Dual Head CO2 Laser Cutting Machine for Plastic Acrylic Wood Leather

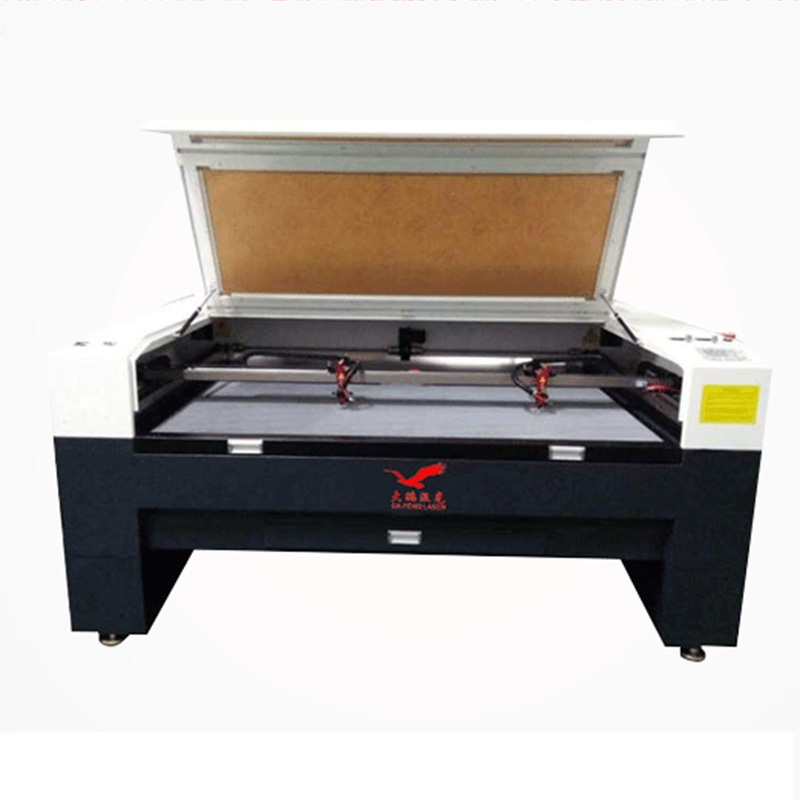

The glass tube CO2 laser cutting machine utilizes a CO2 laser beam to cut materials, employing a glass tube filled with CO2 gas for precise and efficient cutting & engraving. This machine features two laser heads, allowing for simultaneous cutting operations or different cutting settings on various materials. Its dual-head configuration increases productivity by reducing processing time, enabling intricate designs and patterns to be cut with high accuracy.

The machine’s software automatically arranges pattern designs to minimize material waste. Its transmission system enables straight-line cutting, instant speed adjustments, and smooth edges, facilitated by linear motion guides for stable operation.

Equipped with a high-definition camera, the machine captures the entire work area and pattern, allowing the software to generate cutting files accurately. Its variable speed system enables seamless cutting of curves and straight lines, making it suitable for various non-metal material surfaces.

Features:

- With the characteristics of small cutting slit, fast speed and high precision, the accuracy and service life of the equipment are guaranteed.

- Smooth running, fine and clean cutting.

- With the characteristics of safe operation and simple maintenance, it can work continuously for 24 hours.

- Cut fabric, the edges are not yellow, automatic hemming without loose edges and no deformation.

- Can cut any complex shape, high efficiency, low cost, automatic graphic layout.

- Humanized software operation interface, various patterns and text instant cutting, simple operation, flexible and convenient.

Advantages:

Big Working Space: The Pass Through Doors is designed for wide range of laser projects.

Control System: Connected to USB, Digital LCD display, Compatible with Windows.

Support online/offline working, adjustable cutting speed and power.

Equipped control system for CorelDraw/AutoCAD and other advanced software.

