The global laser marking machine market is expected to witness significant growth with the emergence of customized products in the market and their increasing popularity across the globe. Industrial laser marking machine plays a vital role in various industries and is capable of engraving personalized messages on the surface of various products such as stone, plastic, glass, metal, and wood.

With the continuous advancement of laser engraving technology and the growth of market demand, businesses are increasingly adopting industrial laser marking systems to improve production efficiency, meet personalized demands, and remain competitive in the global market.

This flexible and diverse engraving capability allows companies and individuals to add unique marks and features to their products, meeting the demand for personalization. With the ongoing innovation and improvement in laser marking technology, the market prospects will become even broader, bringing new development opportunities to various industries worldwide.

Increase Production Efficiency

Automated laser marking systems can handle large quantities of products with high speed and precision. Compared to traditional manual engraving, automation enhances production speed, reduces production costs, and is suitable for large-scale manufacturing.

Multi-Functional Automated Marking

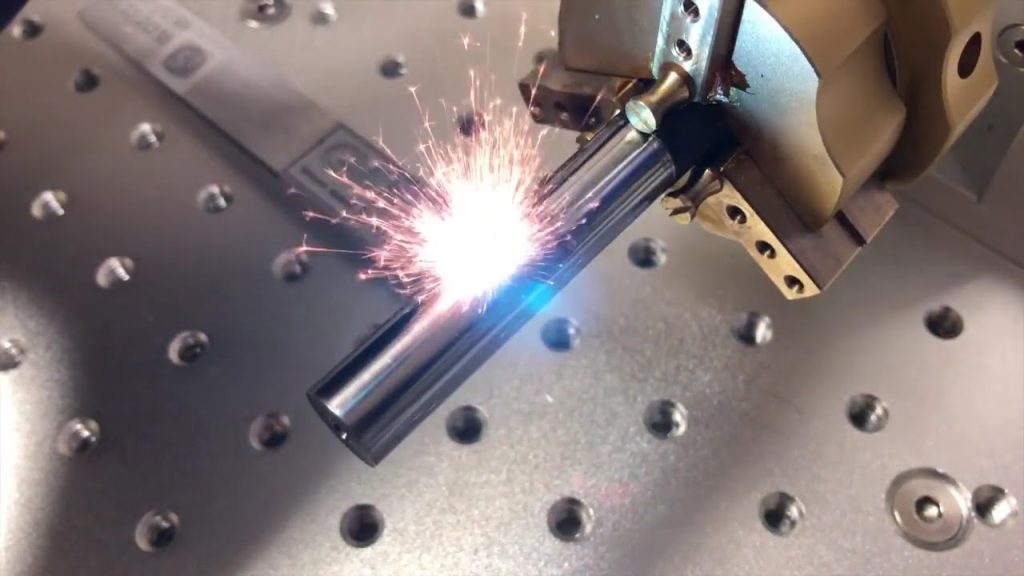

Future automated laser marking machine will evolve towards greater versatility. Currently, automated marking is primarily used for simple markings such as text, patterns, and QR codes. However, with technological advancements, automated marking machines will be capable of more diversified marking tasks. For example, by integrating 3D marking technology, automated marking machines can perform markings on complex curved surfaces, achieving more artistic results.

Moreover, automatic marking technology can be integrated with other processing equipment, such as laser cutting and laser welding, to form an integrated production line, enabling one-time processing of workpieces and enhancing production efficiency and quality.

Collaborative Applications

Industrial laser marking machine will no longer be standalone devices but will collaborate with other intelligent devices. Through interaction with robots, drones, and other equipment, automatic marking system can perform more flexible and efficient marking tasks in complex environments.

For example, in the automotive manufacturing field, automated marking machines can collaborate with robots to achieve automatic marking on various parts of car bodies, reducing manual intervention and improving production efficiency and consistency.

