Laser cutting machine is a technology that uses laser to cut materials, commonly employed in industrial manufacturing. The working principle of fiber laser cutting involves guiding laser output through optical devices to irradiate the material with high energy density, causing localized instantaneous heating and vaporization, ultimately achieving material cutting. This technique is suitable for cutting various metal materials such as stainless steel, carbon steel, brass, and galvanized sheet. How to choose the best components of fiber laser cutting machine?

As is well known, fiber laser cutting machines are ideal tools for the metal processing industry due to their high precision and efficiency. Use the components of laser cutting machine with different parameters leads to varying cutting effects. Therefore, if you intend to purchase a fiber laser cutting machine that is suitable for your industry and offers high cost-effectiveness, the selection of its core components becomes crucial.

Fiber Laser

Fiber laser is the head attachment of fiber laser cutting machine, is the core “power source” of fiber laser cutting machine. Fiber laser has high photoelectric conversion efficiency, good beam quality and low maintenance cost. We use major brands such as Raycus, Max, IPG, BWT, and our low-mode kilowatt-class fiber lasers with output powers ranging from 1 to >100 kW and continuous or modulated mode frequencies up to 5 kHz. These devices operate dynamically from 10% to full power with no change in beam divergence or beam profile over the entire range. Thus, a single laser can be used for both high and low power welding, drilling and precision cutting.

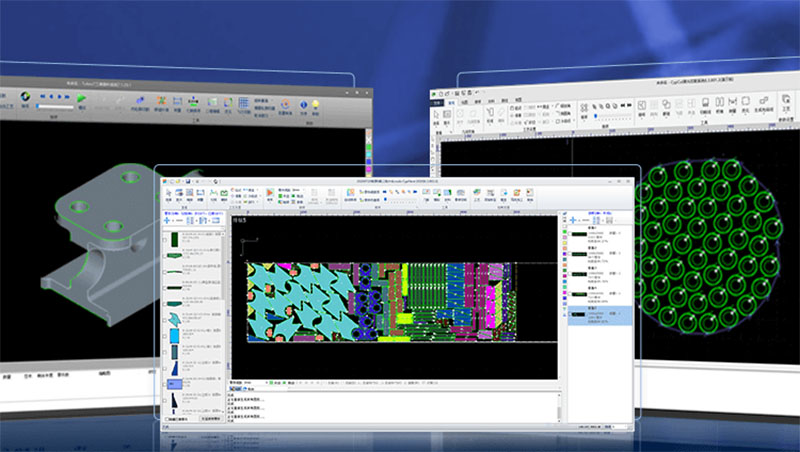

Cutting Control System

The cutting control system is the dominant operating system of the fiber laser cutting machine. The quality determines the stable operation performance of fiber laser cutting machine. It mainly controls the machine tool to realize the movement of X, Y and Z axes, and also controls the output power of the laser. Cypcut and Lantek are the most popular brands, which are suitable for cutting all kinds of metal materials.

DPLASER mainly uses Cypcut laser cutting system. A truly advanced open CNC that allows the user to integrate third party specialized software or technology into the system. It also offers a range of open tools that allow users to customize their own personalized interface and the special features they need.

Features of DPLASER’s Customized Laser Cutting Software

Increased machining efficiency

Early air opening: Air opening in advance of the air transfer process reduces the processing stops caused by air opening.

Senseless perforation: Precise light output in advance of the air shift process, reducing perforation time.

No trace of micro-linkage: Micro-linkage cutting without stopping.

Flying cut with one stroke: Generate flying cut line with any graphic to improve the efficiency of thin plate processing.

Stability Improvement

Bus followers: More stable followers, no jittering of the sharp corner into the knife.

Avoiding obstacles in the air: Accurate lighting in advance of the air moving process, reducing the piercing time.

Machine maintenance: Add maintenance information to remind users to maintain the machine in time.

Adaptive vibration suppression: Automatically adjust the vibration suppression level according to the cutting scenario.

Better Utilization of Leftover Material

Cutting line: Flexible cutting of remnant sheets.

Disc centering: Position the center of a round plate with a single click.

