In today’s highly competitive manufacturing landscape, businesses are constantly seeking more efficient and precise processing solutions to gain a competitive edge. The double head laser marking machine has emerged as a powerful response to these demands, offering high-speed, and high-precision marking capabilities. By allowing simultaneous marking on multiple parts or different surfaces of the same part, this equipment significantly boosts production efficiency and streamlines the overall workflow.

The multi head laser marking machine is designed with multiple laser heads, enabling parallel processing of several workpieces to further enhance overall production line efficiency. At the same time, the multi-station laser marking machine features an intelligent station-switching system that allows for rapid workpiece transitions, reducing loading times and significantly shortening production cycles. These advantages make multi-head and multi-station laser marking machines an ideal choice for businesses aiming to boost productivity and optimize manufacturing processes.

Advantages of the Dual-Head Laser Marking Machine

● High-Efficiency Dual-Head Operation – Save Production Time

The biggest advantage of the dual-head laser marking machine lies in its ability to operate two heads simultaneously. It can process two workpieces or areas at the same time, significantly improving production line efficiency. This is especially ideal for high-volume, continuous production scenarios, helping manufacturers complete more tasks within the same time frame.

● Precise Marking – Compatible with Multiple Materials

The machine offers high-precision positioning and marking capabilities, suitable for a wide range of metal and non-metal materials. Its non-contact laser marking method ensures clear, consistent results while effectively avoiding surface damage, indentations, or deformation that can occur with traditional marking methods.

● Easy Operation – Supports Automated Production

Equipped with an advanced control system, the dual-head laser marking machine enables quick parameter adjustments and fully automated operation. Simple setup without complex debugging allows for rapid deployment, making it easy to meet varying product specifications across different batches. This greatly reduces manual intervention and enhances production continuity.

● Durable and Stable – Ensures Continuous Operation

Built with high-quality core components and mature technology, the machine delivers excellent stability and reliability. Whether running for extended periods or operating in demanding environments, it maintains consistent performance, reduces failure rates, and minimizes downtime-related production losses.

Conclusion

The dual-head laser marking machine not only multiplies efficiency but also excels in precision, automation, and operational stability. It is an ideal choice for manufacturers seeking high productivity with reduced labor costs.

Applications of Multi-Head Laser Marking Machines

To meet the diverse production needs across various industries, Dapeng Laser Technology Co., Ltd. offers a wide range of laser marking machines, including single-head, dual-head, and four-head configurations. These models support a variety of marking applications, from small-batch customization to large-scale manufacturing.

Single-Head Laser Marking Machine

Equipped with a single laser head, this model features a compact structure, user-friendly operation, and low maintenance costs. It is ideal for small-batch production or personalized customization, offering a cost-effective yet high-quality marking solution. It is widely used in industries that require high marking precision, such as watches, jewelry, mobile phones, and electronic products.

Dual-Head Laser Marking Machine

With two laser heads, this model allows simultaneous marking of two workpieces. It maintains high precision while significantly improving productivity, making it well-suited for medium- to large-scale industrial applications. Typical uses include the manufacturing of consumer electronics, plastic components, and metal accessories.

Multi-Head (Four-Head) Laser Marking Machine

Featuring four laser heads, this model enables concurrent processing of multiple workpieces, dramatically increasing production capacity. It is an ideal solution for high-intensity, large-scale production lines. Common applications include automotive parts, motorcycle components, household appliances, and metal hardware. It ensures both high efficiency and superior marking clarity and accuracy.

Is a Dual-Head Laser Marking Machine Worth the Investment?

Absolutely.

Laser marking machines have become essential tools in modern manufacturing and high-tech industries due to their high efficiency, precise marking, and versatile applications. Utilizing advanced laser technology, they deliver consistent, high-quality results across a wide range of materials, ensuring fine and durable markings.

1. Increased Productivity through Dual-Head Design

Unlike traditional single-head machines, dual-head laser marking systems can process two workpieces simultaneously. This parallel operation significantly boosts throughput, making them ideal for medium to large-scale production. By reducing the burden on individual workstations and streamlining workflows, they help businesses meet growing production demands with greater speed and accuracy.

2. High Precision & Versatility across Materials

Powered by advanced laser technology, dual-head machines ensure consistent, high-quality markings. They are suitable for a wide variety of materials—both metal and non-metal—delivering fine, accurate, and durable results.

