Laser equipment is gradually increasing and has become an essential tool in the manufacturing industry. Laser welding equipment is applied in various industries, including molds, advertising boards, hardware products, precision mechanical manufacturing, and kitchenware, among others. Many products such as hood, cooktop, sterilizer, knife, shower head, and sinks use a large number of metal panels, especially stainless steel, with high requirements for product lightweight, dimensional accuracy, and aesthetics. In kitchenware processing, to achieve better welding results, more and more manufacturers are adopting laser welding kitchenware.

Laser Welding Machine is used in Stainless Steel Kitchenware Industry

As consumer demands diversify, the kitchenware industry encompasses an increasingly wide variety of products, including cabinets, range hoods, stoves, sinks, cutlery, pots, and pans, most of which consist mainly of sheet metal panels less than 3mm thick. With a multitude of sheet metal components and rapid product iteration, the kitchenware industry faces complex challenges.

Laser welding machine for home appliances offer several advantages, including fast welding speeds, high-quality results, and exceptional precision. Due to the characteristics of laser welding, it has minimal impact on non-operational areas during the welding process. To produce high-end kitchenware, it is essential to ensure the quality of every detail, and welding is a critical aspect of meeting these demands. Utilizing high-quality handheld laser welding machine in kitchenware ensures the integrity of welding seams, guaranteeing their smoothness and evenness.

