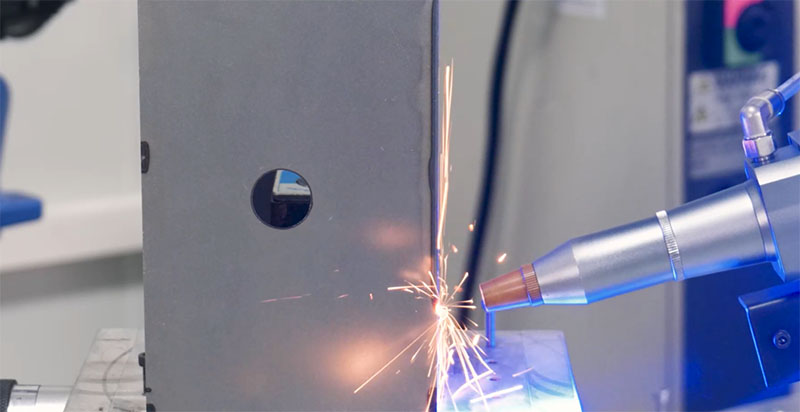

The laser welding machine is a highly efficient and precise welding device, suitable for welding various materials such as stainless steel, aluminum alloys, and copper. To ensure optimal weld quality and efficiency, it is essential to correctly set the welding parameters, including power, pulse frequency, and pulse width. Welding speed plays a critical role in determining weld quality, as it dictates the amount of energy the weld seam receives within a given time, thereby affecting the penetration depth, weld width, and overall appearance of the weld. What factors affect laser welding speed?

What Does Welding Speed Affect?

Welding Speed Affects Penetration Depth and Width

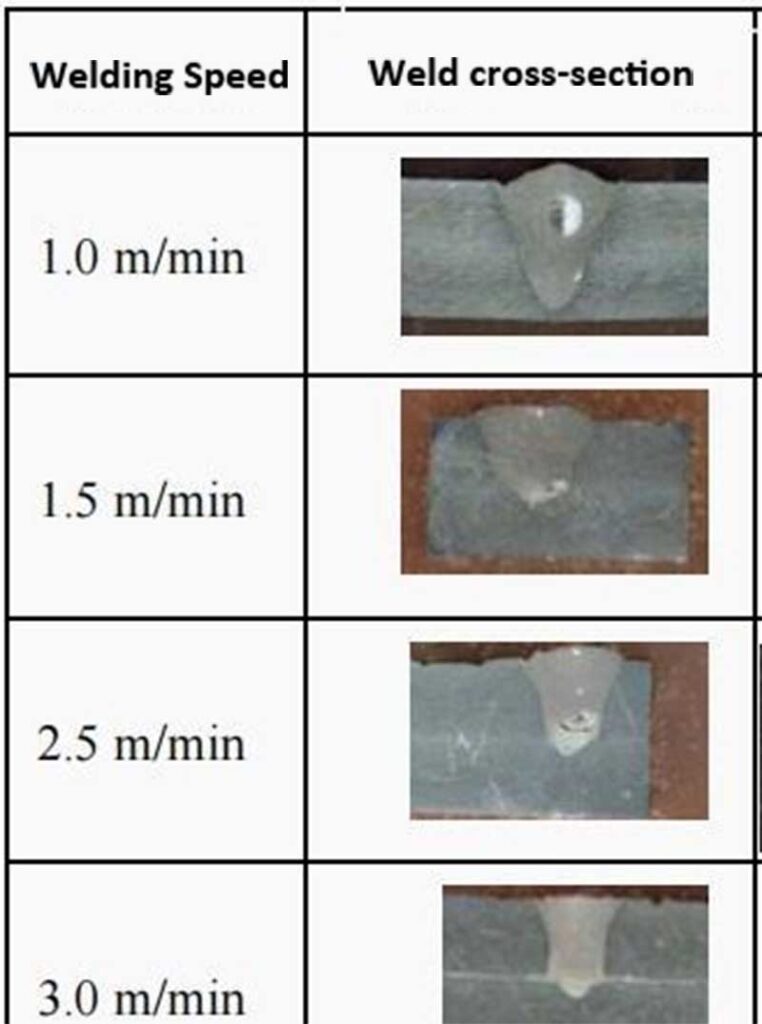

Welding speed primarily impacts the penetration depth and weld width, which are closely related to the linear energy density. As the laser welding speed increases, the area and width of the fusion zone decrease accordingly. This occurs because higher welding speeds shorten the laser’s dwell time on the workpiece surface, reducing the heat conduction area, and consequently, shrinking the fusion zone and heat-affected zone.

