Laser welding machines are high-precision and efficient welding equipment widely used in industries such as automotive, aerospace, electronics, and more. In the laser welding, laser welding wire feeding is a common auxiliary technique that can enhance welding quality and efficiency. While not a new technology, it has been widely employed in traditional TIG welding. Furthermore, due to the laser beam continuous output and stable energy, it can better cooperate with laser welding wire feeder, enabling the automation of the entire welding process.

How Does a Wire Feeder Work?

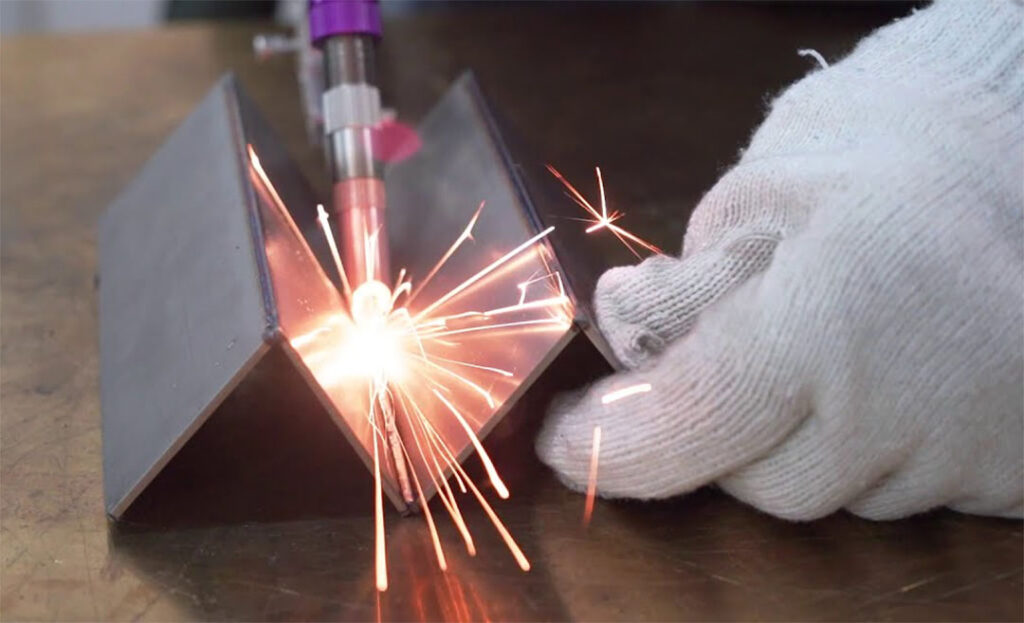

The laser welding machine focuses a laser beam to rapidly elevate the temperature of the welding area to or above the melting point of the welding material. Simultaneously, the wire feeding system delivers welding material (which may be a metal similar to the base material or a brazing material) to the welding area. Under the influence of the laser source, the wire material melts and fill in the base material, forming a weld seam. By adjusting the wire feeding speed and welding parameters, the filling and diffusion of the weld seam are controlled to meet specific workpiece requirements.

Why Need Wire Feeder for Laser Welding?

1. Filling Material:

Wire feeding enables the precise delivery of welding wire into the weld seam, filling it and enhancing welding quality.

2. Welding Depth Control:

By adjusting the wire feeding speed and welding power, welding depth can be controlled, ensuring the consistency and stability of the weld seam.

3. Increased Production Efficiency:

Wire feeding facilitates automated welding, reducing manual intervention and enhancing production efficiency.

4. Welding Speed Control:

Managing welding speed ensures welding quality and production efficiency.