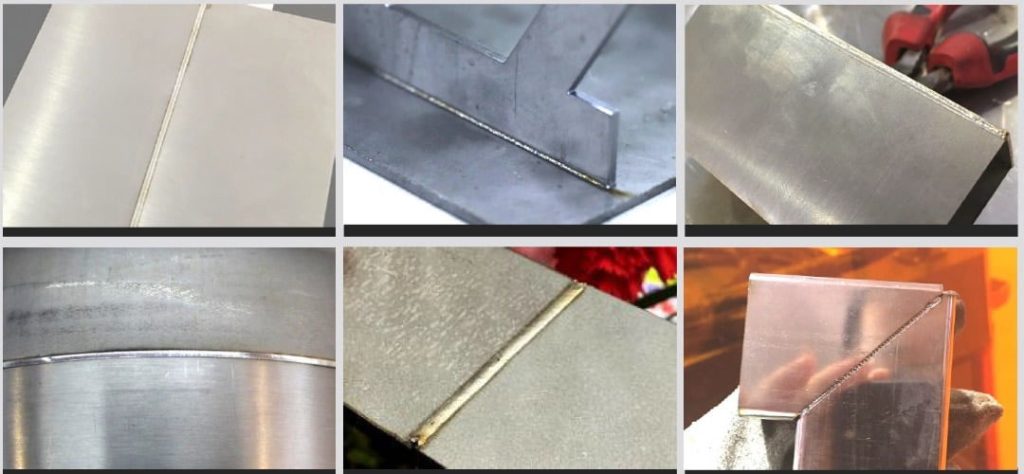

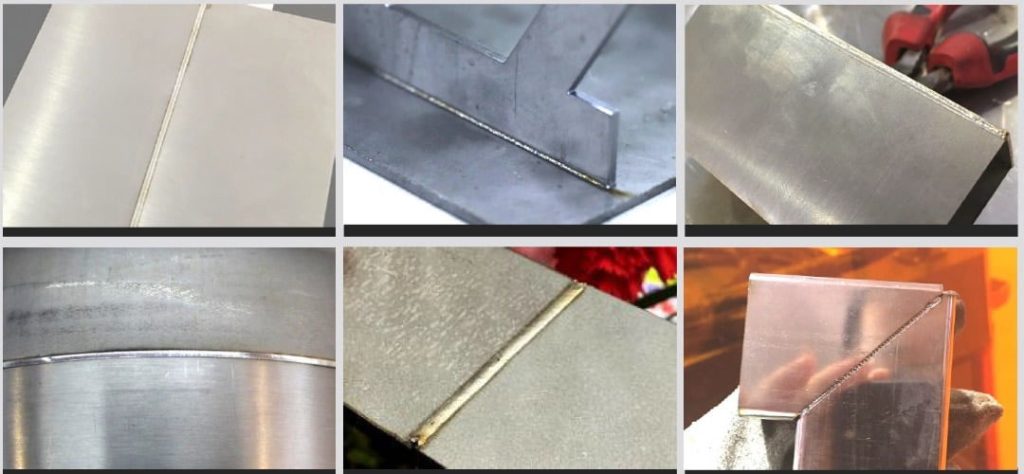

Kitchenware workpiece welding involves stainless steel sheets with thicknesses ranging from 0.5 to 3mm, with butt welding and corner welding being the primary methods. In manufacturing stainless steel kitchenware, an increasing number of kitchenware companies are adopting laser solder to achieve superior welding results.

Why Use Laser Welder for Home Use?

Traditional arc welding and argon arc welding is predominantly manually operated and tends to result in rough welding surfaces, complex post-welding polishing processes, and is susceptible to weld defects such as incomplete fusion and leakage.

In contrast, laser welding is mostly with continuous and pulsed laser welding machines, avoiding the drawbacks of argon arc welding. Laser welding offers several advantages:

- Efficiency: Laser welding is highly automated, leading to increased efficiency. The narrow welding seam and small heat-affected zone contribute to exceptionally smooth welding surfaces. This eliminates the need for secondary processing, enhancing the finished product rate of kitchenware equipment. Ultimately, it significantly improves product quality, shortens production cycles, and reduces costs for businesses.

- Simple to use: Laser welding is a straightforward and user-friendly process. The small focus spot allows for precise seam positioning, reducing the need for frequent welding gun and nozzle changes.

- High Automation Level: The welding process can be highly automated, enabling welding in remote or difficult-to-reach areas.

- Speed and Quality: Laser welding offers rapid welding speeds, high production efficiency, minimal heat-affected zones, low distortion, and high precision. This results in high-quality weld seams and aesthetically pleasing finished workpieces.

- Wide Material Compatibility: Laser welding is versatile and can be used for joining different materials, including various metals like copper, aluminum, steel, and nickel, as well as dissimilar materials such as metal-to-plastic or metal-to-ceramic.

- High Integration: Laser welding can be seamlessly integrated into automated production lines and used in conjunction with robotic systems to further enhance overall efficiency.

The application of laser welding in the kitchenware industry not only improves welding quality but also streamlines manufacturing processes, making it a cost-effective and efficient solution for modern kitchenware production.

Cons.

While laser welding machine for kitchenware welding offers some advantages, it also presents certain challenges:

- High reflectivity of the laser to the material, resulting in high laser energy loss and low welding efficiency or inability to weld.

- High sensitivity to porosity leads to poor weld quality. Need to clean the material surface and weld area, remove oil, rust, oxidized layer and other impurities; choose the appropriate shielding gas and blowing direction, to prevent oxygen and nitrogen in the air and other elements from entering the molten pool.

- The high sensitivity to thermal cracking leads to cracks or fractures in the weld. It is necessary to choose suitable materials and welding methods to improve the plasticity and toughness of the material; preheat the material or use low energy density laser to reduce thermal stress and thermal deformation.

Laser Welding Machine in Kitchenware Industry

Fiber laser welding machines, as a crucial application of laser technology, offer irreplaceable advantages over traditional welding methods. They have found extensive use in various industries, including kitchen appliances, home appliances, cabinets, sheet metal chassis, elevators, and more. In the kitchen and bathroom industry, in the manufacturing of stainless steel kitchenware, kettles, stoves, cabinets, sinks, pipe fittings, showers, electrical components, and more, the fiber laser welder has contributed to improved product durability and aesthetics.

