In the realm of metalworking, aluminum is a widely used material due to its excellent properties, such as lightness, corrosion resistance, and malleability. The best aluminium laser cutting machine for some industry such as electronics, automotive, construction, and aerospace. In the metal processing industry, aluminum and its alloys can be processed using CNC machining, die-casting, and laser cutting techniques.

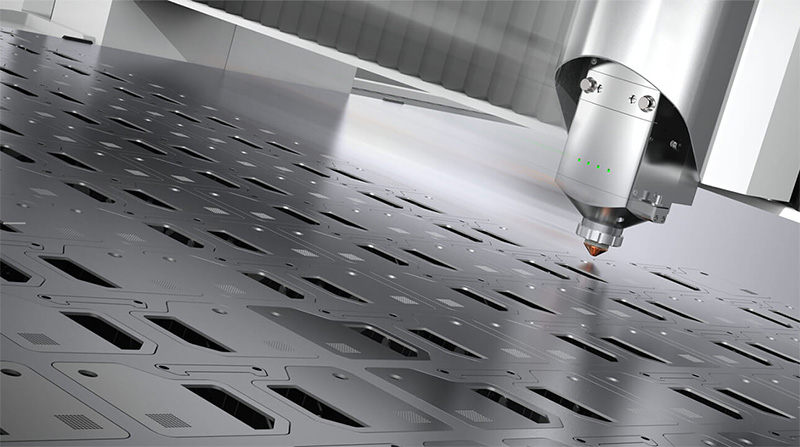

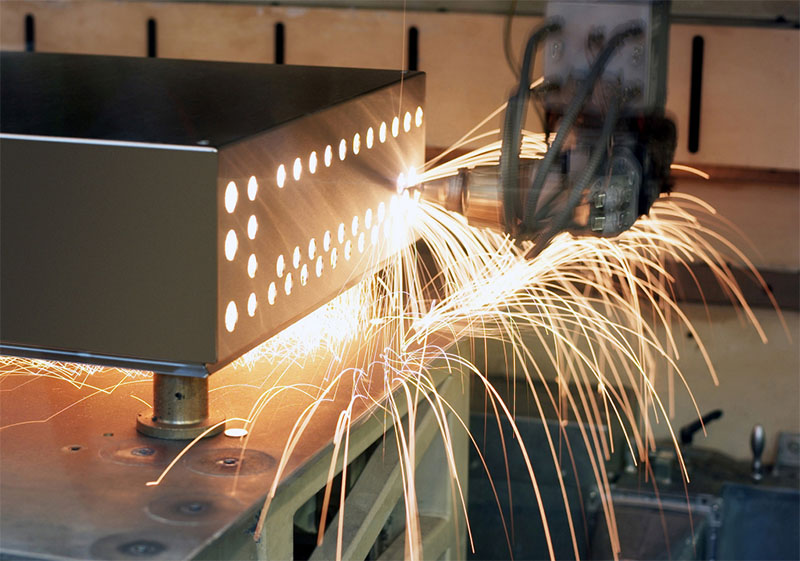

Laser cutting utilizes a focused high-power density laser beam to irradiate the workpiece, rapidly melting, vaporizing, ablating, or reaching the ignition point of the irradiated material. Simultaneously, the melted material is blown away by a high-speed airflow coaxial with the gantry, achieving the cutting of the product.

Can a laser cutting machine cut aluminum? Whether a laser cutting machine can cut aluminum depends on the power of the laser machine. Generally, thick aluminum can be cut, as well as thin aluminum, but the processing cost for thick aluminum plate might be higher.

Types of Lasers Using for Aluminum Cutting Process

Aluminum cutting & engraving is a popular technique used to create intricate designs, markings, or patterns on aluminum surfaces. Various types of lasers are utilized in this process, each offering specific advantages and capabilities.

1. Fiber Lasers:

Fiber lasers are the most common and widely used for aluminum engraving. They utilize optical fibers to amplify the laser beam, resulting in high power density and excellent beam quality. Fiber lasers are well-suited for engraving a wide range of materials, including aluminum, with high precision and speed. They are particularly effective for producing detailed graphics, logos, and text on aluminum surfaces.