Improved Marking Quality

With continuous improvements in laser marking equipment and control system, laser engraving machines have made significant progress in high-speed and high-precision engraving. High-speed engraving enhances production efficiency, while high-precision engraving ensures product quality and fine detail accuracy.

Digitization and Intelligence

With artificial intelligence, machine learning, and automation makes CNC laser machine more intelligent and efficient than ever before. Automated laser engraving systems are often combined with digital design software and intelligent control systems, achieving a more intelligent production process.

Laser Marking Helps Intelligent Production

Laser marking machines play a crucial role in smart production by significantly reducing the need for manual control and minimizing errors in operation. Mechanical equipment can automatically perform tasks such as automatic feeding and retrieval without complex human intervention. The application of this technology not only improves work efficiency and reduces costs but also significantly enhances product quality and reliability.

With the progress of digital transformation, manufacturer are intensifying their technological research and actively promoting the use of vision laser marking equipment to improve product quality and production capacity. Compared to traditional packaging marking methods, laser marking technology is not only more flexible but also more reliable and creative. These advantages bring more possibilities to the medical, packaging, and processing industries, offering greater development opportunities for enterprises.

Industrial automatic laser marking machine as through the promotion of industrial transformation and upgrading of enterprises, improve the competitiveness of the manufacturing industry, enterprises can better cope with market challenges, and achieve sustained development and growth.

Auto Laser Marking Machine Combined With Intelligent Monitoring System

Through the intelligent monitoring system, the auto laser marking machine can realize real-time monitoring, automatic calibration, remote maintenance and other functions, so as to improve the safety and reliability of the production line. The application of this intelligent monitoring system helps to reduce the risk of accidents, improve production efficiency, and bring more convenience and security to the production management of business.

Real-time monitoring of laser working status:

The intelligent monitoring system can monitor the working status of the laser marking machine in real time, including laser power, marking speed, temperature and other parameters. Once an abnormal situation occurs, the system can issue an alarm and stop the laser work in time to avoid potential safety risks.

Automatic calibration and adaptive adjustment:

The intelligent monitoring system can automatically calibrate and adaptively adjust the laser marking machine. Through automated testing and calibration of the equipment, it can ensure the accuracy and stability of marking, reduce the error rate and improve reliability.

Equipment remote monitoring and maintenance:

Intelligent monitoring system makes the laser marking machine can be remotely monitored and remotely maintained. Production managers can remotely monitor the status and working condition of the equipment through the network connection, deal with faults and problems in time, reduce downtime and improve the reliability and continuity of the production line.

Data recording and analysis:

Intelligent monitoring system can record various data in the marking process, such as marking time, energy consumption, material utilization rate. These data can be analyzed and counted to provide reference basis for production line optimization and improvement, further improving production efficiency and reliability.