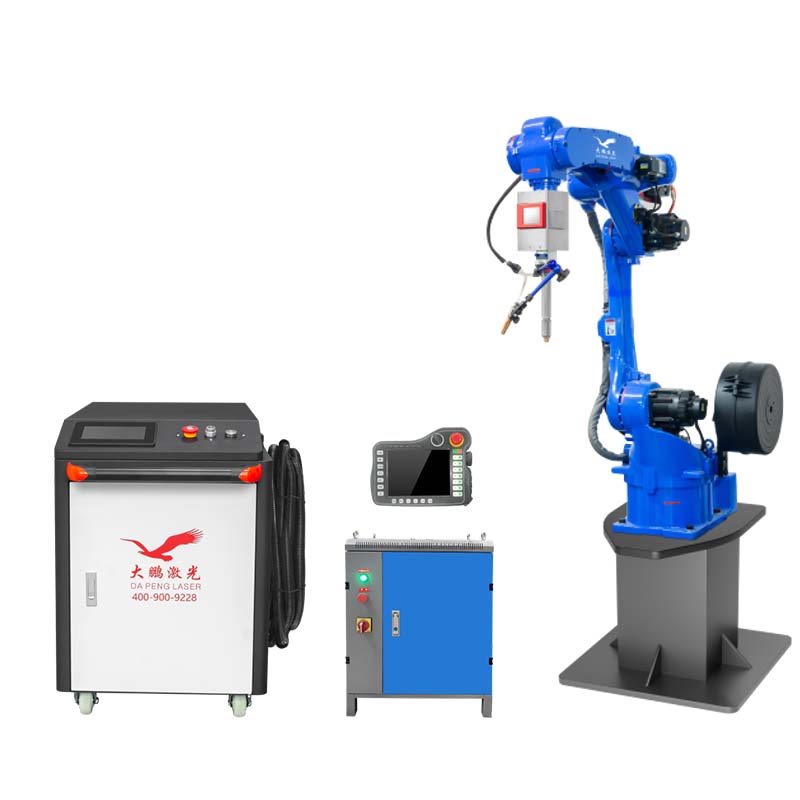

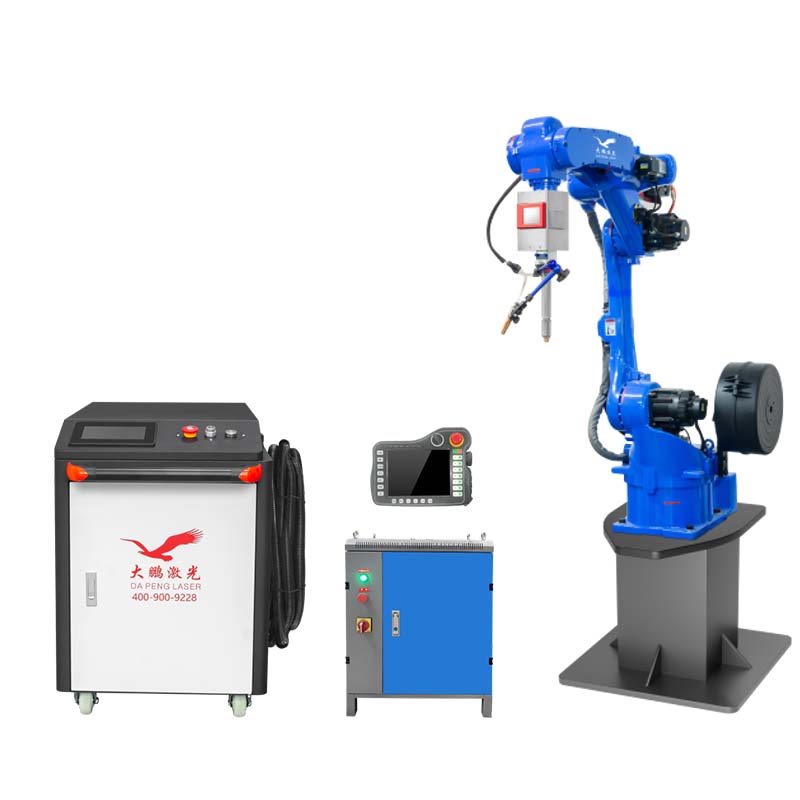

Dual Station Laser Welding Robot

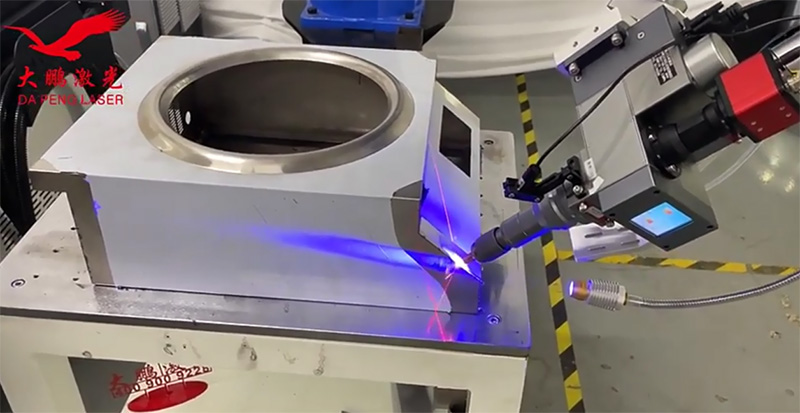

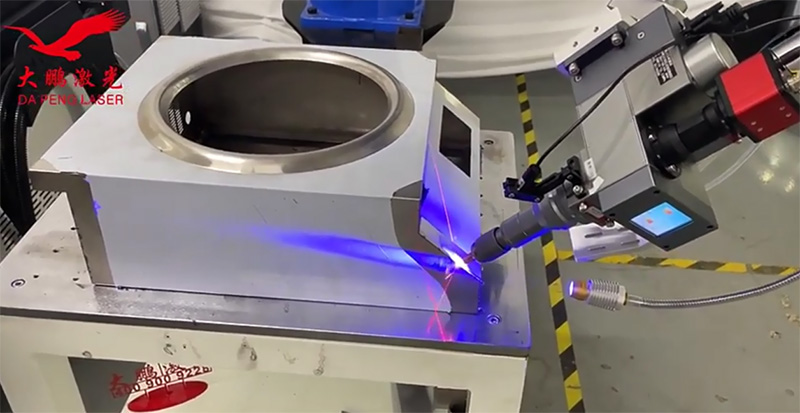

This automatic laser welding system employs manual loading and consists of various components, including robot arm, dual-station rotary positioner, laser source, and visual positioning system. Through internal welding and external loading/unloading processes, this robot laser welding system enhances equipment utilization efficiency and production output. Furthermore, the rotary positioner is typically equipped