Border detection: Automatically shoots light envelopes at the apex when walking the border Border walking: shaped plates walking the border

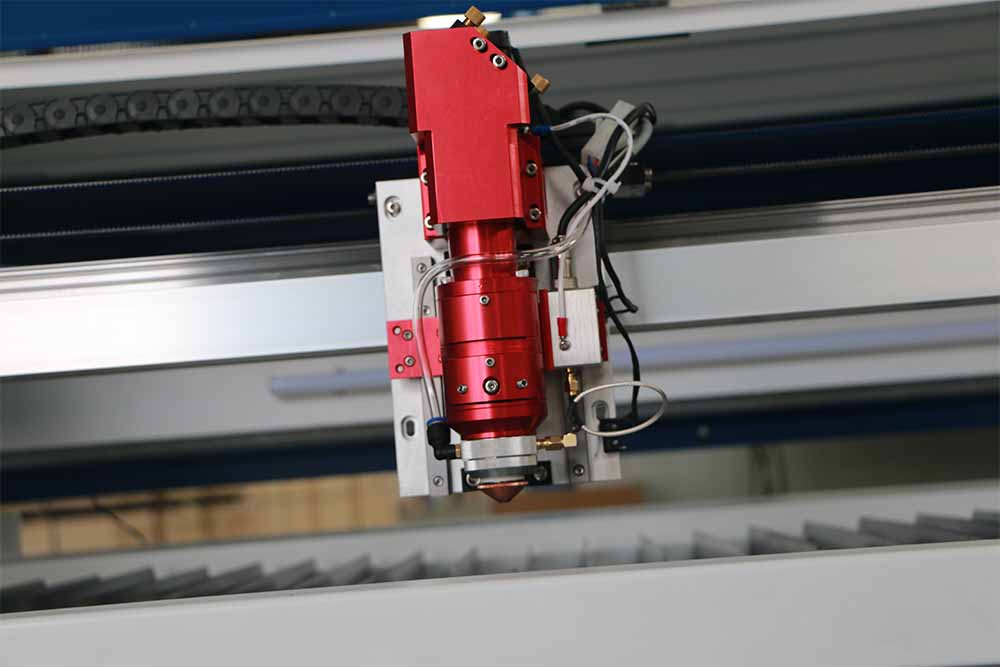

Laser Cutting Head

The laser cutting head of fiber laser cutter is a laser output device composed of a nozzle, a focusing lens, and a focus tracking system. The cutting head of a laser cutting machine moves along the set cutting track, but the height of the laser cutting head needs to be adjusted and controlled according to different materials, thicknesses, and cutting methods.

DPLASER uses BOCI/OSPRI/WSX cutting heads, which are specially optimized and upgraded for specific usage environments, ensuring reliable and stable operation in daily industrial environments for extended periods. Employing ultra-precision and super-smooth lens processing technology, these cutting heads deliver excellent cutting quality and speed, seamlessly integrating with the system for enhanced production efficiency.

Nozzle

The nozzle in a laser cutting machine is a crucial component responsible for maintaining the distance between the laser head and the workpiece. It guides auxiliary gas through the workpiece, creating a high-pressure outlet to improve cutting speed, while simultaneously clearing molten slag and protecting the focusing lens of the laser head. The choice of the nozzle directly affects the quality of laser cutting. The appropriate nozzle aperture should be selected based on the material and thickness of the workpiece.

Focusing Lens

The focusing lens in laser cutting machine is responsible for focusing the laser beam onto the surface of the workpiece to achieve efficient cutting. Choosing the right focal length and high-quality lens is a key factor in ensuring cutting quality, and the protection of the lens is crucial for extending its lifespan.

Focus Tracking System

The focus tracking system automatically monitors the relative position of the laser beam with the workpiece surface and adjusts the position of the laser cutting head in real time to ensure that the focus is consistently and accurately positioned on the workpiece. Using sensors and feedback control, the focus tracking system can adapt to the unevenness of the workpiece surface, ensuring a high-quality focus during the cutting process.