Laser Marking for Industrial Applications

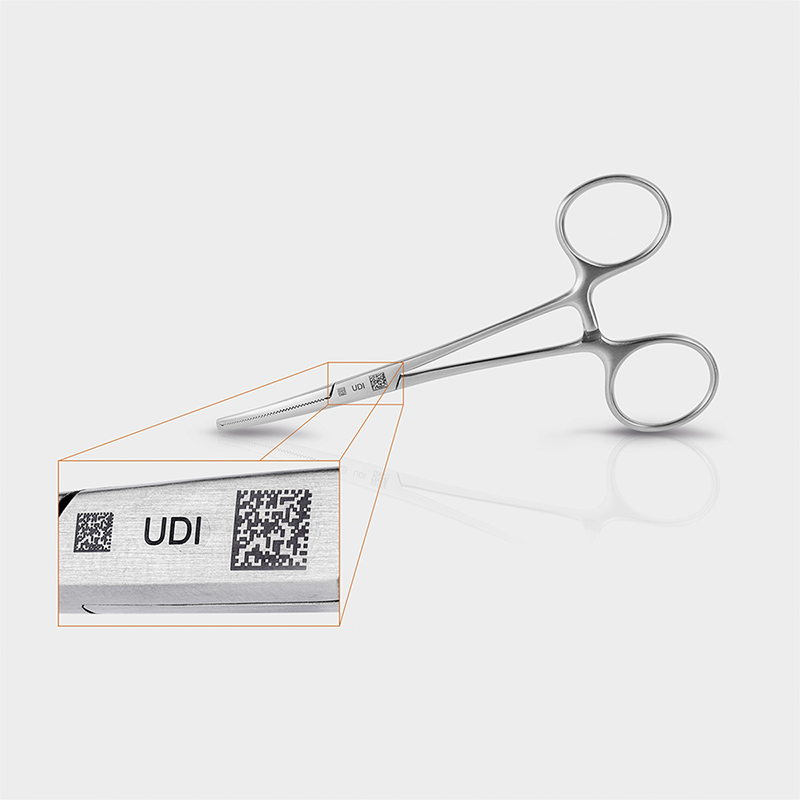

Medical/Pharmaceutical Industry:

Laser marking technology is widely used in the medical and pharmaceutical industry to create markings that withstand sterilization and disinfection processes. It is the preferred method for adding crucial information to surgical tools, syringes, implant chips, medical UDI, and drug packaging.

Electronics Industry:

From personal care products to cleaning supplies and electronics, the appearance and presentation of products’ packaging are critical in influencing consumer purchasing decisions. Laser marking machine offers an effective solution for creating high-quality barcodes, serial numbers, copyrights/trademarks, logos, and other personalized markings on packaging, catering to diverse consumer needs.

Manufacturing & Machining of Parts:

Laser marking machine for industry manufacturing is a reliable and efficient method for adding permanent markings on almost any type of part. Laser marking machines are commonly used to add QR codes, serial numbers, barcodes, or logos, ensuring part traceability, quality control, and process improvement.

Food and Beverage Industry:

Food and beverage companies adopt laser marking technology to mark batch numbers, batch codes, expiration dates, and other crucial information on product packaging. Compared to traditional labeling methods, laser marking uses non-toxic, anti-smudge, and easily readable materials, providing safer and clearer markings on products. High-speed laser marking systems simplify coding and marking processes in bottling and canning operations. For example, the beverage industry often uses laser marking machines to mark glass bottles, plastic bottles, aluminum cans, and other beverage containers.

Packaging Industry:

Laser marking technologies & engraving solutions is economical and efficient for adding precise markings on various common packaging materials, including paper, plastic, organic materials, and textiles. Laser marking can create easily readable labels that do not peel off or get dirty over time, ensuring clear visibility of product information during distribution and use.

PCB (Printed Circuit Board):

With the rapid development of the IT industry, products such as smartphones and wearable electronic devices are trending toward being lightweight and compact. To achieve quality control in the PCB production process, marking characters, barcodes, QR codes, and other information on PCB boards for traceability have become an industry trend. Laser marking offers high precision, fast speed, simple operation, and stable performance. Controlled by a computer, it can print various complex patterns, text, QR codes, and other content, fully meeting the marking requirements of the PCB industry.

Customized Industrial Marking Solutions

The DP LASER laser marking system for industry can also be configured according to specific requirements, such as Laser source, laser heads, workbench tables, rotary axis, fixtures, automation functions and auxiliary accessories, etc. For parts involving small batches or requiring delicate and challenging marking, a customized marking system can be employed to simplify the process. DPLASER’s customized laser marking machine assist small businesses in upgrading their manufacturing capabilities and ensure they can swiftly respond to the new challenges and opportunities in the industry.

Finally:

New developments in automatic marking technology for industrial applications allow us to look forward to more imaginative applications in the future. From intelligent, multi-functional, collaborative applications to digitalization, automatic marking machines will bring higher efficiency, better quality products and more flexible production methods to industrial production lines. We believe that industrial fiber laser solutions for marking will play a more important role in the future manufacturing.