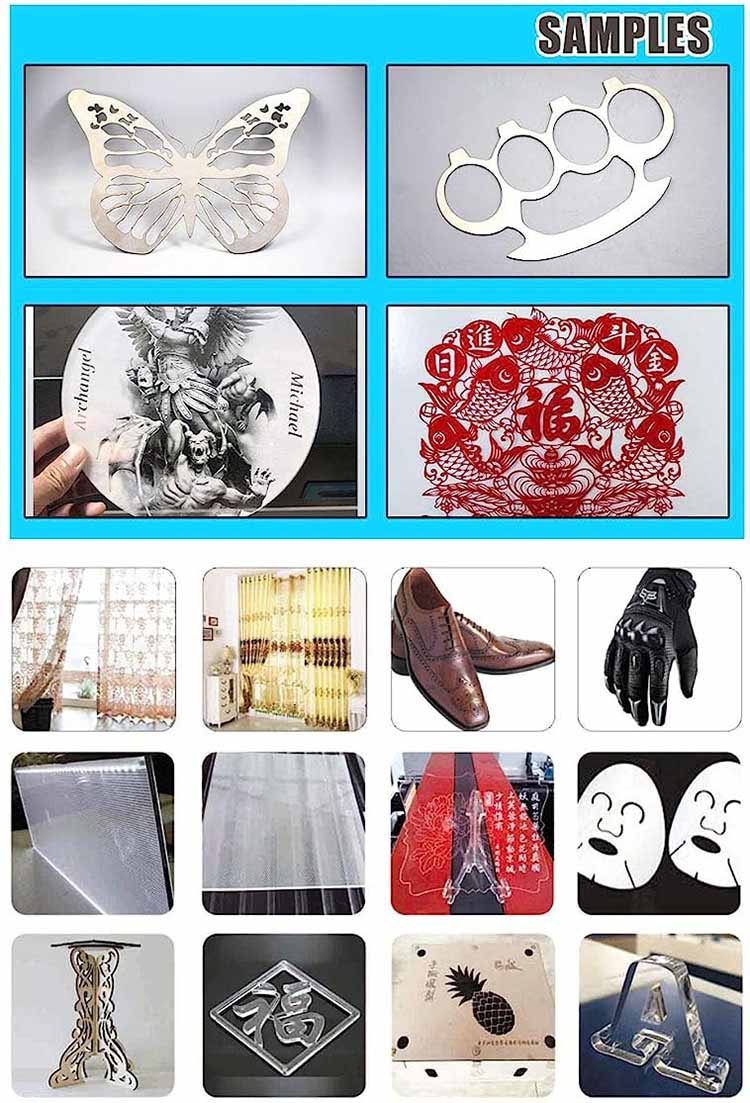

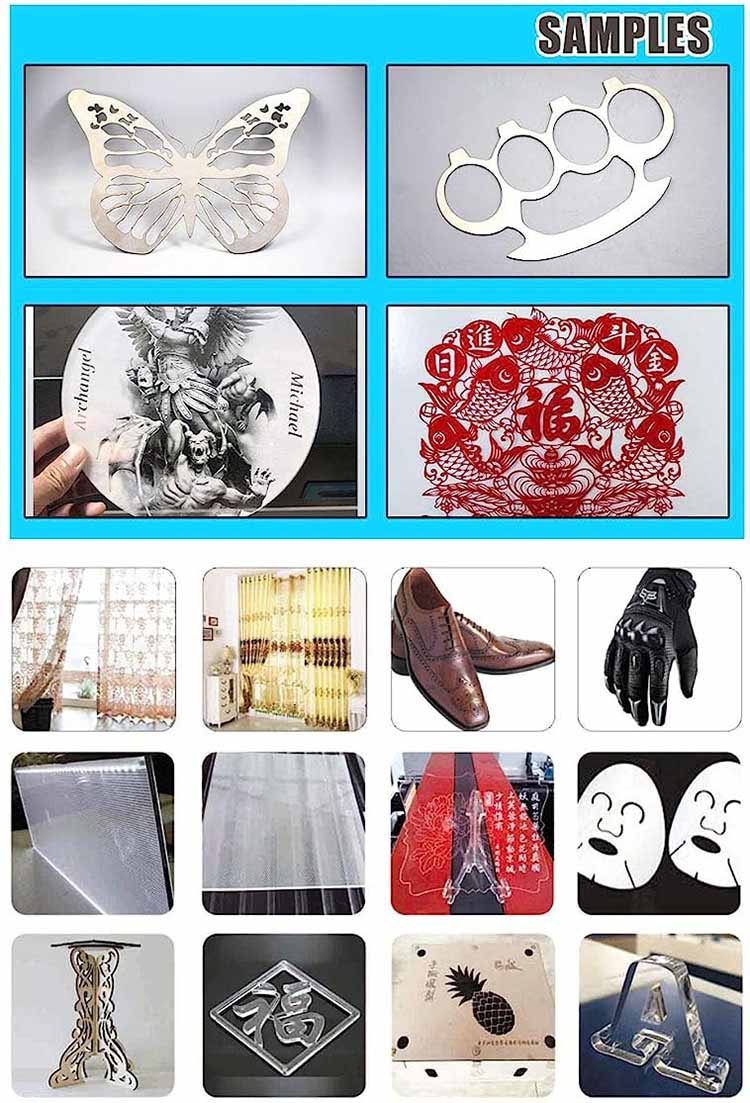

CO2 laser cutter can be applied to the following industries:

- Shoe sample processing, shoe material hollowing and engraving.

- Garment fabric cutting, garment accessories hollowing, punching, cutting edge.

- Leather punching, sampling, cutting.

- Plexiglass, plastic, fiberboard, PVC, paper, wood and bamboo cutting.

- Wood and bamboo, ceramics, granite, shadow carving industry engraving.

Please contact DPLASER for more information. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? cutting or engraving?

2. What material do you need to process?

3. What is the size and thickness of the material?

Reviews

There are no reviews yet.