2. CO2 Lasers:

CO2 lasers are another type used for aluminum engraving. They emit a higher wavelength compared to fiber lasers, making them better suited for thicker aluminum materials. CO2 lasers are versatile and can engrave a variety of materials, but their slower processing speed may be a consideration when engraving aluminum.

3. Nd:YAG Lasers:

Nd:YAG (neodymium-doped yttrium aluminum garnet) lasers are solid-state lasers that can engrave aluminum with precision. They are suitable for both surface marking and deep engraving applications. Nd:YAG lasers are known for their ability to engrave highly reflective metals like aluminum without damaging the material’s surface.

The choice of laser type for aluminum cutting machine depends on factors such as the desired engraving depth, processing speed, level of detail required, and the specific properties of the aluminum alloy.

Benefits of Laser Cutting Aluminum Plates

1. Precision Cutting: Laser cutting aluminum sheets results in a cutting seam typically ranging from 0.1 to 0.2 millimeters.

2. Smooth Cutting Surface: The cut surface of aluminum sheets produced by laser cutting is free from burrs and slag.

3. Minimal Heat Deformation: Laser processing is fast and the laser beam’s narrow width leads to minimal heat transfer to the cut material, resulting in reduced thermal deformation.

4. Material Saving: Laser cutting employs computer programming, allowing nesting of different-shaped aluminum sheet components, significantly improving material utilization and saving substantial material costs.

5. Versatility for Various Thicknesses: Laser cutting is suitable for aluminum sheets of various thicknesses. However, cutting very large-sized sheets may require higher laser power levels and slower cutting speeds. Generally, a 6000W laser can cut aluminum sheets up to 16mm thick, while a 4500W laser can cut up to 12mm thick.

Disadvantages of Laser Cutting Aluminum

Although laser cutting aluminum has many advantages, there are also some limitations to consider:

- High Reflectivity:

Aluminum exhibits high reflectivity to laser beams, difficult to achieve the high temperatures required for laser melting and vaporization of the surface.

- Good Thermal Conductivity:

Aluminum is an excellent thermal conductor and easily dissipates heat. The surface cools rapidly, making it difficult to reach the appropriate high temperatures needed for laser melting and vaporization.

- Secondary Processing Required:

Even if you successfully laser cut aluminum, the sharp edges and burrs produced during the cutting process require secondary processing to obtain smooth edges and a polished surface. Using high-pressure nitrogen gas assistance can help to expel molten metal from the cut, achieving faster cutting speeds and smoother edges.

- Higher Processing Costs:

Achieving high-quality laser cutting of aluminum may require following certain techniques, and depending on the laser and cutting parameters, additional post-processing may be necessary to achieve a smooth surface.

What You Should Know About Aluminum Laser Cutting

1. Coating the surface of aluminum with black can effectively reduce its reflectivity, making it more suitable for laser cutting.

2. During the processing, it is essential to control the cutting parameters carefully as aluminum is not tolerant of high temperatures. Compared to typical metal materials, the cutting process for aluminum is more challenging to master, and burrs are more likely to occur.

3. Laser cutting speed also requires precise control. Cutting too quickly can lead to burrs, while cutting too slowly can cause cracks in the aluminum material, both of which can affect the cutting quality.

4. When using a laser cutting machine to cut aluminum, it is advisable to use nitrogen gas. Due to aluminum’s unique properties, and to ensure even cutting results, nitrogen gas can effectively prevent oxidation and preserve the material’s characteristics, making it a better choice.

5. For cutting thickness, a 3000W laser is suitable for cutting aluminum up to 10mm thickness, a 4000W laser can handle up to 16mm thickness, and a 6000W laser is suitable for cutting up to 20mm thickness. However, in specific cases, they can cut thicker aluminum sheets, but the efficiency and results may be compromised.

The table below shows the cutting range for different laser powers. The main advantage of a fiber laser machine is its ability to produce excellent cut quality on intricate profiles at high cut speeds for thin/medium thick sheets.

| Laser Power | 2 kW | 4 kW | 6 kW | 10 kW |

| Thickness Range | 1 – 6 mm | 1 – 15 mm | 1 – 25 mm | 1 – 25 mm |

What is Aluminum Laser Cutting Used for?