Servomotor

A servo motor is an engine that controls the operation of mechanical components in a servo system. Servo motors can accurately control speed and positional accuracy, and can convert voltage signals into torque and speed to drive control objects. High-quality servo motors can effectively ensure the cutting accuracy, positioning speed and repetitive positioning accuracy of laser cutting machines.

Delta/Yaskawa/Schneider servo motors and drives have signal feedback function, faster speed and low heat radiation performance. With good drive system, the ultra-low speed runs smoothly and effectively ensures the cutting accuracy, positioning speed and repeat positioning accuracy of the laser cutting machine.

Reducer

In a fiber laser cutting machine, the main functions of a speed reducer include matching power and speed, providing sufficient torque to perform rotation operations, and achieving precise speed control to improve positioning accuracy. In addition, the use of gearboxes helps to protect the equipment, minimize shock and vibration, extend the life of mechanical components, and ensure the smooth, precise and reliable operation of the cutting machine.

German TECHMECH gearboxes provide efficient and precise motion transmission performance. Their modular design and adaptability make them widely applicable to laser cutting machines. High performance, wide application, high rigidity, high efficiency, low noise, and more accurate motor performance.

Industrial Chiller

The cooling system is used to cool the fiber laser and QBH connector. HANLI water cooling system assembly input and output control device switch, with cooling water flow, high and low temperature alarm function, equipment performance is more stable.

Working Bed

As most of the plate sizes are about 1500x3000mm, 2000x3000mm, 2000*4000 mm, etc., DPLASER produces fiber laser cutting machines of models 3015, 3020, 4020, etc. The machine beds are made of high quality materials, such as steel, aluminum, aluminum, and aluminum. The machine bed is effectively eliminated from welding and machining-induced stresses through the processes of integral welding, stress relief annealing, rough machining, vibration aging, and finishing, which significantly improves the stability of the machine and maintains the accuracy for a long time.

DPLASER company has a laser cutting machine bed processing department, focusing on independent processing and production of all machine tool structural parts, to ensure that the processing quality and product quality consistency, to ensure that the production of equipment production schedule, so that the quality of each Roc Laser product is always the same.

The bed is installed with double rack and pinion double guide rail and four slider drive structure. Guide way for HIWIN brand (optional SHAC Taiwan), heavy-duty type H level, precision GHH30. Shield for the fully enclosed lightweight fire-resistant oil type. Rack and pinion is SHGH series of Taiwan YYC brand (optional JT Taiwan), grade 6 precision M2 oblique teeth.

Air supply system

The gas supply system of fiber laser cutting machine mainly includes gas source, filtering device and pipeline. Among them, the gas source has bottled gas, liquefied gas, and compressed air and other forms.

Dust Collector

The dust collector extracts the smoke and dust generated during laser cutting and carries out filtration treatment, so that the exhaust gas emission meets the environmental protection standards and does not pollute the environment, thus achieving the purpose of environmentally friendly production.

By understanding these essential components of fiber laser cutting machine, customers can better understand how different combinations affect the performance and suitability of fiber laser cutting system. Different combinations of fiber sources, laser cutting heads, motors and cooling systems can provide customized laser cutting solutions for different applications. This helps customers choose the most appropriate metal laser cutting machine configuration based on their specific project needs, such as material type, cutting thickness, productivity and budget, thus increasing productivity and ensuring the best return on investment.

As a manufacturer and service provider for laser cutting machines, DP LASER is committed to providing customers with cutting-edge and efficient laser cutting solutions through outstanding technology and comprehensive support. Our products not only meet your cutting needs but also emphasize providing comprehensive support for your business, ensuring that your manufacturing processes are smoother and more efficient. No matter how complex your metal processing solution is and how difficult your laser cutting machine customization needs are, we are here to provide you with the highest quality, high fit solution possible, so please don’t hesitate to let me know.

That’s it. We take an in-depth look at the basic components of a laser cutter, revealing the unique role these key building blocks play in the overall cutting process. Learn about the functions and features of each component, such as the laser source, optical path system, and control system. This knowledge will help you precisely select the right laser cutting machine for your needs and achieve the best cutting results.