In today’s fast-paced manufacturing industry, laser welding technology has become a crucial method. Choosing the right 1000W laser welding machine can significantly impact your production efficiency and product quality. This article delves into selecting an ideal 1000w laser welding machine for metal, helping you understand its welding characteristics, applications, and comparison with traditional welding methods. Through our exploration, you’ll make a more informed decision, bringing higher efficiency and quality to your production line.

1000w fiber laser welding machine is a laser welding equipment that is commonly used in industrial manufacturing and processing. It utilizes a laser beam to heat the material to a high temperature to achieve welding. Compared to MIG/TIG welding methods, laser welding offers higher precision, less heat affected zone and faster speed. This type of equipment is commonly used to weld metal parts such as automotive parts, electrical parts, machine building and medical devices.

How thick can a 1000W handheld laser welding machine weld?

1000W handheld laser welding machine is primarily used for laser welding thin sheets and pipes.

- Taking stainless steel as an example, a 1000W welding machine can weld through 3mm thickness.

- For welding a 3mm thick stainless steel plate, if a 500W laser welding machine is used, it can weld through 1.5mm thickness in a single-sided welding operation, or 1.5mm on each side for double-sided welding, effectively welding 3mm thick material.

- For 2mm thick stainless steel plates requiring full penetration welding with finer weld seams, it’s recommended to use a 1000W fiber laser, welding speed of 1m/min is possible.

- 1000W metal laser welding machine for aluminum and its alloys, welding thicknesses ranging from 0.5mm~2mm.

| Material | 1000W Laser Welding Machine for Metal |

| SUS (stainless steel) | 0.5mm-3mm |

| Fe (iron) | 0.5mm-3mm |

| Al (aluminum) | 0.5mm-2mm |

| Cu (brass) | 0.5mm-3mm |

| Galvanized sheet | 0.5mm-3mm |

| Carbon steel | 0.5mm-3mm |

| Mild Steel | 0.5mm-3mm |

Laser Parameters Affecting Welding Thickness

The maximum thickness that a laser welding machine can weld depends on several factors, including the type of laser, laser power, beam delivery system, and welding parameters. 1000w laser welding is most commonly used for welding thin plates, typically with a thickness of less than 6mm, and can produce high-quality, precise, and consistent weld seams.

Indeed, the higher the power, the thicker the material that can be welded with laser. Laser welding is about penetration depth/melting pool and is also related to the thickness and material of the welded parts. For example, welding carbon steel and titanium would require different parameters.

The selection of laser welding parameters is critical to achieving a high quality joint with the required strength and precision. These parameters include laser power setting, welding speed and focal point position.

Laser Power

The laser power setting is adjusted according to the thickness of the material, with lower power being used for thin materials to prevent burn-through, and higher power being required for thicker materials to ensure full penetration.

Welding Speed

Welding speed needs to be moderate, too fast may lead to inadequate fusion of the weld seam, too slow may cause distortion of the workpiece and excess heat; as the material thickness increases, the welding speed should be adjusted downwards accordingly in order to achieve full penetration without defects.

Focus Position

Focal point position plays a key role in weld quality and geometric features. Proper focal point position can equalize the distribution of energy, accurately control the heat-affected zone and form an ideal weld depth-to-width ratio.

Features of 1000W Laser Welding Machine

A 1kW portable laser welding machine is small and easy to operate, capable of performing complex and irregular welding processes. It is mainly used for welding metal and non-metal plates below 3mm thickness, with applications in light industries such as sheet metal, kitchenware, bathroom fixtures, and hardware.