with adjustable workpiece fixtures to accommodate the welding requirements of various workpiece sizes, making it highly versatile.

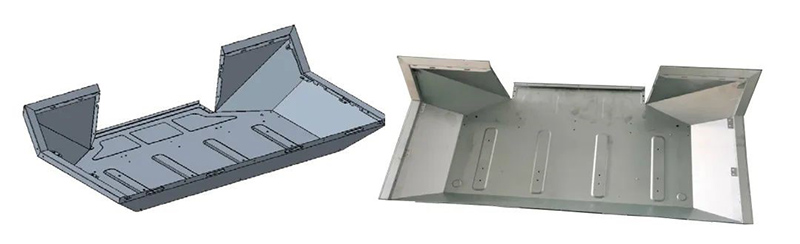

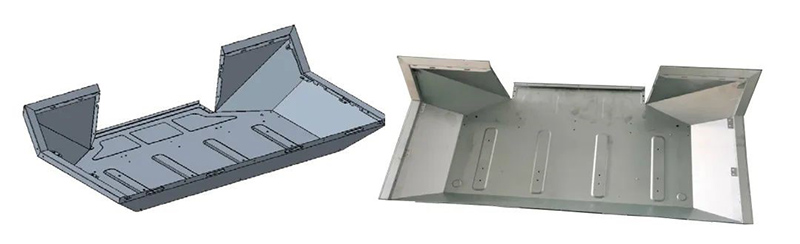

This automated laser welding robot is primarily suitable for medium to large-sized kitchenware workpieces, particularly for welding applications involving long seams, such as sinks, household appliance casings like range hoods, ovens, and more. The application of robot laser welding in the metal kitchenware has significantly improved production efficiency and get excellent welding results.

