In the rapid evolution of the manufacturing industry, fiber laser cutting robots are emerging as leaders on production lines. We will delve into the 3d robot fiber laser cutting machine, comprehensively exploring the advantages and widespread applications of this advanced technology. From efficient cutting to intricate processing, we will reveal how laser cutting robots enhance production efficiency and accelerate production cycles.

What is a Laser Cutting Robot?

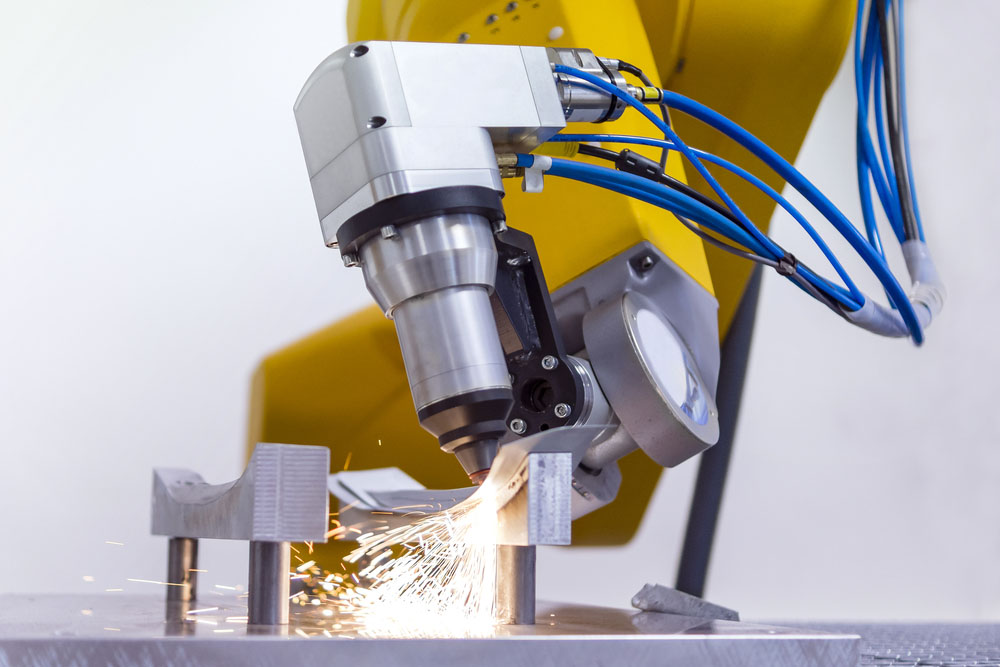

The 3D fiber laser cutting robot system uses advanced components like a fiber optic laser cutting head, precise capacitive tracking system, and an industrial robot arm to flexibly cut metal sheets & pipe of varying thicknesses from different angles and directions.

With the robotic flexibility, it can be programmed for various workpiece sizes, shapes, and paths. By using fiber optics to transmit the laser to the cutting head and then focusing it with a focusing system, it is possible to cut and engrave a variety of three-dimensional metal plates in different directions.

Compared to 2D laser cutting, the 3D laser cutting system continually adjusts the head’s direction to ensure it remains perpendicular to the workpiece surface, ensuring superior cutting quality.

Advantages of Robot in 3D Laser Cutting

Traditional mechanical parts have been replaced by complex 3D profiles such as bending, hydroforming, deep drawing, molding, die-casting tubes or pre-welded assemblies. Laser cutting robot arm have become an effective tool for solving problems of geometric complexity of parts. Their 6-axis nature allows the 3D laser cutting head to freely reach any point of the part, making them ideal for handling complex part geometries.

Robotic laser cutting systems are efficient, flexible automation solutions that allow operators to easily plan and set up cutting tasks through advanced programming interfaces and intelligent algorithms. Compared to multiple conventional laser cutting machines, a single robotic cutting system can achieve equal or better production performance.

In automotive sheet metal component manufacturing, robotic laser cutting offers significant advantages over traditional methods. For three-dimensional cutting of complex structures, robotic laser cutting can solve the problem of open die stamping, plasma cutting or five-axis machine tools. Especially in the trimming and punching process, robotic laser cutting reduces the difficulty of making molds and improves production efficiency. Compared with traditional methods, robotic laser cutting avoids the problem of cracking on the edge caused by multiple stack welding, reduces the scrap rate, and reduces the production cycle and cost.

To meet the demand for automotive sheet metal coverings and chassis parts, a combination of industrial robots and fiber lasers is used for 3D cutting. Although the positioning accuracy of the industrial robot is slightly lower, it is sufficient to meet the automotive industry’s requirements for accuracy. This solution lowers system costs, reduces energy consumption and maintenance, and shrinks the system footprint.