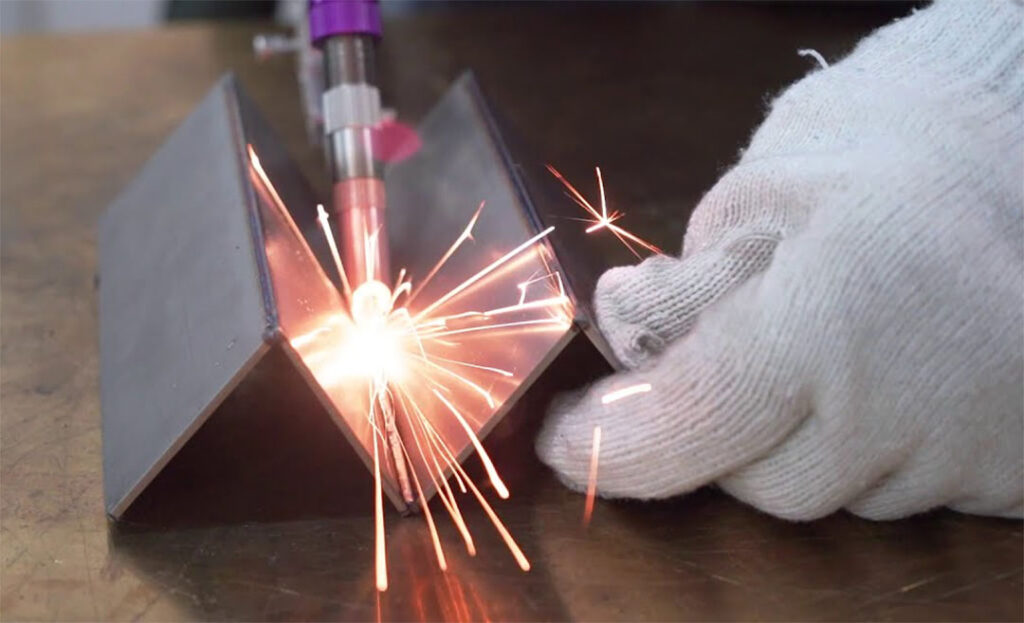

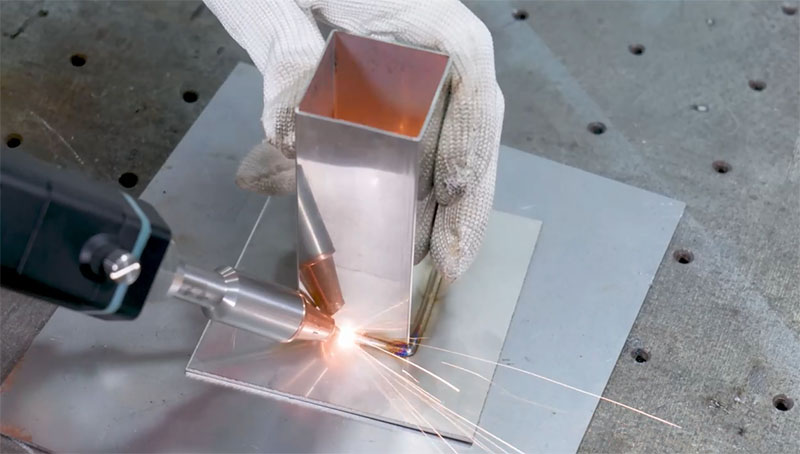

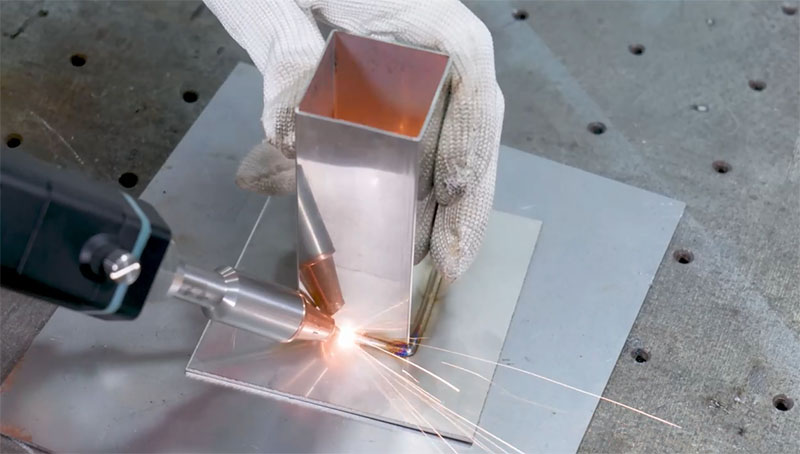

During operation, the handheld welding head has a scanning width, and its beam diameter is small. Therefore, welding is performed by scanning from one point to another, forming straight weld seams.

