In recent years driven by new energy vehicles, lithium batteries, semiconductors and emerging market demand, while benefiting from the continuous improvement of laser power and laser price decline, lower prices can drive more markets, laser welding equipment in various industries penetration rate continues to increase, laser welding is now more and more into the industrial production and home workshops. In the field of welding technology, laser welding has become a transformative technology with precision, efficiency and versatility. In this blog post, we will delve into the future developments in laser welding.

Future of Handheld Laser Welding Trends

Efficiency and Automation Advancements:

Continuous progress in electronic technology, automatic control technology, sensor detection, and information processing is propelling laser welding towards higher efficiency, increased automation, and enhanced intelligence. This transformative evolution addresses the rising demand for flexible and automated production. The forthcoming laser welding technology is anticipated to boast higher power and faster operating speeds, allowing for the processing of thicker materials and consequently elevating production efficiency.

Laser Welding With High Speed and Precision:

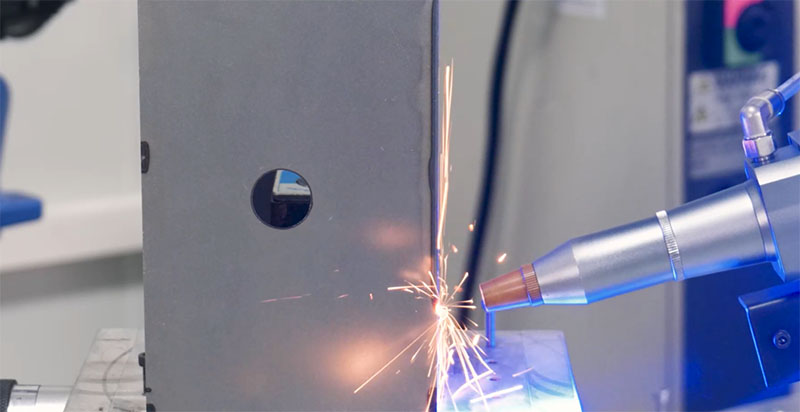

Laser welding stands out for its outstandingly high speed and precision. Its high speed makes the process faster and easier to control and automate remotely. This makes laser welding widely used in automotive manufacturing, new energy battery production and other highly automated industries. High-definition CCD camera, automatic positioning, to meet the requirements of higher precision device automatic processing.

Integrated Laser Welding Solutions:

With the incorporation of CNC processing principles, composite laser welding equipment is progressively emerging as a dominant trend in the welding industry. This category of welding equipment seamlessly integrates diverse functions such as laser cutting, laser deep welding, and laser surface treatment, significantly amplifying production efficiency and flexibility. The modular design of optical systems, motion units, and control systems not only enhances system stability but also streamlines maintenance. This development is poised to revolutionize industries like manufacturing, presenting ample opportunities for the seamless integration and optimization of production processes.

Intelligent Control Systems:

The future of welding industry will incorporate sophisticated control systems, ushering in an era of intelligence that monitors and dynamically adjusts welding parameters in real time, ensuring optimal quality and consistency.

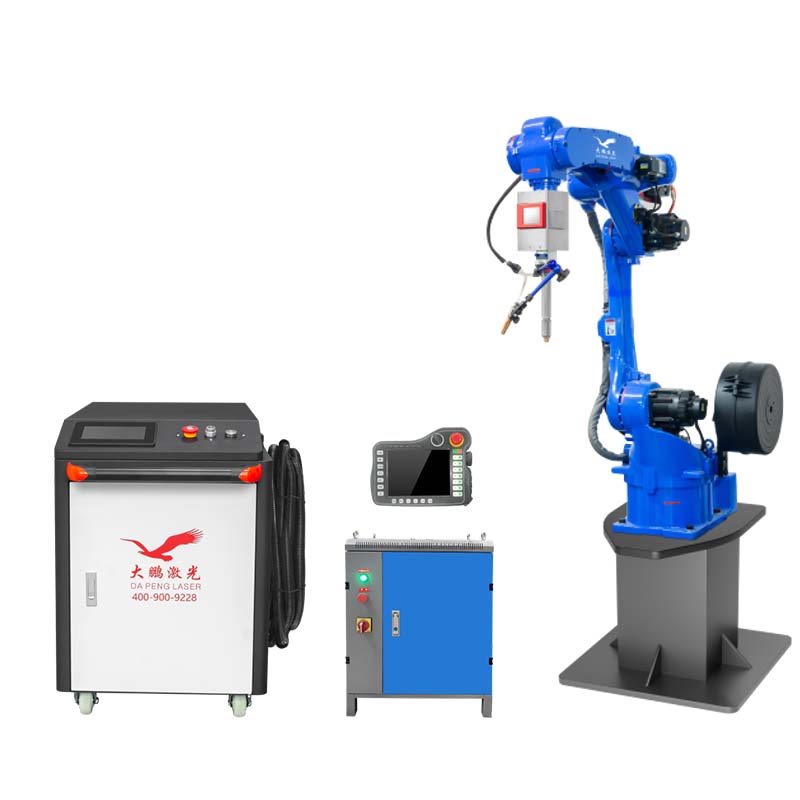

In the welding industry, the integration of robots is gaining traction to ensure consistent quality, maximize productivity, and facilitate cladding applications. Leveraging advanced sensing technology and real-time data processing, welding robots execute welding tasks with precision, significantly boosting productivity and minimizing error rates.