Materials used for decoration, advertising, lighting fixtures, kitchenware, sheet metal parts, electrical cabinet enclosures, elevator panels, engineering plates, and high-low voltage switchgear are typically thin, with thicknesses ranging from 1mm to 5mm, making them suitable for cutting with a medium power fiber laser cutting machine. The versatility and precision of the laser cutting process make it an excellent choice for these applications, providing high-quality results for various sheet metal works.

Laser Cutting for Different Types of Aluminum Materials

Laser Cutting of Pure Aluminum:

Laser cutting of pure aluminum, which has high purity (99% or higher), is highly suitable due to its low hardness and high absorption of laser energy. The laser beam can effectively melt and vaporize the pure aluminum, resulting in precise cutting with minimal heat-affected zone.

Laser Cutting of Aluminum Alloy:

Laser cutting of aluminum alloys depends on their alloy composition and hardness. Aluminum alloys with lower hardness are generally easier to cut using a laser. Higher hardness alloys may require higher power or larger laser pulse energy for effective cutting.

Laser Cutting of Anodized Aluminum:

Anodized aluminum refers to the aluminum surface that has undergone an anodizing process, forming an oxide layer. Laser cutting of anodized aluminum can remove the oxide layer and create precise markings or patterns on the surface. The laser energy can interact with the anodized layer, resulting in changes in color or the addition of images and text.

Laser Cutting and Engraving of Powdered Coated Aluminum:

Powder coated aluminum is aluminum that has a protective and decorative coating of powdered paint applied. Laser cutting and engraving of powder coated aluminum can be achieved by accurately controlling the laser beam to remove the powder coat layer while preserving the underlying aluminum substrate. The laser can create intricate designs, logos, or text on the surface of the powder coated aluminum.

Auxiliary Gases for Laser Cutting Aluminum

There are many gases that can be used for air-assisted cutting, such as oxygen, nitrogen, argon, and air. Generally, nitrogen is the most common gas used for cutting aluminum, but another option is air. Using oxygen may increase cutting speed but can result in aluminum oxidation on the cut edge. On the other hand, nitrogen is the best choice for laser cutting aluminum as it can enhance cutting speed, provide smooth edges, and prevent oxidation effects.

To achieve clean cutting edges when laser cutting aluminum, two things should be considered: high pressure and gas assistance. The combination of these two factors effectively and rapidly jets away any melted material, preventing the accumulation of rough edges. For aluminum, the faster the cutting speed, the smoother the edge. This is why higher power lasers perform better when cutting aluminum, allowing you to push the cutting line faster.