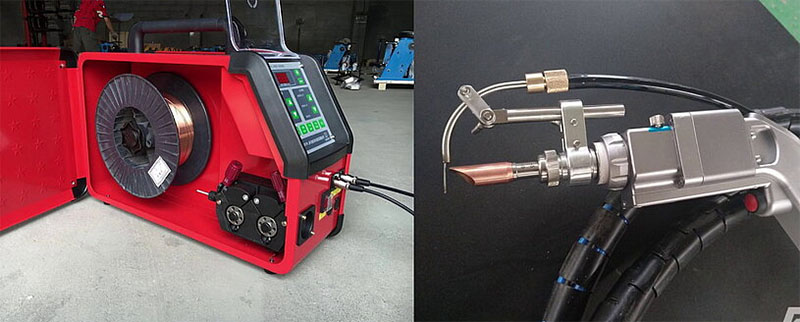

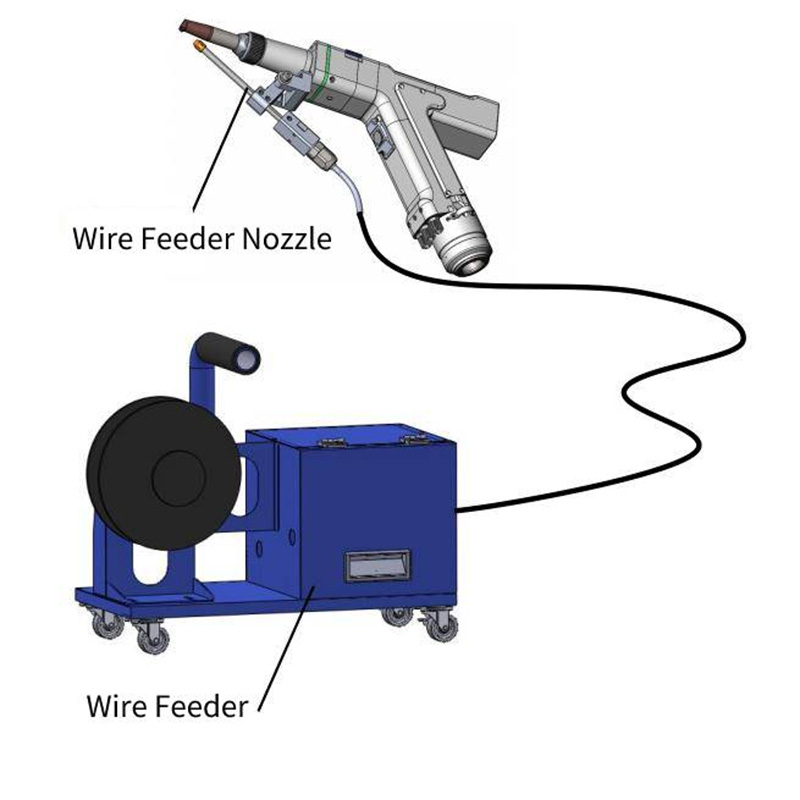

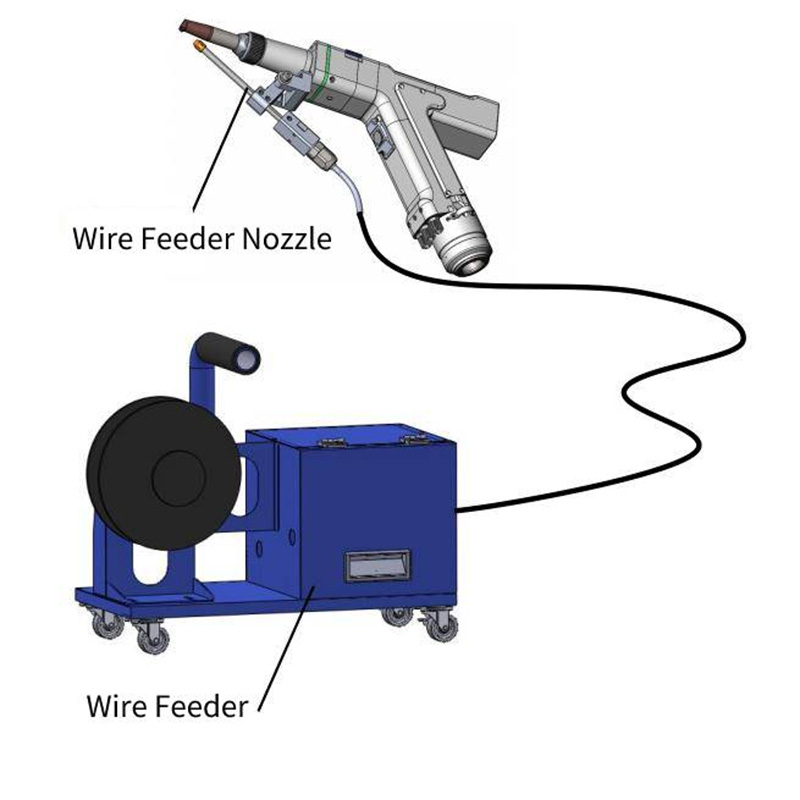

The automatic wire feeding system mainly includes a wire feeding hose, wire spool, and wire feeding mechanism, constituting a crucial component of automated welding equipment. In the CNC laser welding system, the automatic wire feeder can receive commands and operate promptly, achieving intelligent control over the wire feeding speed and direction during the welding process. Various wire feeding methods are available for the automatic wire feeder used in welding. To ensure a stable wire feeding process, users need to choose the appropriate wire feeding method based on factors such as workpiece material, welding parameters, and wire type.

