. The cups may be made of various materials such as plastic, glass or metal. The machine can be customized to meet the specific requirements, including the size, shape, and thickness of the material, and the type of welding.

With a cup laser welder, you can perform a variety of specialized welding applications to create unique and customized cup designs that enhance the overall aesthetic of the cup.

1. Laser etching – You can use the laser beam to create intricate and detailed designs on the surface of the cup, including logos, text, and patterns.

2. Laser cutting – The laser beam can be used to cut out intricate designs or shapes in the material of the cup.

3. Laser welding – You can use the laser beam to weld different types of materials together, such as plastic and metal, to create unique cup designs.

DPLASER can identify your requirements, provide design and development support, and customize a laser welding machine for you.

Advertising Laser Welding Machine

This advertising laser welding machine is designed for welding advertising application. This machine is used in the production of various advertising products, such as LED signs, illuminated letters, display racks, advertising logo and other similar items.

1. Welding of letters and logos – You can use the laser beam to weld letters and logos onto metal sheets or structures to create customized advertising displays.

2. Welding of 3D structures – With a multi-axis welding capability, you can create 3D structures or sculptures, such as brand logos, from metal sheets or pipes.

3. Welding of thin materials – The laser beam can be used to weld thin materials, such as stainless steel or aluminum, with precision and without causing deformation.

4. Welding of dissimilar materials – You can use the laser welding process to weld different types of metals, such as steel and aluminum, together to create unique advertising displays.

The customization process may include the material and thickness of specific components, laser source and power, selecting the appropriate welding method, designing and testing the machine, and training and technical services.

Air-Cooled Handheld Laser Welding Machine

Compared to the water cooling method, air-cooled laser welder does not require additional water cooling system, reducing the device’s size and weight, thereby lowering complexity and maintenance costs. Handheld air-cooled laser welding machine can be easily moved to different welding positions, enhancing portability and flexibility in operations. Its higher cost-effectiveness and greater adaptability have made it a key alternative to traditional argon arc welding, widely adopted in various industries.

Mold Repair Laser Welding Machine

The mold repair laser welding machine is a professional device widely used in mold repair, mold processing, parts repair, cutting, and connection fields. It uses a high-energy laser beam to heat the metal surface, partially melting and solidifying it, thereby achieving precise metal welding and cutting.

The machine is easy to operate, just place the mold or part to be repaired on the device workbench, and set the working parameters through the control panel on the machine to start processing. It has a fast welding speed, high efficiency, and does not affect the internal structure and performance of the processed parts, and has a long service life.

At the same time, the application of mold repair laser welding systems can also greatly save costs, avoiding the problem of traditional welding methods requiring the remanufacture of molds, reducing production cycles and resource usage.

Laser Welding Machine for Jewelry

The jewelry laser welding machine is a professional tool for precision welding and repair of jewelry and small metal components. It provides precision control, high efficiency and quality welding capabilities for professionals in the jewelry industry and metalworking field.

Precision welding: The jewelry laser spot welder has the ability to weld with high precision, allowing for precise welding of tiny areas on jewelry and metal components. This welding method has virtually no heat affected zone, thus minimizing thermal damage to the jewelry.

Repair capabilities: The machine can be used to repair a variety of damages such as breaks, cracks and chips on jewelry and metal components. By using laser spot welding technology, the operator is able to repair in the original position without disassembly and reassembly.

Microscope system: Jewelry laser spot welders are often equipped with a microscope system that allows the operator to clearly view the weld area. This high magnification microscope helps the operator to accurately locate and control the welding process.

Parameter adjustment: The equipment provides adjustment of various welding parameters, such as laser power, pulse duration and frequency. This allows the operator to customize the welding settings for different jewelry materials and restoration needs.

Easy to use: Jewelry laser spot welders often have a simple and intuitive user interface that is easy to operate and control. Operators can easily adjust welding parameters and monitor the welding process.

Small and portable: Jewelry laser spot welders typically have a compact tabletop design that is suitable for small jewelry stores or laboratories. Its portability makes it easy to move and place in limited spaces.

- Laser Welding

Laser Welding

Handheld Laser Welding Machine Brochure-EN

4 in 1 Handheld Laser Welding Machine Brochure-EN

4 in 1 Handheld Laser Welding Machine Beginner Tutorial

3 in 1 Handheld Fiber Laser Welding Machine Manual

Fiber Handheld Laser Welding Machine Brochure-EN

Handheld Laser Welding Machine Brochure-Spanish

Custom Laser Welding Machines

Dapeng Laser Technology Co., Ltd. provides you with professional laser welding technical support and solutions. We will,

🌟Understand your needs:

We need to understand the specific requirements of your welding, welding materials, welding specifications and accuracy.

🌟Provide plan:

We can provide you with a professional laser welding solution, including equipment performance, technical parameters, price and delivery date, etc.