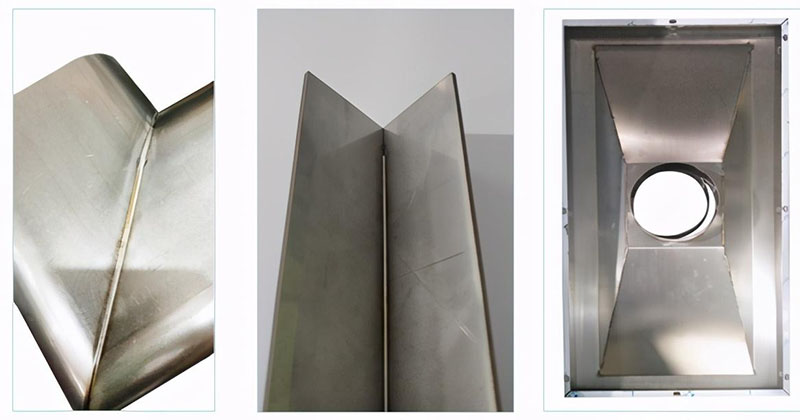

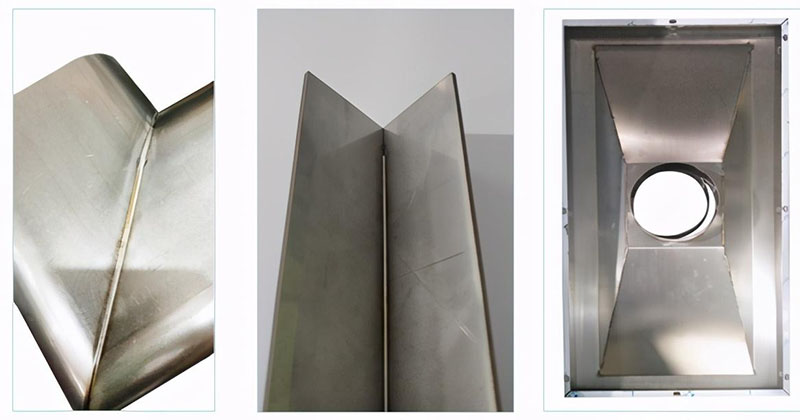

The handheld laser welding machine occupies minimal space and is typically equipped with various handheld heads. It caters to different needs such as external welding, internal welding, right-angle welding, T-joint welding, stack welding, and bevel welding for metal parts. Different handheld welding nozzles can be selected, enabling a wide variety of products to be welded with greater flexibility in product shapes. For small processing and production workshops not requiring large bulk welding, a 1000w handheld laser welding machine is definitely the best choice.

1000W Laser Welder VS. Arc Welding

Handheld laser welding machines have significant advantages over traditional arc welding:

1. Welding speed and cost-effectiveness

Handheld laser welding machine supports single-sided welding, double-sided molding, fillet welding, vertical welding, splicing, replacement welding, and other welding methods, one-step molding. Its welding speed is usually 3 to 10 times faster than conventional welding. Due to the faster welding speed, the number of products completed per unit time increases and the overall processing cost can be reduced by about 30%.