Precautions for Using Wire Feeder of Laser Welding Machine

When using a laser welding wire feeding system, to ensure the smooth progress of the welding process and efficient assurance of the final welding quality, it is important to note the following:

- Avoid Wire Breakage: Check the quality and length of the welding wire to prevent wire breakage, which can impact welding quality and production efficiency.

- Avoid Excessive or Insufficient Welding: Control welding power and speed according to the requirements of the welding material to avoid excessive or insufficient welding.

- Prevent Porosity during Welding: Control welding temperature and speed to prevent the occurrence of pores during the welding process, which can affect welding quality.

- Ensuring the proper functioning of the wire feeder is critical as it directly affects the smoothness of the wire feed. Regular cleaning and lubrication are essential steps.

- The accuracy of the size of the drive rollers also has a direct impact on the uniformity of the wire feed. By using the correct size and style of drive rollers, the smoothness of wire feed can be effectively guaranteed.

- Over time, the contact tips wear out, and debris and dirt on the wire feeder nozzles can also cause problems during wire feed. Therefore, regular maintenance of the wire feeder nozzle is essential to help facilitate a proper wire feeding process.

Dual Wire Feeder vs. Single Wire Feeder

Laser welding machine single wire feed refers to the wire feeding and control through one wire wheel, while double wire feed is through two independent wire wheels for wire feeding and control.

1. Control Mode

The biggest difference is its control mode. In single wire feeding mode, the wire speed and welding current are controlled by the same electronic device. In the double wire feeding mode, two independent devices are needed to control the wire speed and welding current respectively. Therefore, the control mode of double wire feeding is more complicated and requires a higher level of technology to realize precise control.

2. Welding Process

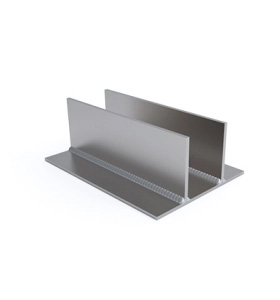

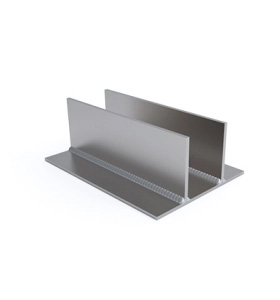

Single wire feeding is suitable for relatively simple welding processes, such as butt welding or multi-layer welding. The double wire feed is more suitable for the welding process of higher requirements of the scene. For example, high-quality, high-speed welding of thicker workpieces or the ability to control two welds individually when corner welding. Typically, single-feed laser welders can handle weld seams of 1.5 to 1.8 millimeters. However, with a dual feed laser welder, seams as wide as 3-4mm can be successfully welded.

3. Cost

The advantages of a single wire feeder are simple control, low cost, and ease of operation. However, the disadvantages are that the quality of the weld seam is more susceptible to compromise and the welding speed is relatively slow. In contrast, the double wire feeding system allows the simultaneous use of two wires, so that the filling of the weld is more uniform, thus realizing faster welding speeds and better welding control; but the disadvantage is the complexity of the equipment and higher costs.

4. Applications

Laser welding machine single wire feeding and double wire feeding applications make a difference. Laser welding machine is a high-precision welding equipment, through the use of laser beam welding, can realize fast, accurate welding process. In the laser welding machine, single wire feed and double wire feed are two different wire feeding methods, the selection of the appropriate wire feeding system depends on the specific welding needs and workpiece characteristics.

What Kind of Wire is used in Laser Welding Wire Feeders?

Stainless steel wire: Stainless steel wire is one of the most widely used welding wires for laser welding machine. Stainless steel wire has the advantages of corrosion resistance, high temperature resistance, high strength, etc. It is suitable for welding steel, aluminum, stainless steel, iron alloy, nickel alloy and other materials.