Industrial Application of 3D Robot Fiber Laser Cutting Machine

Three-dimensional robotic laser cutting machine is widely used in sheet metal processing, metal processing, advertising production, kitchenware, automotive, lamps, saw blades, elevators, metal handicrafts, textile machinery, grain machinery, glasses manufacturing, aerospace, medical equipment, instrumentation and other industries. For some mold extrusion molding parts, due to the high cost of design and manufacture of blanking molds, long manufacturing cycle, poor quality of blanking, etc., the use of three-dimensional laser for nesting and eyelet processing has many benefits.

Molded, deep-drawn, hydraulically formed, die-cast components, bent and hydraulically formed tubes, as well as any three-dimensional complex profiles, are all suitable for the 3D laser cutting robot system.

- Metal Cutting: Robotic laser cutting can be used for a wide range of different types of metals, such as steel, aluminum and copper. This cutting method reduces the heat affected area and enables high precision cutting without damaging the structure and strength of the material. Metal cutting is widely used in industries such as machinery, cabinets, automotive, electronics manufacturing and metal processing.

- Crystal Material Cutting: Robotic laser cutting is suitable for crystal material, maintaining its transparency and optical properties. This type of cutting can be used in industries such as jewelry, watches and optical devices.

- Wood Cutting: Robotic laser cutting can be used for a wide range of woods such as solid wood, wood-based panels, and fiberboards to achieve high precision cutting without chips and burrs. Wood cutting is used in a wide range of applications such as furniture, construction and artwork.

- Plastic Material Cutting: Robotic laser cutting is suitable for all kinds of plastic materials, such as polyethylene, polypropylene, polyvinyl chloride and so on. High speed and high quality cutting without chips and burrs. Plastic cutting is widely used in plastic products, packaging and toy industries.

- Textile Cutting: Robotic laser cutting can be used for textiles such as fabric, leather and textile to realize high-speed, high-precision cutting without burrs and deformation. Textile cutting is widely used in apparel, shoes and hats, and home textiles.

- Electronic Component Cutting: Robotic laser cutting is suitable for a variety of electronic components such as circuit boards, chips and optical fibers. High-precision, contactless and non-thermal influence cutting without affecting the performance and quality of components. Electronic component cutting is widely used in electronic manufacturing and communication industry.

- Packaging Material Cutting: Robotic laser cutting can be used for all kinds of packaging materials such as paper, cardboard and plastic film, realizing high-speed and high-quality cutting without dust and noise. Packaging material cutting is widely used in food, medicine and daily necessities industries.

The Best Robot Laser Cutting Machine

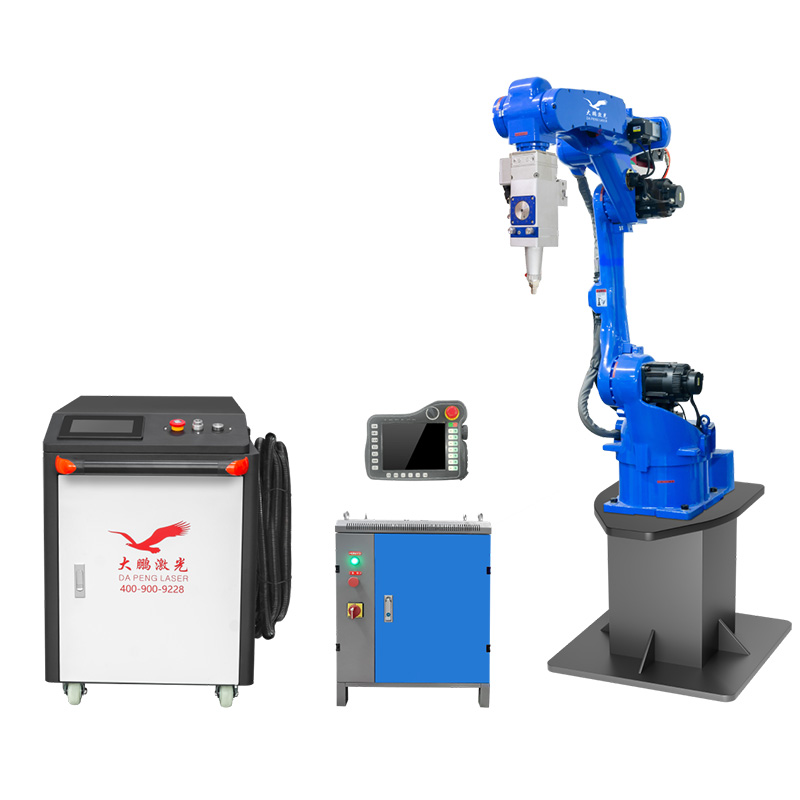

The DPLASER six-axis robotic fiber laser cutting machine enables dynamic 2D and 3D cutting operation, offering flexible processing capabilities. Designed ergonomically, the robot’s overall structure allows for easy operation, even when dealing with the most complex curved surfaces.