2. Material adaptability and welding quality

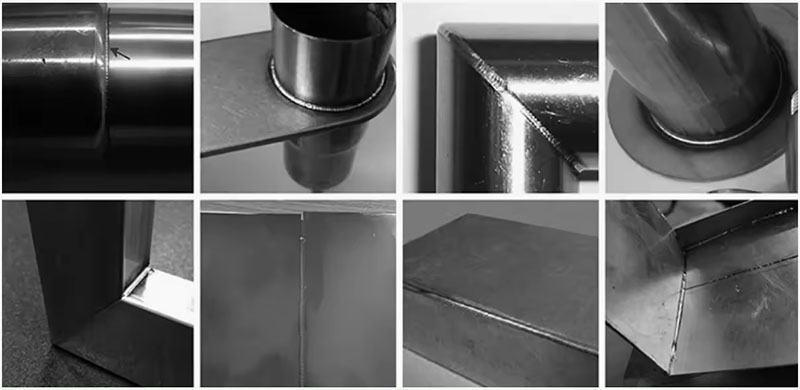

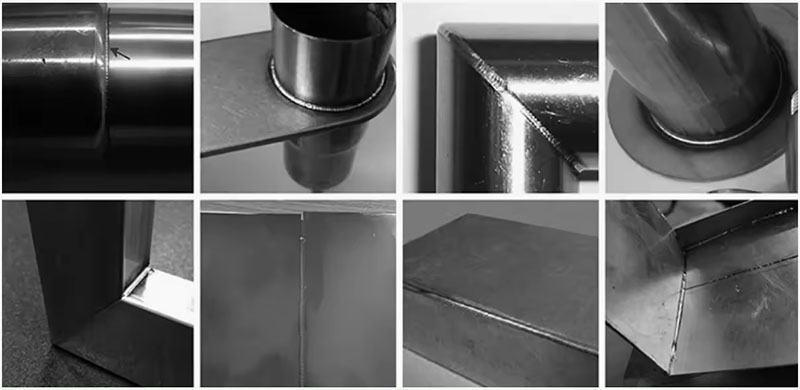

Laser welding is not limited by homogeneous materials and enables high quality welding between different steels and other metals. Precise energy control results in low heat input, small workpiece deformation and narrow heat affected zone. The appearance of the weld is smooth and beautiful, the internal organization structure is more uniform, less porosity, no pollution, especially suitable for tiny open-type parts and precision parts welding.

3. Simplify the post-processing procedures

Due to the small heat-affected area caused by the handheld laser welding machine, the degree of deformation of the workpiece after heat is greatly reduced, the surface after welding is relatively smooth, no need or a small amount of grinding, reducing post-processing hours. Especially for those products with high requirements on appearance, laser welding technology has irreplaceable advantages.

1000W Handheld Laser Welding Machine Applications

Suitable for welding thin metal sheets such as stainless steel, carbon steel, galvanized sheet, copper, aluminum alloy, gold, silver, chromium, nickel, titanium, tantalum, and various other metals or alloys. It is also used for welding between multiple dissimilar materials. Widely applied in industries including sheet metal manufacturing, mold making, medical equipment, kitchen and bathroom fixtures, sinks, lighting fixtures, signage, door and window frames, household appliances, molds, stainless steel doors and windows, crafts, furniture, automotive parts, enclosures, distribution boxes, staircases, elevators, shelves, ovens, stainless steel products, aluminum products, copper products, alloy materials, watches, glasses, jewelry, hardware components, and other industries requiring irregular welding.

Sanitary ware industry

- Precision butt welding of pipe joints and tees

- Sealing welding of internal passages and external shells of valves

- Welding of detail parts such as shower room components, bathtub drains, and faucet components

Household industry

- Welding of handles for kitchen utensils such as stainless steel cookware

- Spot welding of metal frames and hinges for kitchen cabinets and wardrobes

- Safety protection welding of internal heating elements and outer shells of ovens

- Precision welding of stainless steel door handles and locks

- Sealing welding of internal conductive components and outer shells of distribution boxes

- Accurate welding of tracks, brackets, and decorative panels during elevator component assembly

Jewelry & Eyewear industry

- Welding of high-precision eyeglass frames, including connections between temples and rims

- Lightweight design and seamless welding of titanium alloy eyeglass frames

- Welding of dissimilar metal components for eyeglasses with different materials

Hardware industry

- Efficient welding of impeller blades to ensure balance and durability

- Sealing welding of kettle bodies and spouts for everyday items such as kettles and coffee pots