Aluminum alloy wire: suitable for welding aluminum alloy, copper alloy, magnesium alloy and other materials, the wire has good plasticity and good heat-inducing properties, and is not easy to oxidize at high temperatures, so in the aircraft, automotive, electronic equipment and other fields are widely used.

Titanium alloy wire: suitable for welding titanium alloy and other materials, with excellent corrosion resistance and high temperature performance.

Nickel alloy wire: suitable for welding nickel alloy, chromium alloy and other materials, with excellent corrosion resistance and high temperature performance.

Copper alloy wire: suitable for welding copper, copper alloy and other materials, with good electrical conductivity and thermal conductivity properties.

How to Choose the Right Laser Welding Wire for Your Project?

When using a laser welding machine for welding, it is necessary to choose the appropriate welding wire based on different welding materials and requirements.

- The diameter of the welding wire should match the thickness of the welding material to ensure welding quality.

- Choose the appropriate wire diameter; wider gaps may require thicker wires for filling. Thin wires may take a longer time to feed into larger gaps in metal components.

- The composition of the welding wire should be the same or similar to the welding material to ensure welding strength and corrosion resistance.

- The quality of the welding wire should be reliable to avoid issues such as wire breakage or bubbling during welding.

How to Weld With a Wire Feeder

Laser welding with a wire feeder combines the advantages of laser technology with the precision of wire filling and how to start laser weld with a wire feeder:

1. Set Up the Equipment:

Configure laser welding machine with a wire feeder. Choose the appropriate laser settings and wire specifications based on the material and thickness of the workpieces.

2. Prepare the Workpieces:

Clean the surfaces of the materials to be welded to remove any contaminants, rust, or oxidation. Securely clamp the workpieces to prevent movement during welding.

3. Install the Wire Feeder:

Ensure the wire feeder is properly installed and aligned with the laser welding head. Confirm that the wire spool is correctly mounted and the wire is threaded through the feeder system.

4. Adjust Wire Feeding Parameters:

Set the wire feed speed based on the welding requirements. The optimal speed depends on factors like material thickness and laser power. Ensure the wire feed is synchronized with the laser pulsing for precise welding.

5. Focus the Laser Beam:

Adjust the laser beam focus to achieve the desired spot size on the workpieces. Ensure the focal point is aligned with the wire feed location.

6. Position the Laser Welding Head:

Position the laser welding head at the starting point of the weld joint.

Ensure a suitable standoff distance between the laser welding head and the workpieces.

7. Start Welding:

Activate the laser and the wire feeder.

Move the laser welding head along the joint, and the wire feeder will deposit the filler material as needed.

Maintain a steady and consistent speed to achieve uniform welds.

8. Monitor the Process:

Observe the welding process to ensure proper fusion and deposition of the filler material. Adjust parameters if necessary to optimize the welding results.

9. Complete the Weld:

Stop the laser and wire feeder when reaching the end of the weld. Allow the welded joint to cool naturally.

10. Inspect and Finish:

Inspect the welded joint for any defects or inconsistencies. Perform any necessary post-welding processes, such as grinding or cleaning, to achieve the desired finish.

Selecting the Right Wire Feeder for Laser Welder

- Choosing the right wire feeding system is a critical decision that can have a major impact on the success of your welding operation.

- The type of material being welded is a key factor. Whether welding mild steel, aluminum, stainless steel or special alloys, selecting the appropriate wire feeder for the material characteristics is critical to achieving high-quality welding.

- It is also important to evaluate the requirements of a particular application, including factors such as joint configuration, weld location and material thickness. Some wire feeders are designed to perform well in specific welding positions to ensure that the task requirements are met.

- Consideration of the type of wire is equally important, as different wires have different diameters and compositions. The wire feeder must be compatible with the selected wire and is often designed to handle specific wire sizes and types to meet the need for harmonious matching.

- Wire feeders with features such as adjustable speeds and precise control help achieve the desired welding characteristics.

Summary:

Laser welder wire feeder is a critical components in the welding process, essential for achieving precision in welding various workpieces. From choosing the right laser welder wire feeder, wire material and diameter to accurately filling gaps and ensuring strong welds, each step is vital.

You need not worry about achieving the desired welding and wire feeding. With our fiber laser welding machine equipped with an advanced automatic wire feeding system, we offer a more efficient and reliable welding solution. We carefully customize parameters and materials to meet your project’s specific needs, ensuring excellent welding quality and performance. Choose our laser welding solutions for a more efficient and precise welding experience!