Typically, higher welding speeds result in shallower penetration depth and narrower weld width, while lower welding speeds produce deeper penetration and wider weld width.

Weld Strength

Appropriate welding speed ensures good bonding and high strength of the weld. Excessively high or low welding speeds can lead to reduced weld strength, thereby affecting the overall performance of the welded components.

Welding Speed Affects Weld Appearance

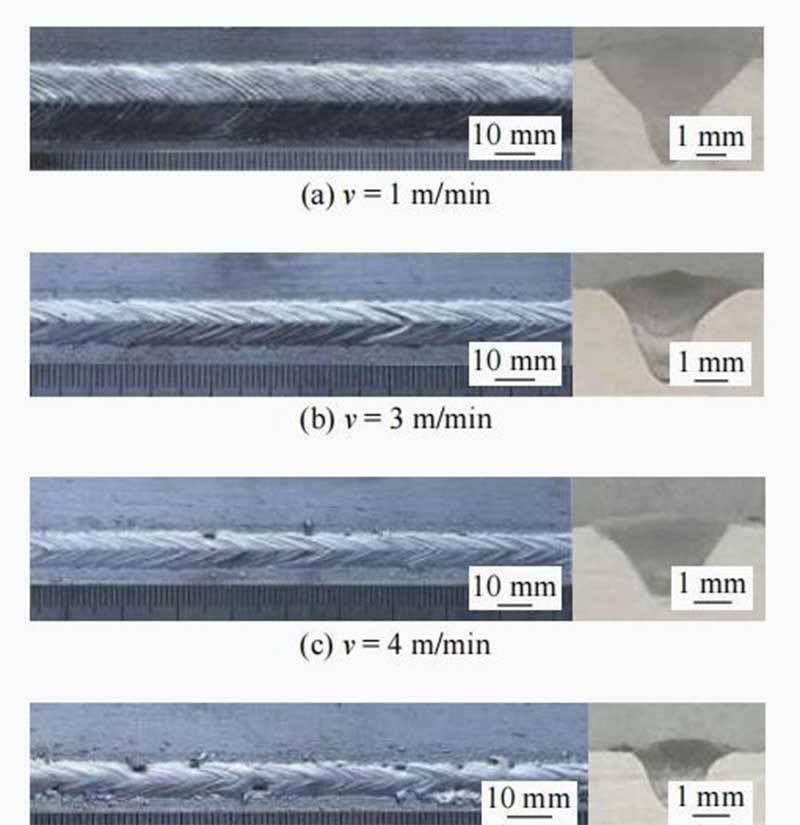

Welding speed also impacts the appearance of the weld. At high welding speeds, the weld may develop “V-shaped” fish-scale patterns, with a rough, uneven surface and discoloration.

High welding speeds can cause defects such as cracks, holes, or incomplete fusion on the weld surface, thereby reducing the weld quality. Conversely, excessively low welding speeds may lead to issues such as excessive melting and weld sagging.

What Factors Affect Laser Welding Efficiency?

Increasing welding speed can significantly shorten the cycle time for each welding task, allowing more welding work to be completed within the same period. This is particularly important for high-volume manufacturing, as it directly enhances production efficiency and capacity. However, increasing welding speed must be done with the condition of maintaining high welding quality and product reliability.

Power

Laser power determine the energy density of the welding process. Higher laser power leads to faster welding speeds because a high-power laser generates more heat, which reduces the heat-affected zone and allows the material to melt quickly and form a stable weld pool, thus increasing the welding speed. The required power varies depending on the thickness of the welding material and the welding speed. Generally, thicker materials require higher power settings, and faster welding speeds also necessitate higher power levels.

However, excessively high power can lead to an overly deep weld pool, potentially burning through the material. Therefore, the laser power should be set based on factors such as material thickness and weld joint shape.

Pulse Frequency

Pulse frequency settings refer to the number of laser pulses emitted per second, measured in Hertz (Hz). Typically, higher pulse frequencies result in faster welding speeds, but this may compromise weld quality. A balance must be struck between speed and quality.

Pulse Width

Pulse width settings refer to the duration of each laser pulse, measured in milliseconds (ms). The pulse width affects the depth and width of the weld. Generally, for thicker materials, the pulse width needs to be increased to maintain the appropriate penetration depth and welding speed.

Focus position

The position of the focal point is a key parameter for the efficiency and quality of laser welding. Correct focusing of the laser beam to the weld area ensures maximum energy density and efficient melting of the material.

The optimal focus position depends on the material thickness and the desired welding characteristics; for deep fusion welding, the focus point is usually located slightly below the material surface.

The focal length of the laser optics determines the depth of focus and the size of the focus point. Shorter focal lengths produce smaller spot sizes and higher energy densities for fine welds, while longer focal lengths increase the depth of focus for thicker materials.