- Welding of gaps, reinforcements, or assembly points between complex stamped parts and castings

Automotive industry

- Reinforcement welding around engine cylinder head gaskets

- Precision welding of sealing rings at the ends of hydraulic lifters to prevent leaks

- High-quality welding of internal electrodes and housings for spark plug components

- Precision welding of filter housings, filter support frames, and other internal structures

Medical industry

- Precision welding of fine parts for stainless steel surgical instruments to ensure sterility and durability

- Sealing welding of complex pipeline systems and joints for medical devices

- Precision welding of high-demand medical structural components such as implants and surgical tools

Electronics industry

- Sealing welding between internal components and encapsulation materials in solid-state relays

- Precision alignment and high-precision welding of miniature connectors

- High-strength welding of electronic component housings, heat sinks, and other metal structural components to meet electromagnetic shielding and heat dissipation requirements

Trustworthy High-Quality 1000W Laser Welding Machine

Handheld laser welding machine, the use of a generation of fiber laser, configured with self-developed welding head, to fill the blank of the laser equipment industry handheld welding, with simple operation, weld seam beautiful, fast welding speed, no consumables advantages, in thin stainless steel plate, iron plate, galvanized plate and other metal materials, welding, can replace the traditional argon arc welding, electric welding and other processes.

Handheld welding gun to replace the traditional fixed optical path to achieve outdoor welding. Handheld laser welding machine is mainly for long distance, large workpiece welding, heat-affected area is small, will not lead to work deformation, weld unevenness, leaving scars problem, to ensure the processing accuracy of the workpiece, and welding depth, weld seam strong and firm.

5 in 1 handheld laser welding machine has spot welding, seam welding, pulse welding, continuous wave welding, filler welding and other welding methods are widely used in cabinet kitchen and bathroom, stairs and elevators, shelves, ovens, stainless steel doors and windows guardrail, distribution boxes, stainless steel home and other industries complex irregular welding process.

Laser Power: 1000W

Welding thickness: ≤3mm

Welding seam requirements: <0.5mm, welding seams larger than 0.3mm are recommended to use a laser welding machine with wire feed

Effectively welding carbon steel, stainless steel, galvanized sheets and other metal materials, suitable for tailor welding, stack welding, internal and external fillet welding, arc welding, and irregular shape welding.

Features of handheld 1000w laser welding machine

1. Integrated cabinet design combines laser, chiller unit, and software control, featuring a compact footprint, strong mobility with omnidirectional wheels.

2. The handheld welding head is equipped with a 10-meter original optical fiber for flexibility and convenience.

3. Handheld operation mode allows for welding at any part and any angle of the workpiece with dedicated welding nozzles.

4. Compatible with various welding type, suitable for a variety of process requirements, achieving one-time forming with minimal deformation, meeting high-quality product standards.

5. Weld seams are aesthetically pleasing, free from scars or discoloration, eliminating the need for subsequent polishing.

6. Strong welding joints with weld strength reaching or even exceeding that of the base material.

7. Applicable for butt welding, overlap welding, inside and outside corner welding, arc welding, and welding irregular shapes.

8. The equipment set is versatile, ergonomic in design, suitable for various working environments.

9. Exclusive laser safety operation protection ensures the safety of operators during work.

10. Simple and easy to learn operation, with low technical requirements for operators, reducing labor costs.

What is the Price of Laser Welding 1000W?

The price of a fiber laser welding machine depends on the equipment configuration, which is based on your processing needs. Typically, a 1000 watt laser welding machine costs around 2,000USD. You are welcome to contact our laser experts for customized laser welding equipment for your workpiece.

Quality and reliability are crucial considerations when choosing a 1000w 1500w handheld metal laser welding machine. As your trusted provider of first-class laser welding solutions, we aim to provide you with the best quality products and services. DPLASER is one of the leading laser equipment suppliers in China, with extensive experience in meeting the precision welding needs of various industries. Our commitment is to provide high quality laser welding machines to ensure that your welding needs are reliably met, thereby enhancing your productivity and product quality levels.