Laser Welding Stainless Steel

Applications of Laser Welding Stainless Steel

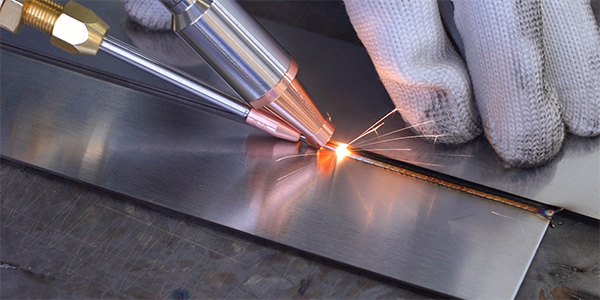

Laser welding is a high-precision, high-quality and efficient method suitable for various thicknesses of stainless steel materials, and it can weld complex shapes and geometric structures, offering exquisite and smooth welded seams, making it suitable for a wide range of industries.

Laser welding is commonly used for joining stainless steel components, such as pipes, containers, brackets, and steel structures. Stainless steel parts: door and window frames, cabinets, kitchenware, sinks, automotive parts, and more.

The stainless steel 300 series (including 304, 316, 321, etc.) is suitable for laser welding and can be used in the manufacturing of food processing equipment, medical devices, railings, door and window frames etc.

The stainless steel 400 series (including 410, 420, 430, etc.) typically contains higher hardness and can be used in the production of cutlery, cookware, tableware, and some mechanical components.

Duplex SS: such as 2205 (UNS S31803), possesses excellent strength and corrosion resistance. Laser welding is suitable for manufacturing marine engineering components, chemical industry equipment, marine equipment, and more.

Stainless steel alloys: Some stainless steel alloys to meet specific application requirements.

Why Choose Laser for Stainless Steel Welding

Laser welding provides a high degree of precision and control over the welding process. The focused laser beam allows for accurate positioning of the weld joint, making it suitable for applications where tight tolerances are essential.

Laser welding generates a concentrated heat source, which results in a small and well-defined HAZ. This minimizes the risk of distortion and preserves the material’s properties, including its corrosion resistance, which is crucial for stainless steel.

Welding speeds 2~5 times faster than conventional welding. Stainless steel, carbon steel wire feed welding, normal speed is 0.7-1.5 m/min. It can complete welds quickly, contributing to increased productivity and efficiency.

Multiple welding processes are available, including spot welding, seam welding, overlay welding, flat welding, inner corner welding, outer corner welding, ring welding and more.

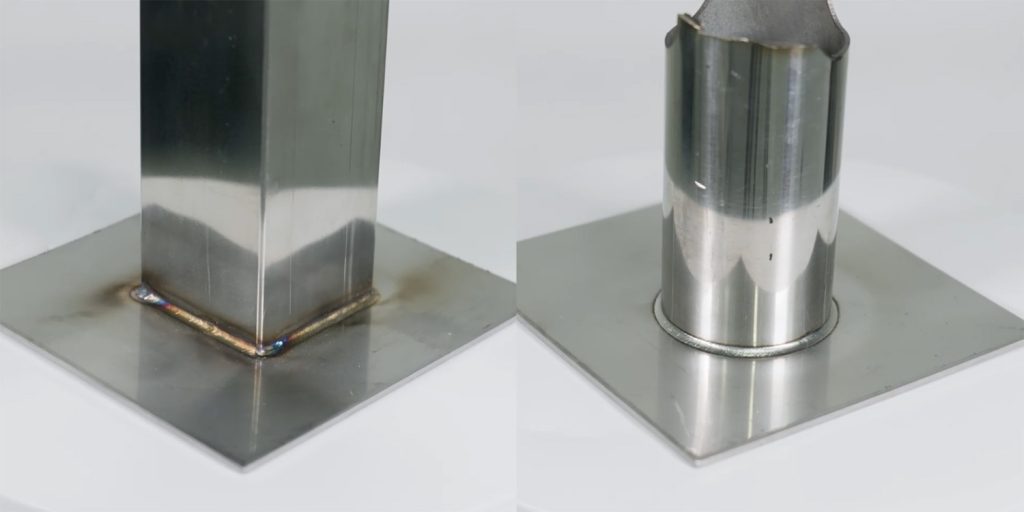

Laser welding produces clean, pleasing welds without polishing. This is particularly important in kitchenware, electronics or architectural structures.

Laser welding can be easily integrated into automated manufacturing processes, leading to consistent and repeatable results. This is beneficial for industries like automotive and electronics manufacturing.

Laser welding can be monitored and controlled more precisely, leading to consistent weld quality. It’s easier to implement quality control measures in laser welding processes.

| Argon Arc Welding VS. Laser Welding | ||

| Items | Argon Arc Welding | Laser Welding |

| Heat | High heat | Low heat |

| Deformation | Prone to deformation | Minimal or no deformation |

| Weld Bead | Large weld bead | Smaller weld bead, adjustable spots |

| Aesthetics | Requires processing, high grinding costs | No need for post processing and low processing costs |

| Penetration | Susceptible to perforation | Not prone to perforation |

| Shielding Gas | Requires Argon gas | Requires Argon/Nitrogen gas |

| Precision | traditional | High precision, Computer numerical control (CNC) |

| Efficiency | traditional | 2-5 times faster |

| Safety | Intense ultraviolet radiation | Safe irradiation, almost no harm |

| Skill Requirements | Skilled welders | No technical requirements |

Stainless Steel Laser Welding Samples

Laser Welding Stainless Steel Parameter

| Material | Gas used | Thickness(mm) | Laser power(W) | Wire diameter(mm) | Wire speed(mm/s) | Scanning speed(mm/s) | Scan width(mm) | Welding frequency(HZ) | Duty cycle | Barometric pressure(bar) |

| Stainless steel | Argon | 1 | 1000 | 1 | 90 | 300 | 2.5 | 1000Hz | 100% | 10 |

| 1.5 | 1000 | 1 | 90 | 300 | 2.5 | 1000Hz | 100% | 10 | ||

| 2 | 1500 | 1.2 | 75 | 300 | 3 | 1000Hz | 100% | 10 | ||

| 2.5 | 2000 | 1.2 | 75 | 300 | 3 | 1000Hz | 100% | 10 | ||

| 3 | 2000 | 1.6 | 60 | 300 | 3.5 | 1000Hz | 100% | 10 | ||

| 4 | 3000 | 1.6 | 60 | 300 | 3.5 | 1000Hz | 100% | 10 |

Get a Free Laser Welding Machine Quote!

Do you have a question for us? Are you looking for career advice on laser machines? Contact us if you have a query about the laser equiment and laser industry.