Handheld Laser Welding Machine for Kitchen Industry

The handheld laser welding machine primarily consists of a laser source, a water cooling system, and the handheld welding head. It has a small footprint, is easy to operate, and requires relatively low skill levels from the operators. With lower initial cost investment and reduced post-welding polishing work for stainless steel kitchenware, the handheld welding machine has become the preferred choice for small-scale kitchenware manufacturers.

Equipped with a 10-meter-long fiber optic cable that connects the welding head, the handheld laser welding machine extends its welding reach, and it features mobile pulleys, allowing for on-the-fly adjustments to the workstations according to specific site requirements, offering enhanced flexibility. The continuous laser beam has good quality and high energy density, and the welding speed is more than 2 times that of solid YAG laser welding and 3-5 times that of argon arc welding.

Platform laser welding machines are limited to fixed welding positions, which may not be suitable for some larger workpieces, limiting their versatility. The handheld welding head offers flexibility and can be equipped with a variety of compatible welding nozzles, supporting various welding techniques, including spot welding, overlap welding, and corner welding, meeting the diverse requirements of kitchen and bathroom equipment, creative designs, and different welding processes.

The handheld laser welding system excels at welding thin sheets and precision materials. It can weld sheets ranging from 0.2mm to 6mm excellently, satisfying the welding needs of thin-sheet components and precision materials commonly found in kitchen and bathroom equipment.

Handheld laser welder is widely used in the kitchen industry in addition to many manufacturing industries:

1. Sheet metal fabrication, household appliances, water tank, meter box

2. Kitchen cabinets, stoves, sinks sealed welding

3. Hardware lights laser welding

4. Door and window frame laser welding

5. Billboards, advertising letters cutting and welding

Custom Laser Welding Solutions for Kitchenware

DPLASER is a leading laser equipment supplier in China, offering a variety of laser welding service solutions designed to meet the manufacturing needs of different industries.

1. Automated Production Lines: DP Laser Company specializes in providing highly automated production lines to customers, including CNC metal cutting, welding, and bending processes. These automated processes not only enhance production efficiency but also ensure high product quality and stability. Customers can rely on DP Laser Company’s technology and expertise to manufacture household appliances and hardware products in a more efficient and reliable manner.

2. Technical Consultation and Training: DP Laser Company offers comprehensive technical consultation and training services to help customers become proficient in using laser welding equipment and mastering automation in production. Through these training services, customers can gain access to the latest technology and best practices, thereby improving their production efficiency and product quality.

3. Customized Services: DPLaser Company provides tailored solutions to meet customers’ individual requirements for product materials, dimensions, processes, and more. Customers can depend on DPLaser’s team of engineers and designers to collaboratively develop laser welding and automation solutions that meet their specific needs. This customized service ensures that the results of using laser welding equipment in production exceed expectations.

DPLaser is committed to providing a range of services to help customers improve production efficiency, product quality, and meet their individualized needs. Whether customers require automated production lines, technical consultation and training, or customized services, DPLaser is a reliable partner offering exceptional support and solutions.

Conclusion:

The application of laser welding machines in the kitchenware industry has completely transformed the manufacturing process. It not only enhances welding quality but also improves efficiency, contributing to the production of high-quality kitchenware that meets the ever-growing consumer expectations. As the laser technology continues to evolve, laser welding device will find broader applications across various manufacturing companies, allowing manufacturers to produce innovative and superior products more rapidly.