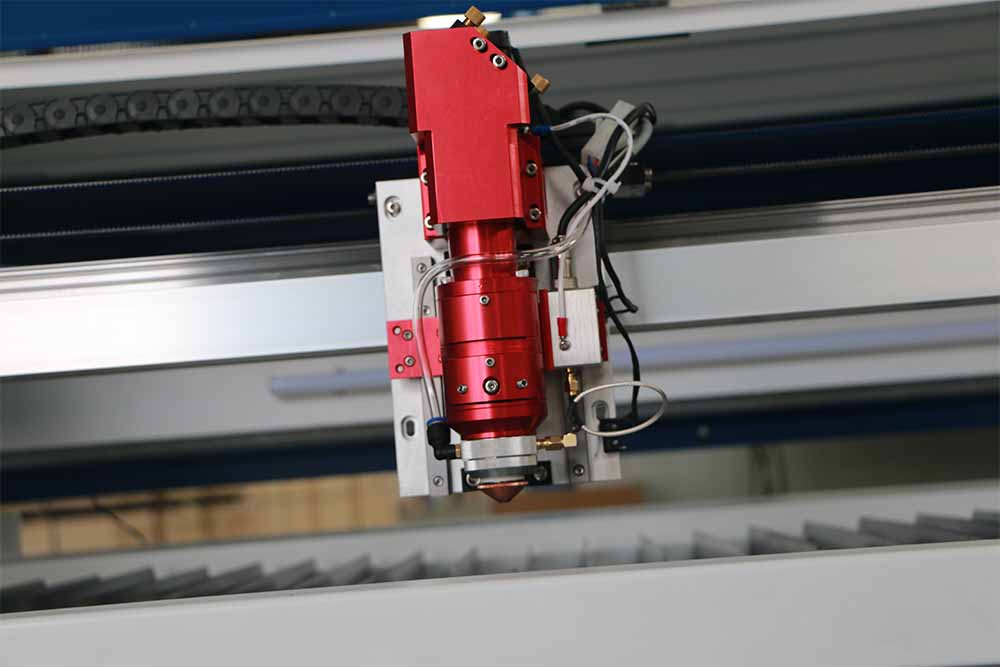

The Best Aluminum Laser Cutting Machine

This is a low and medium power 1500W fiber laser cutting machine, offering various power options ranging from 1500W~6000W. The affordable fiber laser cutting machine is specifically designed for cutting thin metal sheets and is primarily used for metal sheet cutting (up to 12mm thickness). It can process most metal sheets, and due to its low cost and reliable performance, it is widely used.

As an F series cheap aluminum laser cutting machine, it is mainly used for processing thin metal sheets, especially those below 12mm thickness. This fiber laser machine is suitable for nearly all types of metal sheets, such as carbon steel, stainless steel, iron, alloy, aluminum, copper, and other metal sheets. Its versatile material processing capabilities make it widely used in various industries, including the advertising industry, metal cutting, signage, kitchenware, iron cabinets, mechanical parts, electronic products, and more.

Function Control:

– Positioning Accuracy: 0.03mm

– Minimum Kerf Width: 0.15mm

– Maximum Cutting Speed: 110m/min

– Maximum Moving Speed: 110m/min

– Supports Maximum Acceleration: 1.2G

Fiber Laser Machine with Heavy-Duty Steel Frame

This fiber laser cutting machine features a heavy-duty steel frame that has undergone a series of welding processes, allowing it to handle extremely heavy workpieces. The robust steel frame is resistant to deformation and maintain cutting accuracy for a long time, which extends the machine’s service life.

Cast Aluminum Gantry Beam

The cast aluminum gantry beam satisfies the dual requirements of speed and stability. It is lightweight, structurally stable, has good heat resistance, and is less prone to deformation, thereby minimizing the burden on the machine. Additionally, the gantry beam and the mounting base for the drive motor are cast as a single unit, resulting in higher precision and stability for this economic laser cutting machine.

Laser Source

Raycus/Max/IPG/nLIGHT, multiple choice Different brands, different laser power are available. The higher power, the thicker cutting thickness.

Servo Motor

Top brand servo motor, we cooperate with Japan brand YASKAWA, also you can choose France brand Schneider, Italy brand MOTOR POWER and you can choose according to the power you need.

Servo Reducer

We choose top cooperative brands servo reducers with high precision, high durability and low energy consumption, France brand MOTOREDUCER, Japan brand SHIMPO, Germany brand ALPHA.

Taiwan HIWIN Guide

Adopted Taiwan Hiwin linear guide rail, high positioning accuracy, scroll guide, reduce wear to maintain accuracy for a longer time.

Taiwan YYC Gear Rack

High carbon content, high compressive strength and high hardness. Low thermal sensitivity reduce the loss of equipment in using.

Auto Lubrication System

This machine accessory is applied to lubricate the machine rail and block in order that it runs smoothly and fast, improving the working efficiency.

In conclusion, the advancements in laser cutting technology have brought remarkable changes to the world of metalworking, especially when it comes to cutting aluminum sheets. The best laser cutter for aluminum sheet combines precision, speed, and versatility, making it an indispensable tool for various industries, including aerospace & automotive metal parts, precision parts of electronics, and sheet metal processing.

By staying abreast of the latest developments of laser cutting and engraving aluminium, you can make informed decisions in selecting the ideal laser cutter for your aluminum sheet cutting needs. Embracing this cutting-edge technology unlocks a world of possibilities, empowering your business to achieve new heights of precision, productivity, and innovation in the ever-evolving landscape of modern metalworking.