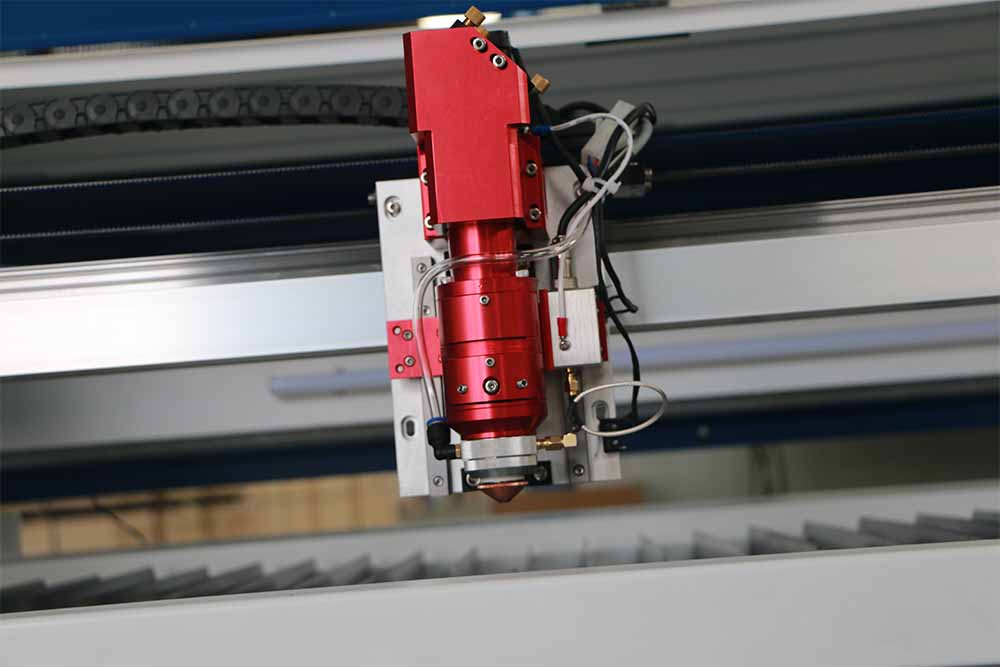

This fiber laser cutting machine consists of a specialized fiber laser cutting head, high-precision capacitive tracking system, fiber optic laser, and an industrial robot system, providing advanced laser cutting capabilities for multi-angle and multi-directional flexible cutting of metal material. The robot tracking system ensures that the cutting head accurately reaches the position of the workpiece to be cut, with high repetitive positioning accuracy.

The power of fiber laser source depends on the thickness of the cutting material and is available in various specifications such as 1000W, 1500W, 3000W, 6000W, etc. Different power lasers come with cooling systems of varying capacities to ensure the normal operation of the laser.

Additionally, the selection of the appropriate length of fiber optic transmission for laser operation is determined by the working radius of the robotic arm and the size of the workpiece’s, meeting the customized requirements of the customers.

- Independently developed and designed PLC system, combined with the flexible and fast action performance of industrial robots, it can carry out demonstration programming or offline programming for different products and trajectories, which is especially suitable for shaped machining of locomotive three-dimensional parts, so it is widely used in the locomotive manufacturing industry for locomotive-type parts, bodywork, door frames, trunks, roof covers, door side seats and so on.

- Equipped with a laser cutting head with follower function, it is compact and lightweight, with double protection of focusing lens and low cost of use.

- It can organize a certain number of cutting units to form an automated production line to meet the demand of medium batch production.

- High-precision industrial robot, six-axis linkage, light weight robot arm, large arm span range, large working area, can process large sheet metal molding parts. The robot can cut along the 3D path in the workspace.

- Configuration of intelligent operation terminal, simple interface, clear logo, easy to learn.

- Embedded process database, flexible use, effectively reducing the difficulty of use.

- The robot and cutting head are equipped with a reliable collision quick reset device, which effectively protects the key components.

- The 3D fiber laser cutting machine has a small footprint, simple operation and maintenance, and low maintenance cost. It is an advanced 3D robotic Laser cutting machine that combines high stability, high precision, high performance and high speed.

DPLASER is a sheet metal fiber laser cutting machine manufacturer specializing in the research, development, production, sales and service of fiber laser cutting machine, fiber laser cleaning machine, laser marking machine, laser welding machine and 3D robot laser cutting machine.

The Bottom Line

In the world of fiber laser cutting robots, we take a deep dive into the superior benefits and diverse applications of this technology. From improving productivity to expanding manufacturing possibilities, laser cutting robotics are both enablers of manufacturing and drivers of innovation.

If you are considering purchasing the best robot laser cutting machine, we offer advice and recommendations that will help you make an informed decision. Choosing the right robot partner for your needs will not only improve the efficiency of your production line, but also lay the foundation for more efficient manufacturing.