Welding Material

Different kinds of materials have different reflectivity to laser light, which affects the absorption and melting speed of laser light on the surface of the workpiece. Metallic materials with high thermal conductivity weld faster, while non-metallic materials with low thermal conductivity weld slower.

In addition, the melting point of different materials is also a factor in welding speed, with materials with lower melting points usually welding faster. Thicker materials require longer heating times, which slows down laser welding.

Weld Surface

High-quality surface preparation promotes efficient laser welding. Any coatings, oil, grease, dust, or oxide layers present on the workpiece surface can interfere with laser beam absorption and cause welding defects. Therefore, it is essential to ensure that the welding area is clean before performing laser welding. Additionally, surface roughness affects the interaction between the laser and the material. Smoother surfaces absorb laser energy more uniformly, which helps to create more consistent and high-quality welds.

Weld Joint Shape

Generally, welding on flat surfaces proceeds faster, while welding irregular joints with many protrusions or depressions tends to be slower. This is because irregular joints have a lower specular reflectivity, making energy absorption more difficult and requiring longer exposure to generate sufficient heat.

Fixtures and Clamping Devices

Effective fixtures and clamping devices are crucial for ensuring the stability and alignment of joints during the laser welding process. Proper fixtures and clamping prevent movement, deformation, and misalignment, thereby enhancing both welding efficiency and quality.

How fast is Laser Welding?

Parameter for Laser Welding

The parameter settings of a laser welding machine are crucial for both welding quality and efficiency. When selecting the appropriate parameters, factors such as material thickness, welding speed, depth, and width need to be considered. For handheld laser welding of thin materials (e.g., 1-3 mm thick stainless steel or carbon steel), the optimal welding speed typically ranges from 10 mm/s~50 mm/s. Adjustments to the parameters based on specific conditions can help achieve high-quality welding results. The table below provides a reference for common materials’ laser welding machine parameters:

| Material | Thickness | Power | Pulse frequency | Pulse width |

| Stainless steel | 0.5mm | 200W | 20Hz | 10ms |

| Stainless steel | 1.0mm | 300W | 25Hz | 12ms |

| Aluminum alloy | 0.5mm | 150W | 15Hz | 8ms |

| Aluminum alloy | 1.0mm | 250W | 20Hz | 10ms |

| Copper | 0.5mm | 250W | 25Hz | 12ms |

| Copper | 1.0mm | 350W | 30Hz | 15ms |

For more welding speed and fiber laser welding machine parameter settings, please refer to the laser welding article.

What is the Speed of Laser Welding?

Laser welding is typically much faster than MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding, especially when working with thinner materials. Due to its high specific energy, laser welding creates a smaller weld pool, allowing for faster formation. Additionally, laser welding enables the rapid expansion of the front end of the weld pool, facilitating quick joint processing. This welding method also supports continuous and uninterrupted welding, further enhancing overall welding speed.

For thin sheets or materials with good weld ability, high-speed welding is recommended. Conversely, when welding thicker plates or materials with poorer weld ability, the speed should be appropriately reduced. Welding speed also affects the shape of the weld pool and weld seam. Lower welding speeds result in a larger and wider weld pool, which is prone to downward collapse. In high-speed welding, the intensely flowing molten metal at the weld seam center may solidify on both sides of the seam before it can redistribute, leading to an uneven weld.

Machine Performance Affects Weld Speed

The efficiency of laser welding is significantly influenced by the quality of the equipment used and its maintenance. Dapeng Laser is one of China’s leading manufacturers of laser welding machines.

Compared to traditional argon arc welding (TIG), handheld fiber laser welding machines can save up to 80%-90% in energy consumption and reduce processing costs by approximately 30%. These welding machines are suitable for various types of steel and other metal materials, offering fast welding speeds, minimal thermal deformation, and a narrow heat-affected zone. They are capable of achieving a high depth-to-width ratio. The welds formed are aesthetically pleasing, smooth, and almost free of pores, often requiring little to no post-processing to meet requirements.

As a pioneer in laser equipment design and manufacturing, Dapeng Laser offers a comprehensive range of laser welding machine models. They provide free samples to help customers select the most suitable laser welding machine.

The Bottom Line:

What factors affect laser welding efficiency? This article delves into how laser welding speed impacts weld quality and efficiency, along with the various factors that affect speed. By understanding these elements, you can more precisely choose the appropriate welding parameters for specific applications. Careful adjustment of a laser welding machine’s settings, especially the welding speed, can greatly improve both weld quality and production efficiency. This ensures optimal weld performance across different materials, resulting in more efficient production and long-lasting welds.