The intelligent control system offers remarkable programming flexibility, enabling the welding robot to seamlessly adapt to diverse welding tasks and specific workpiece requirements. This adaptability empowers companies to effortlessly switch between welding tasks on the production line, resulting in a highly customized and optimized production process.

The articulated arm and joint design enable the robot to navigate freely in confined or intricate work environments, undertaking welding tasks that would be challenging to accomplish manually. This capability not only enhances welding flexibility but also diminishes the need for manual intervention, saving valuable time and resources.

Multi-Wavelength Laser Systems:

Advancements in multi-wavelength laser systems will extend the applicability of laser welding to a broader range of materials, including those traditionally difficult to weld, thereby expanding its scope of applications. Laser welding, known for its speed and adaptability, capable of processing various materials such as sheet metal, plastic tubing, and glass products.

Expansion of Application Areas:

With the rapid development of the new energy vehicle market, the market demand for laser welding equipment will also increase. In electric vehicles, photovoltaic industry and other fields, laser welding has become an indispensable key technology. Its superior performance in material connection and parts manufacturing makes it play an important role in the new energy field. In addition, the application of laser welding technology in the medical and biomedical fields will continue to grow, including the connection of biological materials and the manufacture of micro-fine parts.

Application of New Materials:

With the continuous development of new materials, laser welding will be able to be widely used in the field of composite materials, ceramics and high temperature alloys.

The Fusion of 3D Printing and Laser Welding:

The convergence of 3D printing technology and laser welding promises to create entirely new production methods capable of creating more complex and lightweight parts and assemblies.

Micron and Nano scale Applications:

Laser Welding As industry continues to miniaturize, the need for micron- and nanoscale welding continues to grow. Future developments may enable laser welding at these scales to meet the needs of industries such as electronics, optics and medical devices.

More Customized and Flexible Functions:

With the increase of personalized market demand, the laser welding machine will provide more customized and flexible functions. For example, according to user demand, laser welding machines can realize the free switching of multiple seam forms (straight line, arc, etc.) to adapt to the requirements of different products. Customized service has been called one of the core competitiveness of laser welding equipment manufacturers.

Dapeng Laser Technology

Dapeng Laser has become a leader in the field of laser welding equipment by focusing on R&D innovation and customized equipment capabilities. In China, we are proud to have 27 state-of-the-art manufacturing and sales bases to provide highly customized solutions to our customers. Our strong R&D team continues to push the laser welding technology and is committed to developing more advanced and efficient laser welding equipment to meet our customers’ customized needs. We are committed to meeting the individual needs of our customers by continually optimizing and upgrading our equipment to ensure that our customers receive high-quality, high-efficiency laser welding solutions.

Meanwhile, we have established an extensive after-sales service network worldwide to provide timely and comprehensive technical support to ensure stable equipment operation and customer satisfaction. The use of highly rated handheld laser welding machines can save companies a lot of cost.

Continuously Launch Advanced Handheld Laser Welding

Through superior craftsmanship and advanced optics, our handheld fiber laser welding machines provide welding craftsmen with an unparalleled precision welding experience. Continuous research and innovation have kept our laser equipment technology at the forefront of the industry, including ergonomic designs, the latest laser technology and advanced control systems. We’re not just content with our past accomplishments, but we’re constantly exploring new laser technologies and accessories to ensure that our products are always at the forefront of technology. Choosing one of our handheld laser welding machines means choosing excellence, efficiency and continuous innovation in laser welding solutions.

Will there be Cheap Laser Welders in the Future?

Future price changes for laser welding machines are mainly influenced by technological innovations, competition in the market, as well as the cost of raw materials and components. Prices of high-tech equipment such as laser welding machines usually decrease gradually as evolution of laser welding technology, optimization of manufacturing processes and large-scale production are achieved. In addition, competition among manufacturers may also drive prices down due to increased demand for laser welding. Therefore, it can be expected that the price of laser welding machines will tend to become more affordable in the future.

Final Word

Laser welding is a highly precise and efficient welding technology with a wide range of applications. In order to ensure that optimum welding results are achieved, it is vital to select the best laser welding method for different welding methods and scenarios. With continuous research into laser welding technology, we have gone beyond the boundaries of the technology to push the boundaries of how laser welding can be used to manufacture, create and innovate in a variety of industries. Future of welding industry has great potential to have a profound impact on automotive assembly lines, medical device manufacturing, and microelectronics, and to further drive change and development in these industries.

If you need to know more about laser welding technology or looking for the optimal laser welding solution for your specific needs, please contact us today. As experts in the field of laser welding, we will provide you with professional advice and services to help you achieve excellent welding results.