3. Reduced Labor & Operating Costs

With dual-heads working simultaneously, manual involvement is minimized. The automation reduces labor costs, while faster cycle times contribute to lower overall production costs.

4. Space-Saving

For the cost of a single machine, you gain double the working efficiency. Despite doubling the output capacity, a dual-head laser marking system requires no more floor space than a single-head unit. This efficient footprint allows businesses to optimize factory layouts, reduce equipment redundancy, and improve space utilization.

5. Excellent Return on Investment

While the initial cost of a dual-head laser marking machine is higher than that of a single-head model, the return on investment is typically fast. Higher efficiency, reduced labor input, and space savings contribute to quicker cost recovery and increased profitability.

Conclusion

Dual-head laser marking machines offer a compelling balance of speed, precision, and cost-effectiveness. For manufacturers looking to improve productivity, lower operating costs, and stay ahead of the competition, the multi-head laser marking system is a smart and future-ready investment.

Double Head Laser Marking Machine for Metal – Efficient Industrial Laser Marker Machines

Dapeng Laser Technology Co., Ltd. has developed multi-head laser marking machines to meet the modern industrial demand for efficient marking. The dual-head fiber laser marking machine doubles the processing efficiency, equivalent to two machines. Each head’s marking content can be independently adjusted, allowing for the processing of different products.

The software uses a WINDOWS interface and is compatible with files output from various software such as CORELDRAW, AUTOCAD, PHOTOSHOP, etc. It supports files such as PLT, AI, DXF, BMP, and can directly use TXT and TTF font libraries. It also supports automatic coding, serial numbers, batch numbers, dates, barcodes, and QR codes, with a graphic reversal function.

We also offer a variety of laser marking machines, including fiber laser, CO2 laser, UV laser, and ultrafast laser marking machines, to meet the needs of different materials and application scenarios.

Features:

Dual-head synchronous operation: Two laser heads work simultaneously to achieve high-efficiency marking, significantly reducing processing time.

Wide material compatibility: Laser marking for various materials such as PET, PP, PVC, ABS, wood, stainless steel, aluminum, iron, and more.

Non-contact processing: No physical contact, effectively protecting the workpiece surface, with long-lasting and clear laser markings.

High processing precision: Fine laser beam with a small heat-affected zone, minimizing material loss.

Automation compatibility: Fully computer-controlled, making it easy to integrate into automated production lines.

Applications:

It is widely used in industries such as integrated circuit chips, electrical components, industrial bearings, clocks, automotive parts, home appliances, hardware tools, molds, wires and cables, food packaging, jewelry, and more. It can quickly and efficiently complete graphic and text marking tasks, especially suitable for large-scale production scenarios.