🌟Confirm order:

Once you confirm the laser welding machine plan, we will confirm the order and sign the contract with you.

🌟Manufacturing equipment:

Produce and manufacture the equipment according to the time stipulated in the contract, and keep in touch with you during the manufacturing process.

🌟Installation & debugging:

We will arrange professional technicians to install and debug the laser equipment on site to ensure operation of the equipment.

🌟After-sales service:

We will provide you with free technical support and after-sales service to ensure that your equipment normal and long-term use.

Optional Configuration of Laser Welding Machine

According to the user’s preferences and proficiency, several methods such as touch screen and multi-screen operation, improving production efficiency and easy operating. Before choose a affordable laser welding machine, it is recommended to have a detailed discussion with the us to determine the best configuration. The following are some configurations that can be modified to meet different welding needs,

The power of the laser determines the speed and depth of welding. Depending on the welding task, lasers with different power levels can be selected. Our available laser power ranges from 200W to 3000W.

Laser Type Selection: Choosing the appropriate laser type, such as CO2, solid-state, fiber, or semiconductor, etc. The selection of the laser type should be determined according to the welding application, such as the type and thickness of the welding material.

The optical system consists of components such as lenses, reflectors, and optical fibers, which are used to guide and focus the laser beam onto the welding area. Depending on the welding requirements and the characteristics of the workpiece, different types and configurations of optical systems can be customized.

The welding control system is the core component of the laser welding machine, including hardware and software control systems. Different control systems can be selected according to welding requirements, such as PLC-based control systems, PC-based control systems, DSP-based control systems, etc.

The cooler ensures the heat dissipation of core optical components to maintain consistent welding quality and extend the laser welding equipment’s lifespan. Industrial laser welding systems offer water cooling and air cooling options. Water cooling systems provide higher cooling efficiency, while air cooling systems are more compact and suitable for applications with limited space.

The workbench can be configured, including size, wire feeder, fixture system, automatic lifting loading and unloading system, and other functions.

Handheld Laser Welder Power & Metal Thickness

| Material | Gas used | Thickness(mm) | Laser power(W) | Wire diameter(mm) | Wire speed(mm/s) | Scanning speed(mm/s) | Scan width(mm) | Welding frequency(HZ) | Duty cycle | Barometric pressure(bar) | Welding method |

| Stainless steel | Argon | 1 | 1000 | 1 | 90 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding |

| 1.5 | 1000 | 1 | 90 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding | ||

| 2 | 1500 | 1.2 | 75 | 300 | 3 | 1000Hz | 100 | 10 | Flat welding | ||

| 2.5 | 2000 | 1.2 | 75 | 300 | 3 | 1000Hz | 100 | 10 | Flat welding | ||

| 3 | 2000 | 1.6 | 60 | 300 | 3.5 | 1000Hz | 100 | 10 | Flat welding | ||

| 4 | 3000 | 1.6 | 60 | 300 | 3.5 | 1000Hz | 100 | 10 | Flat welding | ||

| Carbon steel | Argon | 1 | 1000 | 1 | 90 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding |

| 1.5 | 1000 | 1 | 90 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding | ||

| 2 | 1500 | 1.2 | 75 | 300 | 3 | 1000Hz | 100 | 10 | Flat welding | ||

| 2.5 | 2000 | 1.2 | 75 | 300 | 3 | 1000Hz | 100 | 10 | Flat welding | ||

| 3 | 2000 | 1.6 | 60 | 300 | 3.5 | 1000Hz | 100 | 10 | Flat welding | ||

| 4 | 3000 | 1.6 | 60 | 300 | 3.5 | 1000Hz | 100 | 10 | Flat welding | ||

| Galvanized sheet | Argon | 1 | 1000 | 1 | 90 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding |

| 1.5 | 1500 | 1 | 90 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding | ||

| 2 | 2000 | 1.2 | 75 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding | ||

| 2.5 | 2000 | 1.6 | 60 | 300 | 3 | 1000Hz | 100 | 10 | Flat welding | ||

| 3 | 3000 | 1.6 | 60 | 300 | 3.5 | 1000Hz | 100 | 10 | Flat welding | ||

| Aluminum | Nitrogen(N2) | 1 | 1000 | 1 | 90 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding |

| 1.5 | 1500 | 1 | 90 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding | ||

| 2 | 2000 | 1.2 | 75 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding | ||

| 2.5 | 2000 | 1.6 | 60 | 300 | 3 | 1000Hz | 100 | 10 | Flat welding | ||

| 3 | 3000 | 1.6 | 60 | 300 | 3.5 | 1000Hz | 100 | 10 | Flat welding |

Get a Free Laser Welding Machine Quote!

Do you have a question for us? Are you looking for career advice on laser machines? Contact us if you have a query about the laser equiment and laser industry.