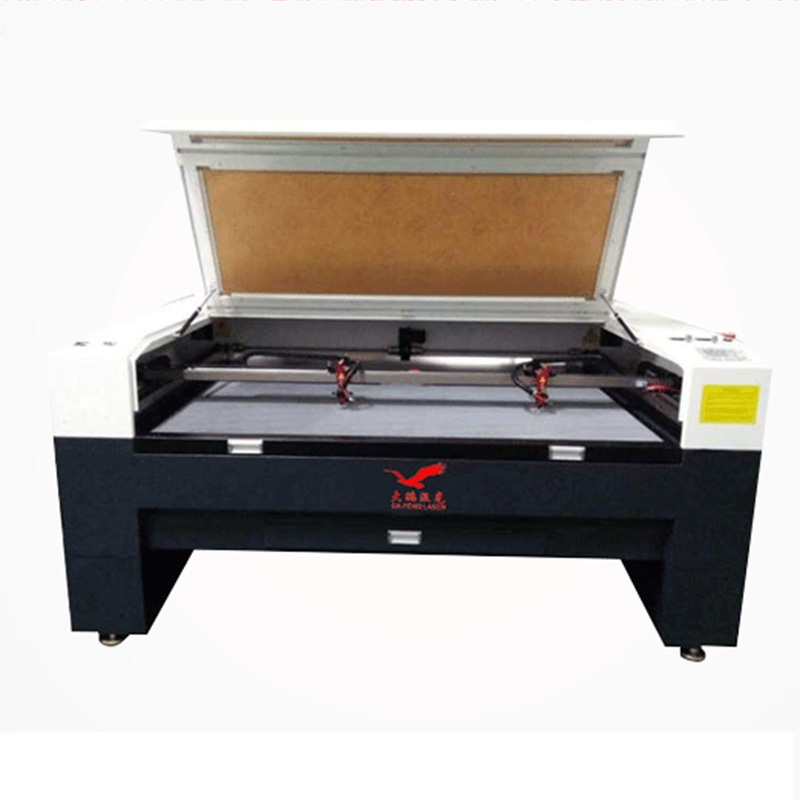

Dual-Head CO2 Laser Cutting & Engraving Machine

The Dual-Head CO2 Laser Wood Cutting Machine is a highly efficient and versatile laser processing equipment, widely applicable for precise cutting and engraving of various non-metal materials such as wood, paper, leather, fabric, acrylic, resin, rubber, crystal, jade, bamboo, and more.

The Dapeng Dual-Head Laser Wood Cutting and Engraving Machine is equipped with two sets of high-performance CO2 laser tubes, power supplies, cooling systems, and laser cutting heads, significantly improving processing efficiency. The dual-head design doubles the production capacity. The machine fully utilizes the motion control system to optimize the laser processing effects, enhancing cutting precision and speed.

From software design to mechanical structure and configuration, the Dual-Head Laser Wood Cutting Machine is engineered for high-efficiency and precise processing at every stage, ensuring high-quality processing in a safe and stable working environment. The machine features two independent workstations, allowing for automatic switching and simultaneous feeding and cutting, which greatly reduces feeding time and improves production efficiency.

Features of the Dual-Head Laser Engraving Machine

- Flying Marking Technology: This innovative technology allows the engraving machine to efficiently mark materials at high speeds, significantly improving processing time and productivity.

- Customization Options: Dapeng offers personalized customization services, allowing you to configure the dual-head laser system according to your specific needs, providing greater flexibility in operation.

- Wide Application Range: The dual-head laser engraving machine is not only capable of fine engraving on metal surfaces but is also suitable for engraving various non-metal materials and wood, making it highly versatile across multiple industries.

Multi Head Laser Marking Machine Price

Laser marking machines come in a wide variety, with significant differences in both functionality and price. To select the right equipment, it’s recommended to compare and consider the following aspects:

1. Price Considerations

The price of a laser marking machine is influenced by several factors, including the brand, model, laser power, and configuration. High-end brands or high-power devices tend to be more expensive, but higher prices do not always equate to better suitability for your needs. The key is to ensure the machine meets your specific production requirements.

2. Performance Considerations

- Laser Source: The core of the equipment, which determines the clarity and stability of the marking results. It’s recommended to choose a laser source that is stable and has a long lifespan.

- Control System: This directly impacts the marking speed and precision. A high-quality system enables fast, high-precision marking while simplifying operation.

- Marking Speed: This is related to both the laser source and the control system. Generally, the larger the power and the more advanced the system, the faster the marking speed.

- Marking Quality: To achieve clear and durable marks, the equipment must strike a balance between laser power, control systems, and speed.

3. Buying Suggestions

- Clarify Your Needs: First, determine your actual production requirements, such as material types, production volume, and marking precision.

- Match with Budget: Choose the appropriate equipment based on your budget. Don’t blindly pursue high-end configurations or big-name brands; practicality is more important.

- Choose a Reliable Brand: Opt for brands or manufacturers with a good market reputation and comprehensive after-sales services.

- Customizability: If you have special requirements, such as non-standard sizes or automation integration, inquire with the manufacturer about customization options.

- After-Sales Service: Understand the after-sales policies, including warranty duration and technical support. Reliable after-sales service ensures peace of mind and timely solutions to any issues that arise.

For entry-level businesses or startups, machines priced between $1,000 to a few thousand dollars are generally sufficient. However, for large bulk production, you may need advanced features such as 3D engraving, dynamic focusing, flying marking, assembly lines, and automated loading and unloading systems. In such cases, the cost may rise to tens of thousands of dollars, especially if integrated with automated robotic arms for a fully automated production process.

Summary: When considering the multi-head laser marking machine price, it’s important to assess not only the initial investment but also how the machine will enhance your production efficiency in the long run. Whether you’re a small business looking to optimize costs or a large-scale manufacturer seeking advanced features, understanding the value each machine brings to your specific needs is key. Don’t miss the opportunity to boost your productivity and quality—contact us now to explore the perfect solution for your marking needs!